Pot-type calcinator multi-level series fin type cooling device for coke after high-temperature calcination

A tank calciner and cooling device technology, which is applied in the preparation/purification of carbon, can solve the problems of insufficient cooling water flow distance and flow strength, and small heat exchange area, so as to increase the effective heat exchange area and enhance the cooling effect. , the effect of increasing the flow distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

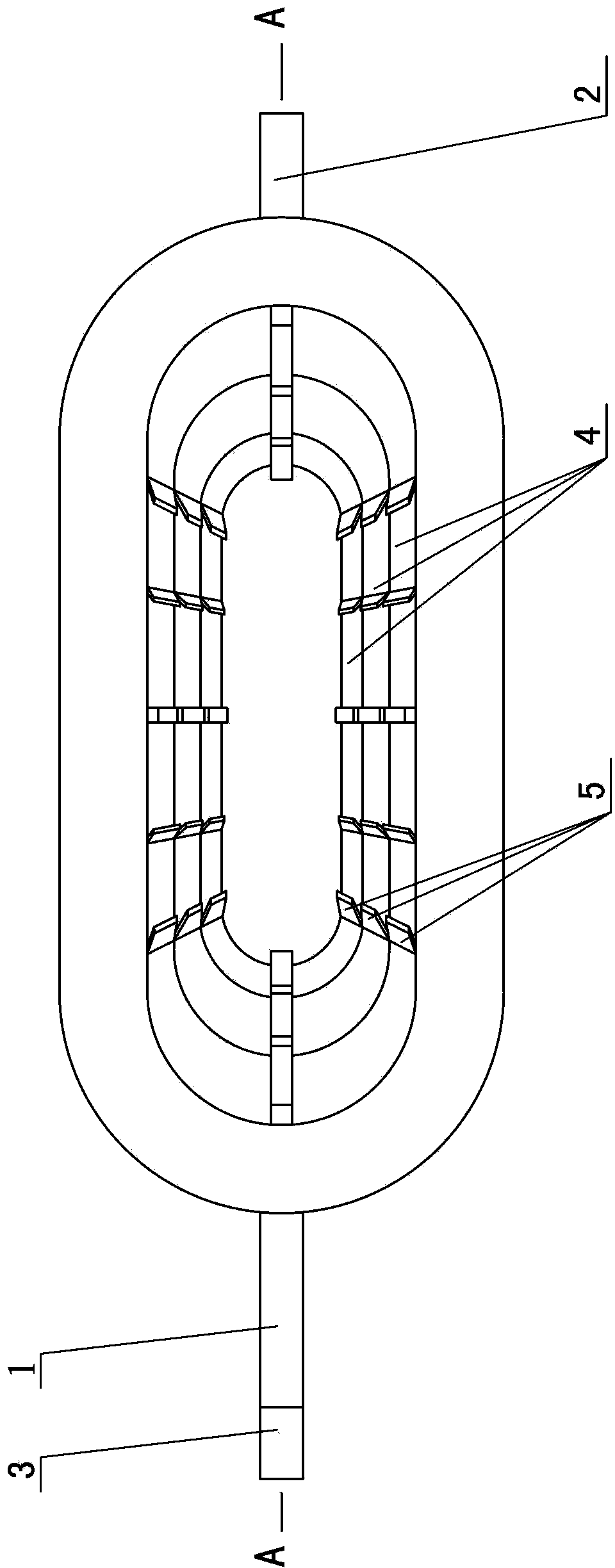

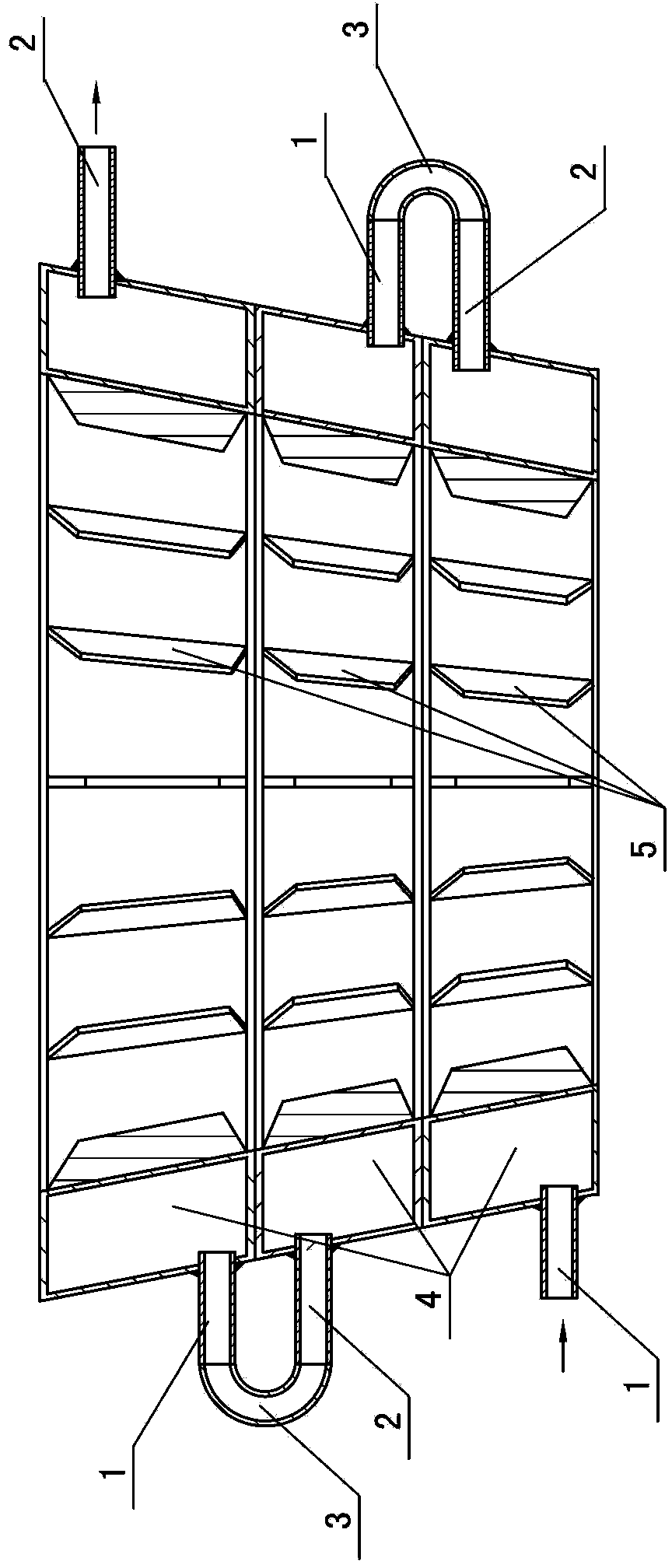

[0013] exist Figure 1-2 In the embodiment shown: 3 cooling water jackets 4 are superimposed and fixedly connected, a plurality of fins 5 are evenly arranged on the outer wall of the inner side of each cooling water jacket 4, and the upper and lower sides of each fin 5 are oblique edges. , the included angle with the horizontal plane is 80°, the fins 5 on the three cooling water jackets 4 are in a corresponding row, and each row of fins 5 is located on the same vertical plane; Correspondingly, a water inlet pipe 1 and a water outlet pipe 2 are provided. Except for the water outlet pipe 2 located at the uppermost cooling water jacket 4 and the water inlet pipe 1 located at the lowermost cooling water jacket 4, the adjacent cooling water jackets 4 are located at the same end. The water inlet pipe 1 is communicated with the connecting pipe 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com