Intermetallic Composite Formation and Fabrication from Nitride-Metal Reactions

a technology of intermetallic composites and metal reactions, which is applied in the field of composite materials, can solve the problems of reduced engine efficiency, large grain structure of composites employing these phases, and poor oxidation resistance of these metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]A preferred embodiment of the invention is now described in detail. Referring to the drawings, like numbers indicate like parts throughout the views. As used in the description herein and throughout the claims, the following terms take the meanings explicitly associated herein, unless the context clearly dictates otherwise: the meaning of “a,”“an,” and “the” includes plural reference, the meaning of “in” includes “in” and “on.”

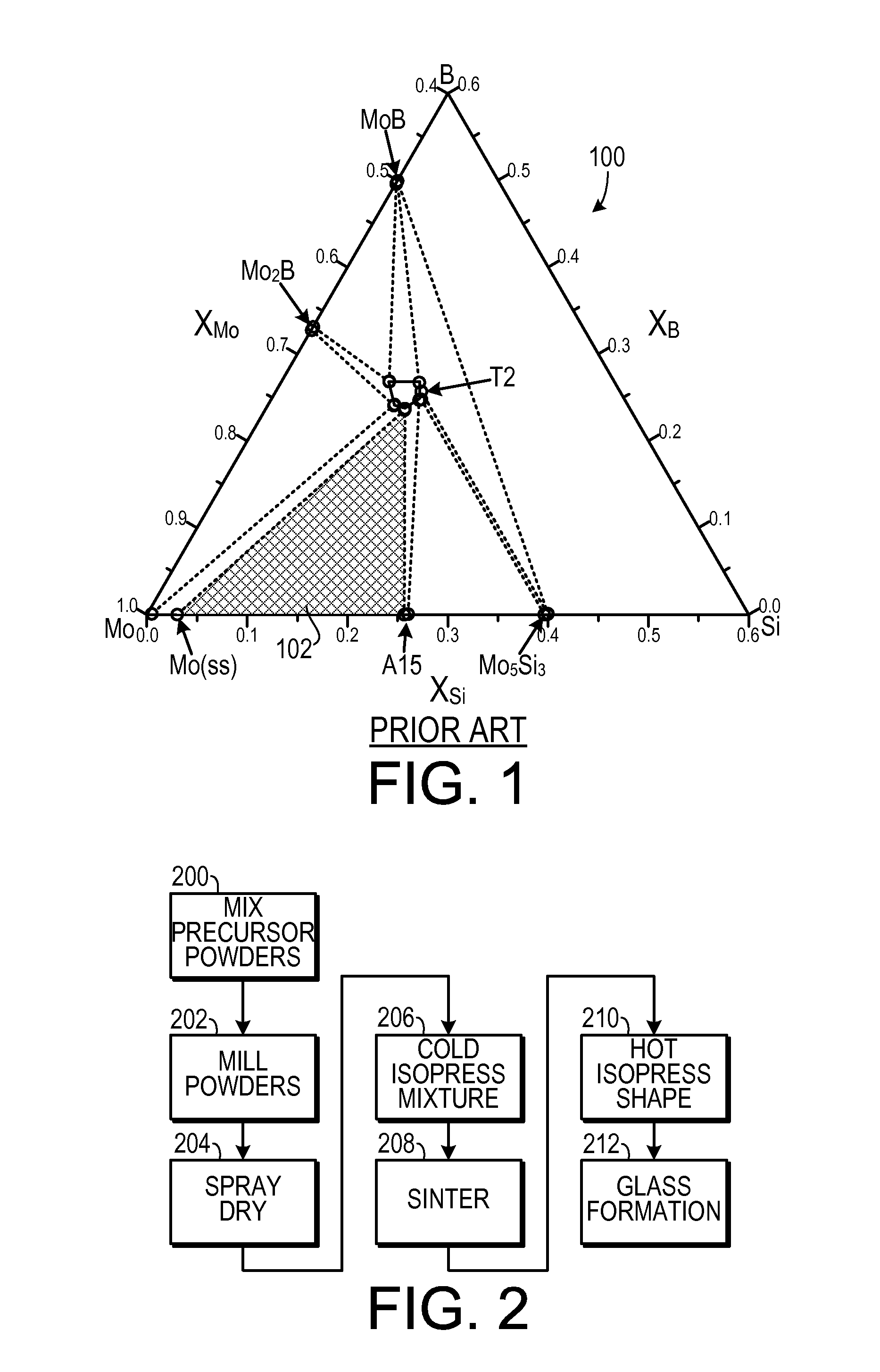

[0025]As shown in FIG. 2, one representative method of making a molybdenum, molybdenum silicide and molybdenum silicon boride composite material, includes mixing 200 a sub-micron boron nitride (such as BN) powder, a sub-micron silicon nitride (such as Si3N4) powder and a sub-micron molybdenum powder to form a composite precursor. The composite precursor may be milled 202 prior to the sintering action to break up agglomerates of the boron nitride powder, the silicon nitride powder and the molybdenum powder. The silicon nitride powder and the molybdenum po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com