Process for co-producing bio-oil and biological carbon by utilizing crop straws and special device

The invention relates to a technology of crop straw and special device, which is applied in the field of technology and special device for using crop straw to produce bio-oil and biochar, and can solve the problems of complex composition and high cost, and achieve less environmental pollution, low production cost and enhanced catalytic effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

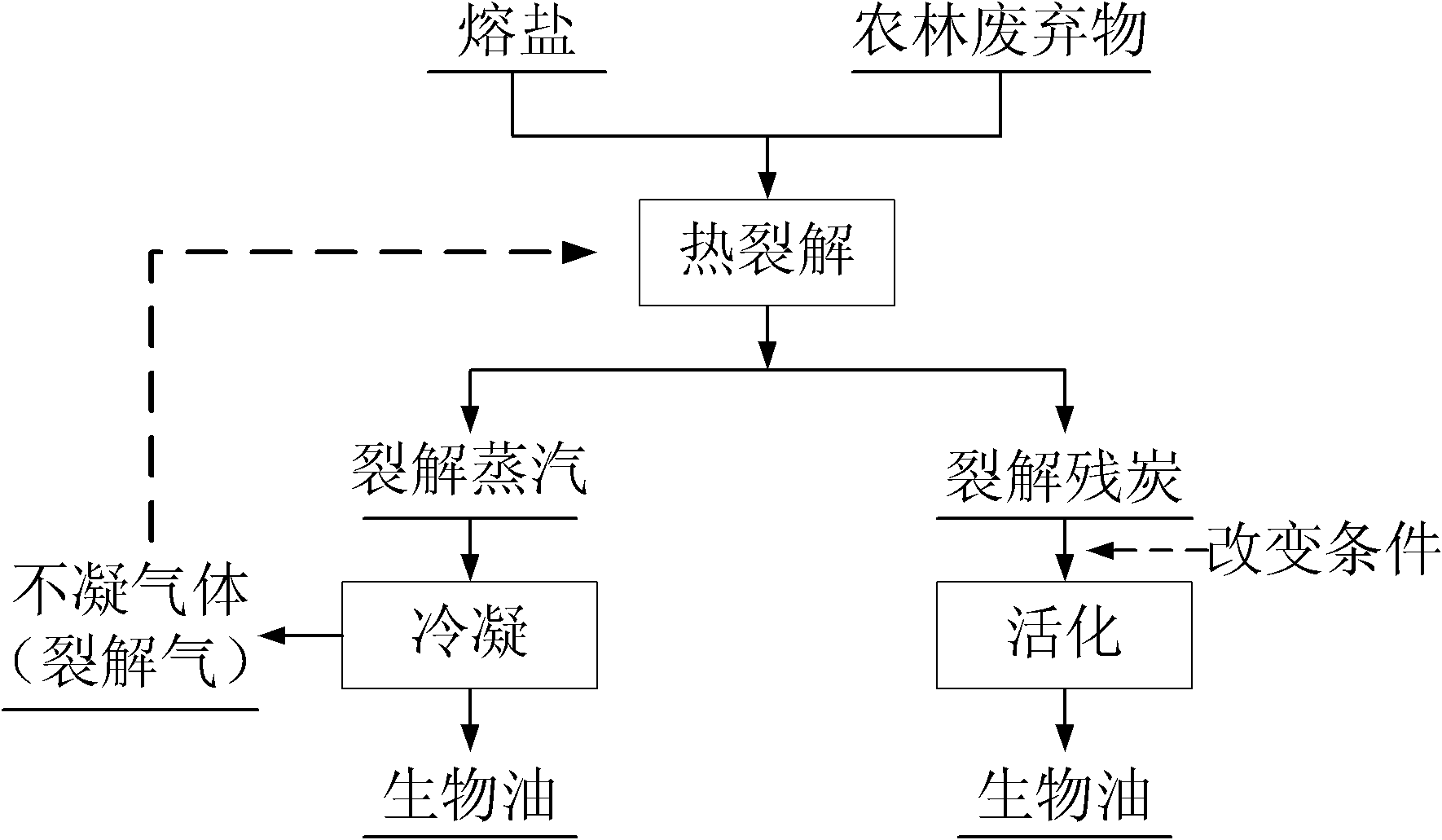

[0035] refer to figure 1 and figure 2 A process for co-producing bio-oil and biochar by utilizing crop stalks, said process comprising the following steps:

