Deferrization method for hydrocarbons raw oil

A raw material oil and hydrocarbon technology, applied in the refined hydrocarbon oil, petroleum industry, etc., can solve problems such as increased carbon residue of regenerated catalysts, reduced catalyst activity, increased SOx emissions, etc., to achieve good iron removal effect and strong iron ion chelation combined ability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

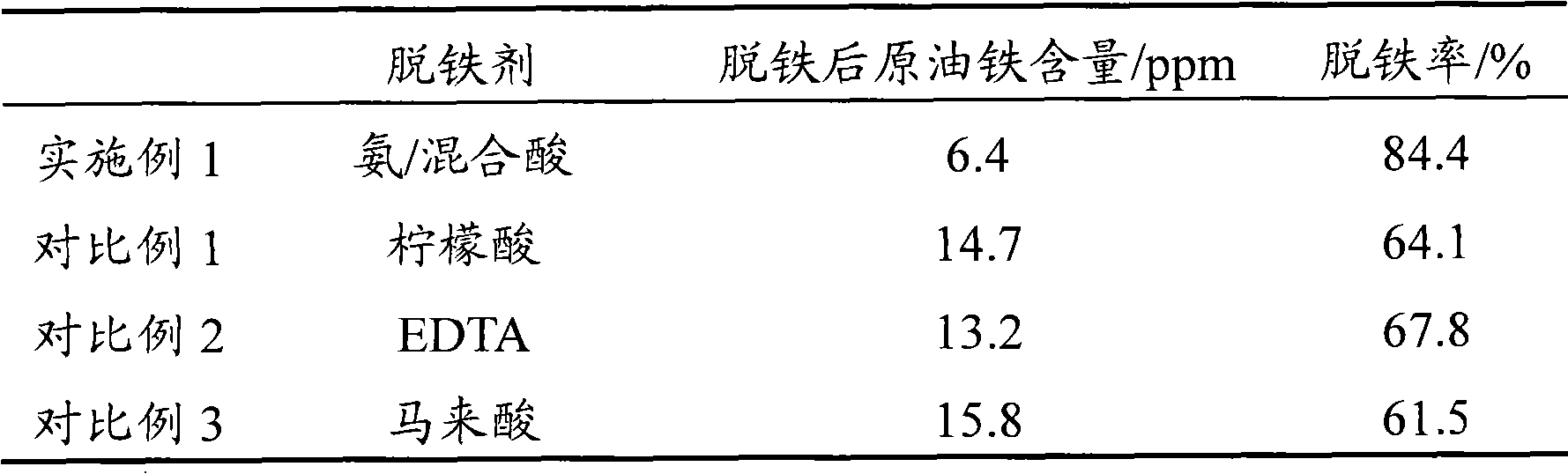

[0020] Mixed acid (maleic acid, citric acid, EDTA molar ratio 1:1:1 preparation) and ammonia water to prepare iron removal agent (carboxylic acid and ammonia molar ratio 1:1), the raw oil is crude oil containing 41 ppm iron , The results are shown in Table 1.

