Stope drilling device and method for open-pit mining

A drilling device and open-pit mining technology, applied in drilling equipment and methods, ground mining, underground mining, etc., can solve the problems of inability to drill in multiple directions in the stope, inconveniently changing the angle of drilling, and increasing labor costs. Achieve the effect of increasing labor cost, improving service life and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

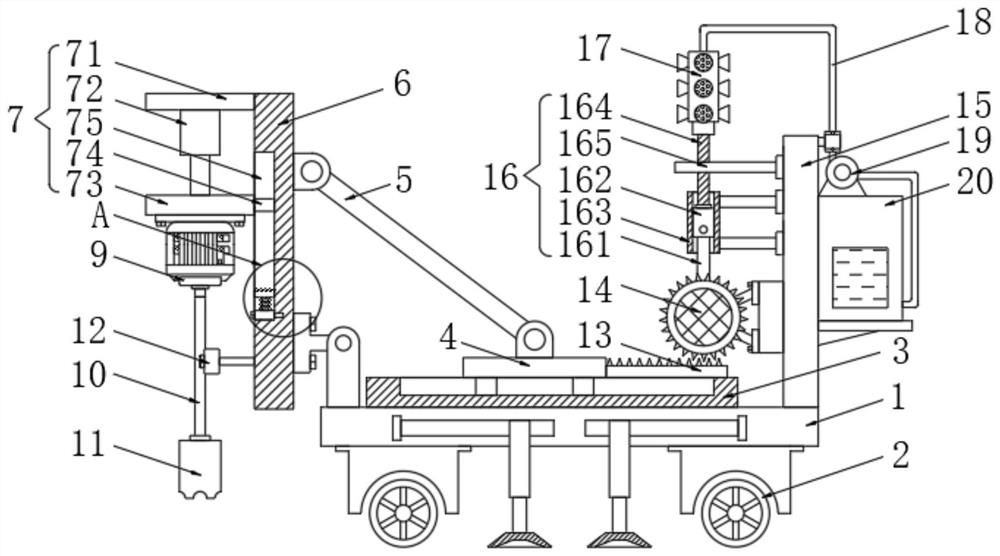

[0029] The present invention provides a technical solution: a stope drilling device for open-pit mining, please refer to figure 1 , comprising a transport vehicle body 1, wheels 2 are installed around the bottom of the transport vehicle body 1, the top of the transport vehicle body 1 is fixedly connected with a fixed plate 3, and the top of the fixed plate 3 is slidably equipped with a movable plate 4, and the movable plate 4 The top is hinged with one end of the pull rod 5, the other end of the pull rod 5 is hinged on the fixed beam 6, the right bottom of the fixed beam 6 is hinged with the transport vehicle body 1 through a hinge, and the left side of the fixed beam 6 is equipped with a height adjustment assembly 7, The height adjustment assembly 7 is connected with a protection assembly 8, and the height adjustment assembly 7 is equipped with a drilling motor 9. The drilling motor 9 is controlled by an external power switch, and the drilling motor 9 is connected to an extern...

Embodiment 2

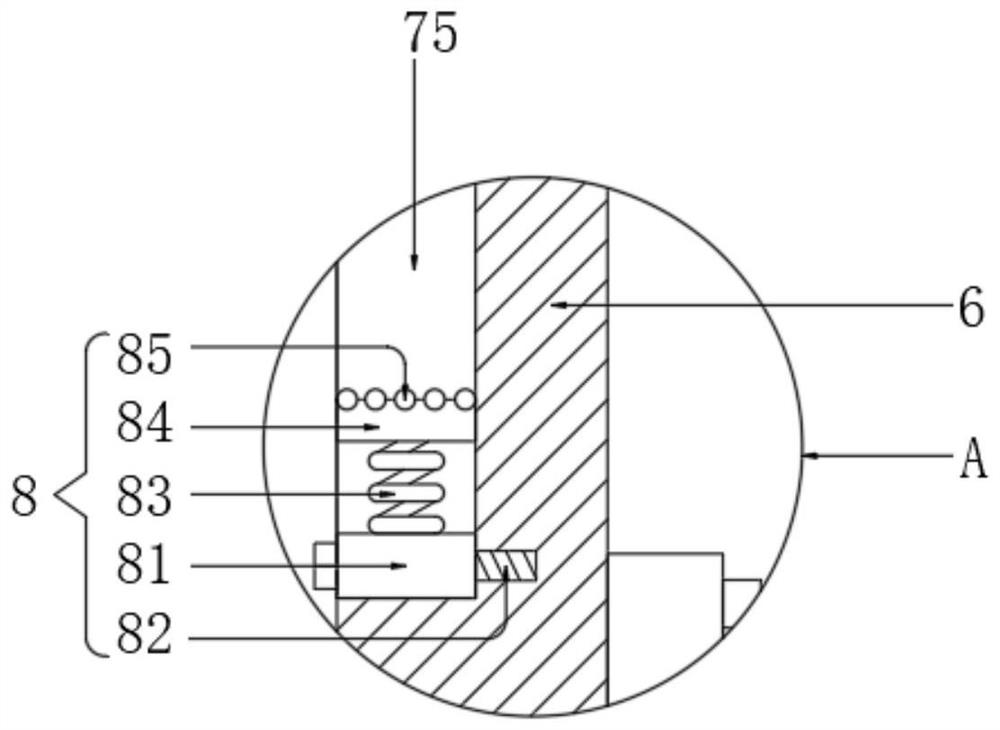

[0038] see figure 2 The difference from Embodiment 1 is that the protection assembly 8 includes a connection block 81 that is movably connected to the bottom of the chute 75, the inside of the connection block 81 traverses through the limit bolt 82, and the right end of the limit bolt 82 is connected to the fixed beam 6, By pulling down the limit bolt 82, the connection block 81 can be replaced, and then the support spring 83 can be replaced. The top of the connection block 81 is connected with the support spring 83, and the top of the support spring 83 is connected to the protection block 84, and the protection block 84 is slidably connected to the chute 75, the top of the protection block 84 is evenly embedded with rubber balls 85, when the slide block 74 moves down and is pressed against the protection block 84, the rubber ball 85 and the support spring 83 are elastically deformed, so that the slide block 74 will not hit To the bottom of the chute 75, the damage of the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com