Strong turbulence combusting system for reducing CO and NOx

A combustion system and turbulent flow technology, applied in the field of domestic waste incineration and pyrolysis gasification, can solve the problems of high original concentration of CO and high original concentration of NOx, and achieve low-oxygen combustion, inhibit the generation of NOx, and inhibit the generation of CO. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

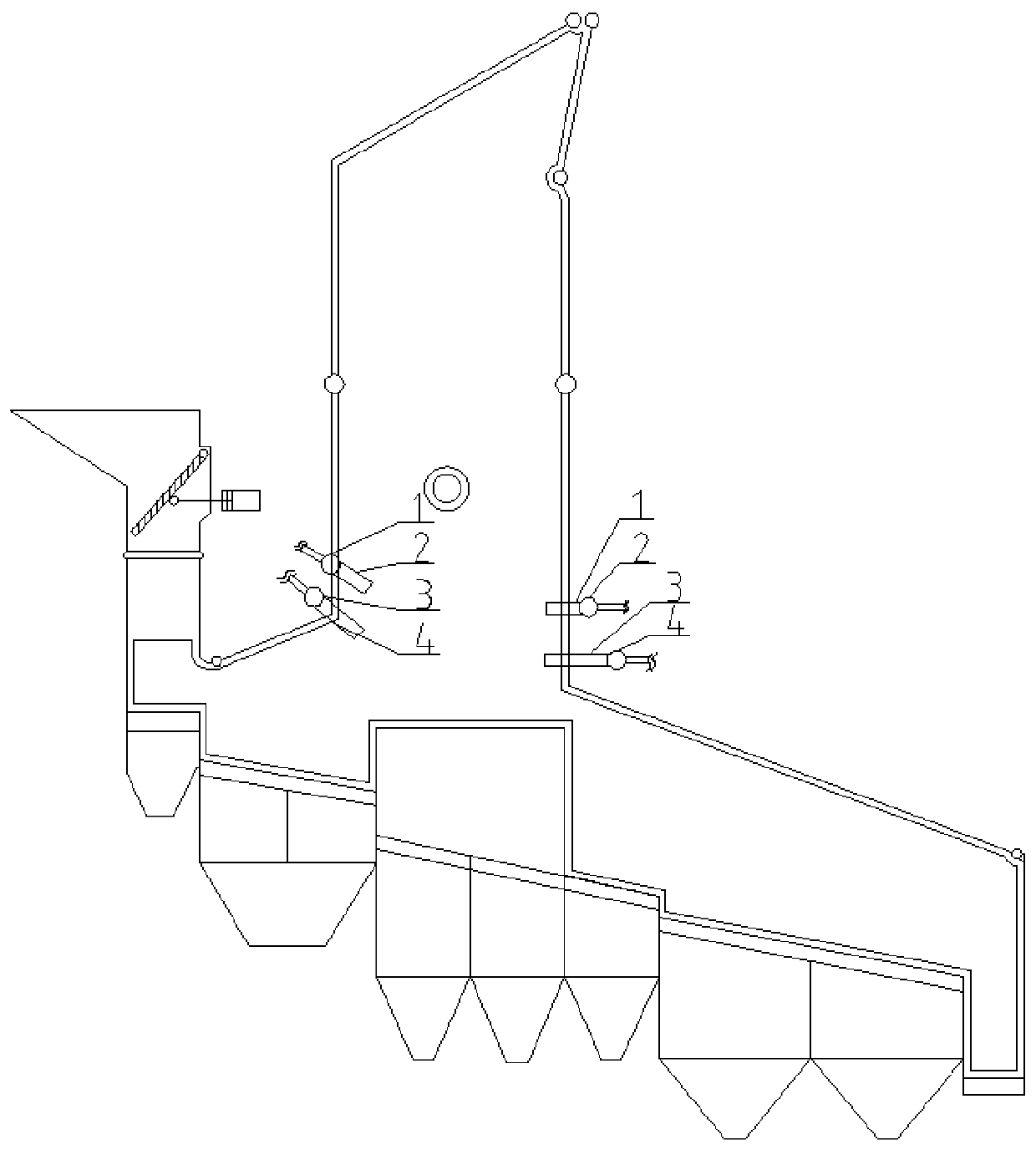

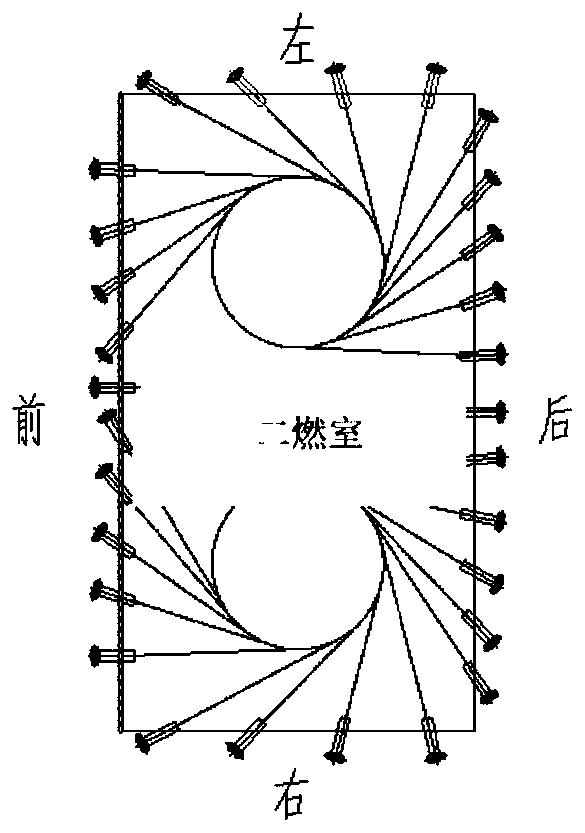

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be clearly and completely described below in conjunction with the accompanying drawings and examples of the present invention;

[0016] When the gas in the secondary combustion chamber is combusted, CO is produced mainly due to the fast flow rate of the combustion flue gas, and the disturbance intensity in the secondary combustion chamber is not enough, so the CO in the flue gas will not be fully combusted in the future.

[0017] There are two main types of NOx generation: thermal NOx and fuel-type NOx. Excessively high temperature or uneven temperature field distribution in the secondary combustion chamber can easily lead to thermal-type NOx generation. The larger the excess air coefficient is, the easier it is to generate fuel-type NOx. When the gas in the second combustion chamber is burned, CO is produced mainly because the flue gas velocity is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com