A manually controlled body swing mechanism for electric logistics vehicles

A controlled, animal technology, applied in the field of logistics vehicles, can solve problems such as easy rollover and rollover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

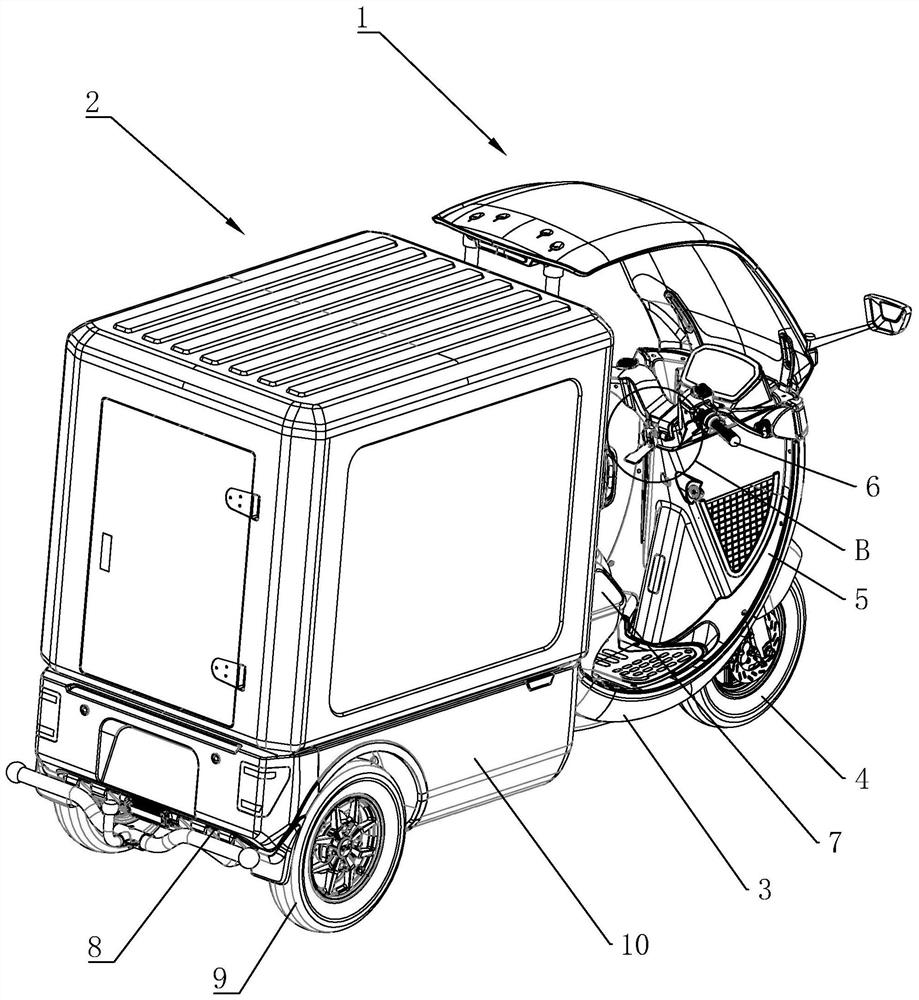

[0040] Such as figure 1 As shown, an electric logistics vehicle includes a front vehicle part 1 and a rear vehicle part 2. The front vehicle part 1 comprises a front vehicle frame 3, a front wheel 4 and a front vehicle body 5, the front wheel 4 is rotatably connected to the front vehicle frame 3, the front vehicle body 5 is fixedly installed above the front vehicle frame 3, and the front vehicle body 5 is far away from one end of the rear vehicle part 2 A handle 6 for controlling the direction is provided. Seat 7 is installed in front vehicle body 5 middle parts. The rear vehicle part 2 comprises a rear vehicle frame 8, a rear wheel 9 and a rear vehicle body 10. The rear wheel 9 is provided with two coaxial rotations connected to the rear vehicle frame 8, and the front wheel 4 and the rear wheel 9 form a triangular support.

