Patents

Literature

63results about How to "High leak detection accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

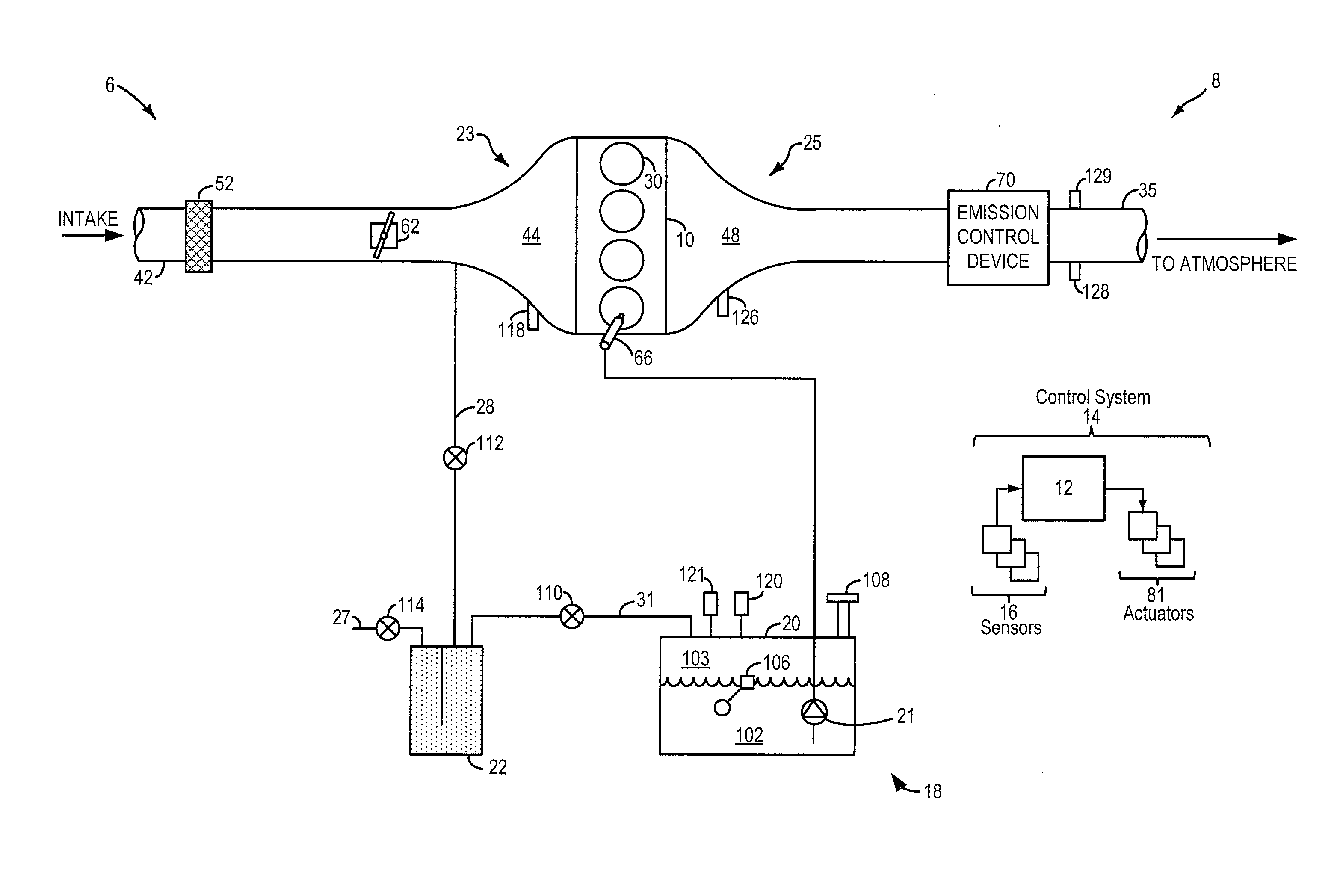

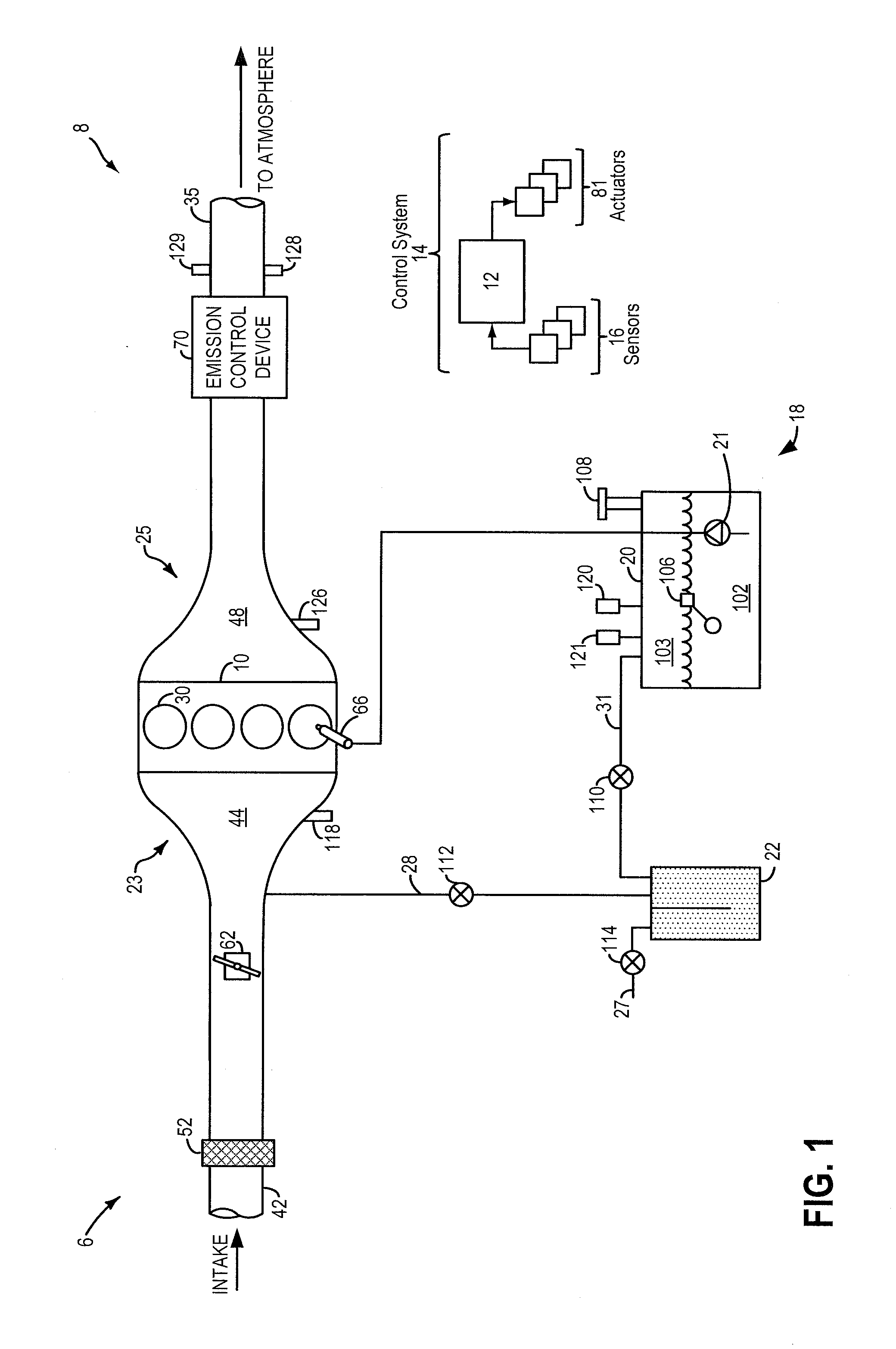

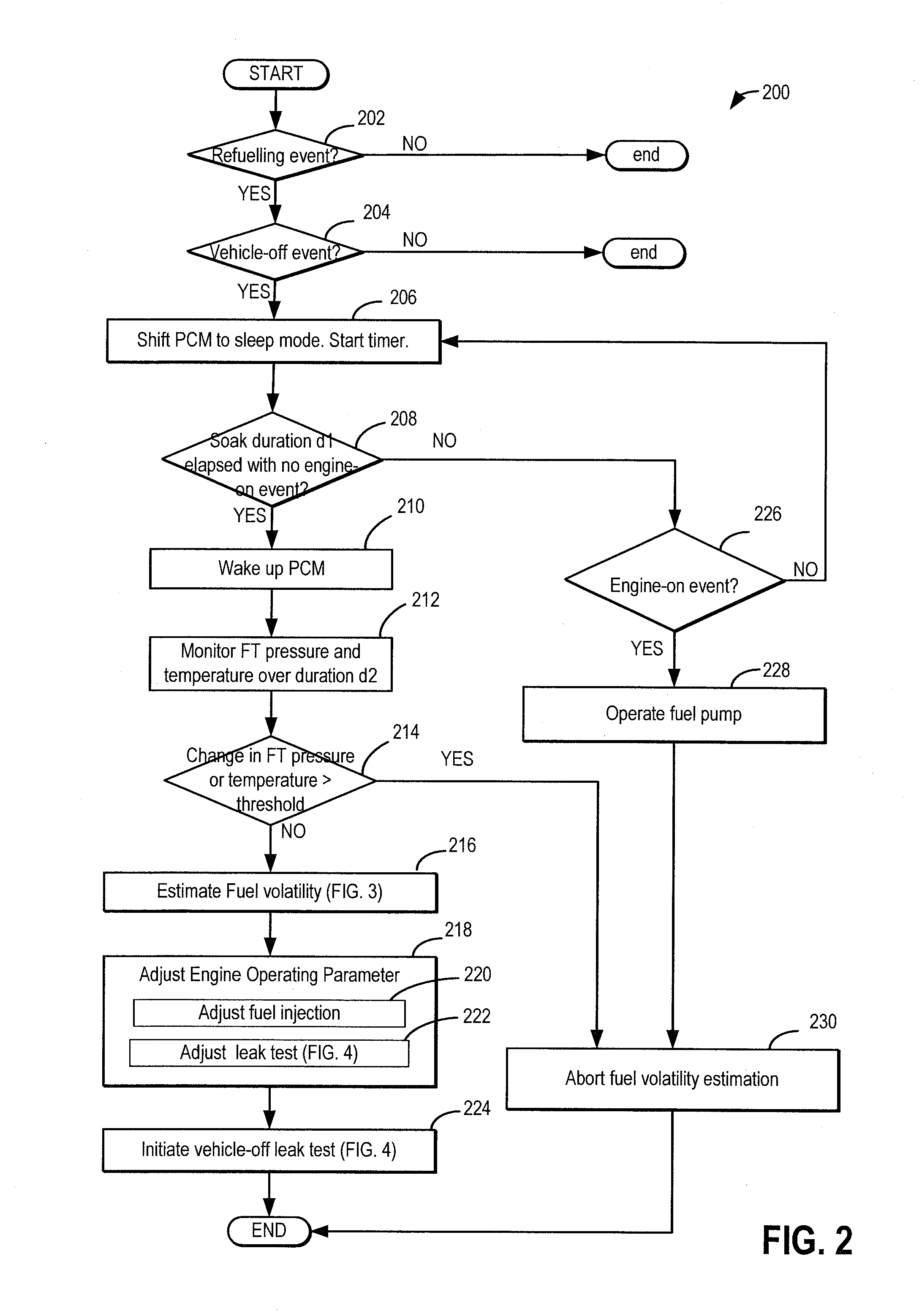

Estimating vehicle fuel reid vapor pressure

InactiveUS20140297071A1Fuel volatilityImprove leak detection accuracyVehicle testingHybrid vehiclesReid vapor pressureFuel injection

