Strengthened micro cyclone separator and high-pressure separation device with same

A cyclone separator, a miniature technology, applied in the direction of the swirl flow can reverse the axial direction of the device, the swirl device, etc., can solve the problem of large material consumption and floor space, limited continuous operation time, large gas pressure loss, etc. problem, to achieve the effects of small footprint, improved continuous operation time, and small resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further explained below with reference to specific embodiments and accompanying drawings.

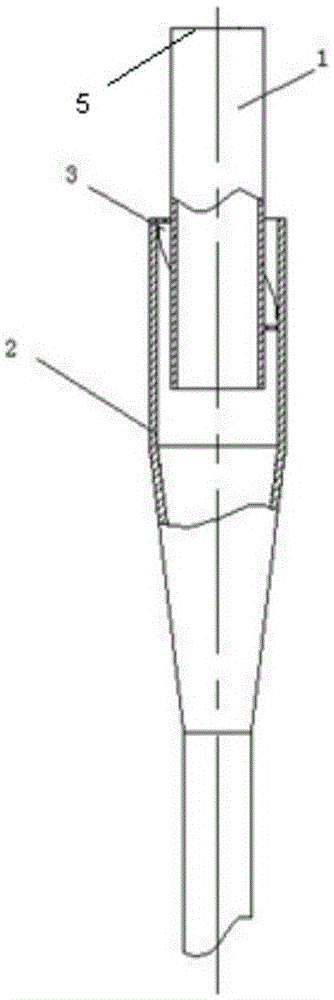

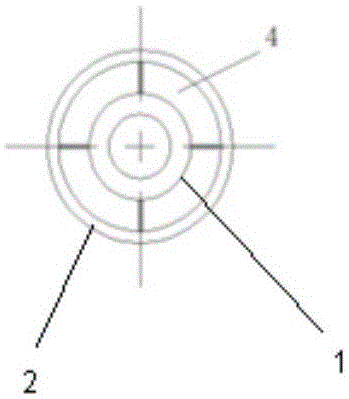

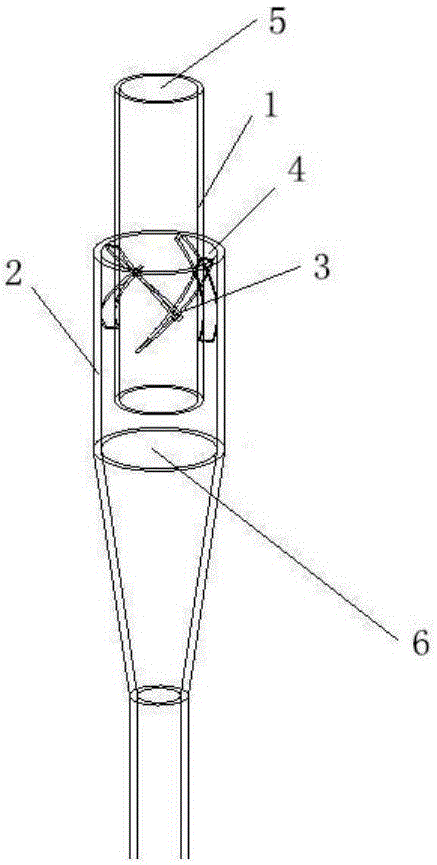

[0030] An enhanced micro-cyclone separator according to an embodiment of the present invention, such as figure 1 As shown, the outer tube 2 and the inner tube 1 are included. The inner pipe 1 is a straight pipe; the outer pipe 2 includes an upper straight pipe part, a middle conical part and a lower straight pipe part with a smaller diameter, and a part of the lower part of the inner pipe 1 enters the upper part of the outer pipe 2 . The top of the inner tube 1 is the gas outlet 5 of the cyclone separator, and guide vanes 3 are arranged between the inner and outer tubes. like figure 2 As shown, the axial opening between the outer tube 2 and the inner tube 1 is the cyclone inlet 4 . In this embodiment, the axial air inlet 4 of the reinforced micro cyclone separator 6 makes the air intake mode axial and increases the air intake area, so as to achie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com