Method for treating oil field measure shaft backflow liquid to prepare rilling fluid

A technology of flowback liquid and measure well, which is applied in the direction of filtration treatment, sedimentation treatment, water/sewage treatment, etc., and can solve the problem that acid flowback liquid and high-viscosity flowback liquid cannot be treated simultaneously, achieving remarkable iron removal effect, The effect of reducing production cost and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

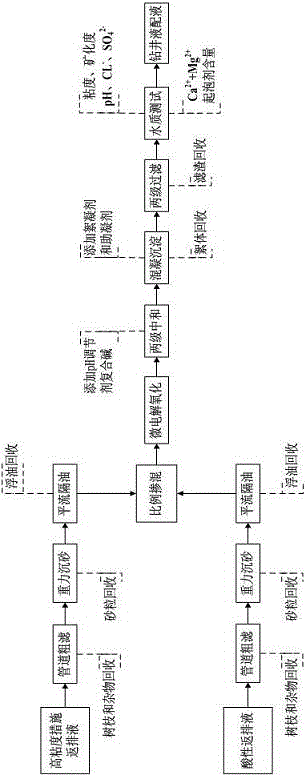

[0051] In order to overcome the problem that the acidic flowback liquid and the high viscosity flowback liquid cannot be simultaneously processed in the existing treatment method, the present invention provides such as figure 1 Shown is a method of oil field measure wellbore flowback fluid treatment for drilling fluid mixing, to realize the synchronous treatment of acidic flowback fluid and high viscosity flowback fluid, so that the viscosity, pH, ore of the flowback fluid after treatment Chemical degree, CL - , SO 4 2- , Ca 2+ +Mg 2+ And the foaming agent content meets the requirements of drilling fluid mixing. The micro-electrolysis technology integrates redox, flocculation adsorption, complexation and electro-precipitation, and is suitable for the viscosity reduction and purification treatment of wellbore flowback fluid in oilfields. According to the principle of the original battery, the acidic electrolyte environment can enhance the electric field effect, accelerate t...

Embodiment 2

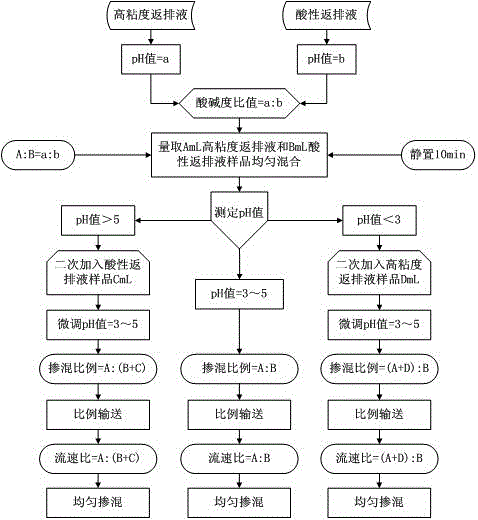

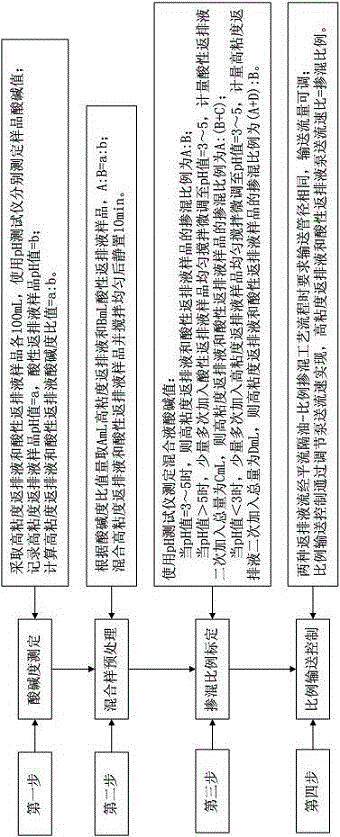

[0073] Based on Example 1, in this example, in the step 4), the blending ratio is determined by measuring the pH value of the acidic flowback liquid and the high viscosity flowback liquid, and blended into a partial pH value of 3-5. Acid liquid; specific steps are:

[0074] The first step is to measure the pH of the high-viscosity flowback liquid and the acidic flowback liquid; take 100 mL of each flowback liquid sample, and use a pH tester to measure the pH value of the sample; record the pH value of the high-viscosity flowback liquid sample = a, and The pH value of the drainage sample = b; calculate the pH ratio of the two flowback fluids = a:b;

[0075] The second step is to carry out the pretreatment of the mixed sample of high-viscosity flowback liquid and acidic flowback liquid; measure the samples of AmL high-viscosity flowback liquid and BmL acidic flowback liquid according to the pH ratio, mix and stir evenly and let stand for 10 minutes. Requirements A:B =a:b;

[0...

Embodiment 3

[0103] Based on the above embodiments, this embodiment takes the implementation process of proportional blending of flowback fluid in Changqing Oilfield CQML-18 wellbore acidizing operation and CQCH-05 wellbore secondary fracturing operation as an example. The water quality characteristics of the two flowback liquids before treatment are shown in the table below.

[0104]

[0105] CQML-18 wellbore acidizing operation flowback fluid and CQCH-05 wellbore secondary fracturing operation flowback fluid proportional blending and synchronous water quality characteristics are shown in the following table, the results show that the present invention can meet the oilfield measures wellbore flowback fluid treatment Afterwards, it is used for the reuse purpose of drilling fluid dosing.

[0106]

[0107] Taking Changqing Oilfield CQJY-27 wellbore acidizing operation flowback fluid and CQAS-15 wellbore pre-acid fracturing operation flowback fluid proportional blending implementation p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com