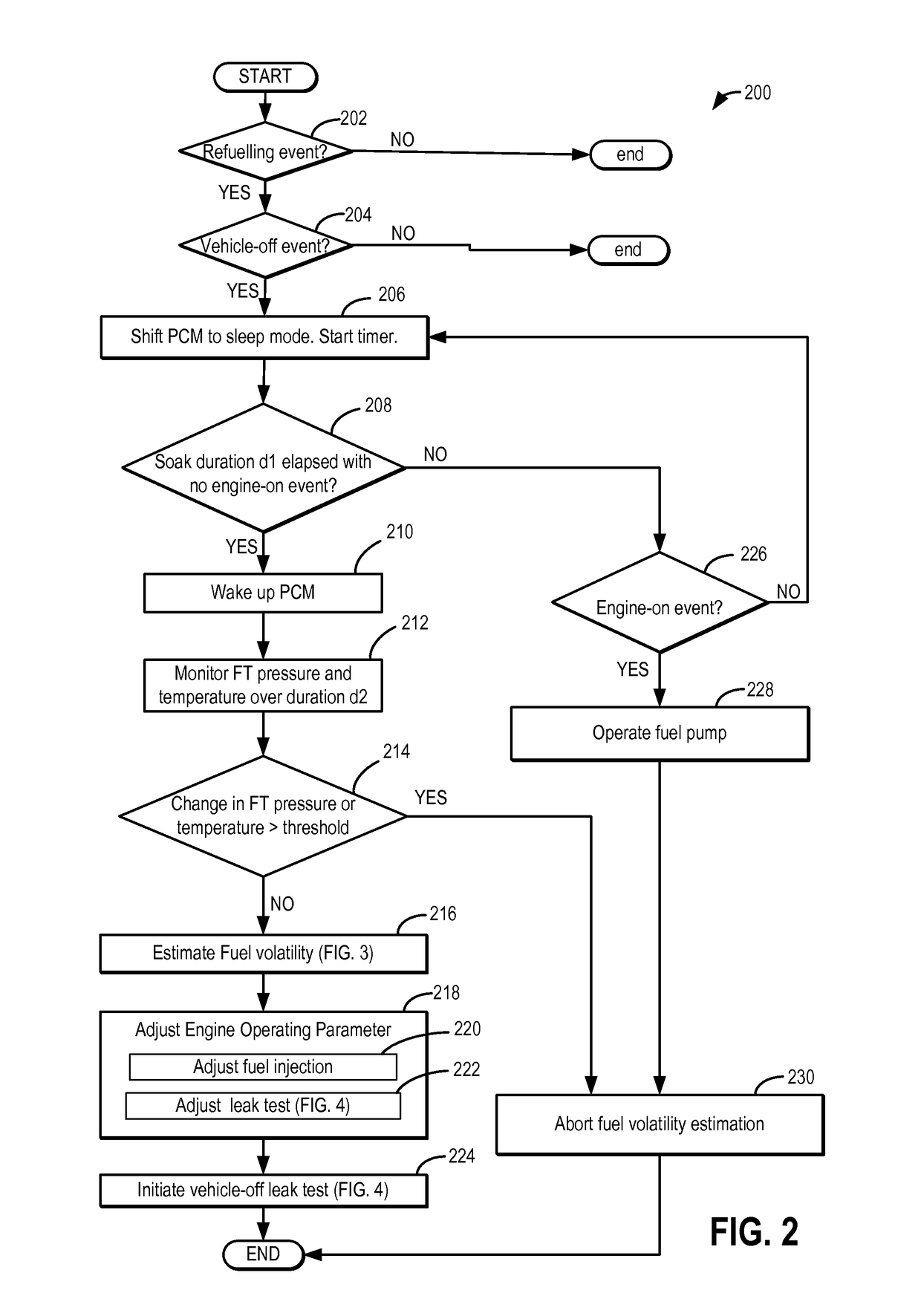

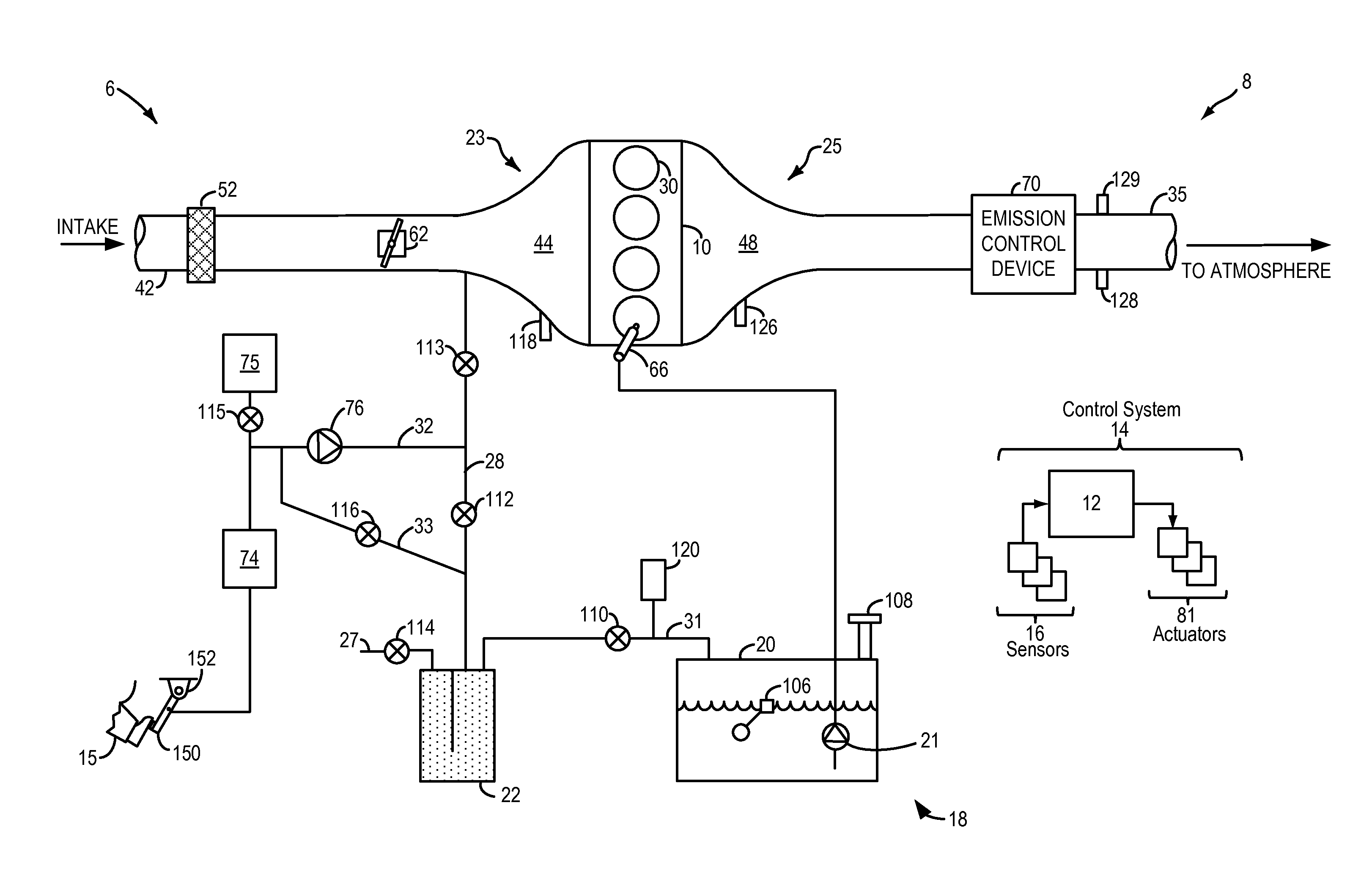

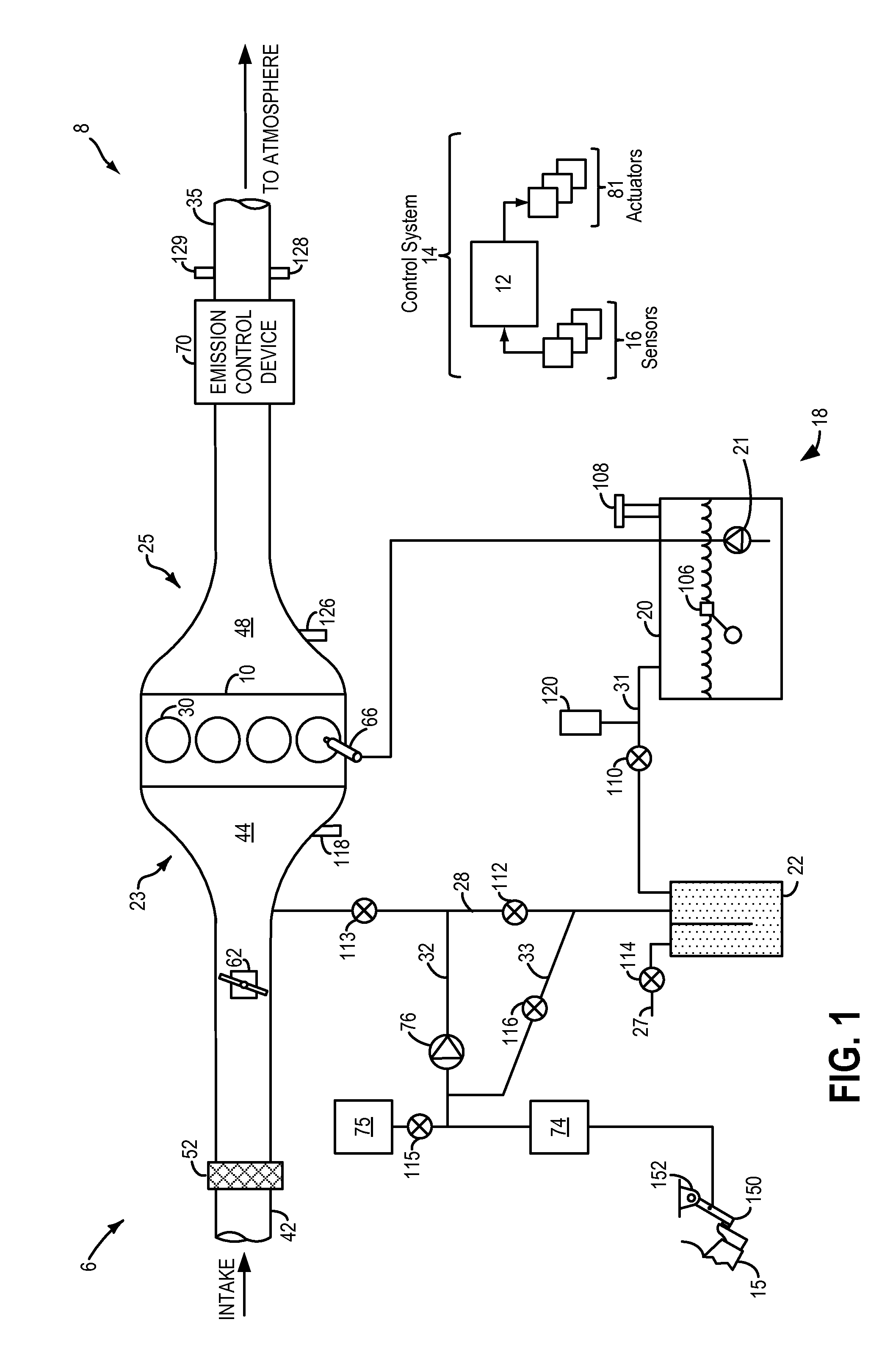

Methods and systems are provided for estimating fuel volatility. During a vehicle-off condition following a refueling event, fuel volatility may be estimated. Based on estimated fuel volatility, fuel injection amount and leak test thresholds may be adjusted.

