Small-sized refuse disposal device

A garbage disposal device and garbage technology, which are applied in the combustion type, combustion method, lighting and heating equipment, etc., can solve the problem that the heat of the flue gas cannot be fully utilized, and achieve the effect of solving the incomplete utilization and optimizing the combustion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

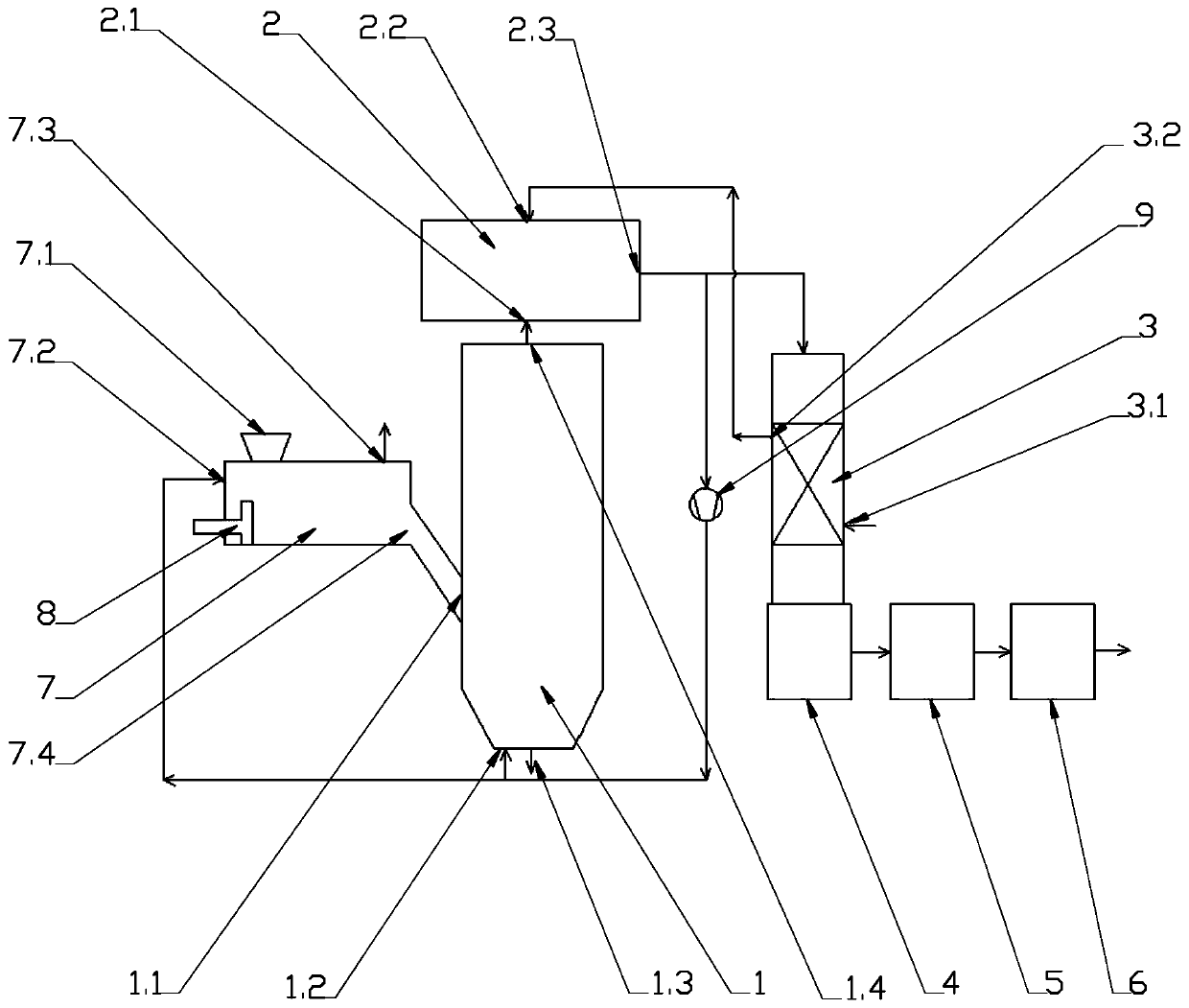

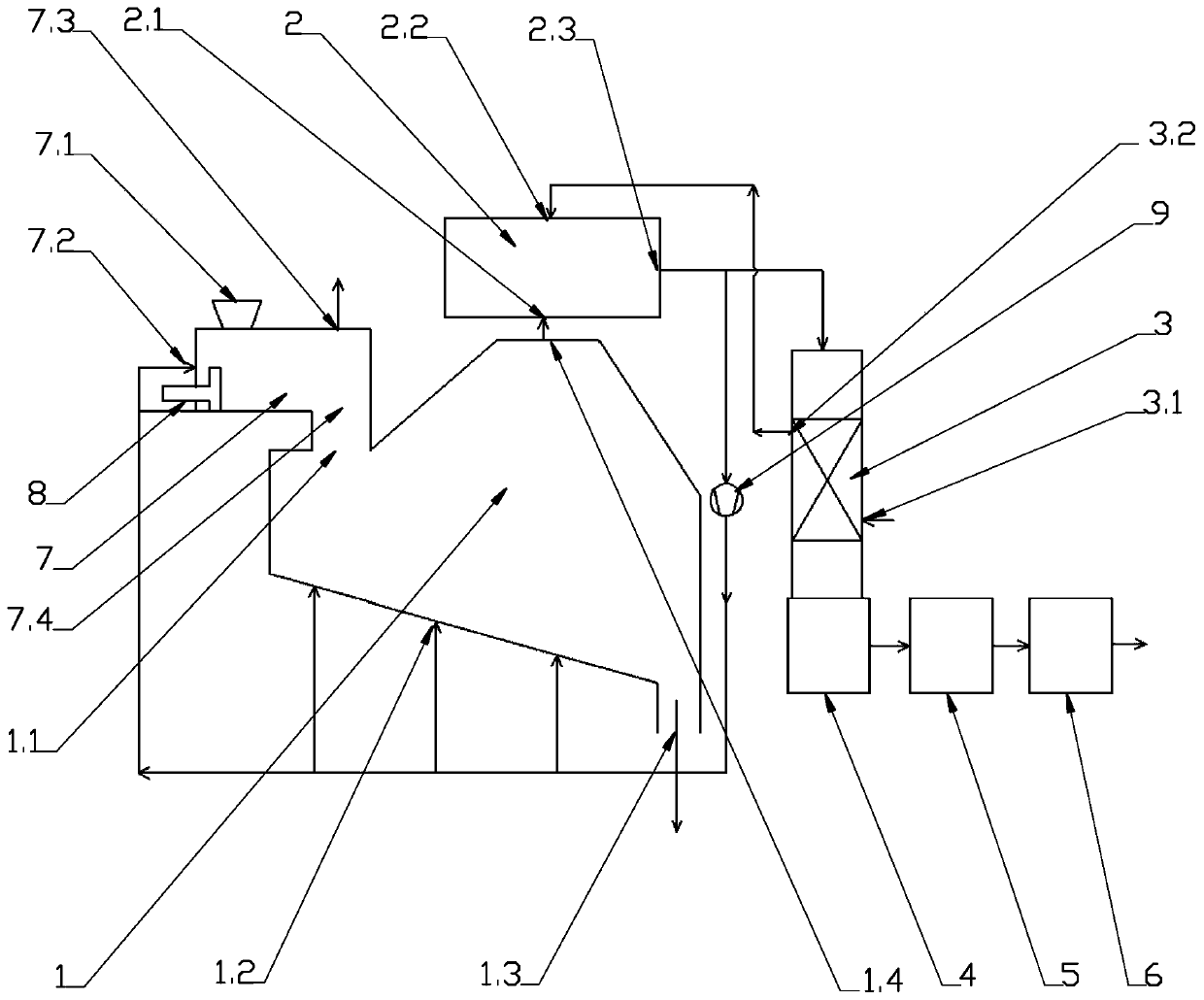

[0026] figure 1 It is a structural schematic diagram of the first embodiment proposed by the present invention. figure 1 As shown in , in this example, the waste pyrolysis gasifier adopts a fluidized bed furnace.

[0027] figure 1 In this example, a small-scale garbage treatment device includes a pyrolysis gasifier 1, a secondary combustion chamber 2, an air preheater 3, a semi-dry desulfurization system 4, an activated carbon injection system 5, a bag filter 6, Garbage push rod 8 and drying box 7.

[0028] As shown in the figure, the front portion of the furnace of the pyrolysis gasifier 1 is provided with a waste feed port 1.1, and the bottom of the pyrolysis gasifier is provided with a high-temperature flue gas inlet 1.2 and an ash outlet 1.3. The upper part is provided with a combustible gas outlet 1.4.

[0029] The upper part of the drying box 7 is provided with a garbage inlet 7.1, the drying box 7 is also provided with a high-temperature flue gas inlet 7.2 and a flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com