Electro-hydraulic hybrid driven electric shovel hoisting system

A technology of electro-hydraulic mixing and hoisting system, which is applied in open-pit mining, earthwork drilling, special mining, etc. It can solve the problems of high peak current of hoisting device, grid current impact, harmonic interference, etc., so as to improve work reliability and stability, improve work stability, and reduce the effect of installed power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

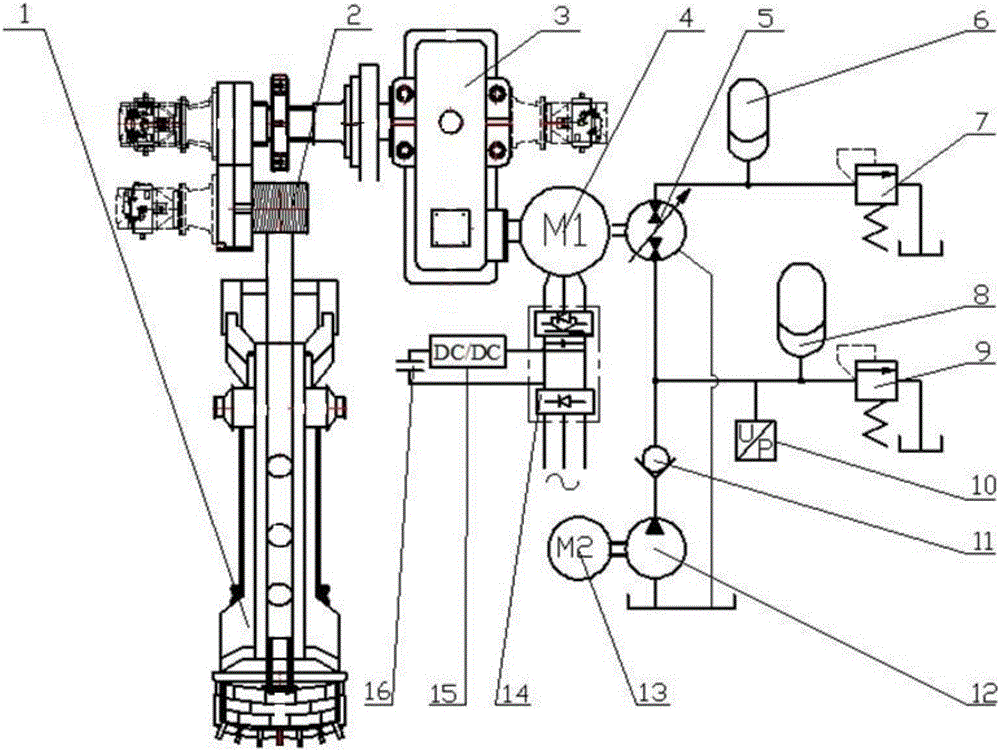

[0018] Example 1: figure 1 As shown, the electric shovel lifting system driven by electro-hydraulic hybrid includes bucket 1, lifting reel 2, speed reducer 3, lifting motor 4, hydraulic pump / motor 5, high-pressure accumulator group 6, the first overflow valve 7, Low pressure accumulator group 8, second relief valve 9, pressure sensor 10, check valve 11, charge pump 12, charge pump motor 13, frequency converter 14, DC / DC converter 15, super capacitor group 16. The hydraulic pump / motor 5 is placed on the output shaft of any transmission shaft between the reducer and the motor, as attached figure 1 As shown, the outline drawing of the hydraulic pump / motor drawn by the dotted line indicates the position where the hydraulic pump / motor 5 can be placed. If the hydraulic pump / motor is directly connected to the lifting motor 4, the lifting motor 4 is a double-outlet shaft motor. The DC / DC converter 15 is connected to the DC bus of the hoisting motor 4 frequency converter 14, and the D...

