Deferrization process for steel scoria and application of steel scoria fine powder thereof

A technology of steel slag and process, which is applied in the field of secondary utilization of steel slag, can solve the problems that it can only be used as waste as a raw material for asphalt concrete, the amount of addition is limited, and the zero discharge of steel slag cannot be completely solved, so as to solve the problem of low early strength and stability Poor, simple process, good iron removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

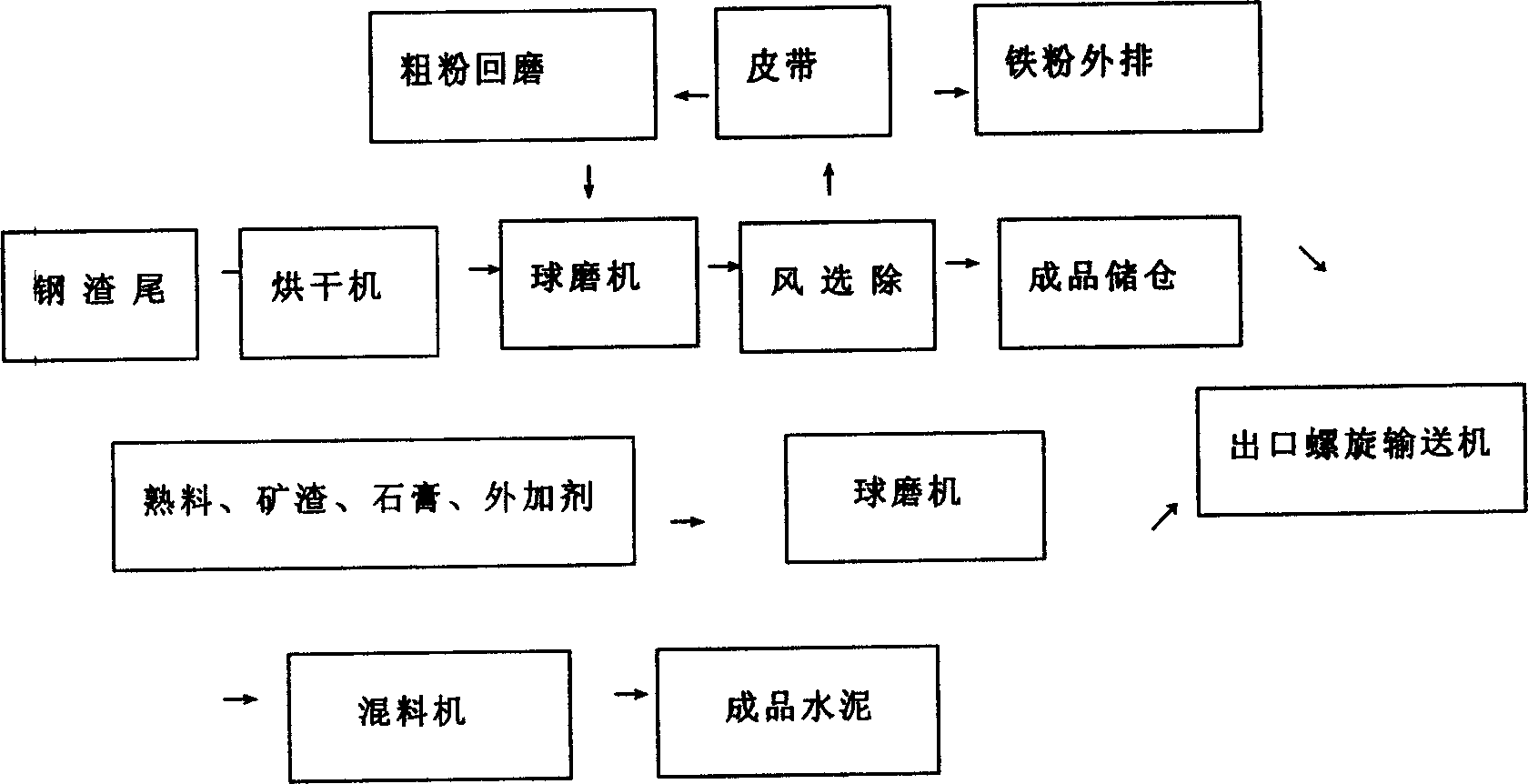

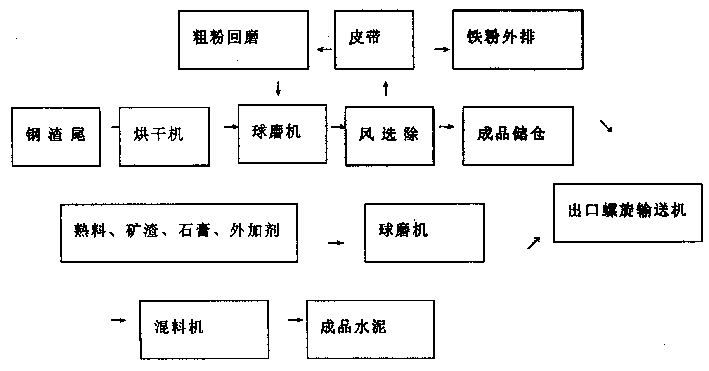

[0012] The specific process flow of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] As shown in the figure, the present invention dries the magnetically separated steel slag with an iron content (percentage by weight, the same below) less than 3% and a particle size of 0 to 10mm through a φ2.2×12m rotary dryer, and the moisture Less than 1%, the steel slag is dried to make it easy to grind, and can also ensure the quality of the cement made from the steel slag. The dried steel slag enters the intermediate warehouse, and then is transported to the φ2.2×7.0m ball mill for grinding by a belt conveyor.

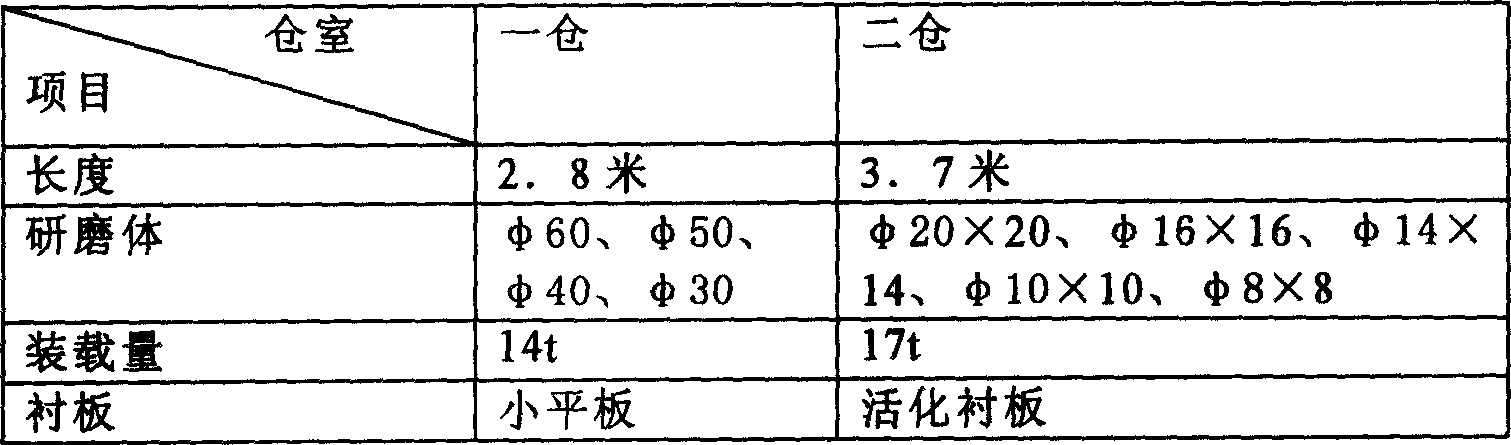

[0014] The ball mill of the present invention is provided with two compartments, the first compartment of the grinding body in the mill adopts φ60~φ30 steel balls, and the second compartment adopts φ20×20~φ8×8 steel forging; the steel slag powder after grinding is sent into the high-efficiency powder separator, and its...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com