Owner:FORD GLOBAL TECH LLC

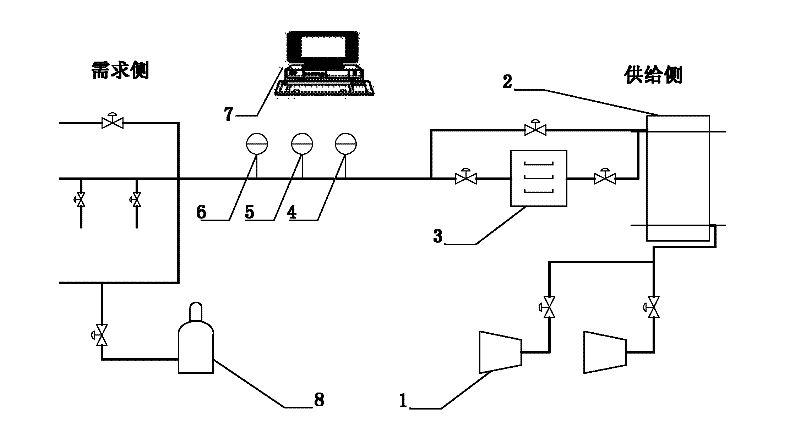

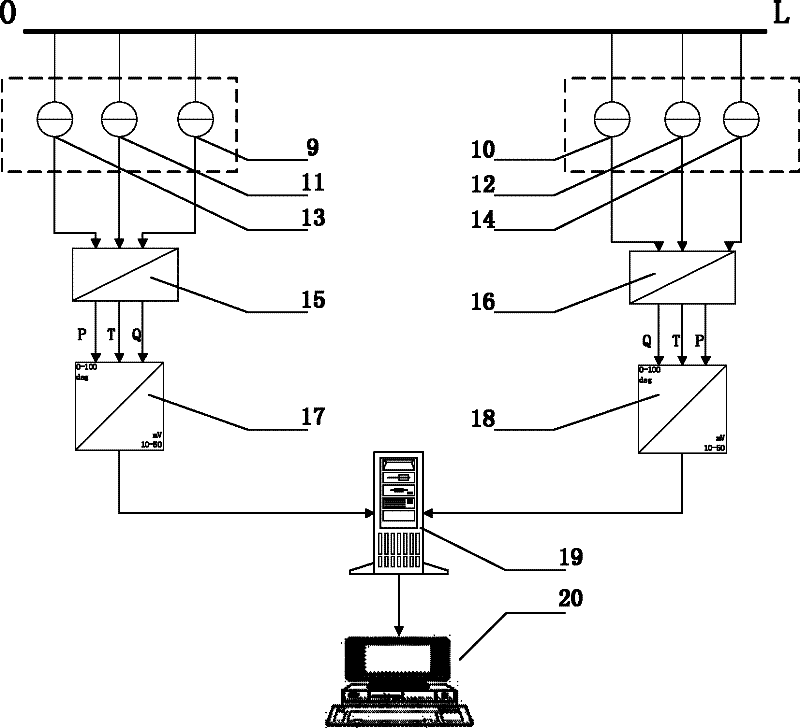

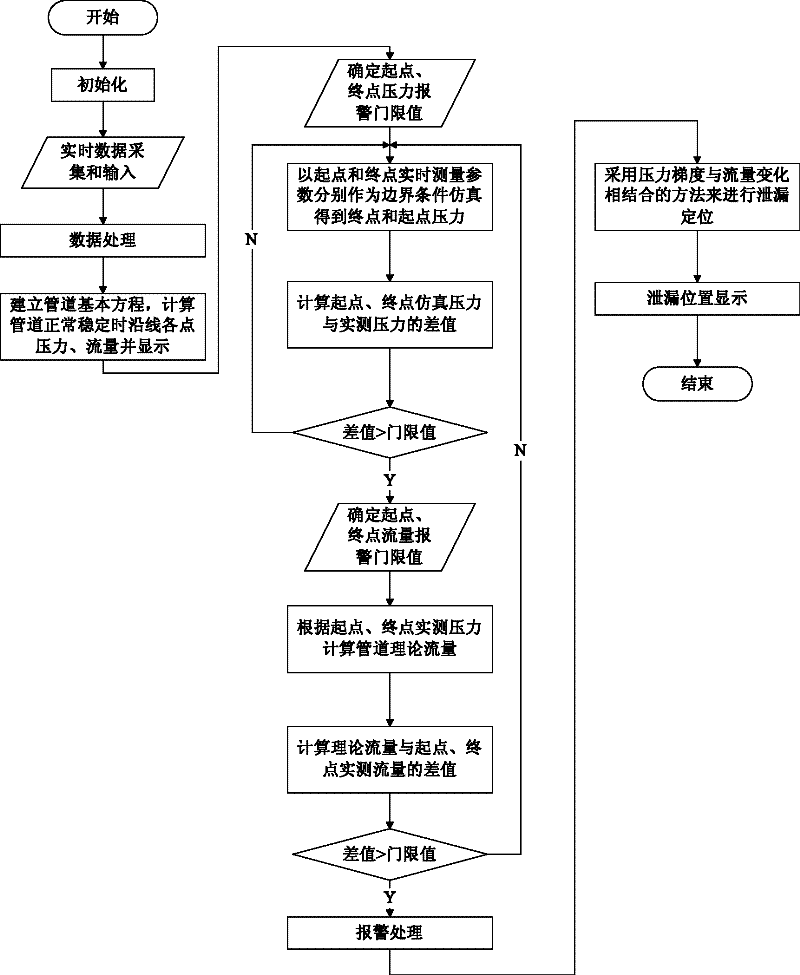

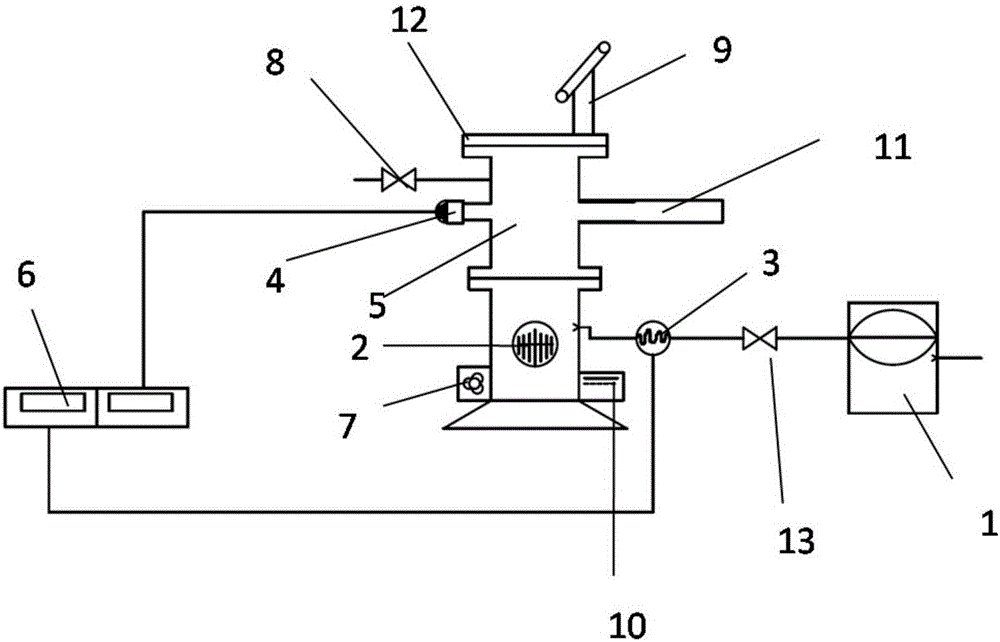

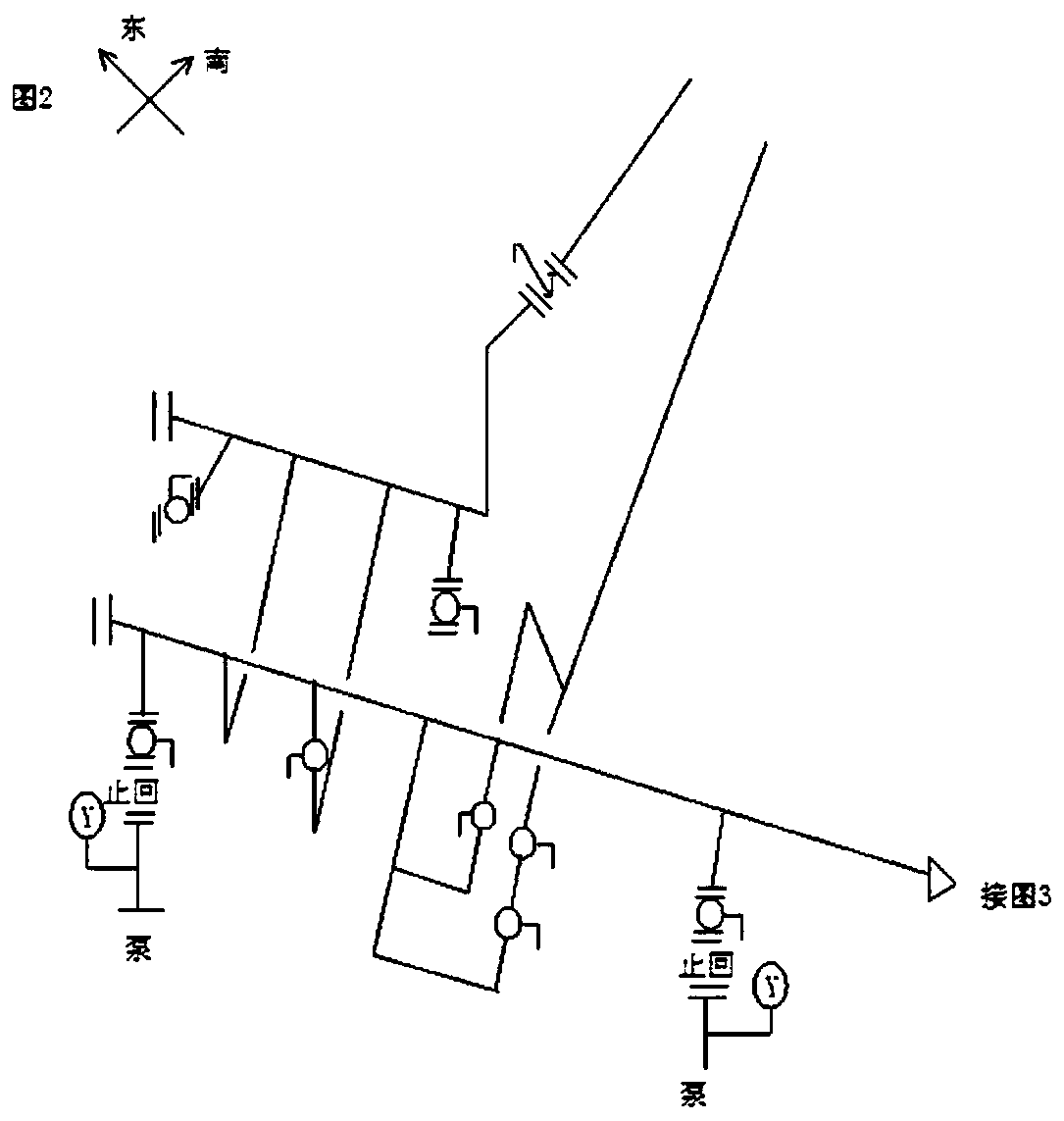

Compressed air system and intelligent pipe network leakage detecting method for same

ActiveCN102563362AHigh leak detection accuracyHigh sensitivityPipeline systemsFalse alarmTubular network

The invention relates to technology of fault diagnosis, and aims to provide a compressed air system and an intelligent pipe network leakage detecting method for the same. The intelligent pipe network leakage detecting method includes that signals of the pressure, the temperature and the flow of compressed air are acquired by a sensor mounted on a terminal delivery pipe network, and are transmitted to a low-pass filter circuit, received signals are coarsely filtered and are transmitted back to an upper computer by an A / D (analog / digital) conversion circuit via a lower computer, the upper computer obtains change relation of flow parameters along with time and the length of a pipeline according to actually measured data of a starting point and actually measured data of a finish point, and then a pipeline leakage detection function is realized by means of comparing theoretic output with actual output. The intelligent pipe network leakage detecting method adopting detection technology is high in leakage detection accuracy which is higher than 95 degrees, false alarm rate is lower than 3%, detection time is shorter than 55 seconds, sensitivity is high, and leakage quantity higher than 1.5% of delivery quantity of the pipeline can be detected. In addition, when the intelligent pipe network leakage detecting method is used for positioning a leakage point, precision is high, positioning precision error is lower than 1% of the total length of the pipeline, shutdown of a factory is avoided by means of online detection, and labor intensity of manual detection is reduced by means of online detection.