Embodiment 2

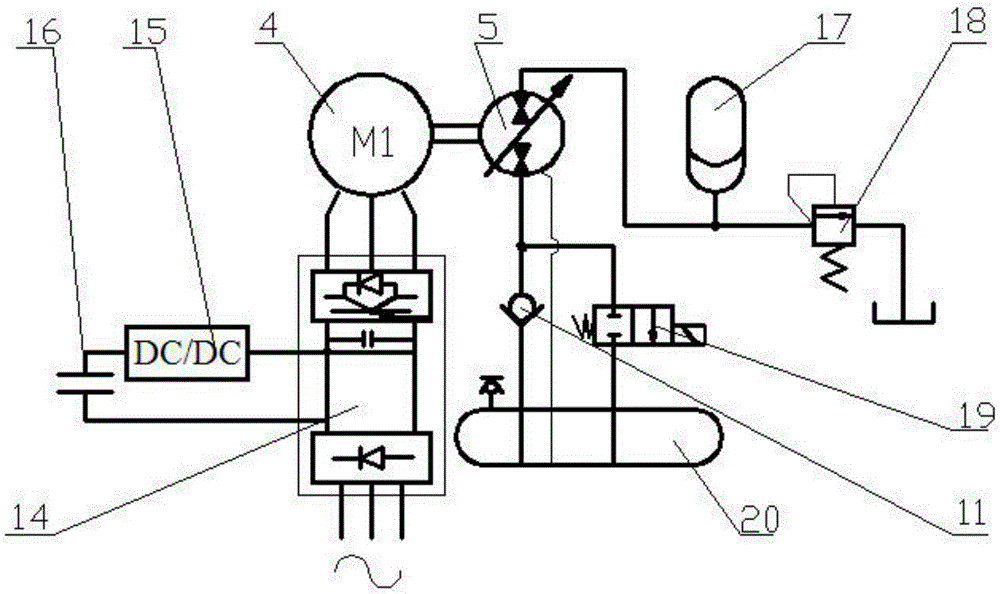

[0023] Example 2: figure 2 As shown, the working principle of this embodiment is similar to that of Embodiment 1, and the difference is that the charging pump 12, the charging pump motor 13, the high-pressure accumulator group 6 and the first overflow valve 7, the low-pressure accumulator group 8 and the first overflow valve 7 are eliminated. II Relief valve 9, increase two-position two-way electromagnetic reversing valve 19 and pressurized oil tank 20.

[0024] When the electric shovel bucket falls, the lifting motor 4 is in the power generation state, the DC bus voltage in the frequency converter 14 rises, and the supercapacitor group 16 is charged through the DC / DC converter 15, and at the same time, the hydraulic pump / motor 5 is in pumping operation state, the oil suction port is connected to the one-way valve 11, and the oil discharge port is connected to the accumulator group 17 to store energy for the accumulator group 17, and convert the gravitational potential energy...

Embodiment 3

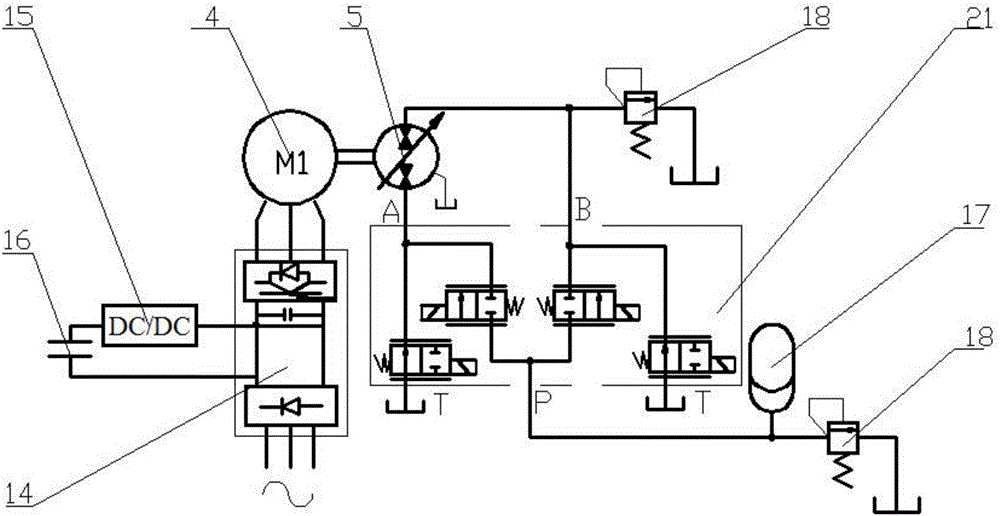

[0026] Example 3: image 3 As shown, the working principle of this embodiment is similar to that of Embodiment 1, and the difference is that the charging pump 12, the charging pump motor 13, the high-pressure accumulator group 6 and the first overflow valve 7, the low-pressure accumulator group 8 and the first overflow valve 7 are eliminated. II Relief valve 9 adds a proportional directional control valve group 21 composed of four two-position two-way proportional directional control valves. The two two-position two-way proportional directional control valves connected to the P port are normally closed, and T The two two-position two-way proportional directional control valves connected to the port are in the normally open state. By adjusting the throttle opening of any one two-position two-way proportional directional control valve, the speed of the hydraulic pump / motor can be adjusted, and the system can be increased at the same time. damping to improve system stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com