Bottom spray-type fluidization coating equipment

A fluidization and coating technology, used in coatings, devices for coating liquid on surfaces, special surfaces, etc., can solve problems such as the inability to guarantee the quality of the coating, increase the effective air intake area, improve work efficiency, increase Effect of fluidizing airflow strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

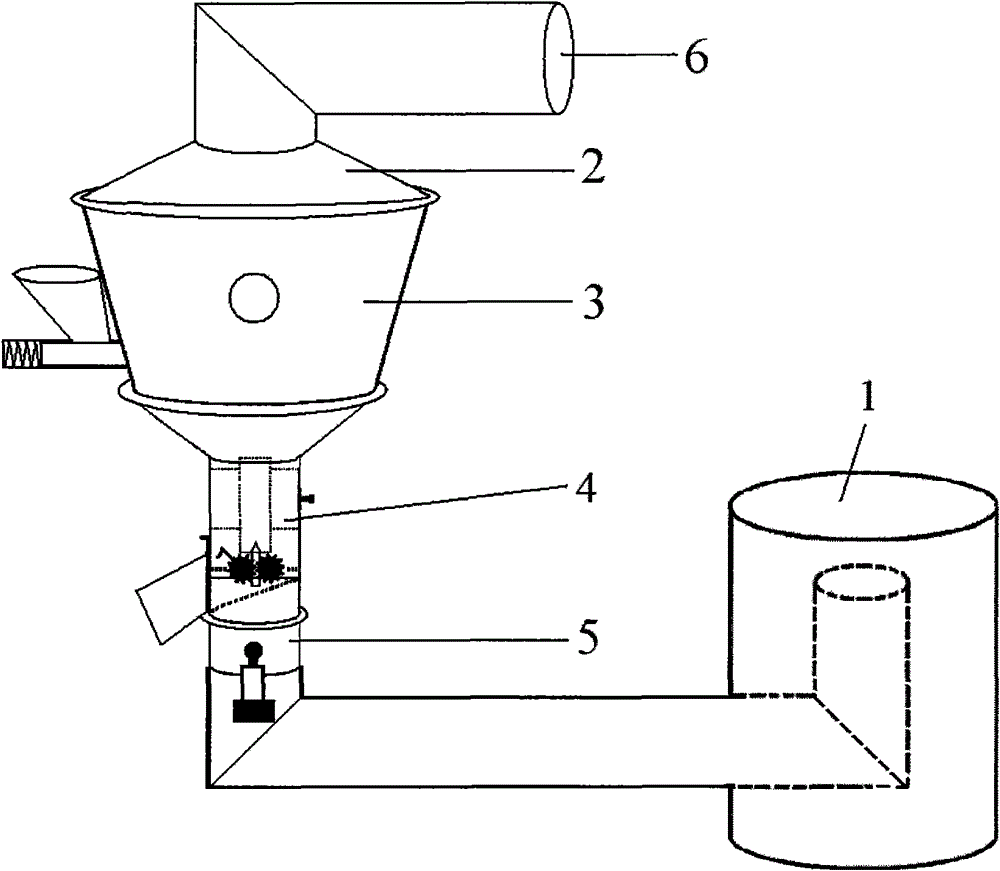

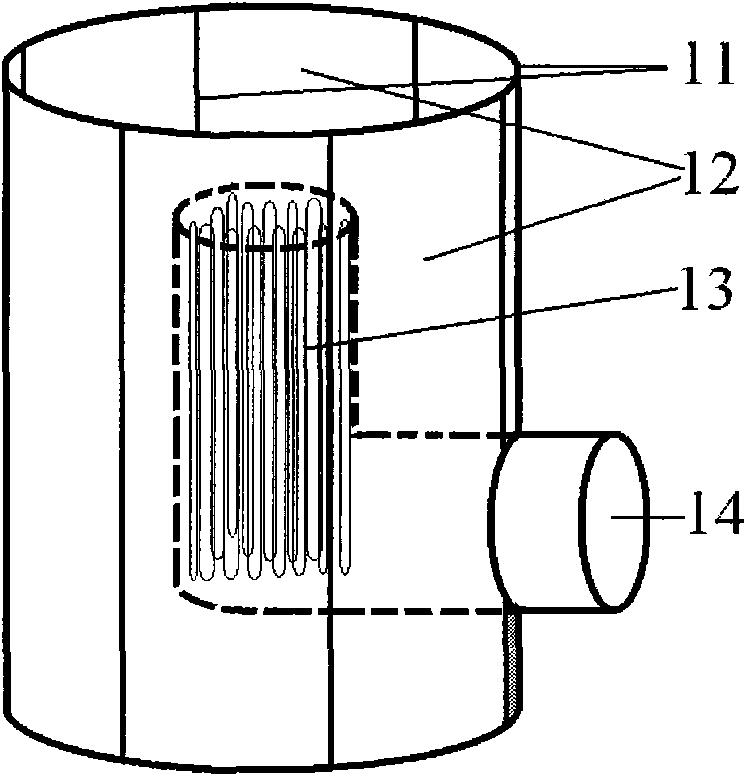

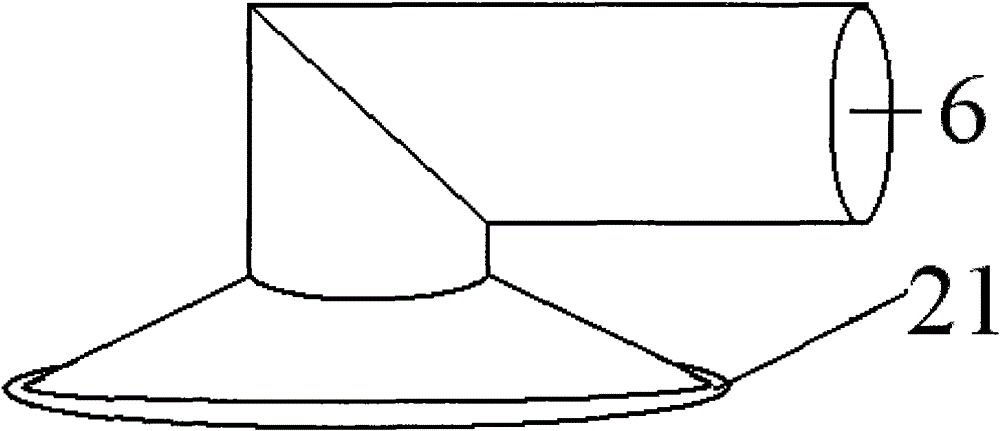

[0034] Fluidized coating equipment generally has three major parts: heating equipment, coating equipment, and air induction equipment. We start by ensuring the pipeline of the whole set of equipment is smooth, increase the effective air intake area of the air inlet of the heating equipment, and use stainless steel screens with larger apertures in the fluidized bed to effectively increase the wind force in the fluidized equipment and make the fluidized particles The flipping effect is more obvious. Secondly, we have improved the structure of the guide cylinder to make the adjustment of the position of the guide cylinder more convenient. No matter how the position of the guide cylinder is adjusted within a certain range, the coaxiality of the guide cylinder and the coating cylinder can be guaranteed, effectively avoiding the general fluidization trap. It is easy to tilt when adjusting the height of the guide cylinder of the membrane equipment, and it is also easy to maintain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com