High-temperature infrared energy-saving coating based on boride ceramics and preparation method thereof

A technology of high-temperature infrared and energy-saving coatings, applied in coatings and other directions, can solve the problems of polluting products in the furnace, easy oxidation of coatings, fast decay of energy-saving effects, etc., and achieve the effect of less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

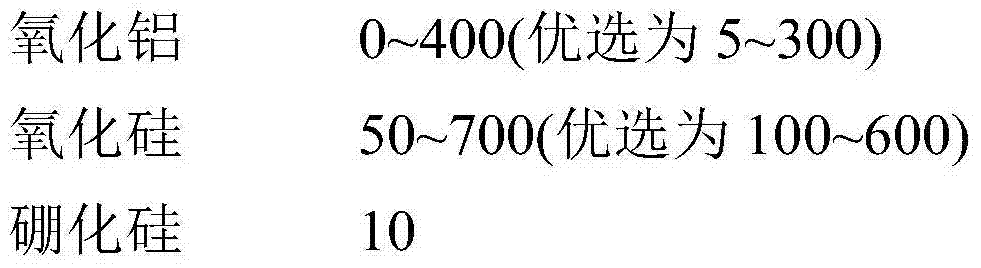

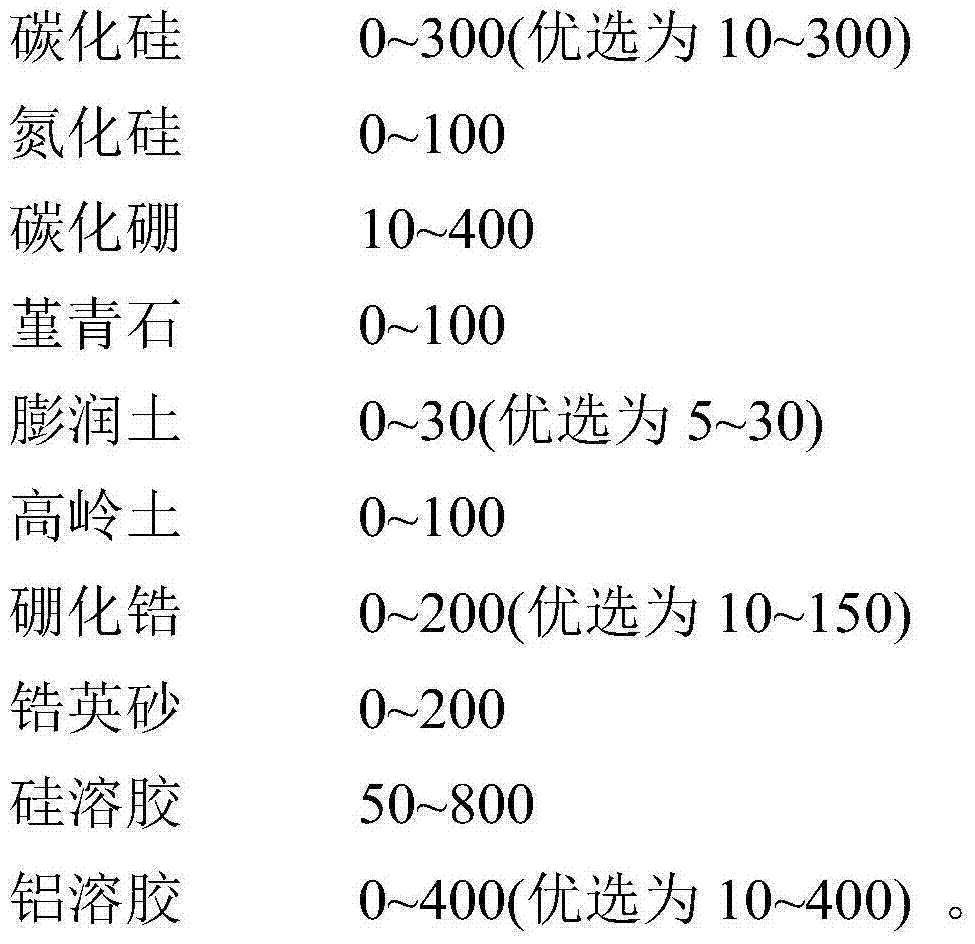

[0015] The high-temperature infrared energy-saving coating based on high-emissivity boride ceramics is composed of the following components by weight, based on the weight of silicon boride:

[0016]

[0017]

[0018] The particle size of the solid components in the above components is at least 320 mesh, and the particle size of the particles in the silica sol is less than 100 nanometers.

[0019] The preparation method is as follows:

[0020] The above-mentioned components are weighed according to the proportion, mixed, then put into a dispersing and grinding machine, and stirred at a high speed to make a viscous suspension fluid, and a high-temperature infrared energy-saving coating product based on high-emissivity boride ceramics is obtained.

[0021] The high-temperature infrared energy-saving coating based on high-emissivity boride ceramics was tested with a dual-band emissivity tester, and the infrared emissivity at room temperature was 0.89.

Embodiment 2

[0023] The high-temperature infrared energy-saving coating based on high-emissivity boride ceramics is composed of the following components by weight, based on the weight of silicon boride:

[0024]

[0025]

[0026] The particle size of the solid component in the above components is at least 320 mesh, and the particle size of the particles in the silica sol and aluminum sol are both lower than 100 nanometers.

[0027] The preparation method is as follows:

[0028] The above-mentioned components are weighed according to the proportion, mixed, then put into a dispersing and grinding machine, and stirred at a high speed to make a viscous suspension fluid, and then a high-temperature infrared energy-saving coating product based on high-emissivity boride ceramics can be obtained.

[0029] The high-temperature infrared energy-saving coating based on high-emissivity boride ceramics was tested with a dual-band emissivity tester, and the infrared emissivity at room temperature w...

Embodiment 3

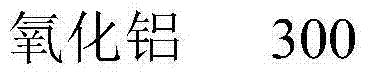

[0031] The high-temperature infrared energy-saving coating based on high-emissivity boride ceramics is composed of the following components by weight, based on the weight of silicon boride:

[0032]

[0033] The particle size of the solid component in the above components is at least 320 mesh, and the particle size of the particles in the silica sol and aluminum sol are both lower than 100 nanometers.

[0034] The preparation method is as follows:

[0035] The above-mentioned components are weighed according to the proportion, mixed, then put into a dispersing and grinding machine, and stirred at a high speed to make a viscous suspension fluid, and then a high-temperature infrared energy-saving coating product based on high-emissivity boride ceramics can be obtained.

[0036] The high-temperature infrared energy-saving coating based on high-emissivity boride ceramics was tested with a dual-band emissivity tester, and the infrared emissivity at room temperature was 0.87.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com