Heavy-pitch ultra-thick coalbed fully-mechanized caving mining three-dimensional similar material simulation test bed

A technology for simulating test benches and extra-thick coal seams, which is applied in the field of three-dimensional similar material simulation test benches, can solve problems such as poor test conclusions and inaccurate execution of time similarity ratios, and achieve reliable test conclusions and accurate execution time similarity ratios. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments.

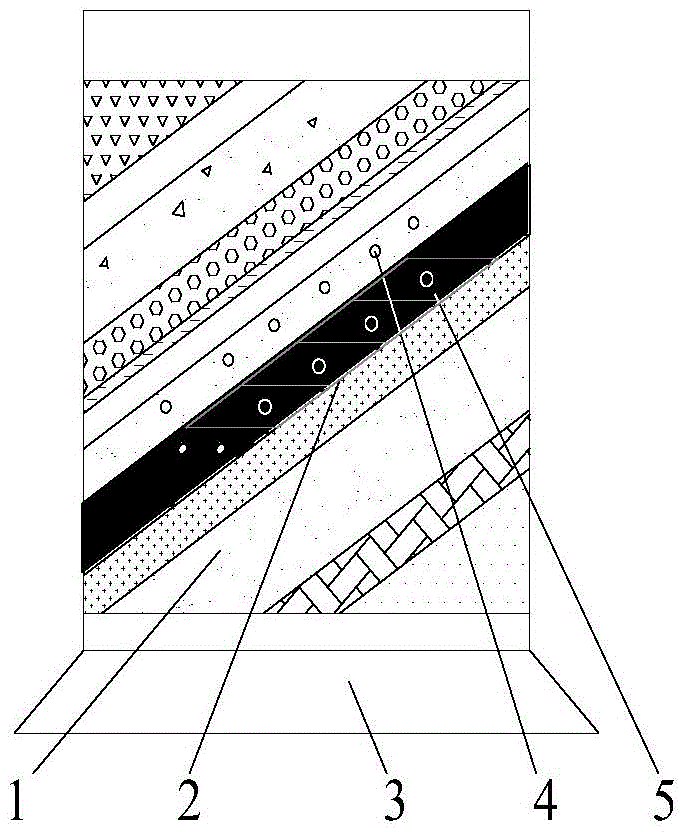

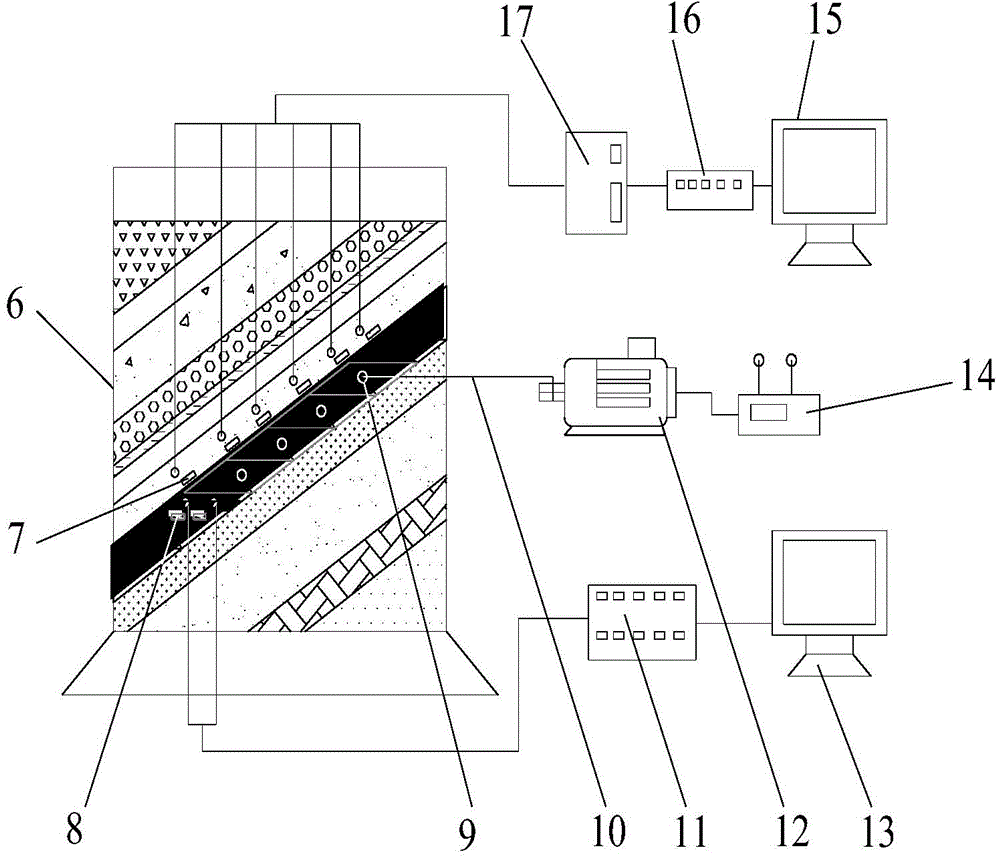

[0031] Such as figure 1 , figure 2 As shown, a three-dimensional similar material simulation test bench for fully mechanized caving mining in steeply inclined and extra-thick coal seams includes four parts: test box 6, coal seam mining simulation system, acoustic emission monitoring system and stress monitoring system.

[0032] Above-mentioned test box body 6 comprises base, front and rear baffles and left and right baffles, wherein, base part is a trapezoidal prism structure, top surface is a rectangle, and the area of top surface is less than the area of bottom surface, and the edge part of top surface is provided with The screw hole belt, the front and rear baffles, and the left and right baffles are all made of high-strength transparent organic glass, and the left and right baffles are provided with a parallelogram jack 2, and the bottom edge of the parallelogram ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com