Embodiment 2~4

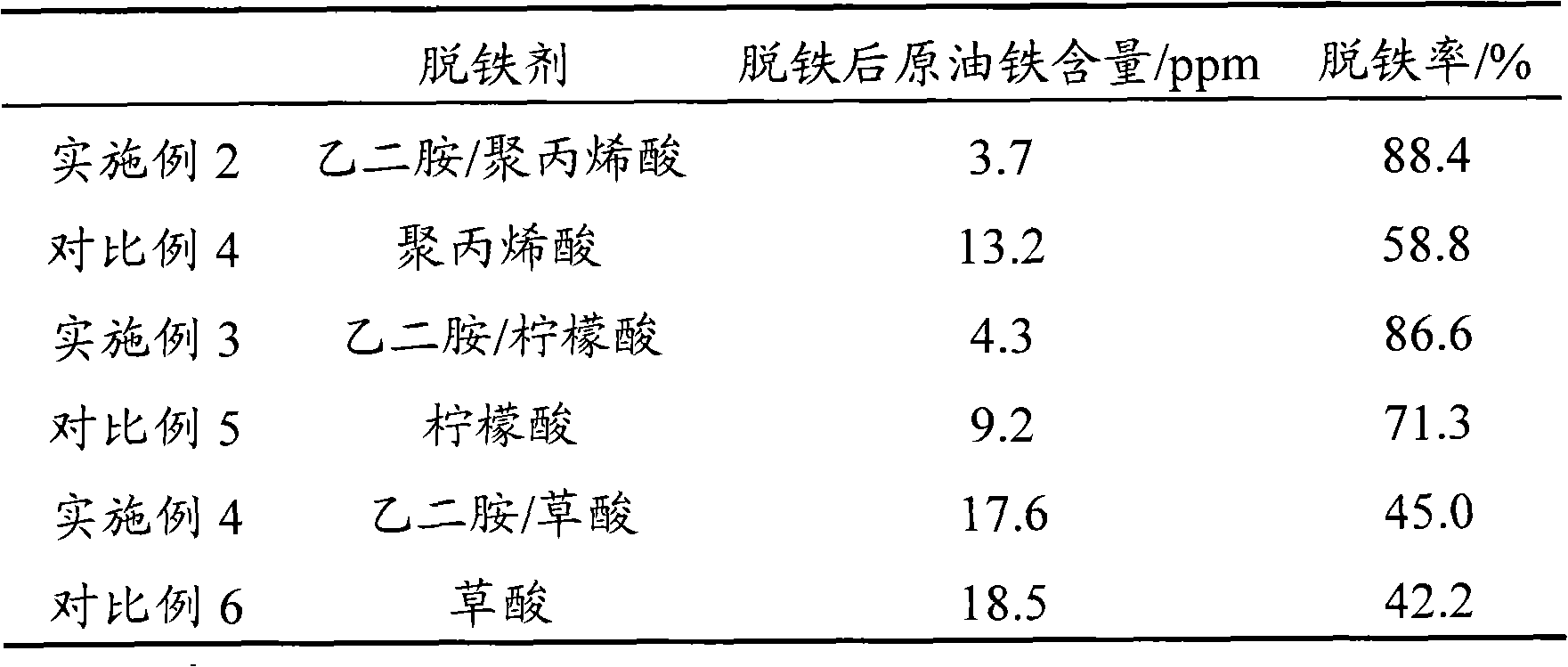

[0026] Three different organic acids (polyacrylic acid, citric acid and oxalic acid) were mixed with ethylenediamine at a molar ratio of 2:1 to prepare iron removal agent. The effect of iron removal was investigated. The raw oil was crude oil with 32ppm iron. The results are shown in the table. 2 shown.

Embodiment 5~7

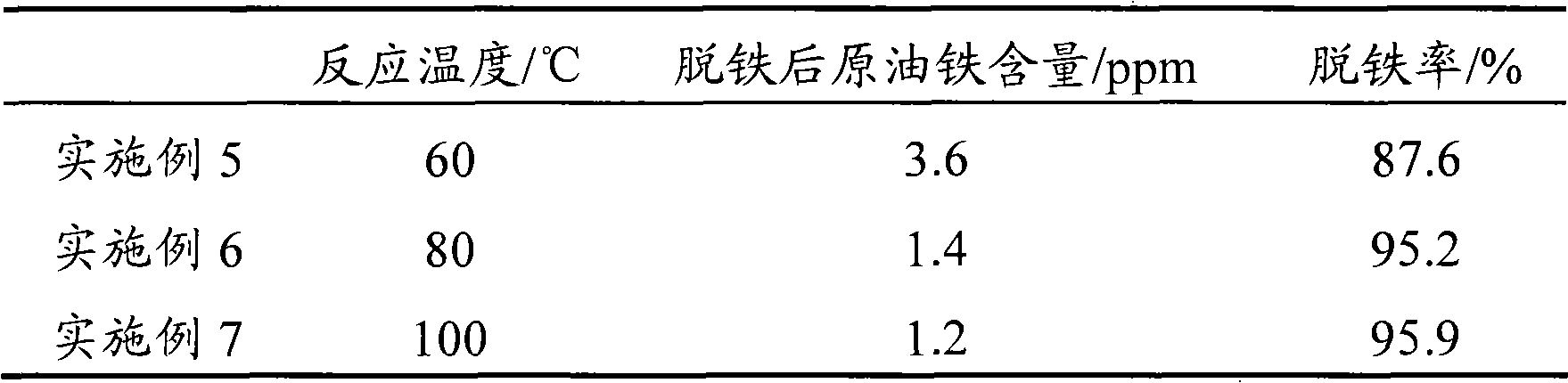

[0032] Compare the iron removal effect of the iron remover prepared by mixing citric acid and tetraethylenepentamine at a molar ratio of 3:1 at different reaction temperatures. The raw material oil is coker diesel oil with 29 ppm iron. The results are shown in Table 3.

[0033] Table 3 Deironing effect of coking diesel at different reaction temperatures

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com