Owner:HANGZHOU ZETA TECH

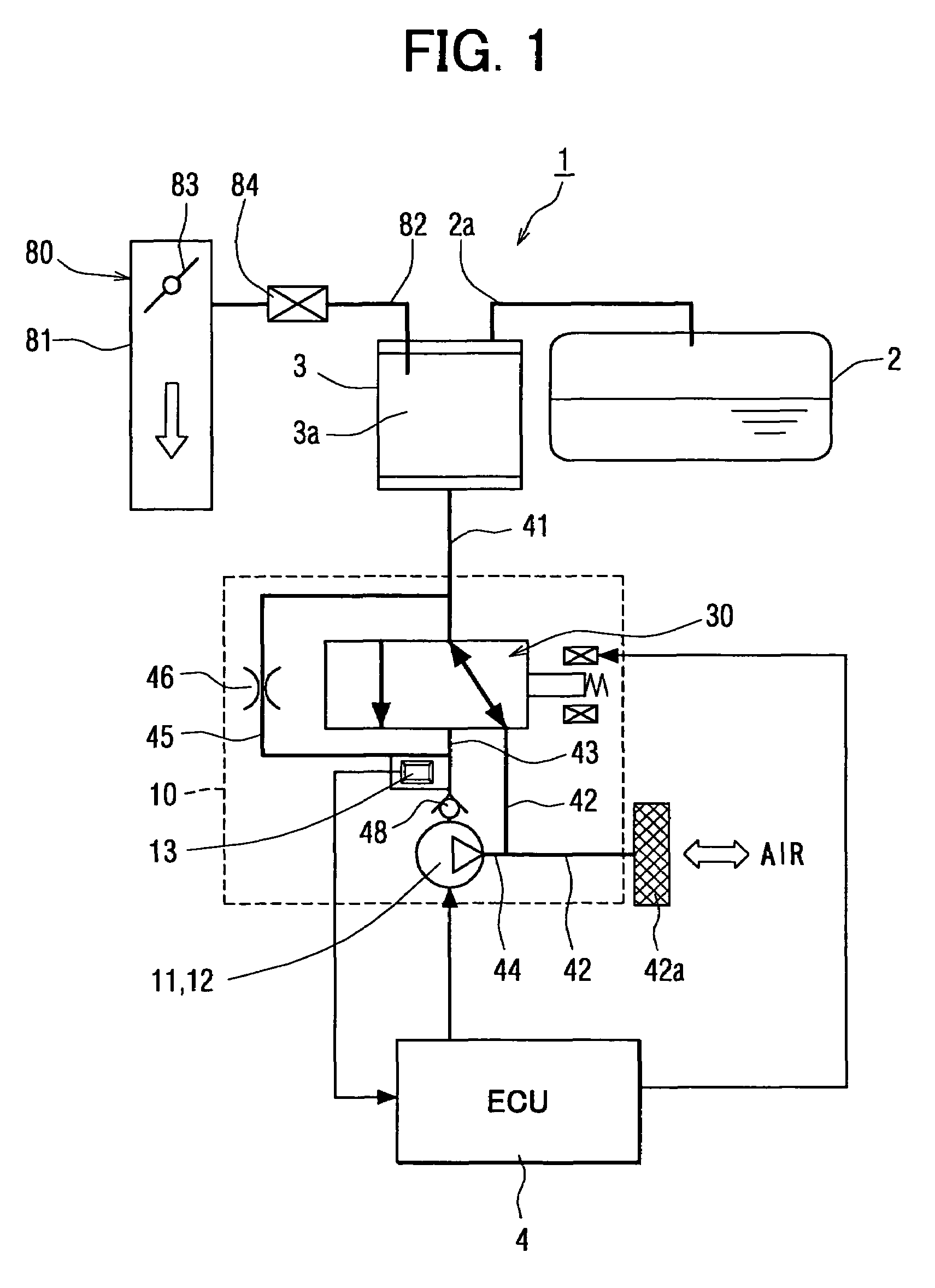

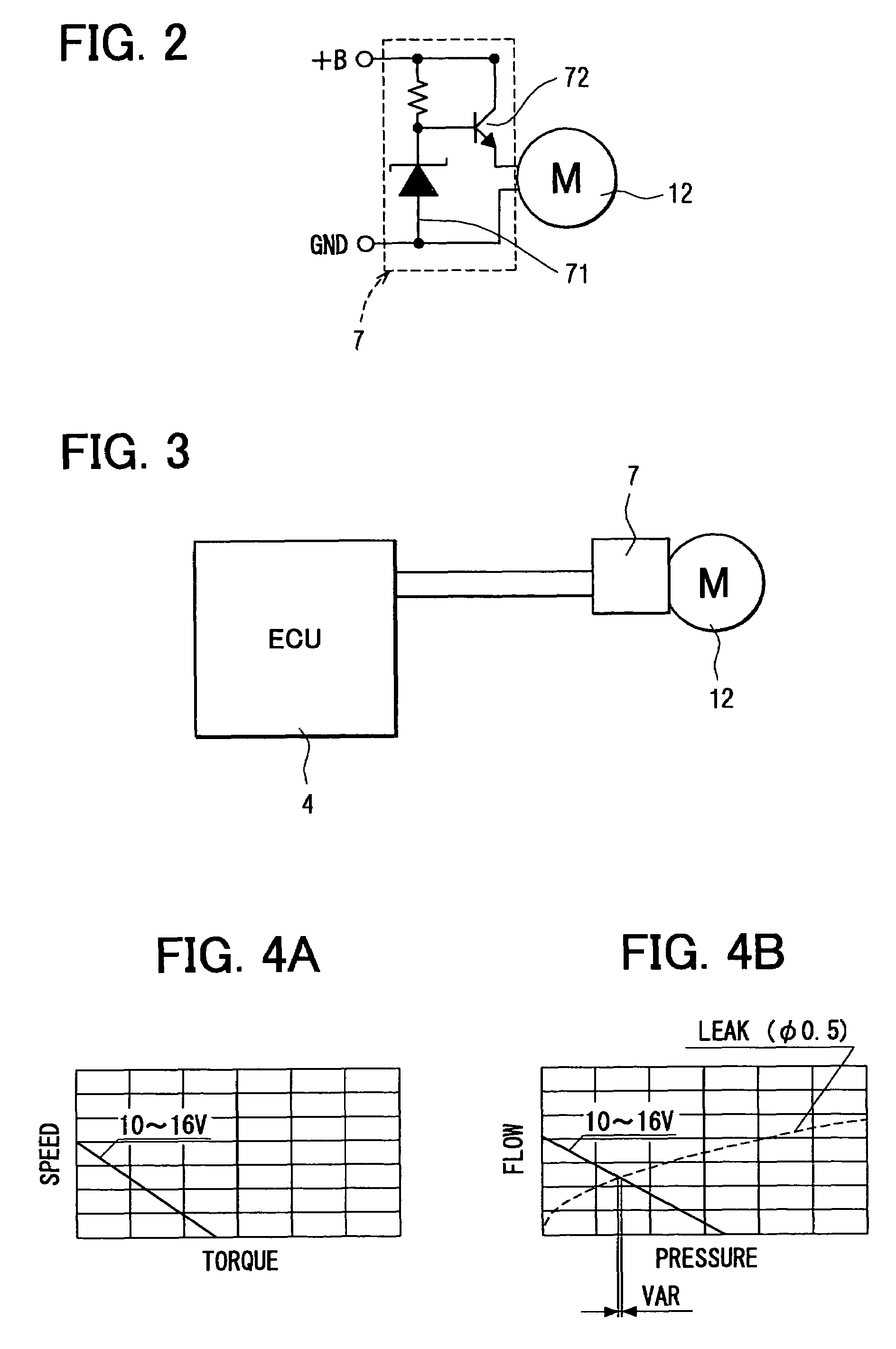

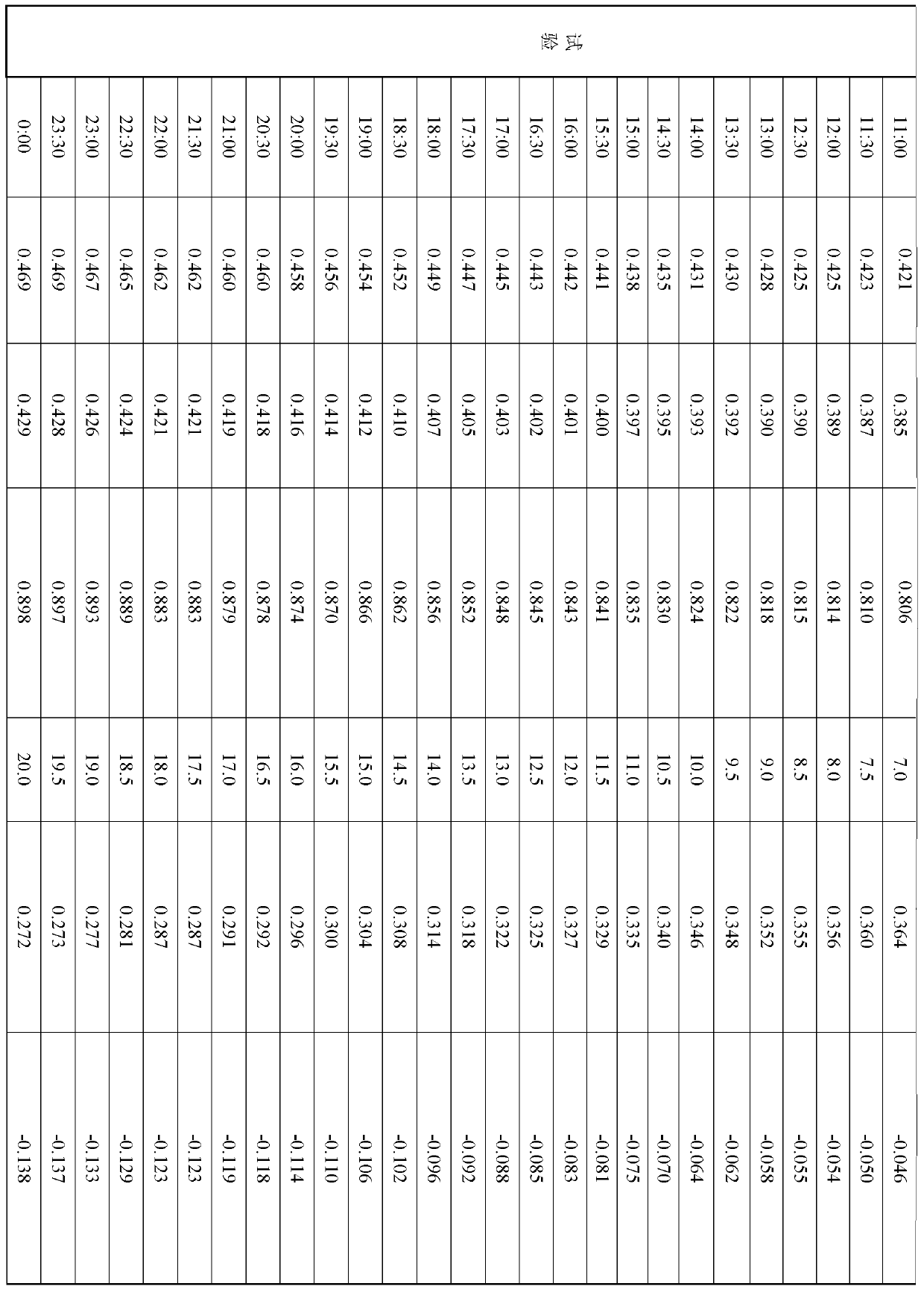

Leak check device for evaporated fuel purging system

ActiveUS6993957B2High leak detection accuracyImprove accuracyDetection of fluid at leakage pointInternal-combustion engine testingElectrical batteryIn vehicle

An evaporated fuel purge system has a fuel tank, an adsorption filter and a purge control valve. The evaporated fuel purge system is pressurized and depressurized through a venting flow path by a pump, so that the state of leakage therefrom is thereby inspected. For this inspection, a motor unit for driving the pump which applies or reduces pressure, an in-vehicle battery and a voltage control circuit which controls a battery voltage to a predetermined voltage and supplies the motor unit with a current are provided. A switchover valve is integrated with the pump, the motor and the like into a single module.

Owner:DENSO CORP

Nuclear power plant generator whole air tight test method

ActiveCN103091053AEliminate adverse factorsHigh precisionDetection of fluid at leakage pointRecording durationPressurized water reactor

The invention belongs to the key technical field of million kilowatt level advanced pressurized water reactor nuclear power plants, and discloses a nuclear power plant generator whole air tight test method. The test method includes that gas is inflated into a generator and a hydrogen system, the pressure is increased to working pressure to be maintained, a leakage point is detected to be handled, the test can be finished when pressure maintaining time of leakage rate meets a predetermined requirement and is larger than or equal to 24 hours, and mixed gas of air and hydrogen is inflated to the generator and the hydrogen system. The test method further comprises a temperature control operating step and an anti-oil-swapping operation step, wherein the temperature control operating step is used for maintaining balanced temperature inside the generator, and the anti-oil-swapping operation step is used for controlling swapping of sealing oil on the airside and the hydrogen side not to cause gas leakage. The test method further comprises sealing oil tank liquid level monitoring step in the process of pressure maintaining. Recording duration for monitoring of gas temperature, pressure, ambient atmosphere pressure and sealing oil tank liquid level inside the generator is every 20-40 minutes in the process of the pressure maintaining. The nuclear power plant generator whole air tight test method is short in time limit for construction and high in test precision.

