Wear-resistant lining plate of bucket wheel machine hopper

A technology of wear-resistant liner and bucket wheel machine, which is applied in the field of metal materials, can solve the problems of further improvement of wear resistance and low carbide content, and achieve the effects of stable and uniform quality of finished products, simple preparation process, and avoiding pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

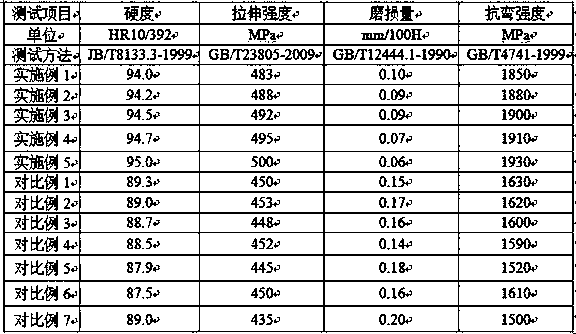

Examples

Embodiment 1

[0031] A wear-resistant liner for a bucket wheel hopper, characterized in that the composition in terms of weight percentage is: 0.5% carbon, 0.1% germanium, 1.5% manganese, 0.05% technetium, 0.2% copper, 0.4% zirconium, and 0.05% tantalum , yttrium 0.01%, holmium 0.02%, silicon boride 0.05%, sulfur ≤ 0.03%, phosphorus ≤ 0.03%, and the balance is iron.

[0032] The preparation method of the wear-resistant liner of the bucket wheel machine hopper includes the following steps:

[0033] Step S1: mixing carbon, germanium, manganese, technetium, copper, zirconium, tantalum, yttrium, holmium, silicon boride, sulfur, and phosphorus according to weight percentage, and then placing them in a ball mill for ball milling to obtain a mixture; The rotating speed of described ball mill is 180rpm, and described ball milling time is 3 hours;

[0034] Step S2: Using pig iron and steel scrap as the source of iron, adding the pig iron to the induction furnace to heat and melt, then desulfurizing...

Embodiment 2

[0041] A wear-resistant liner for a bucket wheel hopper, characterized in that the composition in terms of weight percent is: 0.6% carbon, 0.15% germanium, 1.6% manganese, 0.06% technetium, 0.3% copper, 0.5% zirconium, and 0.06% tantalum , yttrium 0.015%, holmium 0.025%, silicon boride 0.06%, sulfur ≤ 0.03%, phosphorus ≤ 0.03%, and the balance is iron.

[0042] The preparation method of the wear-resistant liner of the bucket wheel machine hopper includes the following steps:

[0043] Step S1: mixing carbon, germanium, manganese, technetium, copper, zirconium, tantalum, yttrium, holmium, silicon boride, sulfur, and phosphorus according to weight percentage, and then placing them in a ball mill for ball milling to obtain a mixture; The rotating speed of described ball mill is 190rpm, and described ball milling time is 3.5 hours;

[0044] Step S2: Using pig iron and steel scrap as the source of iron, adding the pig iron to the induction furnace to heat and melt, then desulfurizi...

Embodiment 3

[0051] A wear-resistant liner for a bucket wheel hopper, characterized in that the composition in terms of weight percentage is: 0.65% carbon, 0.2% germanium, 1.7% manganese, 0.08% technetium, 0.35% copper, 0.65% zirconium, and 0.065% tantalum , yttrium 0.02%, holmium 0.03%, silicon boride 0.08%, sulfur ≤ 0.03%, phosphorus ≤ 0.03%, and the balance is iron.

[0052] The preparation method of the wear-resistant liner of the bucket wheel machine hopper includes the following steps:

[0053] Step S1: mixing carbon, germanium, manganese, technetium, copper, zirconium, tantalum, yttrium, holmium, silicon boride, sulfur, and phosphorus according to weight percentage, and then placing them in a ball mill for ball milling to obtain a mixture; The rotating speed of described ball mill is 200rpm, and described ball milling time is 4 hours;

[0054] Step S2: Using pig iron and steel scrap as the source of iron, adding the pig iron to the induction furnace to heat and melt, then desulfuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com