Iron modified peanut shell magnetic biochar as well as preparation method and application thereof

A peanut shell and biochar technology, applied in chemical instruments and methods, water pollutants, alkali metal compounds, etc., can solve problems such as difficulty in separating adsorbents from polluted water bodies, and achieve resource utilization, low price, and good environment. The effect of benefit and social benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

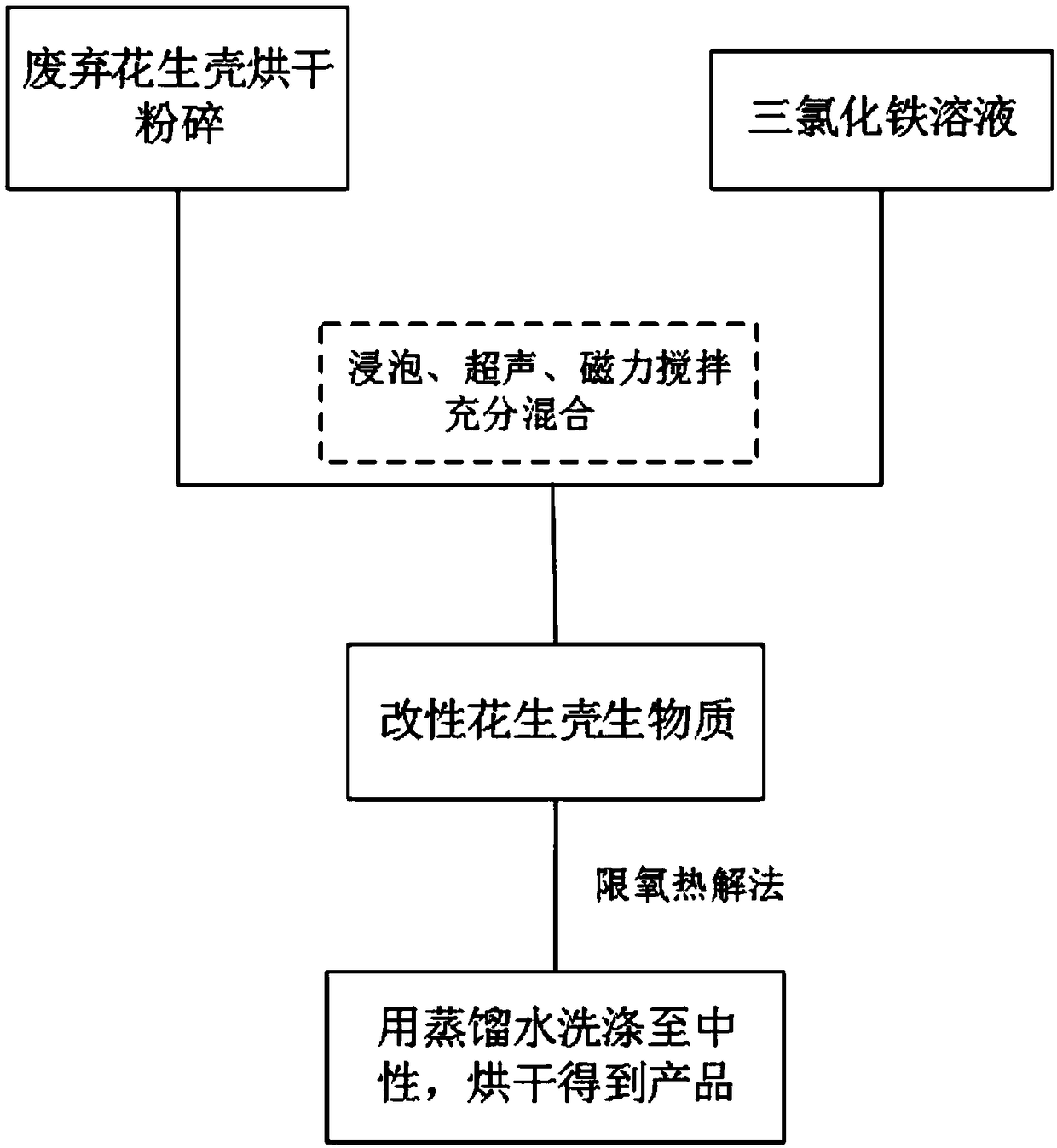

[0035] Such as figure 1 Shown, an iron-modified peanut shell magnetic biochar is prepared by the following steps:

[0036] (1) Wash the collected discarded peanut shells, place them in an oven, and dry them at 60°C for 48 hours at a low temperature to obtain completely dried peanut shells, which are then pulverized into powder with a pulverizer, and then the peanut shells are powdered 60 mesh sieve for use.

[0037] (2) Weigh 32.442g of anhydrous ferric chloride with a balance, dissolve it all in a glass bottle with 100mL of distilled water, and prepare a 2mol / L ferric chloride solution, then weigh 10g of sieved peanut shells The biomass was added to the prepared 100mL 2mol / L ferric chloride solution according to the solid-to-liquid ratio of 1:10, ultrasonically dispersed for 15min, and magnetically stirred for 24h to fully mix the two.

[0038] (3) Wash the soaked biomass several times, wash with distilled water until the supernatant is neutral (6.5-7.0), collect the solid ...

Embodiment 2

[0073] An iron-modified peanut shell magnetic biochar, prepared by the following steps:

[0074] (1) Wash the collected discarded peanut shells, put them in an oven, and dry them at 80°C for 48 hours at a low temperature until completely dried peanut shells are obtained, then crush them into powder with a pulverizer, and then grind the peanut shells into powder Pass through 80 mesh sieve for later use.