Owner:CHINA GENERAL NUCLEAR POWER CORP +1

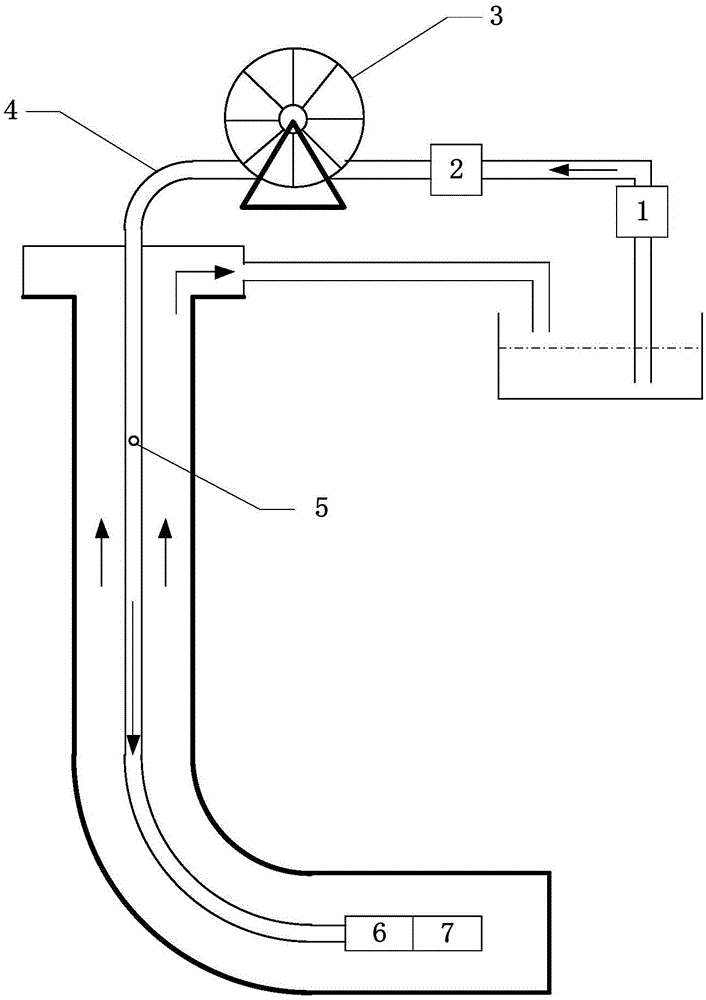

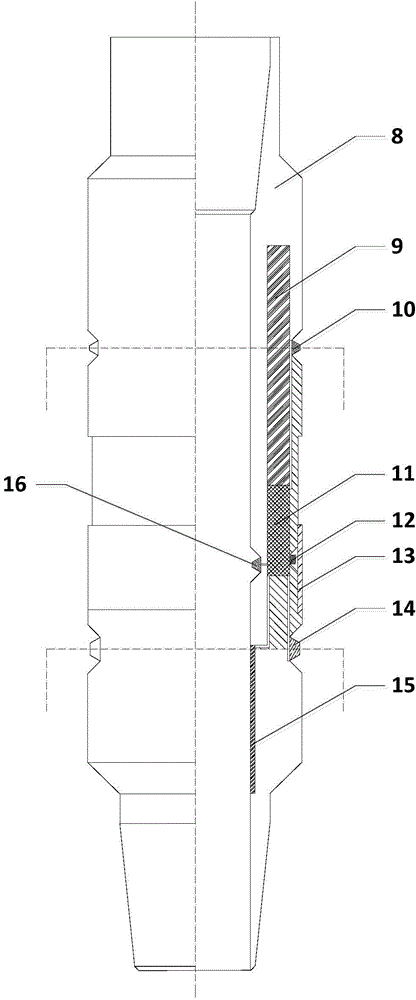

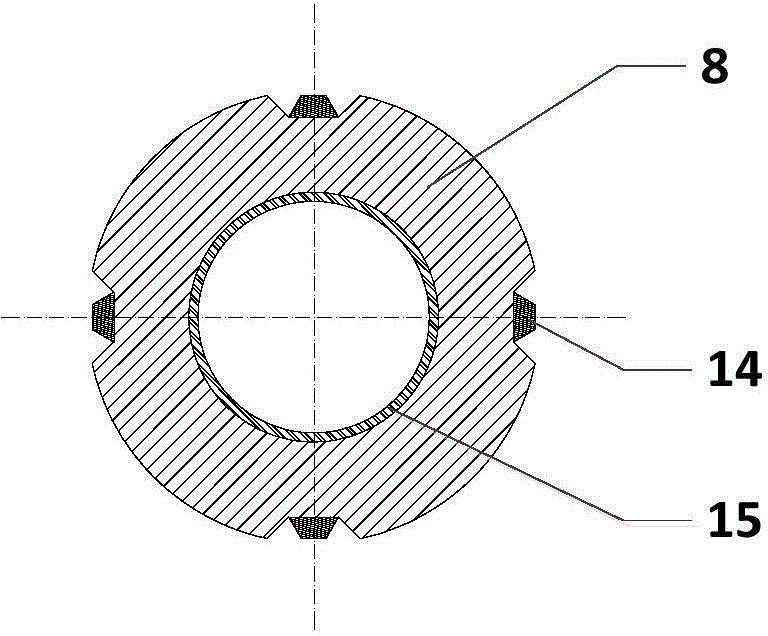

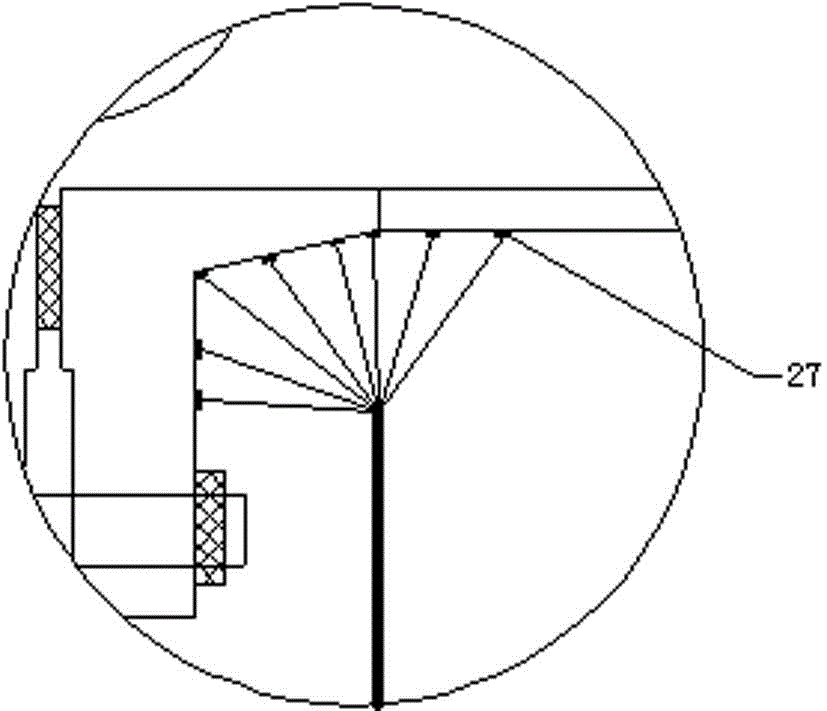

Shaft leakage detecting device used for continuous coiled tube drilling

The invention discloses a shaft leakage detecting device used for a continuous coiled tube. The shaft leakage detecting device comprises an underground leakage finding short joint and a coiled tube. The underground leakage finding short joint is connected with other underground equipment at the tail end of the coiled tube, and the underground leakage finding short joint comprises a short joint body, at least one sensor set, a circuit system and an RFID tag reading coil. The RFID tag reading coil is installed on the inner wall of the short joint body and is connected to the sensor set through the circuit system, the sensor set is used for obtaining corresponding parameters of the environment where the sensor set is located, and the circuit system is used for controlling the sensor set to be started and storing the environment parameter data read by the sensor set when the RFID tag reading coil reads an RFID starting tag carrying a starting order. The shaft leakage detecting device is easy to operate, high in reliability and low in cost.

Owner:CNPC BOHAI DRILLING ENG

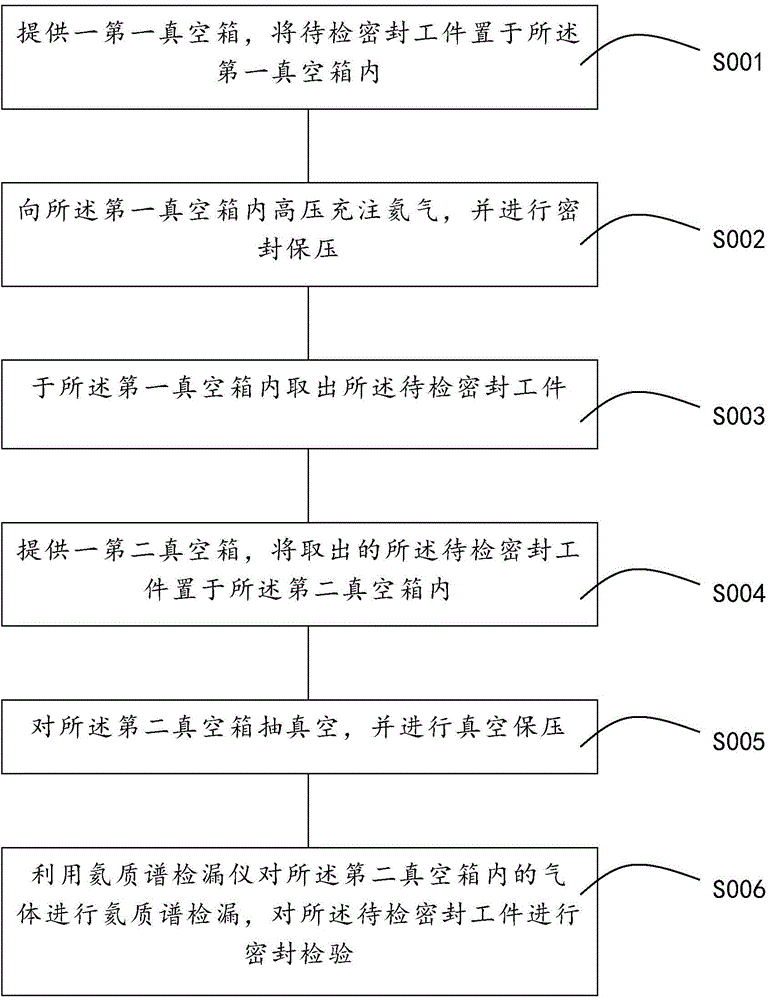

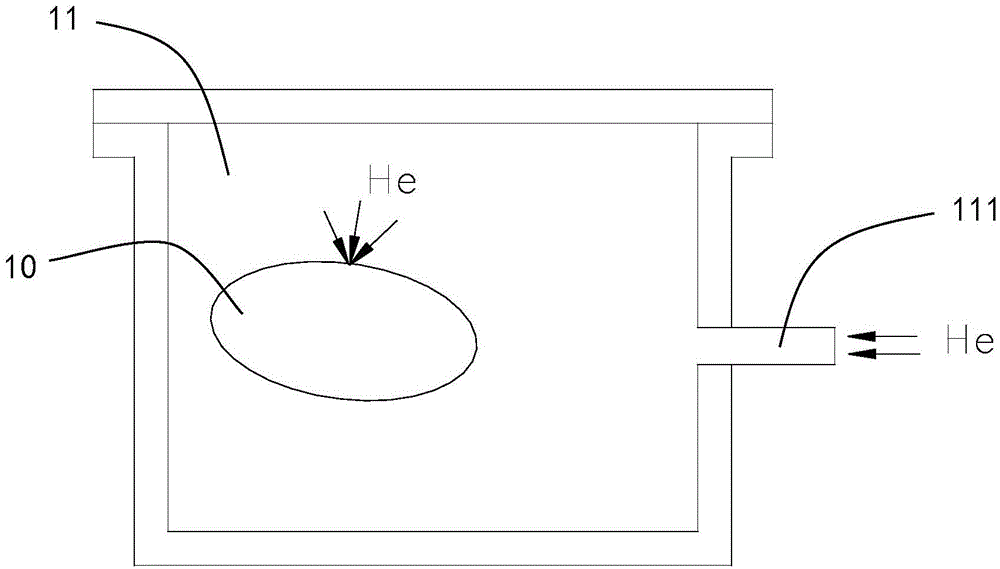

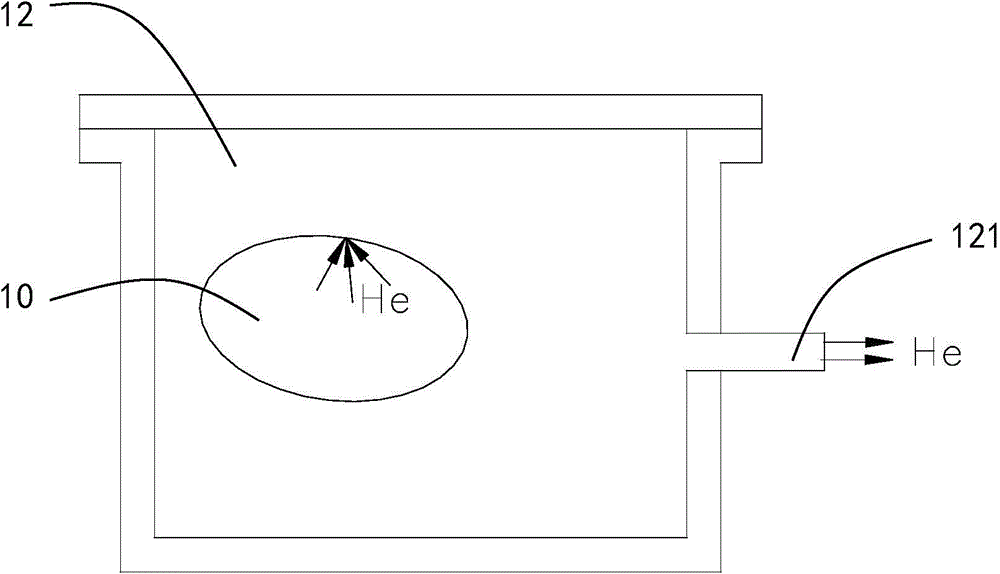

Helium mass spectrometer leak detection method for sealing workpiece

InactiveCN104568336AHigh detection sensitivityHigh leak detection accuracyDetection of fluid at leakage pointVacuum pressureEngineering

The invention discloses a helium mass spectrometer leak detection method for a sealing workpiece. The method includes the steps that a first vacuum box is provided, and the sealing workpiece is placed in the first vacuum box; helium is injected into the first vacuum box, and sealing pressure maintaining is performed on the box; the sealing workpiece to be detected is taken out of the first vacuum box; a second vacuum box is provided, and the sealing workpiece taken out is placed in the second vacuum box; the second vacuum box is vacuumized, and vacuum pressure maintaining is performed on the second vacuum box; helium mass spectrometer leak detection is performed on gas inside the second vacuum box. A helium molecule pressing-in and pumping-out detection method is adopted, the method has the advantages of being high detection flexibility and detection accuracy, and the needed helium-containing pressure value is set according to pressure-resistance requirements of a to-be-detected closed container; the higher the pressure is, the higher the leak detection efficiency is; accordingly, the leakage amount of the to-be-detected closed container can be truly reflected, and special tools and fixtures are not needed; multiple workpieces can be detected at the same time to improve production efficiency, and the method can be widely applied to the temperature control pinger industry and the like.

Owner:SHANGHAI SIZE AUTOMATION EQUIP

Estimating vehicle fuel Reid vapor pressure

InactiveUS9850853B2Accurately estimating fuel volatilityMore robust and accurate leak diagnostic resultsHybrid vehiclesElectrical controlFuel tankReid vapor pressure

Methods and systems are provided for estimating fuel volatility. During a vehicle-off condition following a refueling event, fuel volatility may be estimated by operating a fuel pump of a fuel system immediately after the refueling event while a fuel tank temperature is stable. Based on estimated fuel volatility, fuel injection amount and leak test thresholds may be adjusted.

