Gob-side entry retaining method of a solid filling coal mining half-section one-leg shed

A solid filling and single-leg technology, applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of coal resource loss, complex construction technology, low work efficiency, etc., to save roadway excavation costs, improve recovery rate, and operate easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

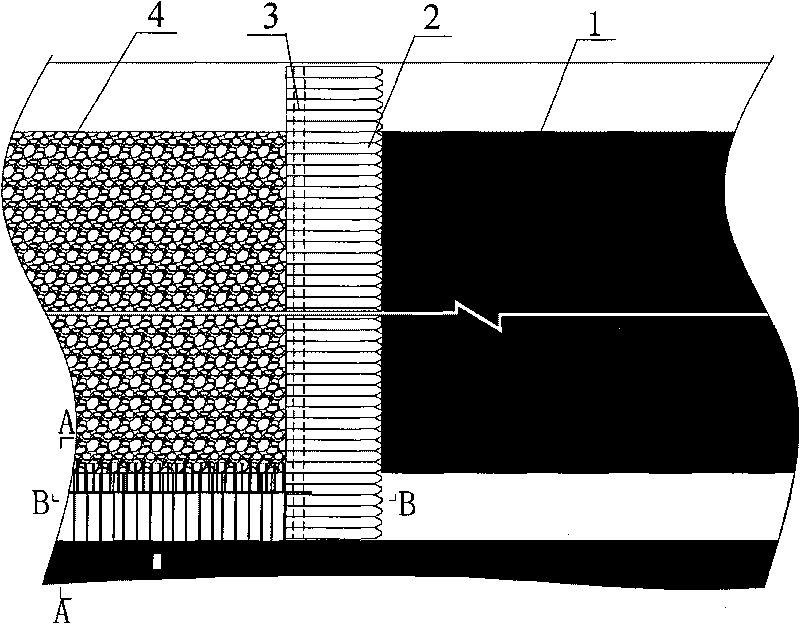

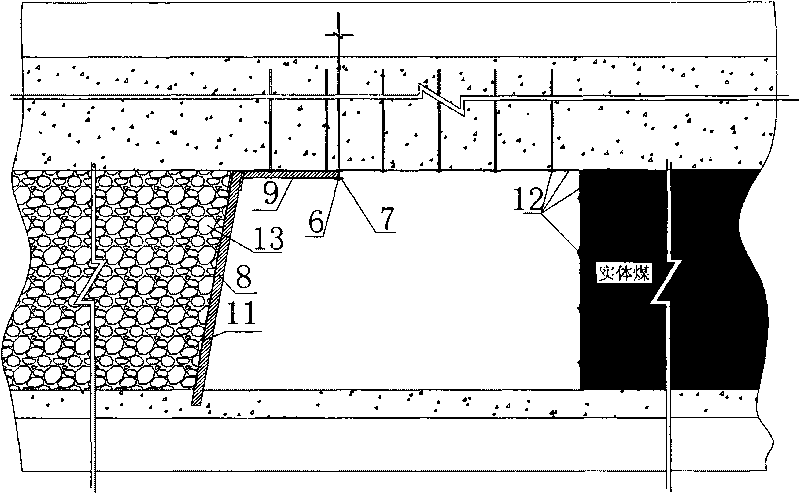

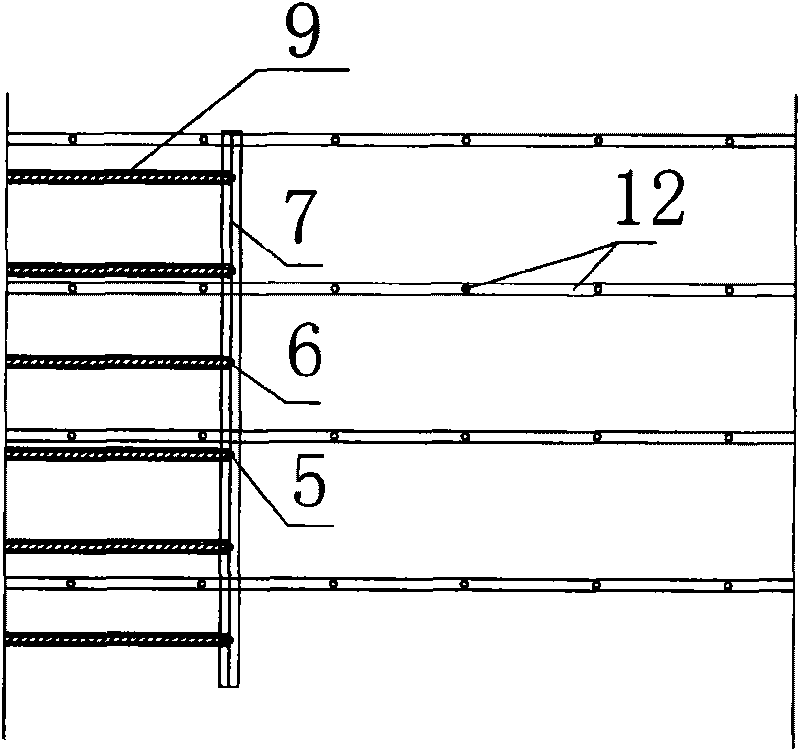

[0015] figure 1 Shown is a schematic diagram of the layout of the coal mining face. The coal mining filling hydraulic support 2 is arranged behind the filling coal mining face 1, and the roof support 12 is implemented on the solid coal side of the working face and roadway bolts. As the working face advances, the mined-out area 4 is filled by the filling mining conveyor 3, and at the same time, anchor rods 5 with a spacing of about 2500mm and Φ22×2200mm are used along the direction of the roadway at the 1 / 3 distance between the top plate of the working face and the gob. and Φ17.8×6500mm anchor cable 6 are inserted to fix a row of H-shaped steel 7, figure 2 As shown, the size of the H-shaped steel 7 is 100×100 mm; as the coal mining filling hydraulic support 2 moves forward by one step, the conventional step is about 0.6 meters. First lay a section of metal mesh 11 outside the goaf, Figure 4 As shown; then erect the side wall I-beam 8; then lay the metal mesh 11 in the roof ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com