Novel lifting system for deep-sea mining

A deep-sea mining and lifting system technology, applied in the mining of minerals, special mining, earth-moving drilling, etc., can solve the problems of ecological environment damage, damage to the surface seawater ecosystem, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

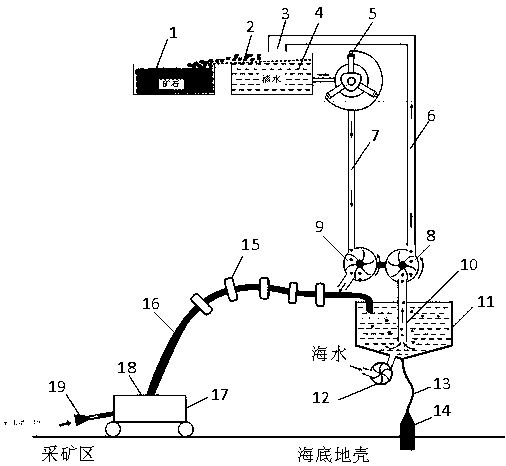

[0018] The novel deep-sea mining lifting system of this embodiment, such as figure 1 As shown, including a mining mechanism, a mineral water lifting mechanism and a mineral water separation mechanism, the mining mechanism includes a mining vehicle 17 set on the seabed, the mining vehicle ore suction port 19 is arranged in the front of the mining vehicle 17, and the mining vehicle ore suction port 19 is arranged at the rear of the mining vehicle. Ore conveying pump 18; mineral water lifting mechanism includes high-pressure pump 5, lifting main pipe 6, water pump 7, intermediate bin 11, lift pump 8, driving water turbine 9 and make-up pump 12, and the intermediate bin 11 is fixed on the seabed by the intermediate bin 13 cable 13 It is connected with the fixed pile 14 arranged on the bottom shell of the seabed, and the intermediate bin 11 is connected with the mining vehicle 17 through the hose 16, and the floating body 15 is arranged on the hose 16; , the mineral water separatio...

Embodiment 2

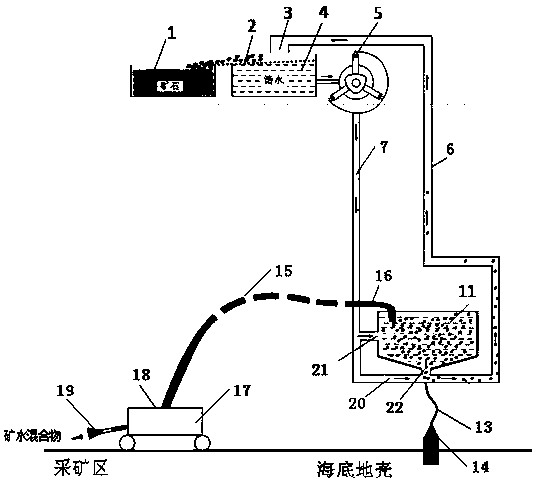

[0022] The novel deep-sea mining lifting system of this embodiment, such as figure 2 As shown, including a mining mechanism, a mineral water lifting mechanism and a mineral water separation mechanism, the mining mechanism includes a mining vehicle 17 set on the seabed, the mining vehicle ore suction port 19 is arranged in the front of the mining vehicle 17, and the mining vehicle ore suction port 19 is arranged at the rear of the mining vehicle. The ore conveying pump 18; the mineral water lifting mechanism includes a high-pressure pumping pump 5, a lifting main pipe 6, a water pumping pipe 7, a high-speed clean water pipe 20 connected to the middle silo 11 and the hoisting main pipe 6. The fixed piles 14 on the bottom shell are connected, and the intermediate silo 11 is connected with the mining vehicle 17 through the hose 16, and the floating body 15 is arranged on the hose 16; With the ore mixing inlet 22 , the mineral water separation mechanism includes an ore storage tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com