Furan resin laminating core sand for train component casting and preparing method of furan resin laminating core sand

A furan resin and component technology is applied in the field of furan resin-coated core sand for casting of train parts and its preparation, which can solve problems such as affecting product quality and harming human health by toxic gases, and achieves accelerated hardening time, which is beneficial to workers' health, The effect of reducing the amount of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A furan resin-coated core sand for train component casting, which is prepared from the following raw materials in parts by weight (kg): fused magnesia 140, chromite sand 30, ceramsite sand 20, glass pumice 14, furan resin 3. Molecularly distilled monoglyceride 0.5, aluminum phosphite 2, calcium stearate 3, spherical quartz powder 8, nano-tungsten oxide 3, silicon boride 5, triphenolyl methane triglycidyl ether 2, triethylenetetramine 0.2 , Toluenesulfonic acid 2, methyl sulfate 5, sulfuric acid 2, phosphoric acid 4, methanol 8, ethanol 6, water 20.

[0017] A preparation method for furan resin-coated core sand for casting train parts, comprising the following steps:

[0018] (1) Mix toluenesulfonic acid, methyl sulfate and sulfuric acid at a temperature of 65-70°C for 50-60 minutes, add methanol after cooling down to 55-60°C, keep warm for 40-50 minutes, then add phosphoric acid and water and mix well Back discharging, obtains resin curing agent;

[0019] (2) Mix chro...

Embodiment 2

[0022] A furan resin-coated core sand for the casting of train parts, which is prepared from the following raw materials in parts by weight (kg): 150 parts by weight of fused magnesia, 35 parts of chromite sand, 25 parts of ceramsite sand, 15 parts of glass pumice, and furan resin 4. Molecularly distilled monoglyceride 0.6, aluminum phosphite 3, calcium stearate 4, spherical quartz powder 9, nano-tungsten oxide 4, silicon boride 6, triphenolyl methane triglycidyl ether 2.5, triethylenetetramine 0.3 , 3 toluenesulfonic acid, 6 methyl sulfate, 2.5 sulfuric acid, 5 phosphoric acid, 9 methanol, 7 ethanol, 25 water.

[0023] The preparation method is the same as in Example 1.

Embodiment 3

[0025] A furan resin-coated core sand for train component casting, which is prepared from the following raw materials in parts by weight (kg): 160 parts by weight of fused magnesia, 40 parts chromite sand, 30 parts ceramsite sand, 16 parts glass pumice, and furan resin 5. Molecularly distilled monoglyceride 0.7, aluminum phosphite 4, calcium stearate 5, spherical quartz powder 10, nano-tungsten oxide 5, silicon boride 7, triphenolyl methane triglycidyl ether 3, triethylenetetramine 0.4 , 4 toluenesulfonic acid, 7 methyl sulfate, 3 sulfuric acid, 6 phosphoric acid, 10 methanol, 8 ethanol, 30 water.

[0026] The preparation method is the same as in Example 1.

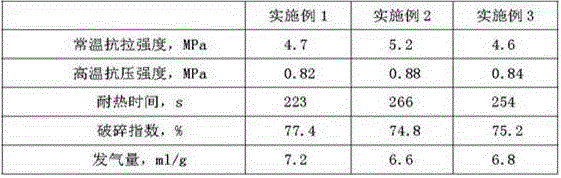

[0027] The performance detection result of the furan resin coated core sand that above-mentioned embodiment 1-3 makes is shown in the table below:

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com