Apparatus for removing iron in powder

A powder and box technology is applied in the field of powder iron removal devices, which can solve the problems of energy consumption in the cooling system, fine powder entering the iron removal port, and difficulty in applying iron removal, so as to achieve a small occupied space and a good iron removal effect. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

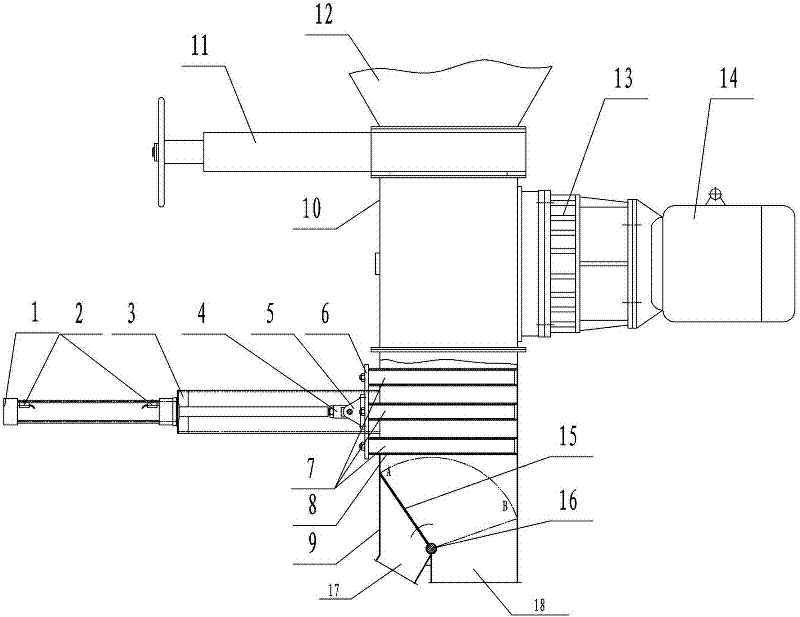

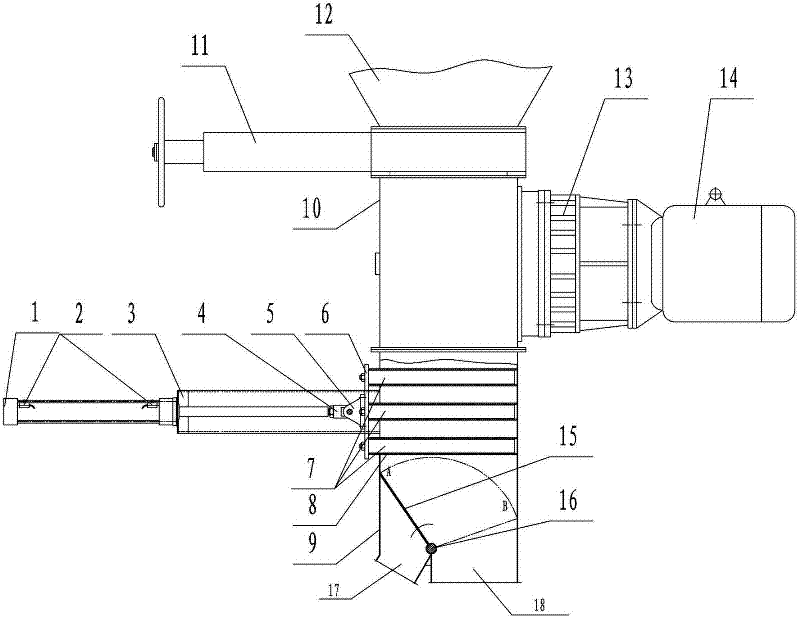

[0019] Example 1 A powder iron removal device, see figure 1 , including a feeding mechanism, a magnetic separation mechanism and a support, the magnetic separation mechanism includes a box body, three sets of magnetic rod groups 7 equidistantly distributed up and down (the number of magnetic rods in each magnetic rod group decreases successively from top to bottom, each The magnetic rods in the group (made of NdFeB magnets, whose magnetic strength is not less than 12000Gs, and whose intrinsic coercivity ≥ 14kOe) are distributed symmetrically and equidistantly along the center line of the box), and magnetic Magnetic rod casing (thin-walled stainless steel casing) corresponding to the number of rods, magnetic rod group drive unit, flap valve, PLC controller, the feeding mechanism includes a rigid impeller feeder 10, a reducer 13, a motor 14. Motor frequency converter (control the motor speed to adjust the size of the feeding amount, not shown in the figure) and the feeding bin 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com