[0036] (1), select alkaline earth metal halide or alkali as molten salt, and molten salt is put into molten salt pyrolysis reactor;

[0037] (2) Turn on the electric furnace of the molten salt pyrolysis reactor, raise the temperature to 110° C. to 130° C. to evaporate the moisture in the molten salt, and then heat to the pyrolysis reaction temperature of 350° C. to 650° C.

[0038] (3), start the screw feeder, and send the crop straw into the molten salt pyrolysis reactor, and the mass-number ratio of the crop straw to the molten salt is: 1:0.5~3.5;

[0039] (4) Part of the steam generated by thermal cracking in the molten salt pyrolysis reactor is condensed to obtain a liquid product, that is, bio-oil, and the non-condensable part is a gaseous product;

[0040] (5) Adjust the temperature of the molten salt pyrolysis re...

example 1

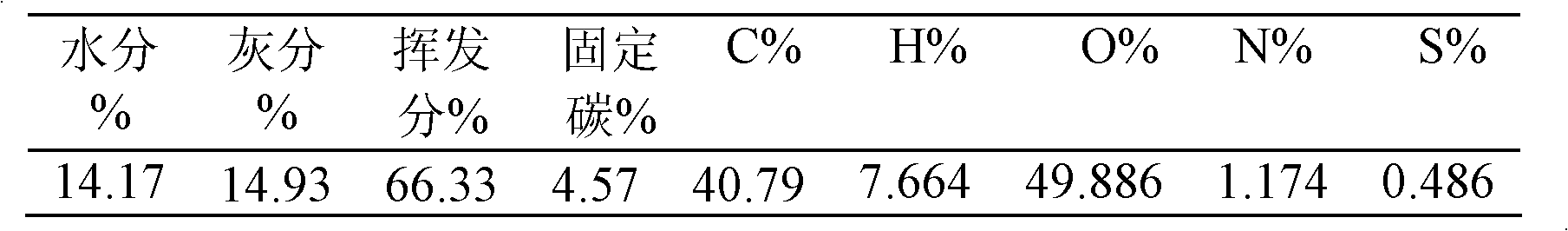

[0052] Example 1: Select rice stalks produced in East China as raw materials. The contents of cellulose, hemicellulose and lignin were measured by X.H. Bochinnock analysis method to be 31.7%, 19.0% and 21.5% respectively, and the elemental analysis and industrial analysis results are shown in Table 1 below.

[0053]

[0054] Table 1

[0055] For sieving treatment, select biomass raw materials with a particle diameter of 0.45 mm (40 mesh), and put them into an oven at 100° C. for 3 hours to remove the naturally adsorbed moisture.

[0056] Under the conditions of 450°C and a nitrogen flow rate of 200L / h (corresponding to a laboratory-scale reactor with an inner diameter of 95 mm and a height of 150 mm), rice straw was cracked with zinc chloride molten salt. The yield of liquid products was 9.3%, and the yield of solid products was 9.3%. The yield was 65.5%, and the gaseous product yield was 25.2%.

[0057] The solid product was activated at 600 °C for 1 h. The methylene bl...

