Method for magnetically separating and removing ion from fly ash

A technology for removing iron and fly ash by magnetic separation, applied in high gradient magnetic separators and other directions, can solve the problems of difficult to completely remove iron impurities, difficult to separate iron impurities from fly ash, poor iron removal effect, etc. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

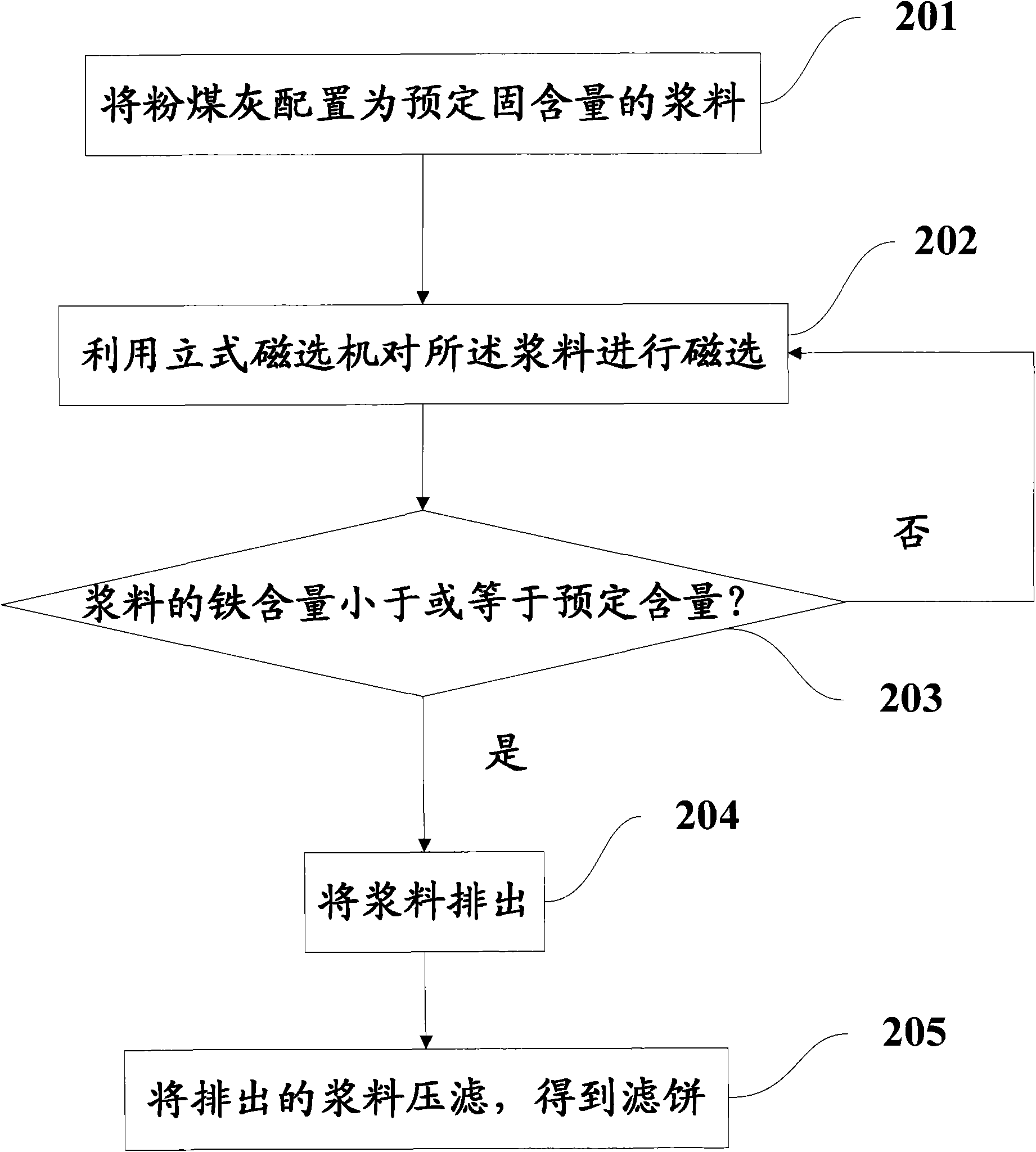

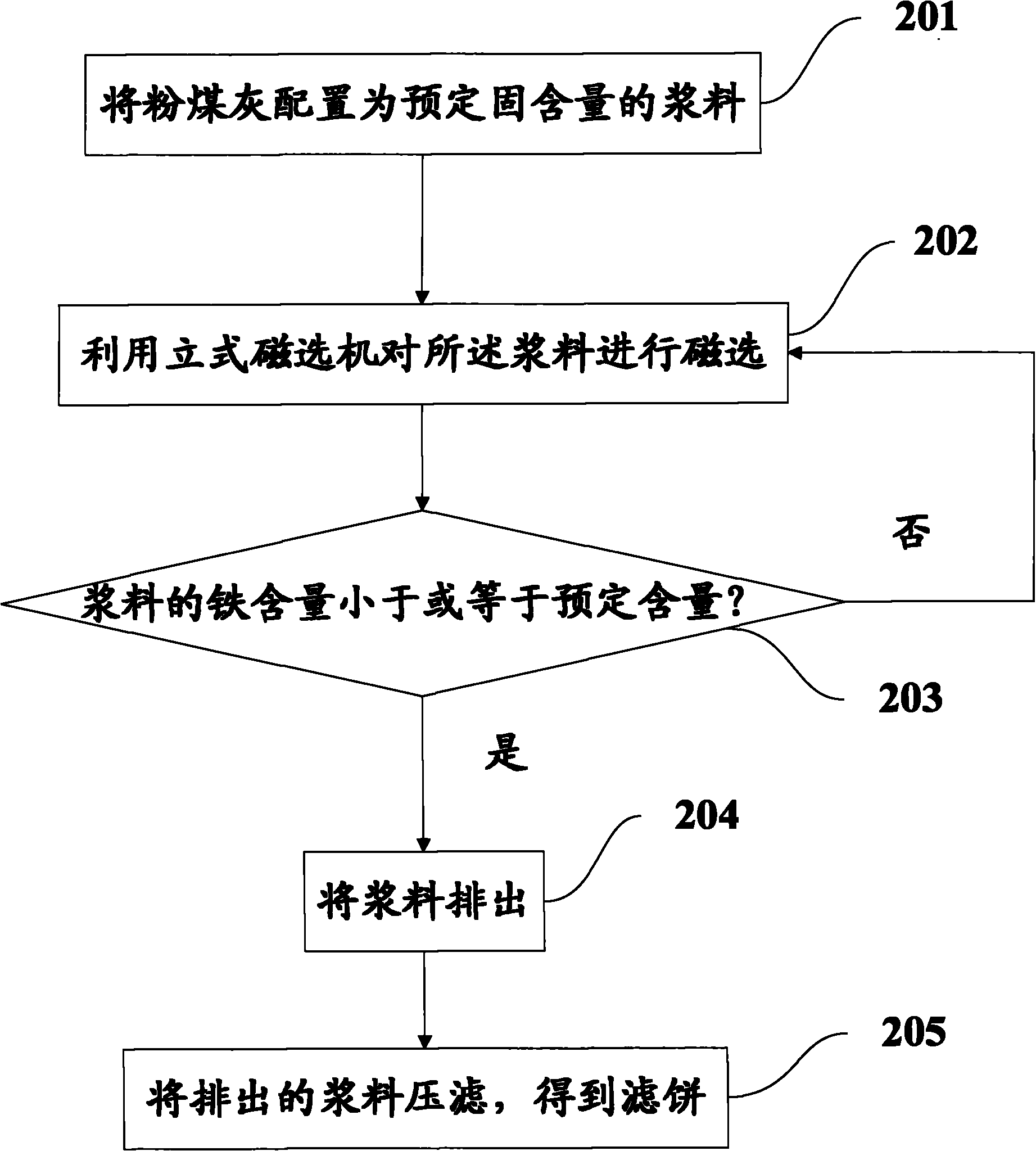

Method used

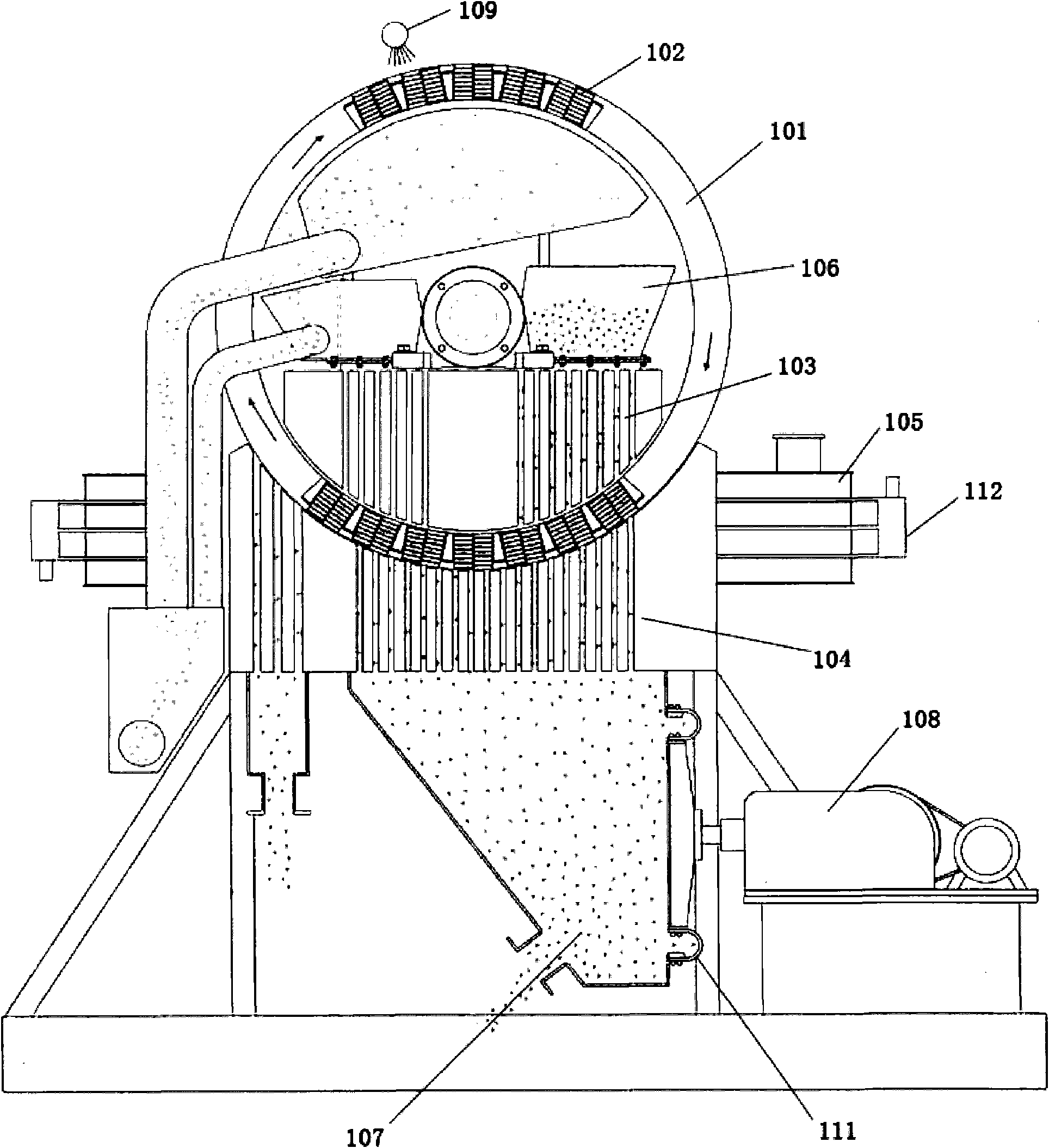

Image

Examples

Embodiment 1

[0044] Get fluidized bed ash and add water to make the slurry that solid content is 33%, carry out magnetic separation under the magnetic field of 1.75Gs with vertical ring magnetic separator, after each magnetic separation, get the slurry after 10 grams of magnetic separation, through After drying at 110°C, detect the content (wt%) of ferric ions (TFe2O3) and ferrous ions (FeO), and after three times of magnetic