Owner:FORD GLOBAL TECH LLC

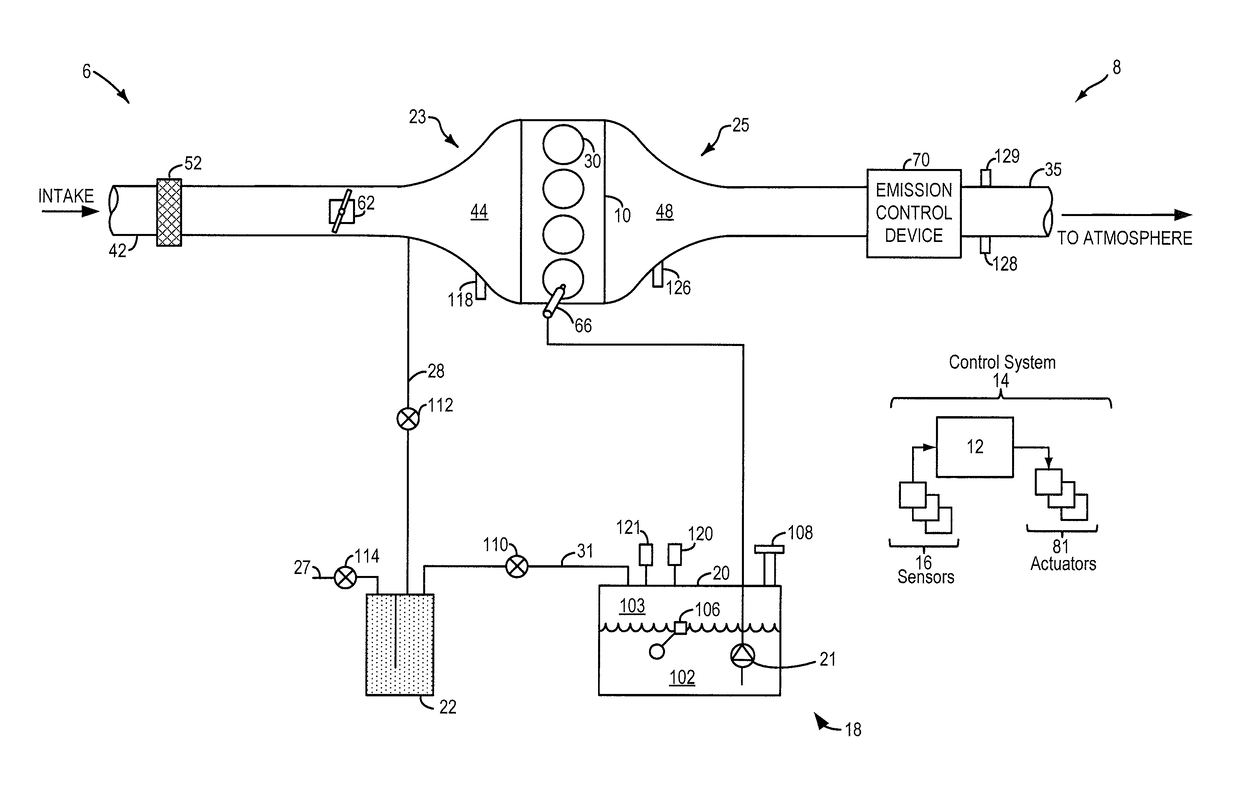

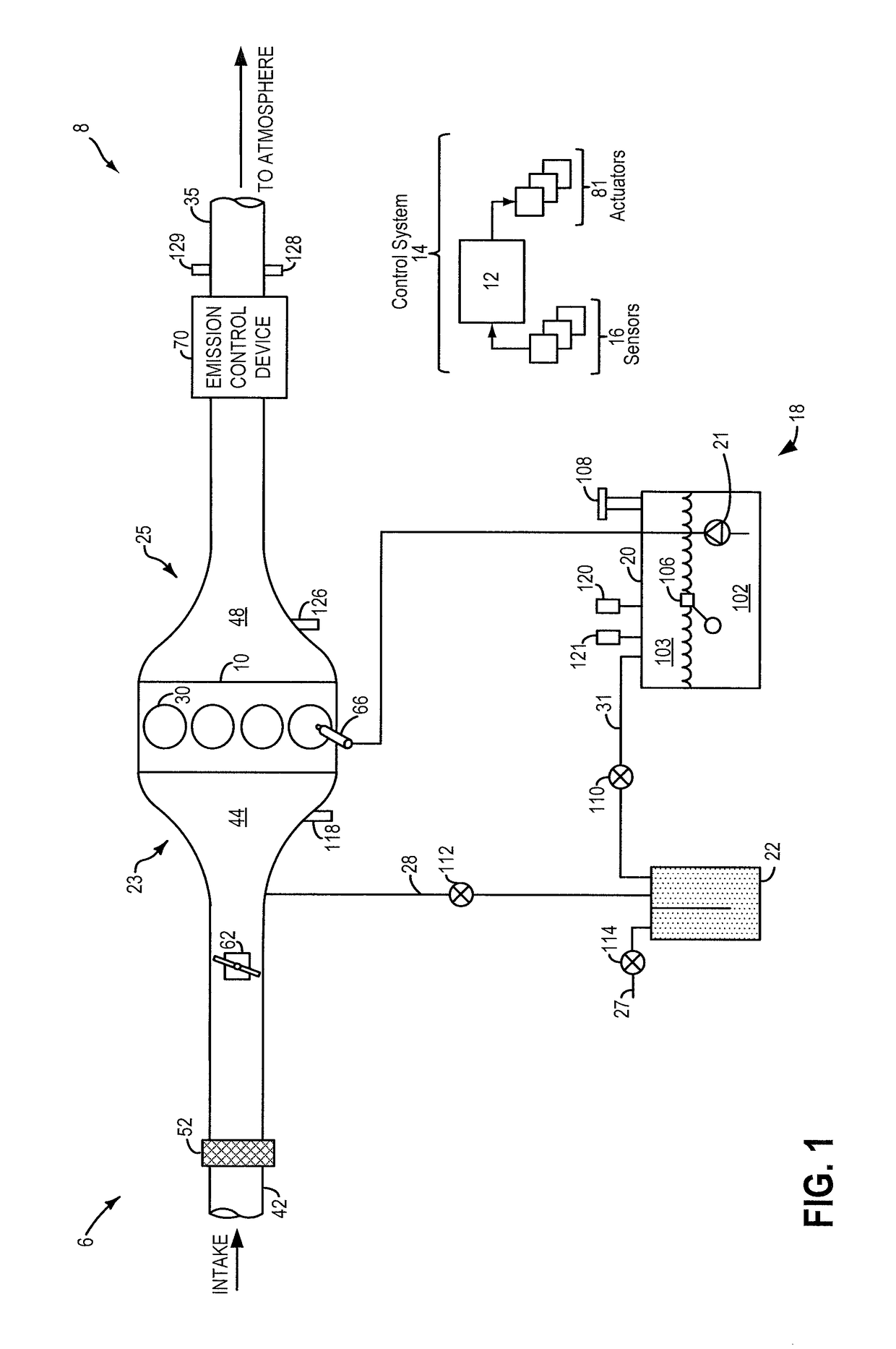

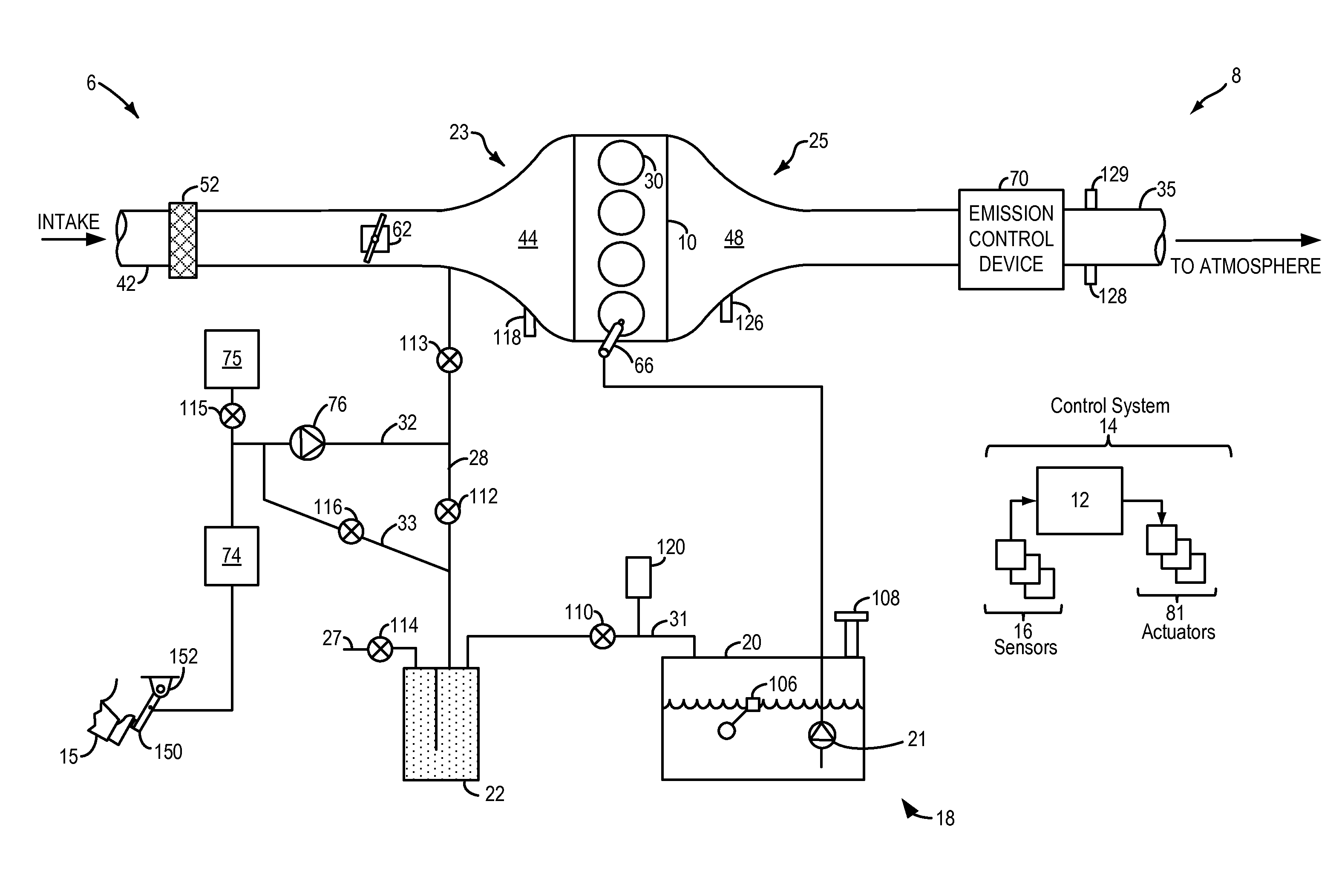

Fuel system diagnostics

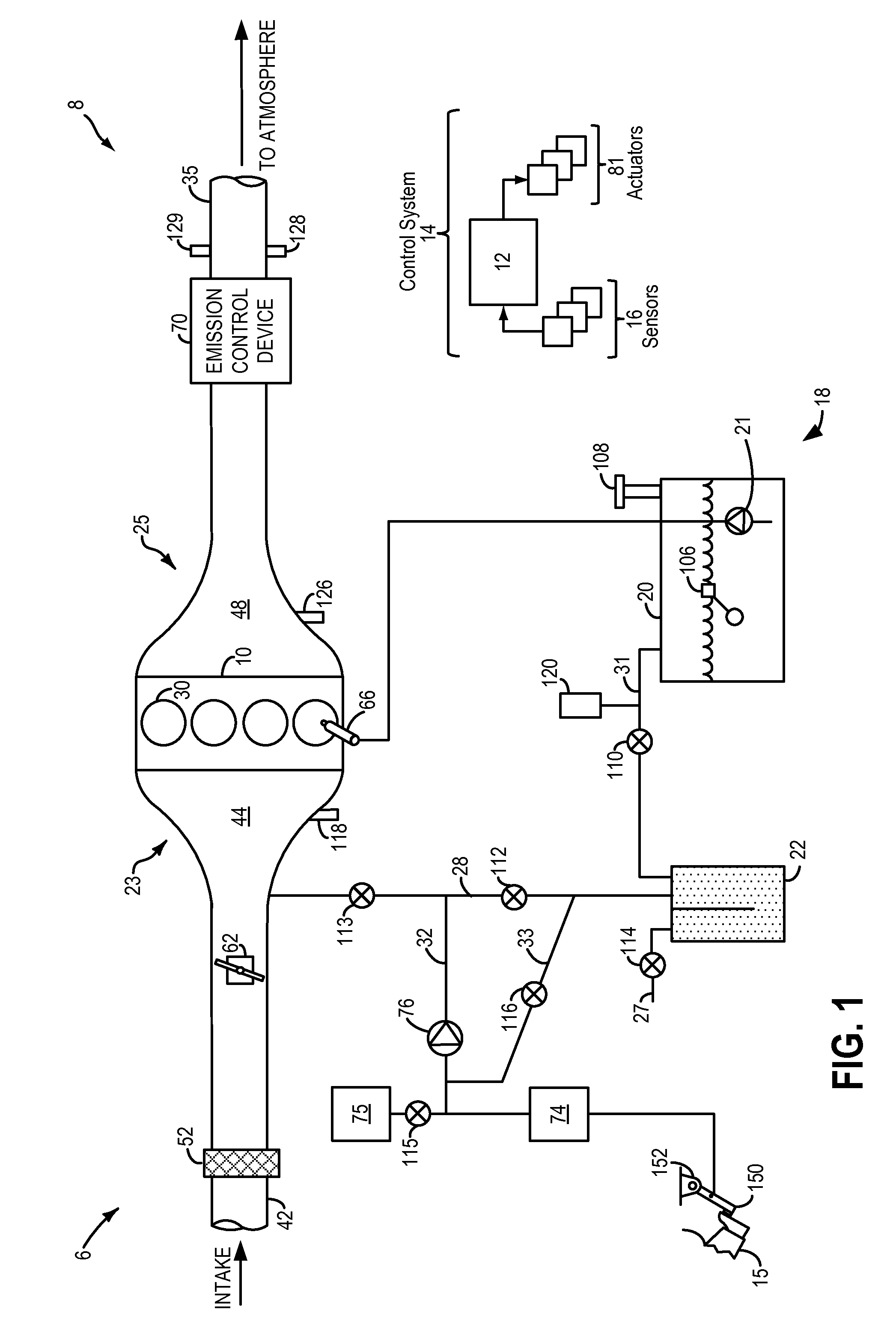

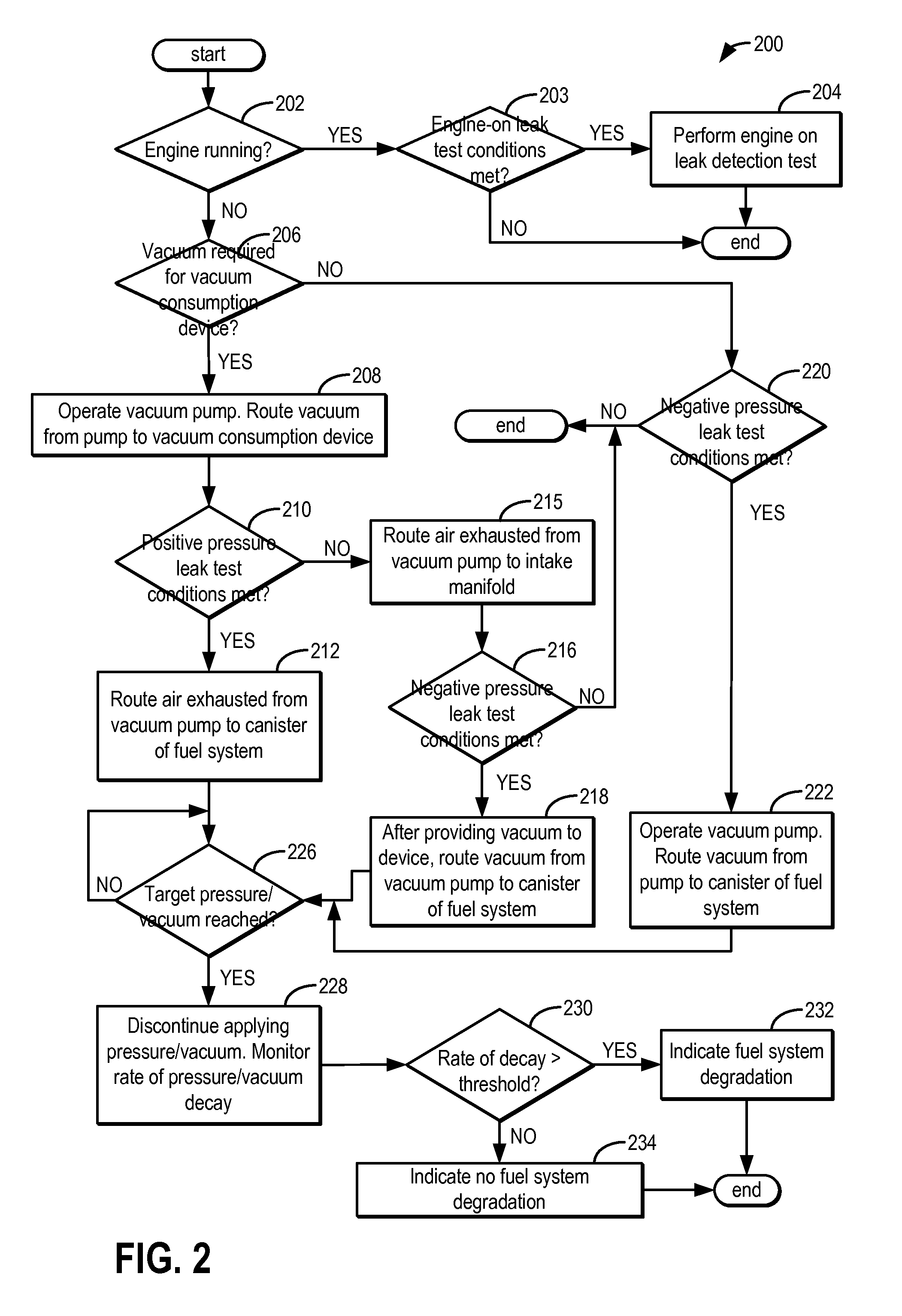

ActiveUS20140060160A1High leak detection accuracyNo additional benefitInternal-combustion engine testingDetection of fluid at leakage pointEngineeringPositive pressure

