Mining multi-shaft dump truck

A mining dump truck and frame technology, which is applied to vehicle components, tilt-bearing vehicles, substructures, etc., can solve the problems of high manufacturing cost, rapid damage to rear axle tires, prone to overturning, falling off cliffs, etc. Increased stability and safety, longer tire life, and avoidance of overloading the rear axle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

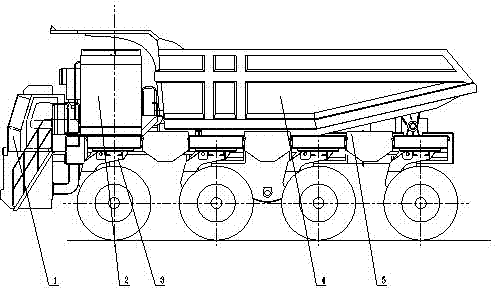

[0022] A four-axis, all-wheel drive, all-wheel steering, 220-ton mining dump truck, such as figure 1 As shown, it is composed of power system 2, driving system, braking, steering, electric drive, cab 1, cargo compartment 4, lifting mechanism, and integrated vehicle management system. The driving system and steering system are introduced as follows:

[0023] 1) Driving system

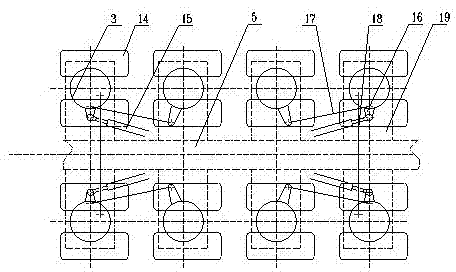

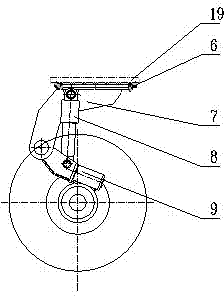

[0024] like figure 2 and image 3 As shown, the driving system includes a vehicle frame 5 and eight hydraulic suspensions 3, wherein an axis is formed by every two suspensions. This driving system has four axes. The vehicle frame 5 is a middle box beam structure, and the middle box girder The wing beams 19 protrude to both sides, and the hydraulic suspension 3 includes a slewing bearing 6, a swivel frame 7, a swing arm 9, a suspension cylinder 8, a swing shaft 10, and wheels 14; The lower plane of the spar 19, the upper end of the swivel frame 7 is connected with the movable pin of the swing arm 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com