Deironing method for rubber powder and apparatus thereof

A technology of rubber powder and equalization device, which is applied in chemical instruments and methods, transportation and packaging, filtering and sieving, etc. It can solve the problems of unclear separation of materials and iron filings, high manufacturing cost, complicated powder making process, etc., and achieve iron removal Clean and thorough, low manufacturing cost, simplified process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

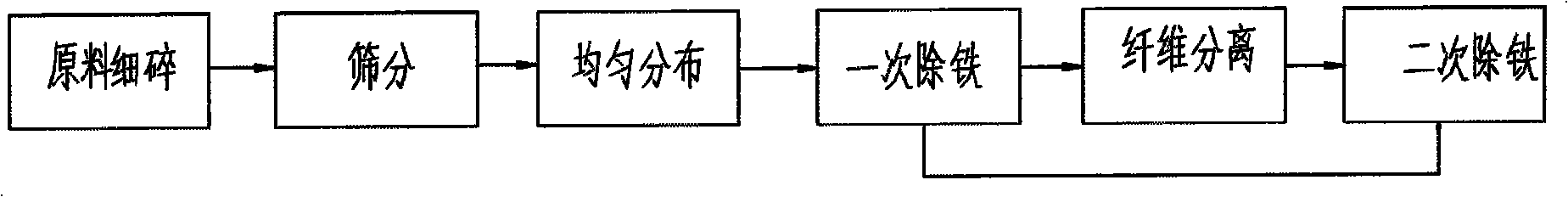

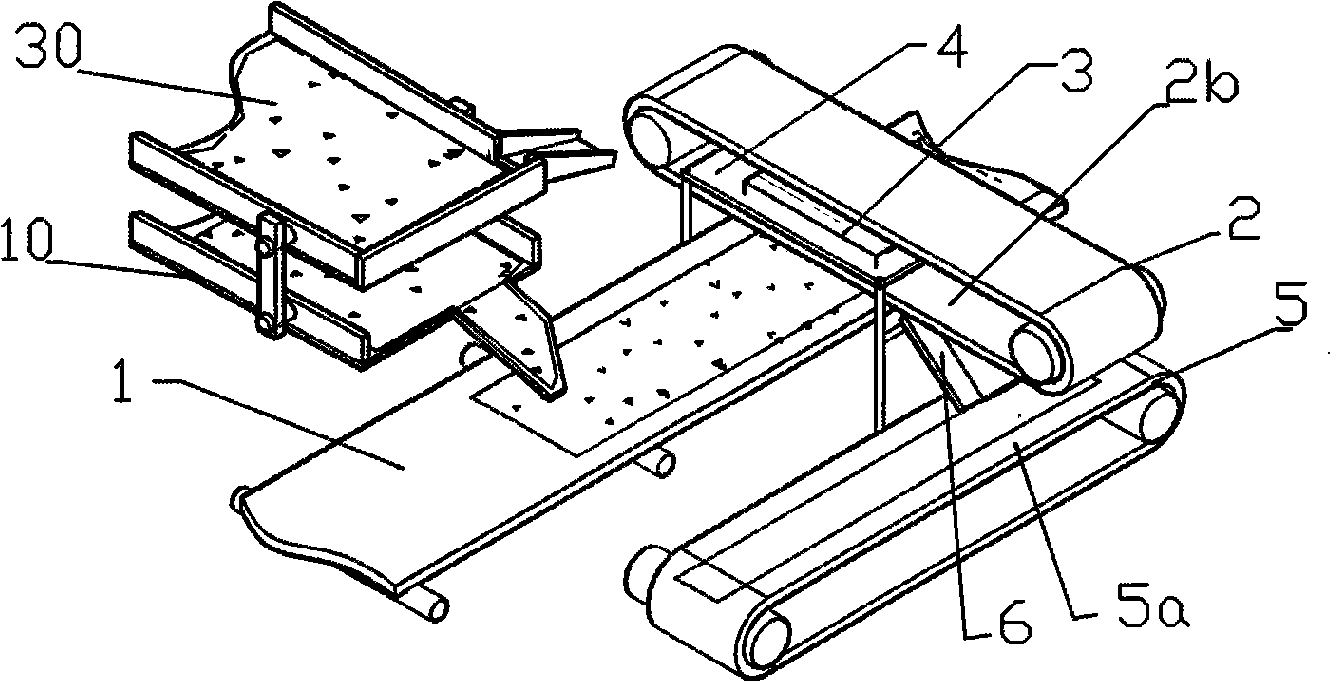

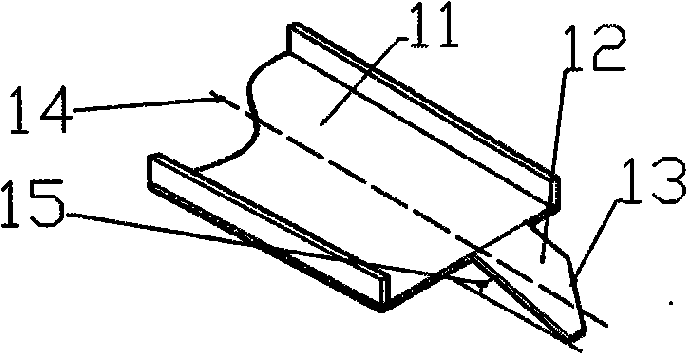

[0017] The present invention will be further described through embodiment now in conjunction with accompanying drawing. The iron removal method of the present invention is: raw material fine crushing-screening-uniform distribution-first iron removal-second iron removal or second iron removal after fiber separation. The finely crushed and sieved powder is transported to the next process by installing an iron removal device, and before the powder is transported to the iron removal device, an equalizing device is installed to evenly distribute the powder and then remove iron. That is, the powder that has been screened and entered into the hopper is evenly conveyed to the conveyor belt, and the iron is removed by the primary iron removal device installed on the conveyor belt.

[0018] In the second embodiment of the method of the present invention, carrying out iron removal to the powder twice is to remove the fiber from the powder after the first iron removal by the second time o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com