Method for extracting bio-oil through normal-pressure continuous thermal pyrolysis of straws and equipment used in same

A thermal cracking and bio-oil technology, applied in the preparation of liquid hydrocarbon mixtures, biofuels, petroleum industry, etc., can solve the problems of increasing power consumption, increasing operating costs, hidden safety hazards, etc., so as to improve oil yield and reduce power consumption. and running costs, the effect of no noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

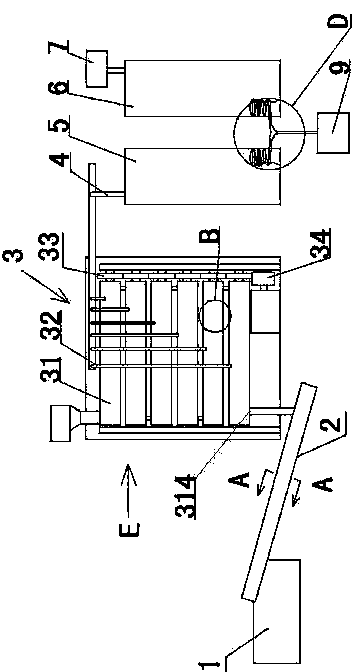

[0018] 1. Dry and crush the straw in turn until the length does not exceed 2 cm;

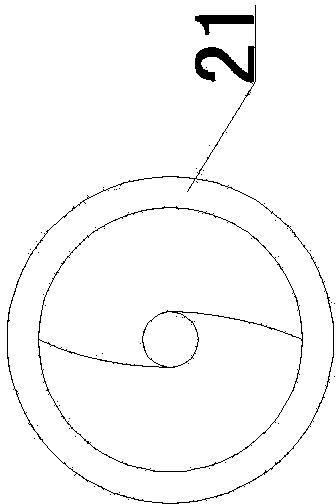

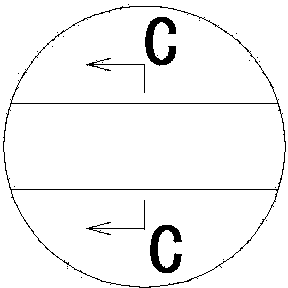

[0019] 2. See Figure 6 , the crushed stalk is sent into the thermal cracking equipment 3 in operation through the screw feeder 15, and said thermal cracking equipment is (see figure 1 ), six screw feeders 31 are connected end to end (referring to the connection between the outlet of the previous screw feeder and the inlet of the next screw feeder), reciprocating arrangement from top to bottom, see image 3 and 4 , the electric heating tube 312 is evenly laid on the surface of each screw feeder pipe 311, and then the electric heating tube is wrapped on the surface of the steel pipe with a bandage 313 made of heat insulating material, and the upper part of each screw feeder tube cavity Set a pyrolysis gas pipeline 32, after the gas outlets of the six pyrolysis gas pipelines are connected in parallel, they are connected with the parallel pipe 4 and the condensation pipe in turn, and the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com