separation, the content of ferric ions is lower than the predetermined value of 0.8wt%, reaching 0.7wt% . The slurry was discharged, and the discharged slurry was press-filtered with a basket filter press to obtain a filter cake with a solid content of 37.5%. The chemical composition of described filter cake is as shown in table 2 (wt%):

[0045] SiO 2

[0046] Table 2

Embodiment 2

[0053] Get the fluidized bed ash and add water to make a slurry with a solid content of 20%, and carry out magnetic separation under a magnetic field of 1.5Gs with a vertical ring magnetic separator. After each magnetic separation, get 10 grams of the slurry after the magnetic separation. After drying at 110°C, the content (wt%) of ferric ion (TFe2O3) and ferrous ion (FeO) was detected, and after magnetic separation three times, the content of iron ion was equal to the predetermined value of 0.8 wt%. The slurry was discharged, and the discharged slurry was press-filtered with a basket filter press to obtain a filter cake with a solid content of 45.0%. The chemical composition of described filter cake is as shown in table 4 (wt%):

[0054] SiO 2

[0055] Table 4

Embodiment 3

[0062] Get the fluidized bed ash and add water to make a slurry with a solid content of 20%, and carry out magnetic separation under a magnetic field of 2.0Gs with a vertical ring magnetic separator. After each magnetic separation, get 10 grams of the slurry after the magnetic separation. After drying at 110°C, detect the content (wt%) of ferric ions (TFe2O3) and ferrous ions (FeO), and after three times of magnetic separation, the content of ferric ions is lower than the predetermined value of 0.8wt%, reaching 0.75wt% . The slurry was discharged, and the discharged slurry was press-filtered with a basket filter press to obtain a filter cake with a solid content of 50.0%. The chemical composition of described filter cake is as shown in table 6 (wt%):

[0063] SiO 2

[0064] Table 6

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com