Ceramic membrane coating for interior decorative plate of urban rail transit vehicle

A technology for urban rail transit and porcelain film coating, applied in the field of vehicles, can solve the problems of poor temperature resistance of fluorocarbon paint, shorten the time for passengers to escape, and achieve the effects of convenient construction and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of ceramic film coating used for interior panels of urban rail transit vehicles, the mass percentage of its raw material components is , which is divided into three components, wherein the first component is 60%, the second component is 28%, and the second component is 60%. The three components are 12%;

[0039] The first component is color paste, which includes silica sol, filler, pigment, water and solvent, wherein,

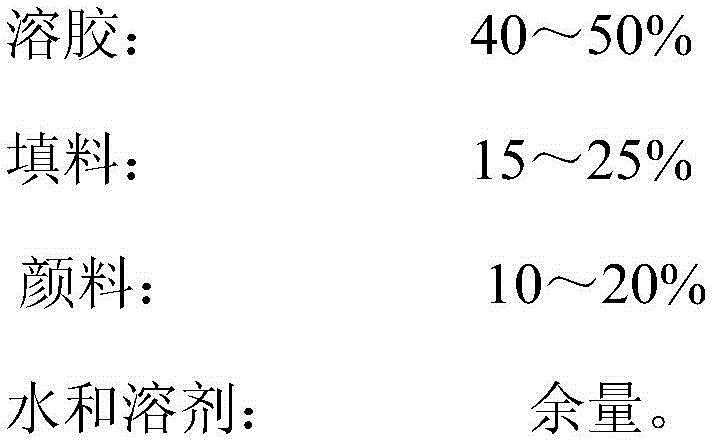

[0040] The raw material mass percentage of the first component is:

[0041] Silica sol: 40%

[0042] Filler: 15%

[0043] Pigment: 10%

[0044] Water and solvents: 25%;

[0045] The mass ratio of water and solvent is 1:1;

[0046] The silica sol is water-dispersible nano-scale silicon oxide with a particle size of 10-100 nm and a silicon oxide content of 20-50%.

[0047] The fillers are hollow glass microspheres, kaolin, mica powder, silicon whiskers, potassium titanate whiskers, precipitated barium sulfate and nano silicon boride.

[0048]...

Embodiment 2

[0065] A kind of ceramic film coating used for interior panels of urban rail transit vehicles, the mass percentage of its raw material components is , which is divided into three components, wherein the first component is 62%, the second component is 30%, and the second component is The three components are 8%;

[0066] The first component is color paste, which includes silica sol, filler, pigment, water and solvent, wherein,

[0067] The raw material mass percentage of the first component is:

[0068] Silica sol: 45%

[0069] Filler: 20%

[0070] Pigment: 15%

[0071] Water and solvents: 20%;

[0072] The mass ratio of water and solvent is 1:1;

[0073] The silica sol is water-dispersible nano-scale silicon oxide with a particle size of 10-100 nm and a silicon oxide content of 20-50%.

[0074] The fillers are hollow glass microspheres, kaolin, mica powder, silicon whiskers, potassium titanate whiskers, precipitated barium sulfate and nano silicon boride.

[0075] The n...

Embodiment 3

[0091] A kind of ceramic film coating used for interior panels of urban rail transit vehicles, the mass percentage of its raw material components is , which is divided into three components, wherein the first component is 65%, the second component is 34%, and the second component is The three components are 1%;

[0092] The first component is color paste, which includes silica sol, filler, pigment, water and solvent, wherein,

[0093] The raw material mass percentage of the first component is:

[0094] Silica sol: 50%

[0095] Filler: 25%

[0096] Pigment: 20%

[0097] Water and solvents: 5%

[0098] The mass ratio of water and solvent is 1:1;

[0099] The silica sol is water-dispersible nano-scale silicon oxide with a particle size of 10-100 nm and a silicon oxide content of 20-50%.

[0100] The fillers are hollow glass microspheres, kaolin, mica powder, silicon whiskers, potassium titanate whiskers, precipitated barium sulfate and nano silicon boride.

[0101] The nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com