Embodiment 2

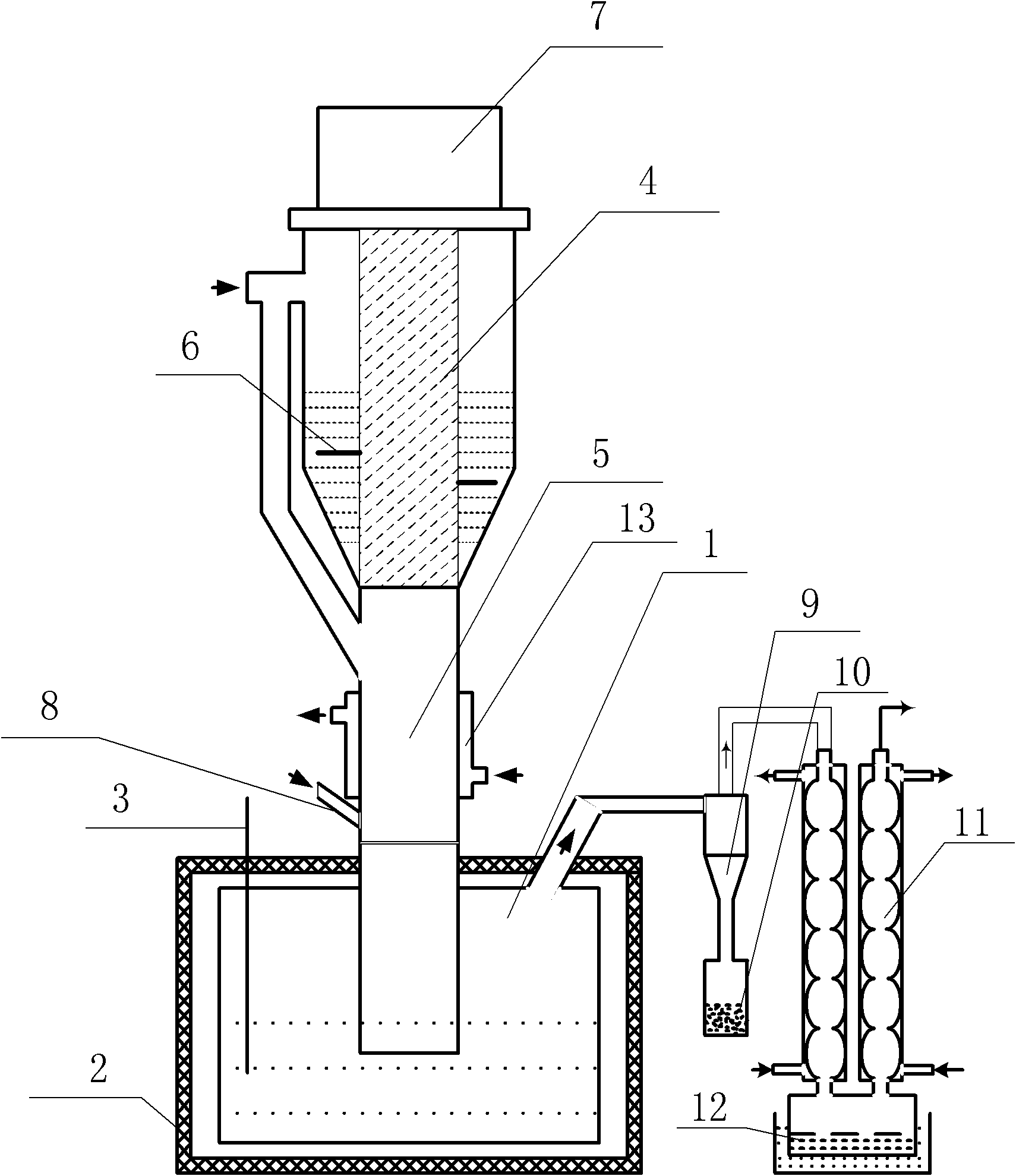

[0070] refer to figure 1 and figure 2, a special device for co-producing bio-oil and biochar by using crop stalks, the device includes a molten salt pyrolysis reactor 1, and the molten salt pyrolysis reactor includes a shell, an electric heating furnace 2, a feed inlet and a discharge The temperature sensor 3 is located in the shell, and the feed port communicates with the discharge pipe 5 of the screw feeder 4. The screw feeder 4 includes a stirrer 6 and a motor 7, and the stirrer 6 is connected to the stirring motor 7. The feed rate can be adjusted by adjusting the motor speed. The feed port is connected to the inert gas charging pipe 8, and the discharge port is connected to the inlet of the cyclone separator 9. A collection box 10 for collecting biochar, the gas outlet of the cyclone separator 9 is connected to a condenser 11, and a collection tank 12 for collecting bio-oil is arranged below the condenser 11.

[0071] The outer wall of the discharge pipe is covered with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com