Equidistant drilling device for new energy automobile parts

A new energy vehicle and drilling device technology, applied in positioning devices, feeding devices, boring/drilling and other directions, can solve the problems of low production efficiency, damaged parts, low degree of automation, etc., and achieve good cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

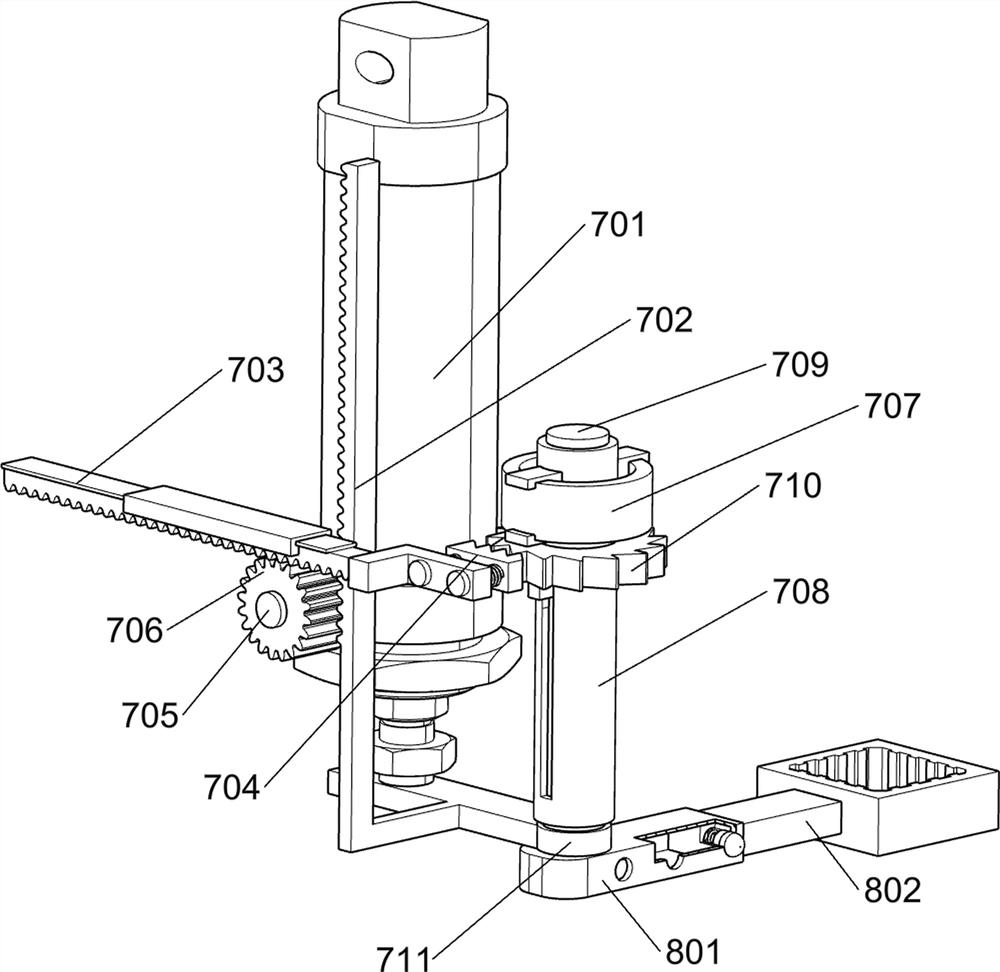

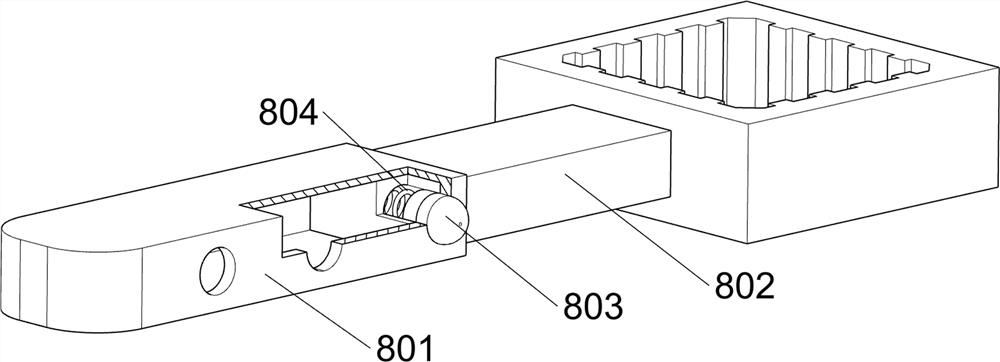

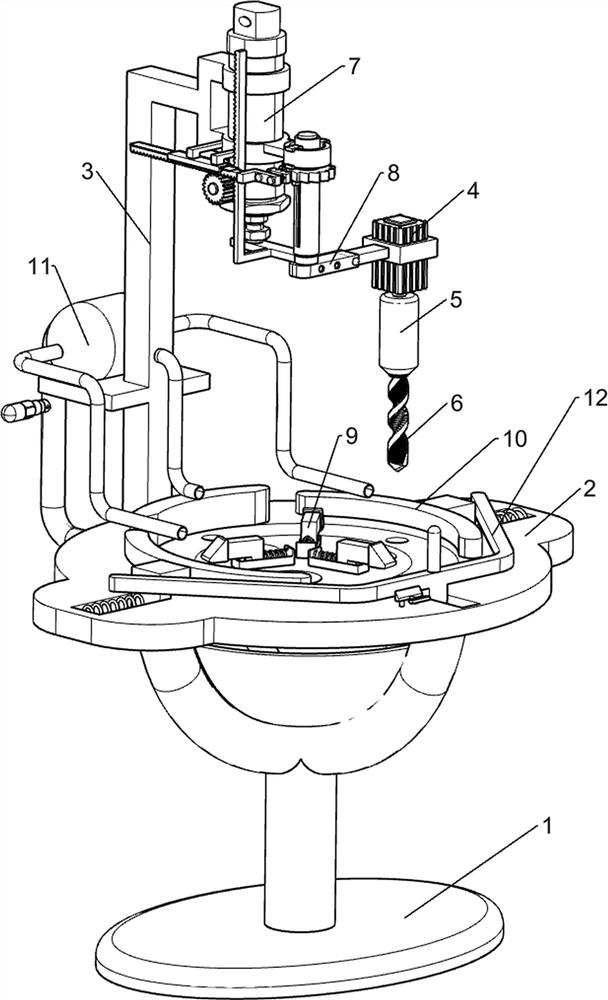

[0026] An equidistant drilling device for new energy automobile parts, such as Figure 1-Figure 7 As shown, it includes a base 1, a workbench 2, a support frame 3, a motor 4, a drill chuck 5, a drill bit 6, a rotating assembly 7, an adjusting assembly 8 and a positioning assembly 9. The top of the base 1 is provided with a workbench 2, and the workbench 2 There is a support frame 3 on the left side of the top, a rotating assembly 7 is provided on the left side of the upper part of the support frame 3, an adjustment assembly 8 is provided on the rotation assembly 7, a motor 4 is provided on the adjustment assembly 8, and a drill is provided on the output shaft of the motor 4. Chuck 5, drill bit 6 is provided at the bottom of drill chuck 5, and positioning assembly 9 is provided at the top of workbench 2.

[0027] When people need to carry out equidistant drilling to auto parts, people place the auto parts on the workbench 2, so that the positioning assembly 9 fixes the parts, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com