Technology and complete equipment for industrial sand making and building garbage processing

A technology for construction waste and complete sets of equipment, applied in grain processing, use of liquid separators, combined devices, etc., can solve the problem of less complete sets of equipment, and achieve the effects of reducing energy consumption, reasonable matching and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

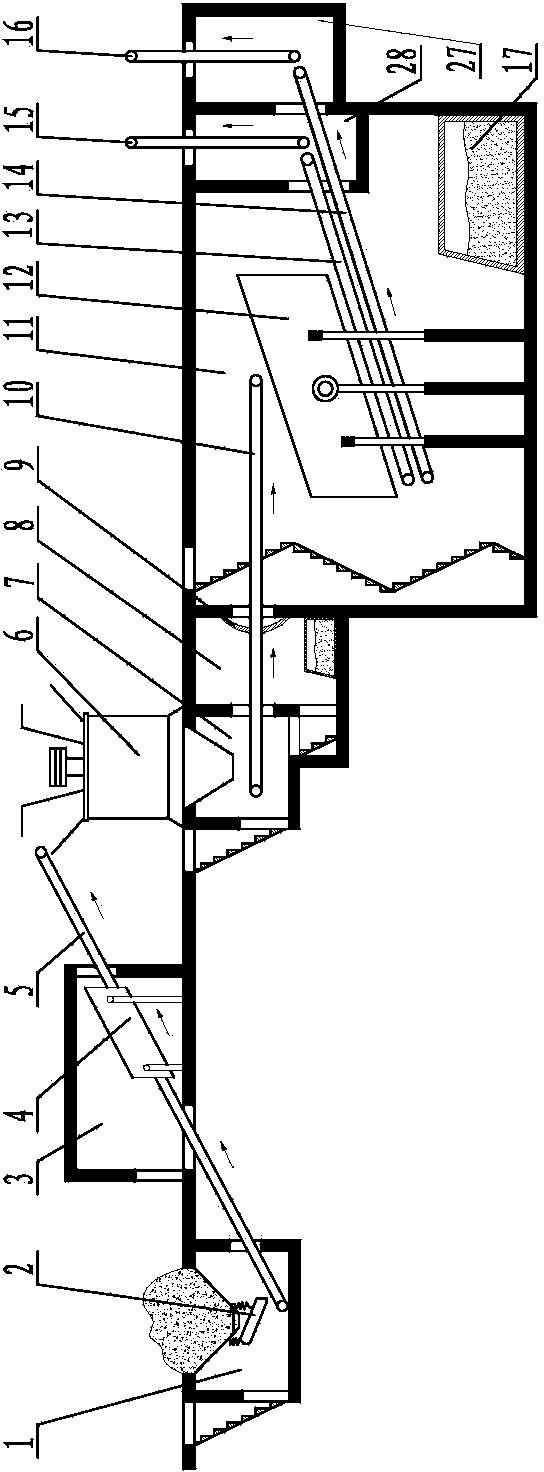

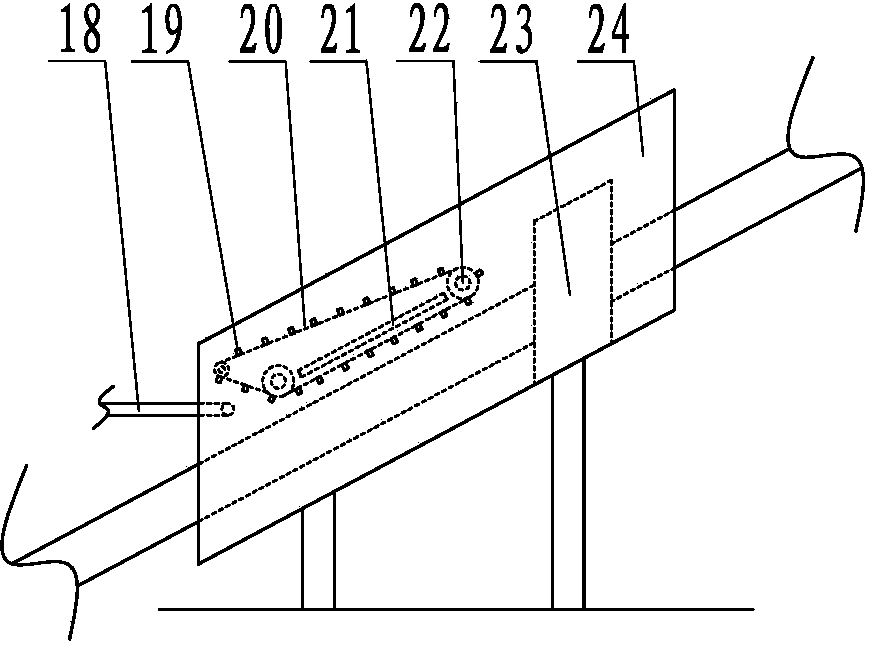

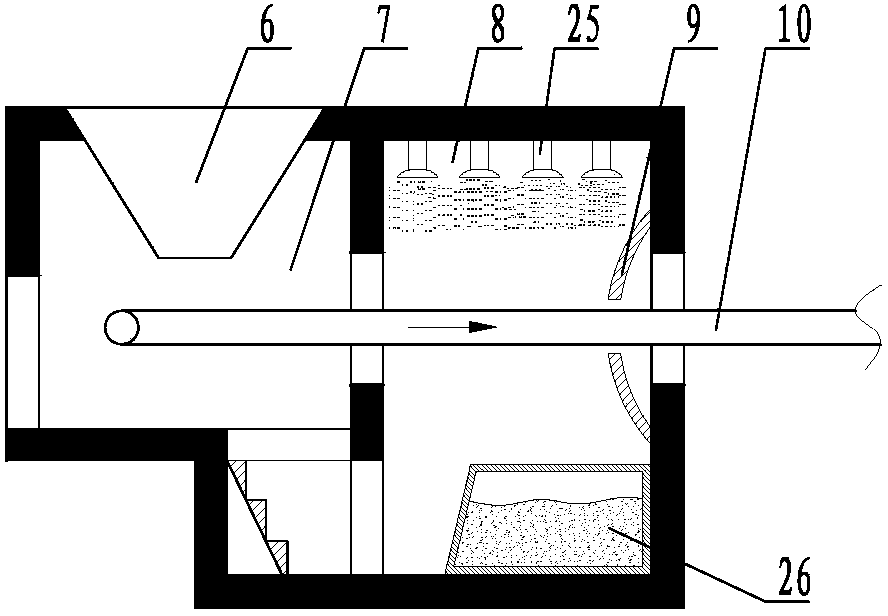

[0039] Such as figure 1 As shown, the complete set of industrial sand making and construction waste treatment equipment includes five functional zones, including feedstock settlement zone 1, iron removal zone 3, crushing settlement zone 7, dust removal settlement zone 8 and vibrating screening settlement zone 11. The zones are connected by conveyor belts. Feeding settlement zone 1 is located below the ground and connected to the ground by stairs. Feeding settlement zone 1 is provided with a discharge hopper 2, and a conveyor belt A5 is set below the discharge hopper 2. The conveyor belt A5 transports the material in the discharge hopper 2 to the ground Iron Zone 3. An iron removal detection device 24 is provided in the iron removal zone 3, and a conveyor belt A5 is enclosed in the iron removal detection device 24. The iron removal detection device 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com