[0075] (2) Weigh a certain amount of anhydrous ferric chloride with a balance, dissolve it all in a glass bottle with 100mL distilled water, prepare a 1mol / L ferric chloride solution, and then weigh 10g of sieved peanuts The shell biomass was added to the prepared 100mL 1mol / L ferric chloride solution according to the solid-to-liquid ratio of 1:15, ultrasonically dispersed for 15min, and magnetically stirred for 24h to fully mix the two.

[0076] (3) The soaked biomass was washed several times, washed with distilled water until the supernatant was neutral, the solid matter on...

Embodiment 3

[0086] An iron-modified peanut shell magnetic biochar, prepared by the following steps:

[0087] (1) Wash the collected discarded peanut shells, put them in an oven, and dry them at 80°C for 48 hours at a low temperature until completely dried peanut shells are obtained, then crush them into powder with a pulverizer, and then grind the peanut shells into powder Pass through a 100-mesh sieve for later use.

[0088] (2) Weigh a certain amount of anhydrous ferric chloride with a balance, dissolve it all in a glass bottle with 100mL distilled water, prepare a 1mol / L ferric chloride solution, and then weigh 10g of sieved peanuts The shell biomass was added to the prepared 100mL 1mol / L ferric chloride solution according to the solid-to-liquid ratio of 1:10, ultrasonically dispersed for 15min, and magnetically stirred for 24h to fully mix the two.

[0089] (3) The soaked biomass was washed several times, washed with distilled water until the supernatant was neutral, the solid matter...

PUM

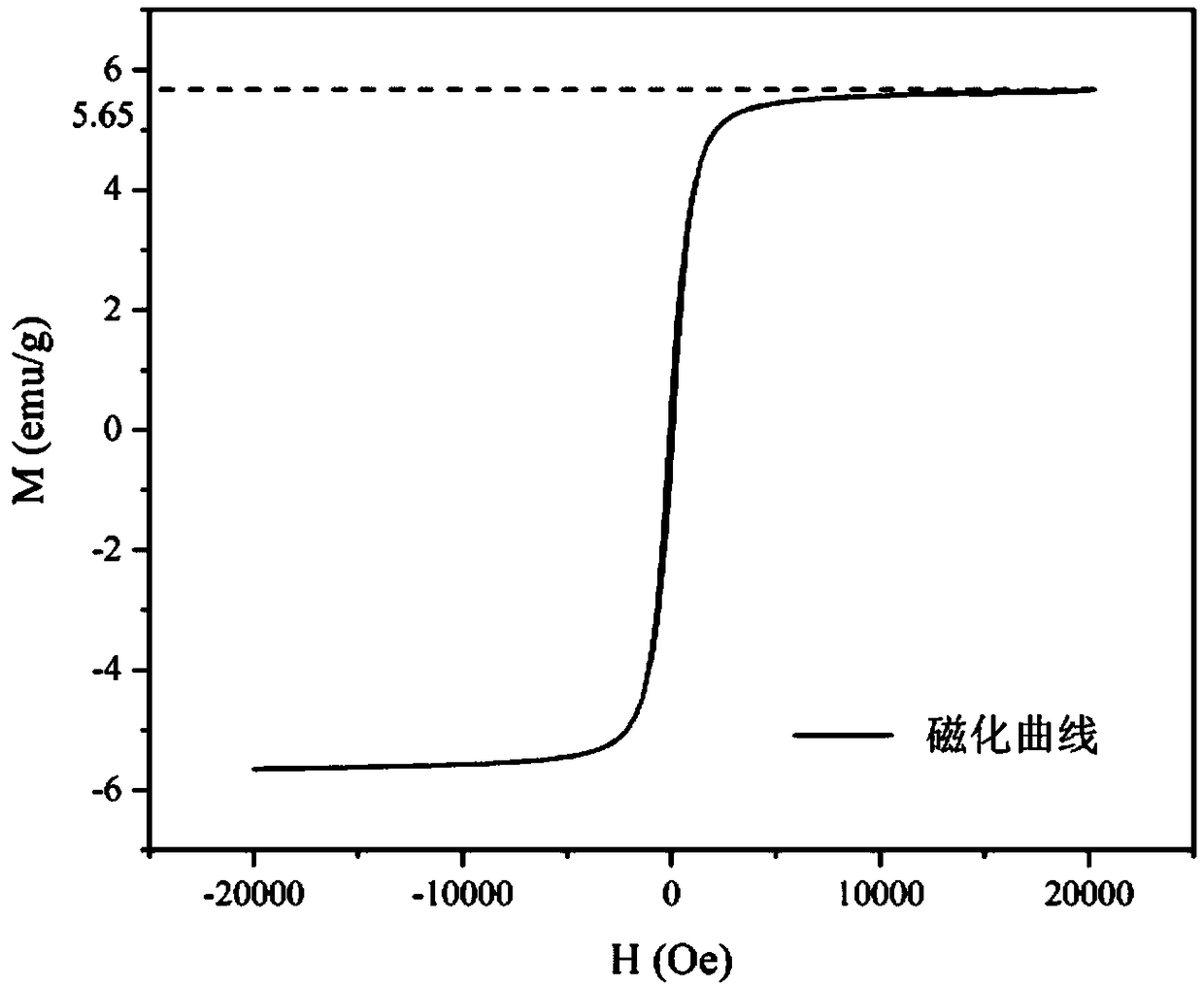

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Maximum saturated adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com