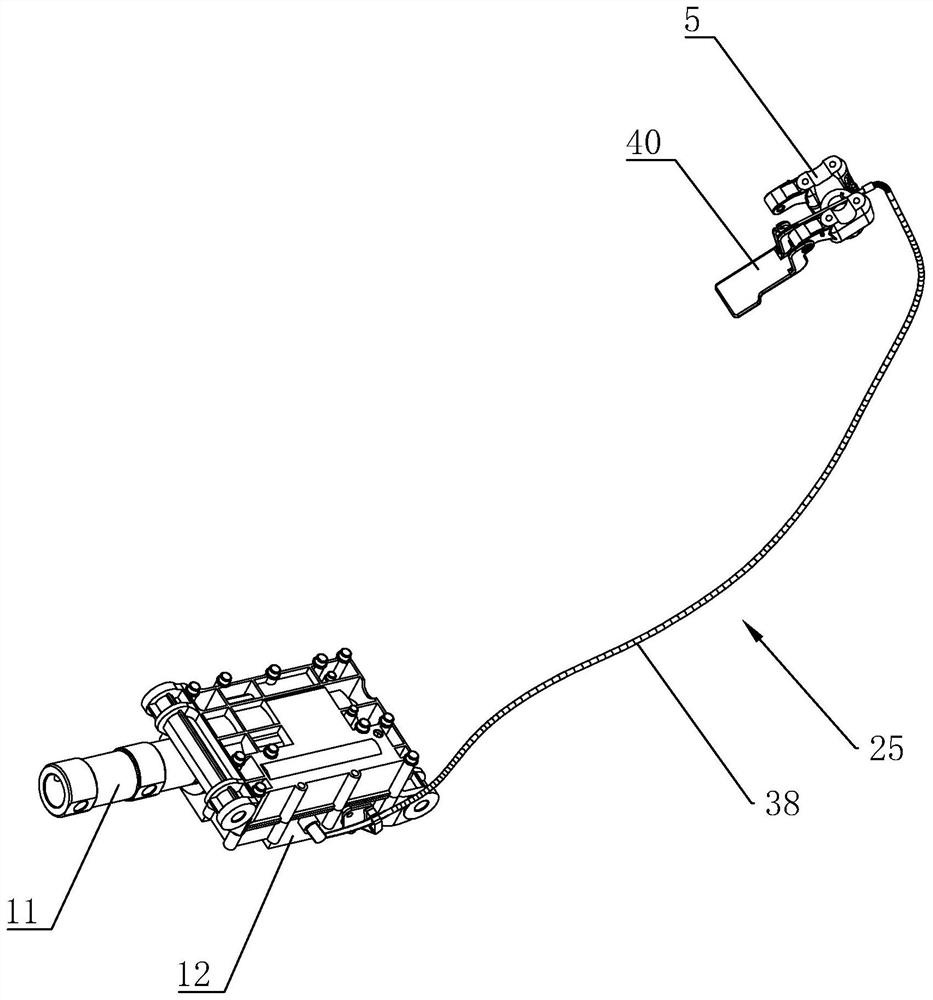

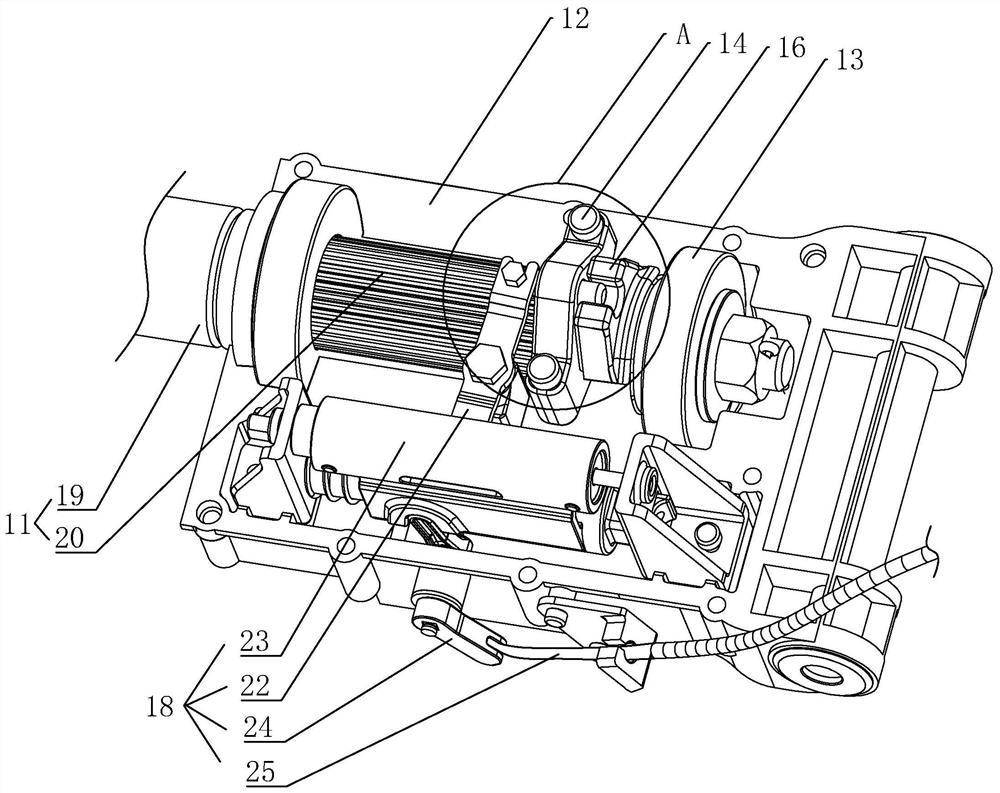

[0041] In order to make the logistics vehicle turn more flexibly, such as figure 1 and figure 2 As shown, a manually controlled vehicle body swing m...

Embodiment 2

[0058] The difference between embodiment two and embodiment one is: as Figure 9 and Figure 10As shown, in order to facilitate the return of the front body 5, the outer wall of the rotating shaft 11 is provided with several abutment parts 41 along its circumference, and an accommodation chamber 42 is formed between two adjacent abutment parts 41, and an elastic damping member is arranged in the accommodation chamber 42 43 , and the elastic damping member 43 abuts against the inner wall of the accommodating chamber 42 . The elastic damping element 43 is fixedly connected to the rotating part 12 . Specifically, the elastic damping member 43 is made of elastic rubber, and the two ends of the elastic damping member 43 are respectively provided with protrusions 44, and the protrusions 44 are embedded in the rotating part 12, so that the elastic damping member 43 is fixedly connected to the rotating part 12. .

[0059] When the front frame 3 swings relative to the rear frame 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com