Goaf open-type packing method

A goaf, open technology, applied in the fields of backfill, mining equipment, earthwork drilling, etc., can solve the problems of limited application and promotion, complex filling process, low production efficiency, etc., to improve filling and coal mining efficiency, The effect of good filling density and low filling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

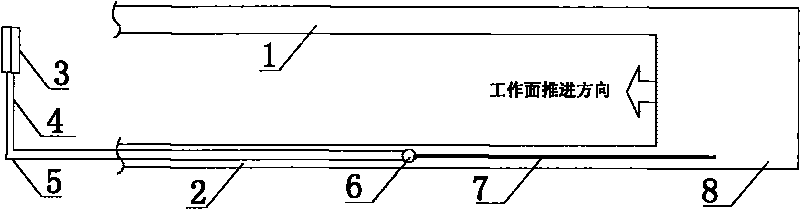

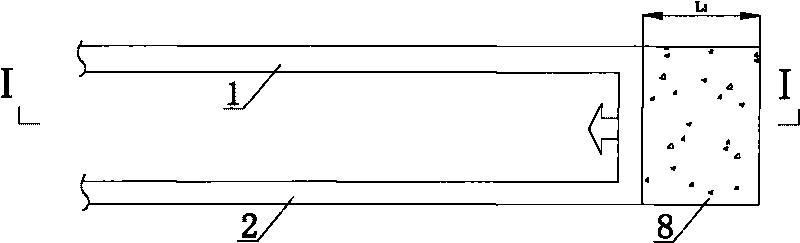

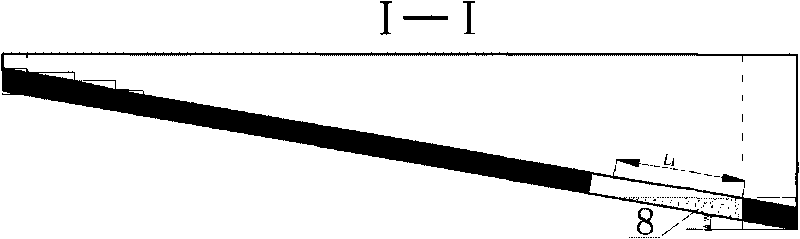

[0021] As shown in the accompanying drawings, the open filling method of the goaf of the present invention: the mixing pump 6 is set in the track inclined roadway 2 of the inclined coal mining face with a coal seam inclination angle α>12°, and the mixing pump 6 is set at a distance from the mining area. The empty area is within the range of 20m ~ 100m. The feeding end of the mixing pump 6 is respectively connected with the A material delivery pipeline 4 and the B material delivery pipeline 5 connected with the delivery pump 3; the mixing slurry delivery pipe 7 leading to the goaf is connected at the output end of the mixing pump 6 ;Firstly, from the cut-out hole, the span L of the initial pre-filled roof 1 Filling in the goaf section; the delivery capacity of the delivery pump 3 is required to be 120m 3 / h or more, the conveying capacity is 120m 3 The delivery pump 3 with a water content of more than 85% sends the high-water materials A and B used together at a ratio of 1:1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com