Deironing water separation device used for garbage disposal

A technology for waste disposal and molten iron, applied in the directions of magnetic separation, solid separation, wet separation, etc., can solve the problems of complex components and different sizes of waste, and achieve the effects of high degree of automation, convenient and quick removal, and convenient discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

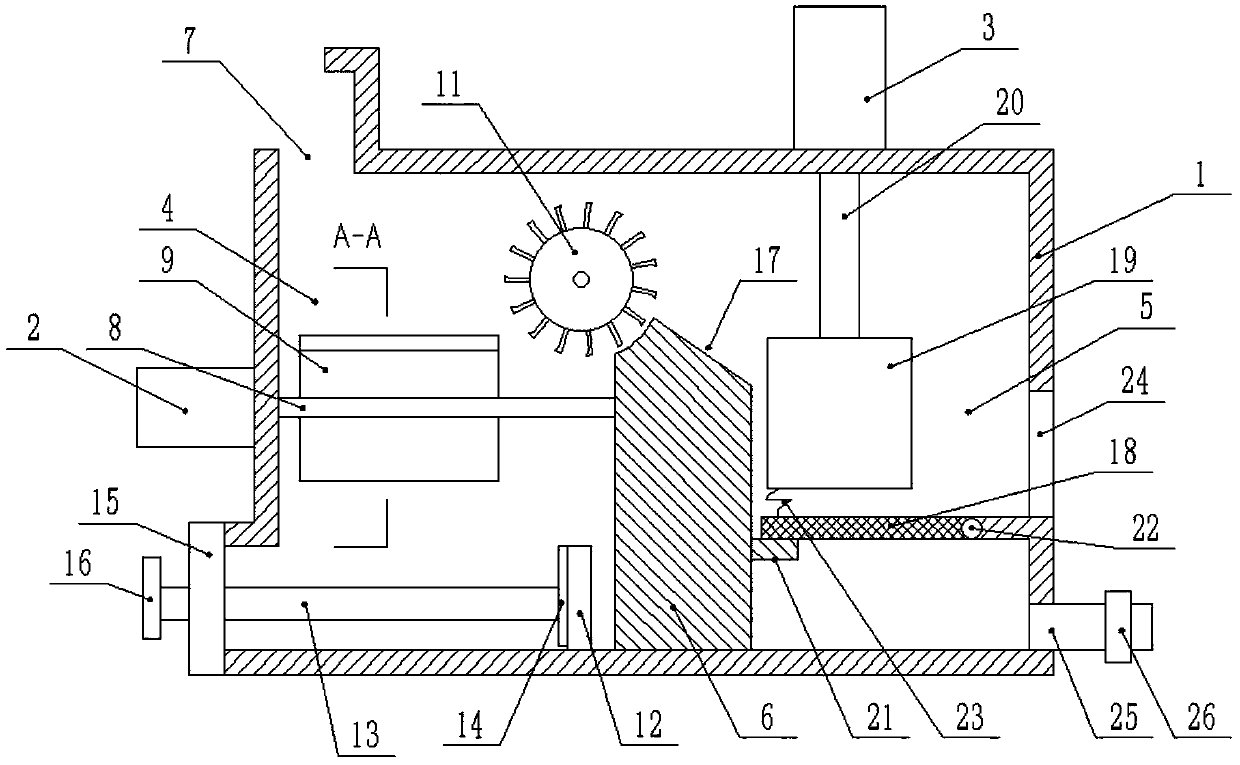

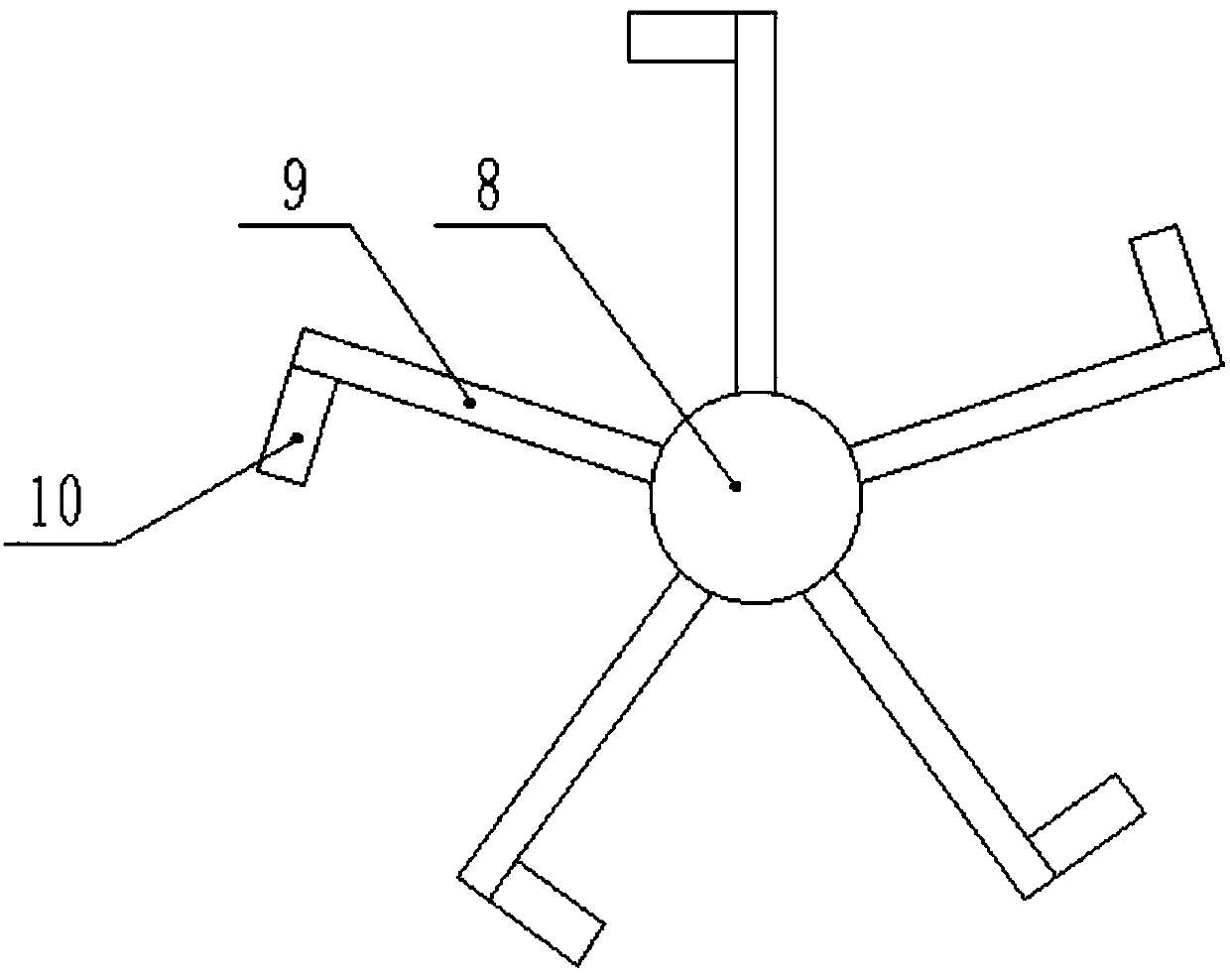

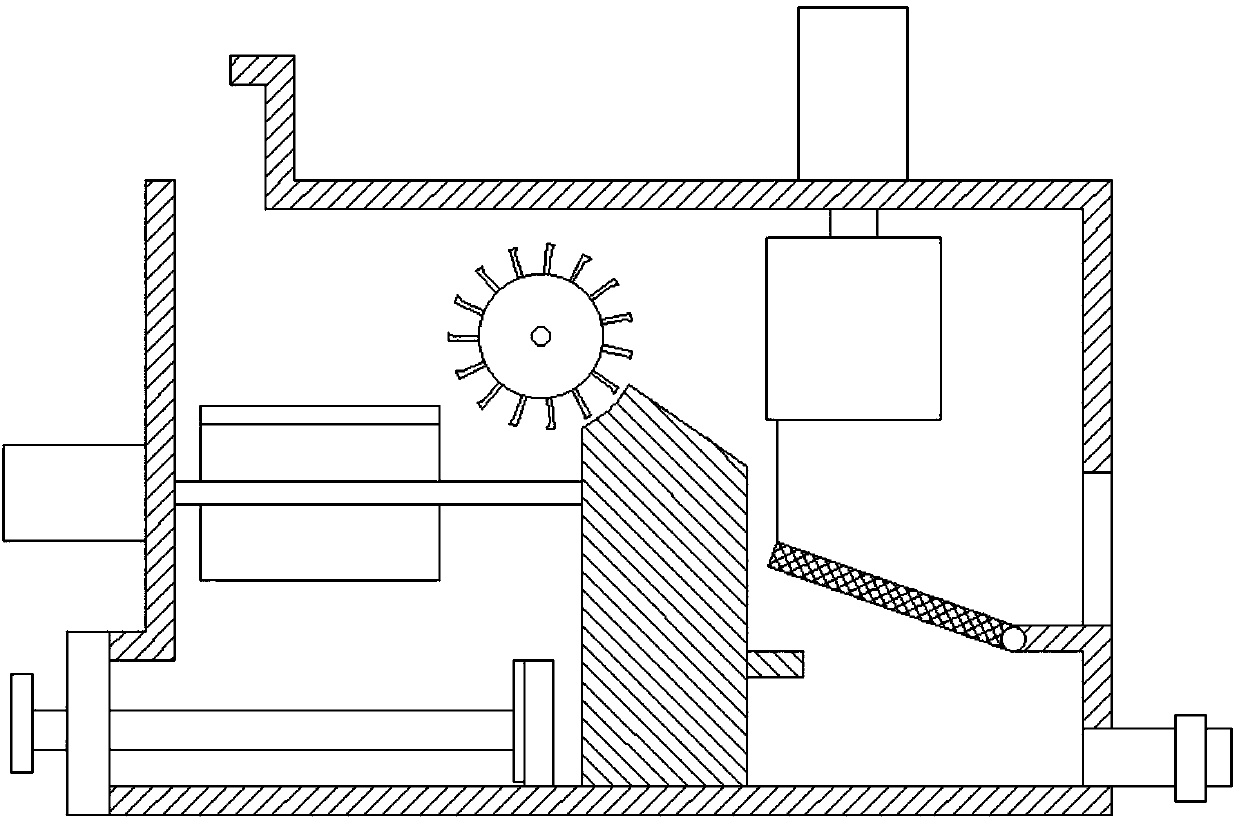

[0019] Please refer to the figure, in the embodiment of the present invention, a water separation device for iron removal for garbage treatment includes a housing 1, a motor 2, a hydraulic drive device 3 and a partition 6; the partition 6 is vertically fixed in the housing 1 The separator 6 divides the interior of the housing 1 into the water selection chamber 4 and the extrusion drainage chamber 5, and an inclined material guide plate 17 is arranged on the top of the separator 6, and the lower end of the material guide plate 17 faces the extrusion drainage chamber 5 , make the water and the rubbish on the top of the dividing plate 6 transport to the extruded drainage cavity 5 along the material guide plate 17 .

[0020] The top of the water selection chamber 4 is provided with a feed inlet 7, and garbage is loaded into the water selection chamber 4 from the feed inlet 7, and water is filled in the water selection chamber 4, and the water level is flush with the top of the divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com