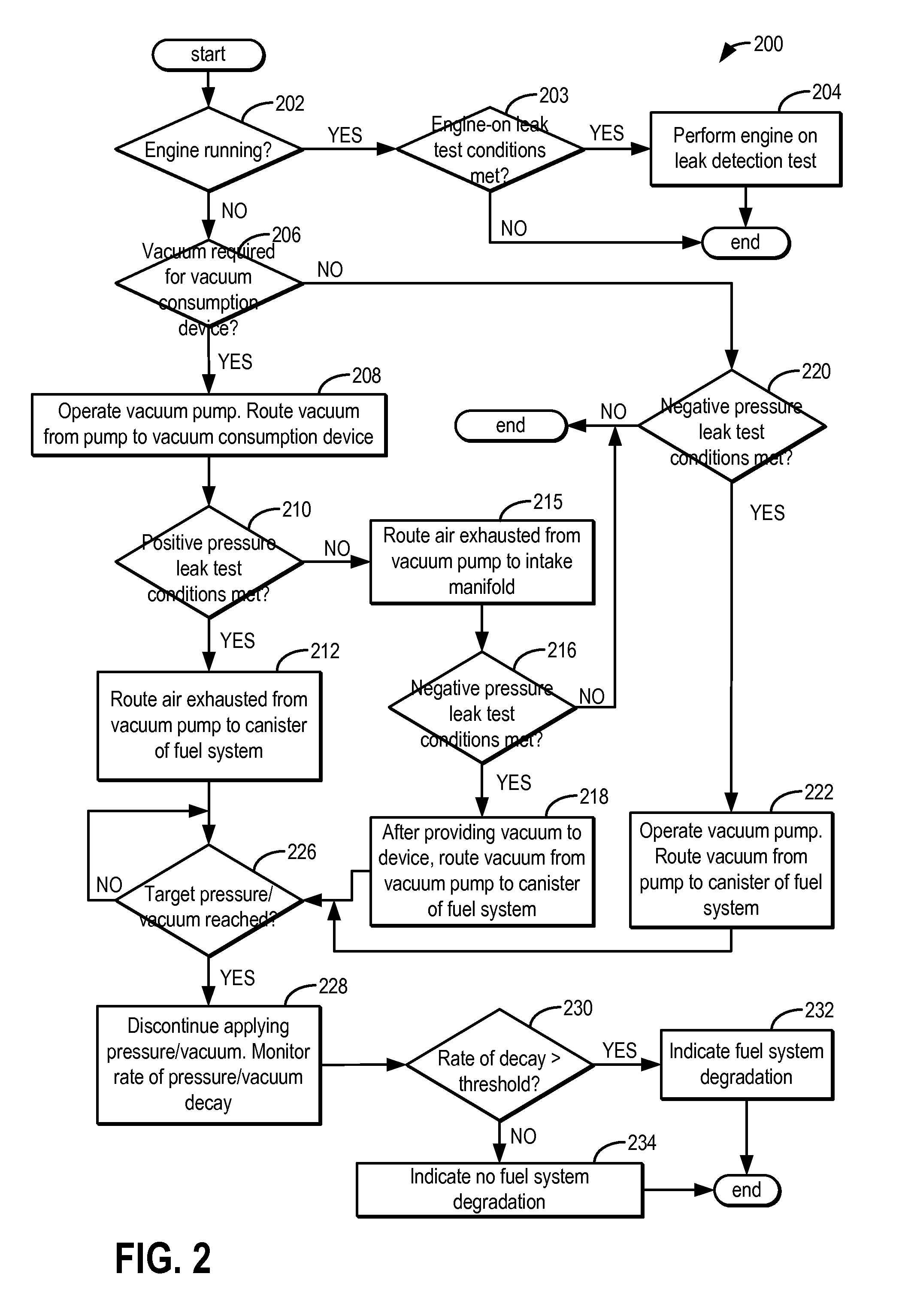

Methods and systems are provided for detecting a fuel system leak. While a system vacuum pump is operated to supply vacuum to a vacuum consumption device, air exhausted from the vacuum pump is routed to a fuel system to apply positive pressure thereon. A fuel system leak is identified based on a rate of decay of the pressure applied from the vacuum pump.

