Silicon carbide refractory material and preparation method thereof

A technology of refractory materials and silicon carbide, which is applied in the field of refractory materials, can solve the problems of low strength and poor oxidation resistance, and achieve the effects of strong oxidation resistance, small thermal conductivity and increased thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A silicon carbide refractory material, comprising the following components by weight:

[0038] 25 parts of silicon carbide powder, 4 parts of silicon powder, 1 part of aluminum powder, 5 parts of titanium dioxide, 5 parts of zirconia, 0.5 part of cage polysilsesquioxane, 0.5 part of molybdenum carbide, 0.5 part of silicon boride, erbium acetate 0.5 parts, 0.5 parts of ytterbium oxide, 1 part of diamond, 3 parts of binder;

[0039] Among them, the particle size of silicon carbide powder is 20-40 μm, the particle size of diamond is 10-20 μm, and the cage polysilsesquioxane is aminopropyl isobutyl silsesquioxane;

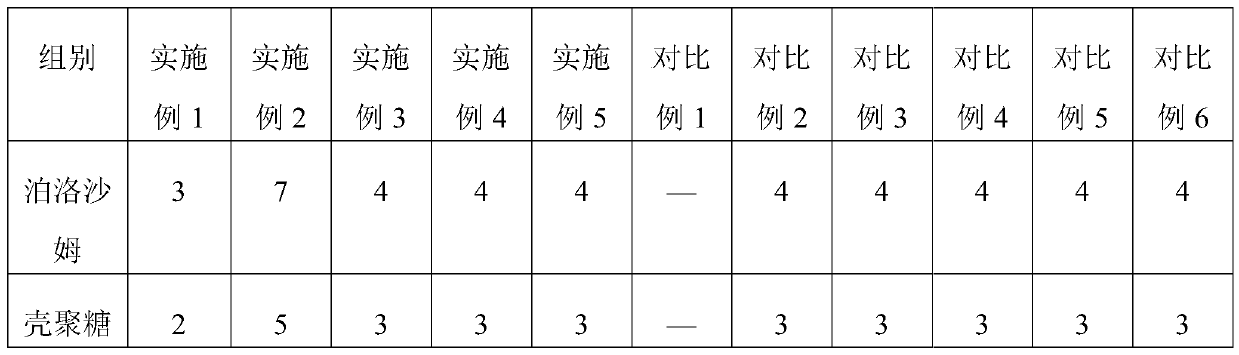

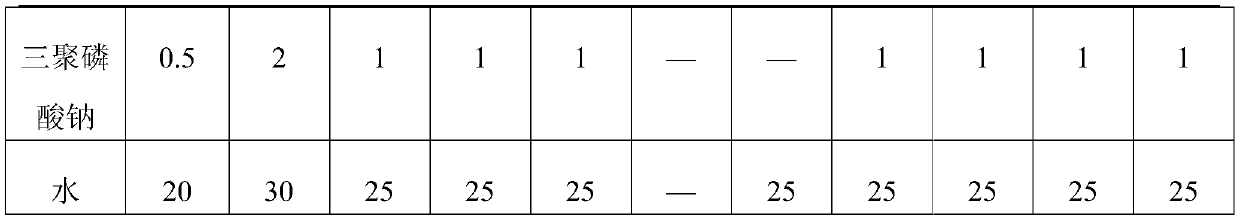

[0040] The binder is composed of the following components in parts by weight: 3 parts of poloxamer, 2 parts of chitosan, 0.5 part of sodium tripolyphosphate, and 20 parts of water. The preparation method is to first add poloxamer to water, dissolve Add chitosan and sodium tripolyphosphate, and mix well to obtain a binder;

[0041] Its preparation method compri...

Embodiment 2

[0051] A silicon carbide refractory material, comprising the following components by weight:

[0052] 40 parts of silicon carbide powder, 8 parts of silicon powder, 5 parts of aluminum powder, 13 parts of titanium dioxide, 10 parts of zirconia, 3 parts of cage polysilsesquioxane, 2 parts of molybdenum carbide, 2 parts of silicon boride, erbium acetate 1.5 parts, 1.5 parts of ytterbium oxide, 3 parts of diamond, 5 parts of binder;

[0053] Among them, the particle size of silicon carbide powder is 20-40 μm, the particle size of diamond is 10-20 μm, and the cage polysilsesquioxane is aminopropyl isobutyl silsesquioxane;

[0054] The binder is composed of the following components in parts by weight: 7 parts of poloxamer, 5 parts of chitosan, 2 parts of sodium tripolyphosphate, and 30 parts of water. The preparation method is to first add poloxamer to water, dissolve Add chitosan and sodium tripolyphosphate, and mix well to obtain a binder;

[0055] Its preparation method is wit...

Embodiment 3

[0057] A silicon carbide refractory material, comprising the following components by weight:

[0058] 30 parts of silicon carbide powder, 5 parts of silicon powder, 2 parts of aluminum powder, 8 parts of titanium dioxide, 6 parts of zirconia, 1 part of cage polysilsesquioxane, 1 part of molybdenum carbide, 1 part of silicon boride, erbium acetate 0.8 parts, 0.8 parts of ytterbium oxide, 1.5 parts of diamond, 3.5 parts of binder;

[0059] Among them, the particle size of silicon carbide powder is 20-40 μm, the particle size of diamond is 10-20 μm, and the cage polysilsesquioxane is aminopropyl isobutyl silsesquioxane;

[0060] The binding agent is composed of the following components by weight: 4 parts of poloxamer, 3 parts of chitosan, 1 part of sodium tripolyphosphate, and 25 parts of water. The preparation method is to first add poloxamer to water, dissolve Add chitosan and sodium tripolyphosphate, and mix well to obtain a binder;

[0061] Its preparation method is with em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com