Still kettle door-opening safety interlocking structure

A technology of safety interlocking and autoclave, which is applied to kitchen utensils, household utensils, cooking utensils, etc., can solve the problems of many operation steps, labor and time, and achieve the effect of preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

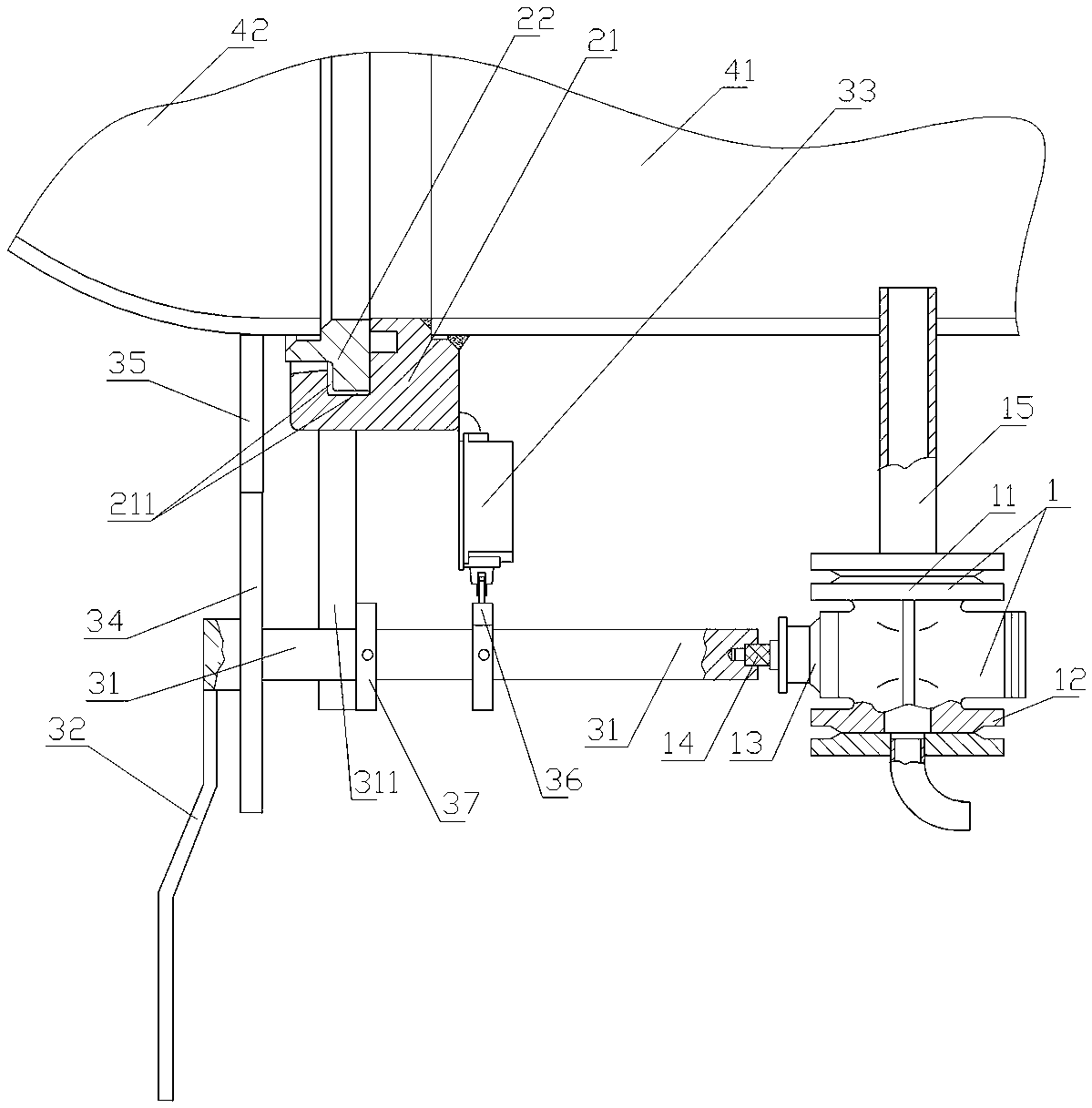

[0022] As shown in Figure 1: an autoclave door opening safety interlock structure, which includes a pressure relief valve 1, a door lock mechanism and an interlock mechanism; the pressure relief valve 1 includes a valve seat 11, a valve body 12, a valve core 13 and a valve Rod 14 and valve core 13 are installed in valve body 12, valve rod 14 is connected with valve core 13, valve body 12 is installed on the outside of kettle body 41 of autoclave through valve seat 11 and valve seat bracket 15; The cavity communicates with the inner cavity of the kettle body 41 through a pipeline.

[0023] The door lock mechanism includes a lock catch 21 connected to the still body 41 and a lock pin 22 connected to the still door 42. The lock catch 21 is provided with a draw-in groove 211 corresponding to the lock pin 22, and the lock lock 21 can be opened by rotating the still door 42. The lock pin 22 is rotated into the slot 211, and the lock pin 22 can be rotated out of the slot 211 by rever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com