Medium-thickness coal seam gob-side entry retaining method and support system

A technology for thick coal seam and empty roadway retention, which is applied in earth-moving drilling, mining equipment, installation of bolts, etc., can solve the problems of high cost and complicated process of roadway retention, and achieves low cost, simple construction process and good safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

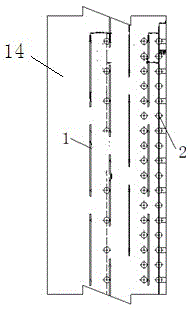

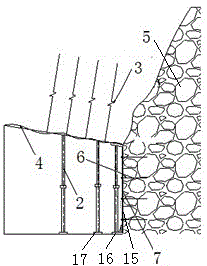

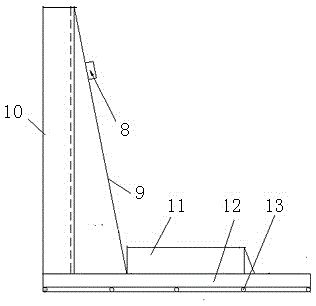

[0028] The support system for gob-side entry retention in medium-thick coal seams of the present invention is as follows: figure 1 , figure 2 As shown, including the entry tunnel 14, the entry tunnel is provided with four channel steel anchor cables 1 support, three hydraulic props 2 are installed along the gob-side entry section within the mining line of the entry tunnel, and the top of the hydraulic prop passes through a The word hinged top beam is connected with the cross hinged top beam, and the hydraulic prop is integrated with the top beam, and the bottom of the hydraulic prop wears iron shoes 17. A hydraulic pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com