Owner:FORD GLOBAL TECH LLC

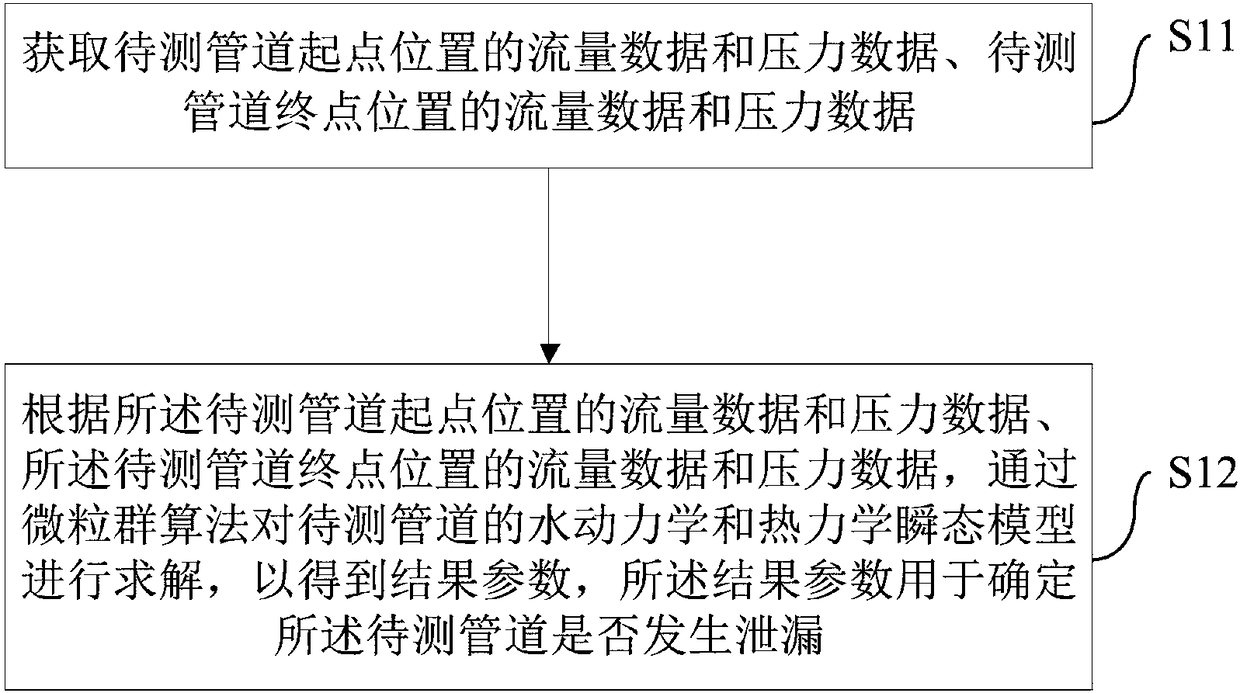

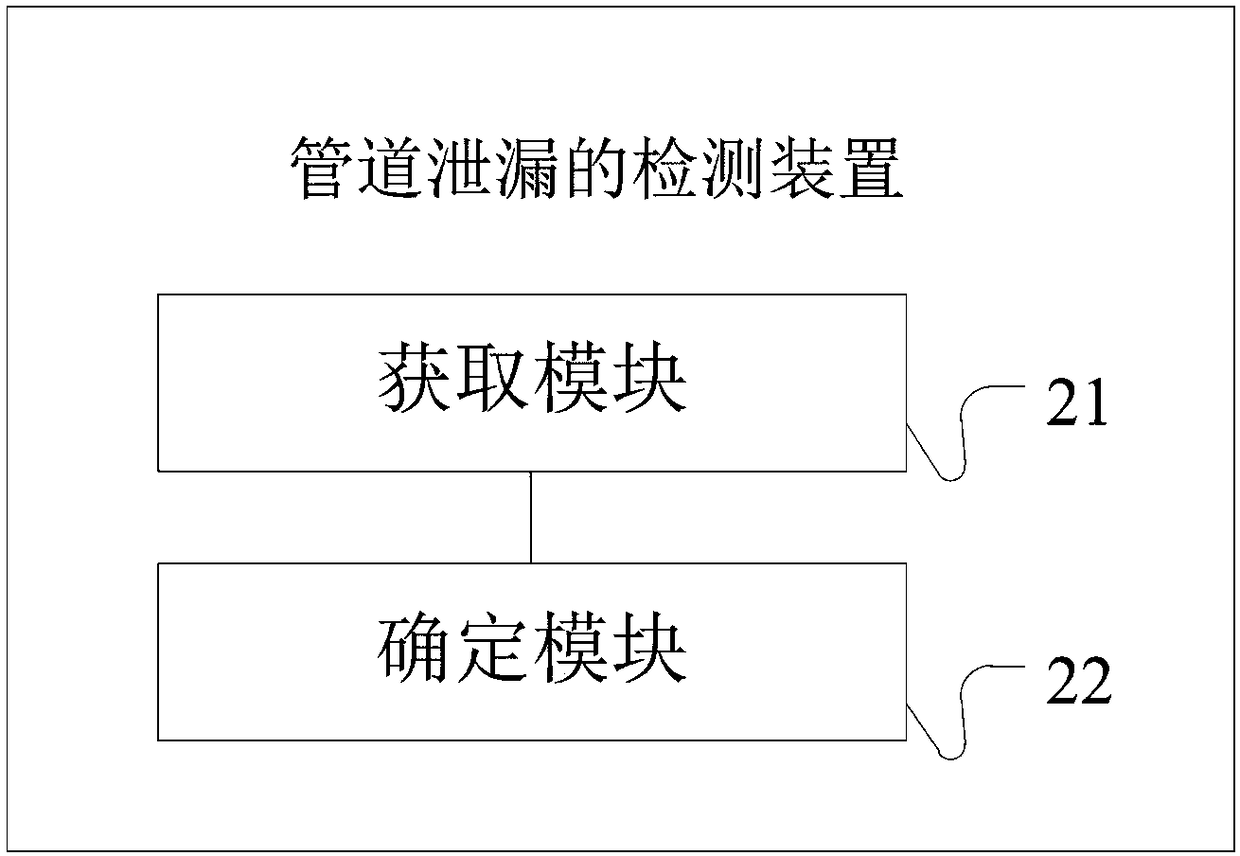

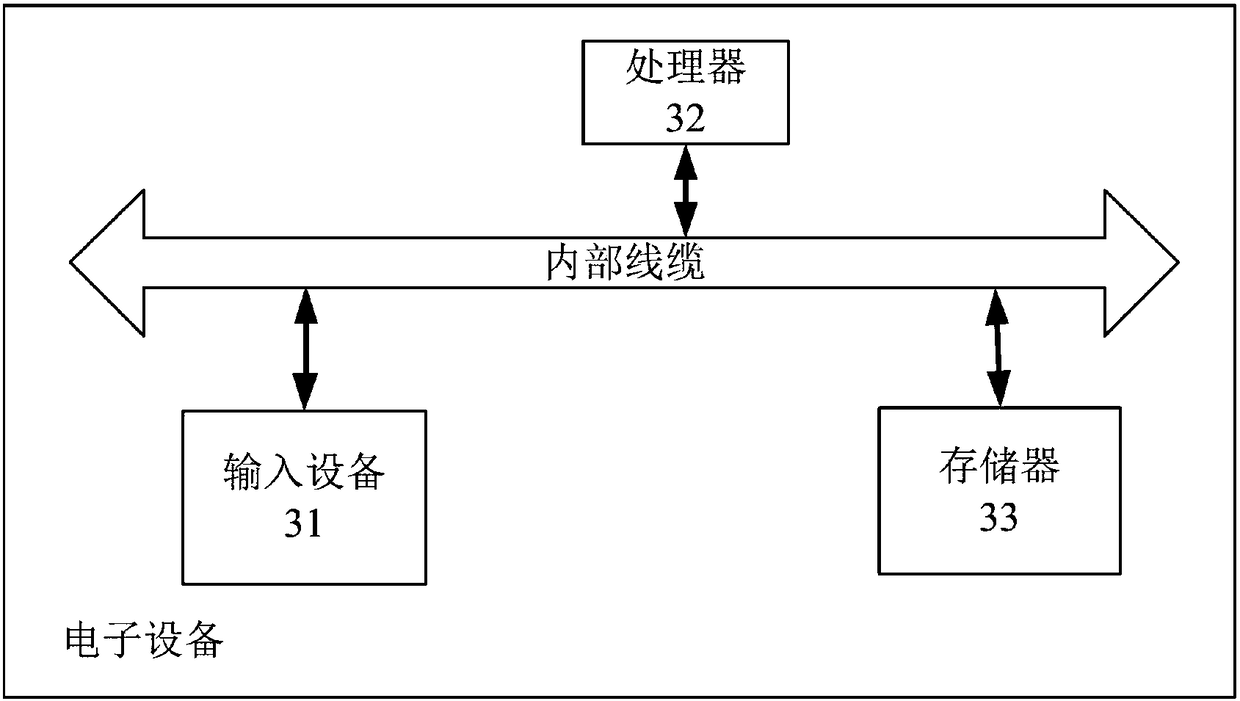

Detection method and device for pipeline leakage

ActiveCN108591836AImprove detection accuracySolution rangeArtificial lifePipeline systemsTransient analysisPressure data

The invention provides a detection method and device for pipeline leakage. The detection method comprises the following steps that 1, flow data and pressure data at the start position of a to-be-detected pipeline are obtained, and flow data and pressure data at the end position of the to-be-detected pipeline are obtained; and 2, according to the flow data and the pressure data at the start position of the to-be-detected pipeline and the flow data and the pressure data at the end position of the to-be-detected pipeline, a hydrodynamic transient model and a thermodynamic transient model of the to-be-detected pipeline are solved through the particle swarm optimization so as to obtain a result parameter, and the result parameter is used for determining whether the pipeline leakage occurs or not. According to the detection method, the particle swarm optimization is combined with hydrodynamics transient analysis and thermodynamic transient analysis, the transient models are solved through the particle swarm optimization so as to determine the running condition of the pipeline, and therefore the technical problem that an existing method is limited in application range and poor in leak detection accuracy is solved, and the technical effect of effectively improving the leakage detection accuracy is achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

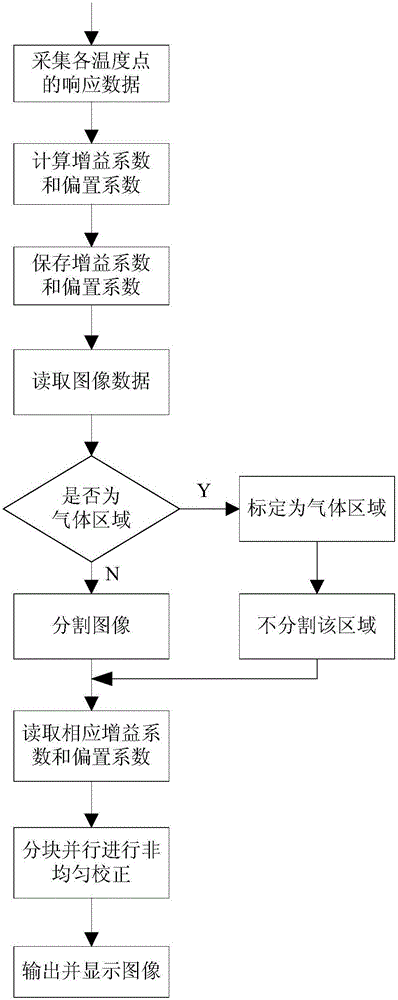

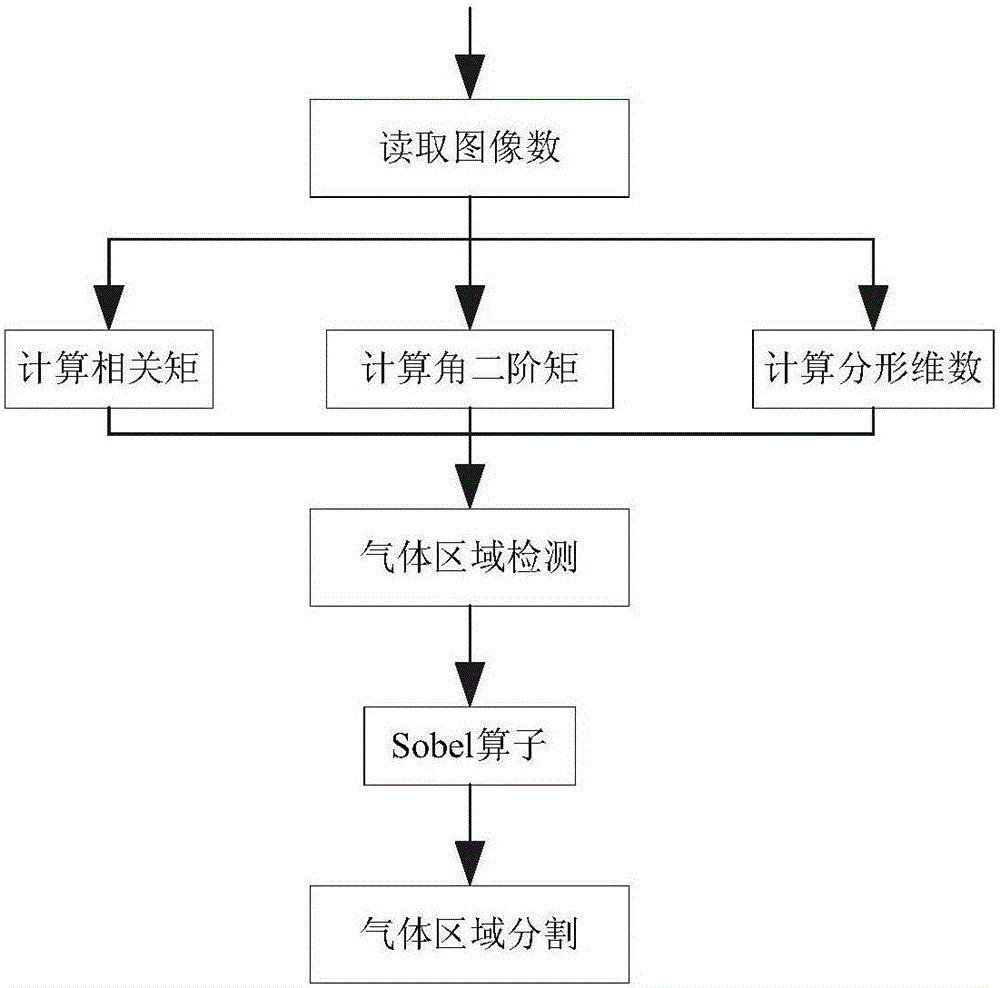

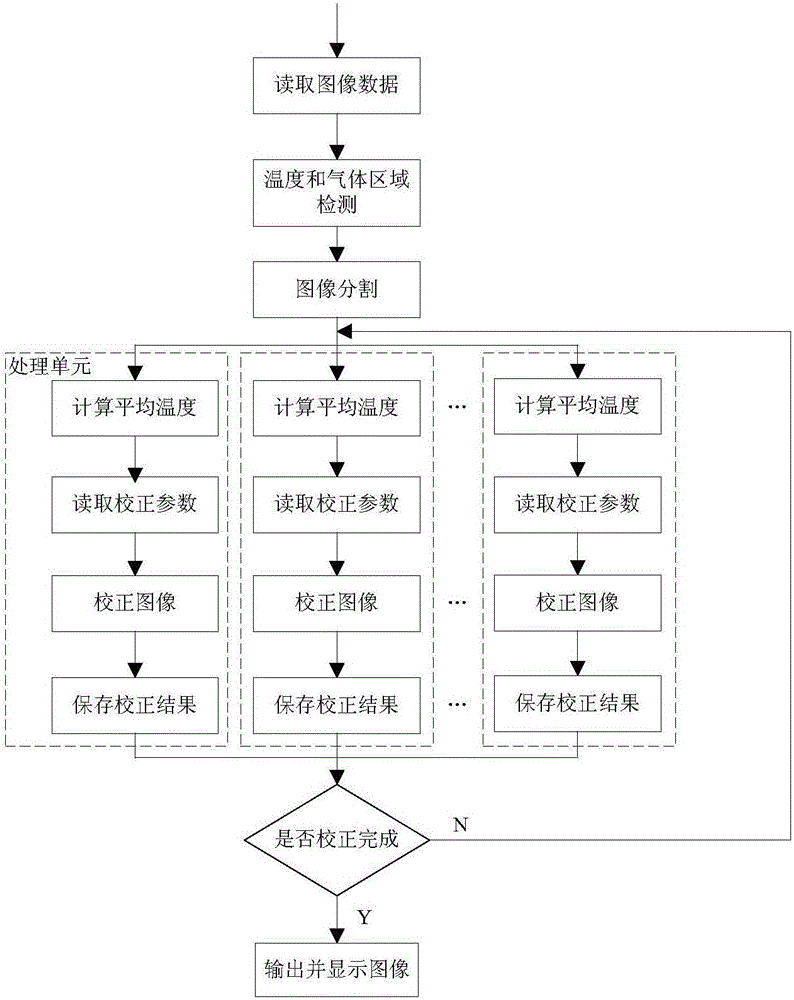

Non-uniformity correction method for gas leakage detection and gas leakage detection device

ActiveCN105865723AImprove the effect of non-uniformity correctionImproved effect of non-uniformity correctionDetection of fluid at leakage pointInfrared windowGain coefficient

The invention relates to the technical field of data identification, in particular to a non-uniformity correction method for gas leakage detection. The non-uniformity correction method comprises the following steps: a gas leakage detection device acquires a gain coefficient Gij and a bias coefficient Qij of each temperature section and stores acquired infrared images; gas areas in the infrared images are identified through texture and edge features; the temperature of each point of images in non-gas areas is detected, and the areas are divided; non-uniformity correction is performed on images in each sub-area through a non-uniformity correction unit. The invention further provides the gas leakage detection device. The gas leakage detection device comprises a casing, wherein a main control chip is arranged in the casing and connected with an infrared imaging module, a display module and a power module, the power module supplies power to the other modules, and the infrared imaging module comprises an infrared lens, an infrared window and an infrared image sensor which are arranged sequentially. The non-uniformity correction method for gas leakage detection and the gas leakage detection device can improve the gas non-uniformity correction effect and improve the gas leakage detection precision.

Owner:CHINA SAFETY TECH OPTOELECTRONICS CO LTD SHANDONG

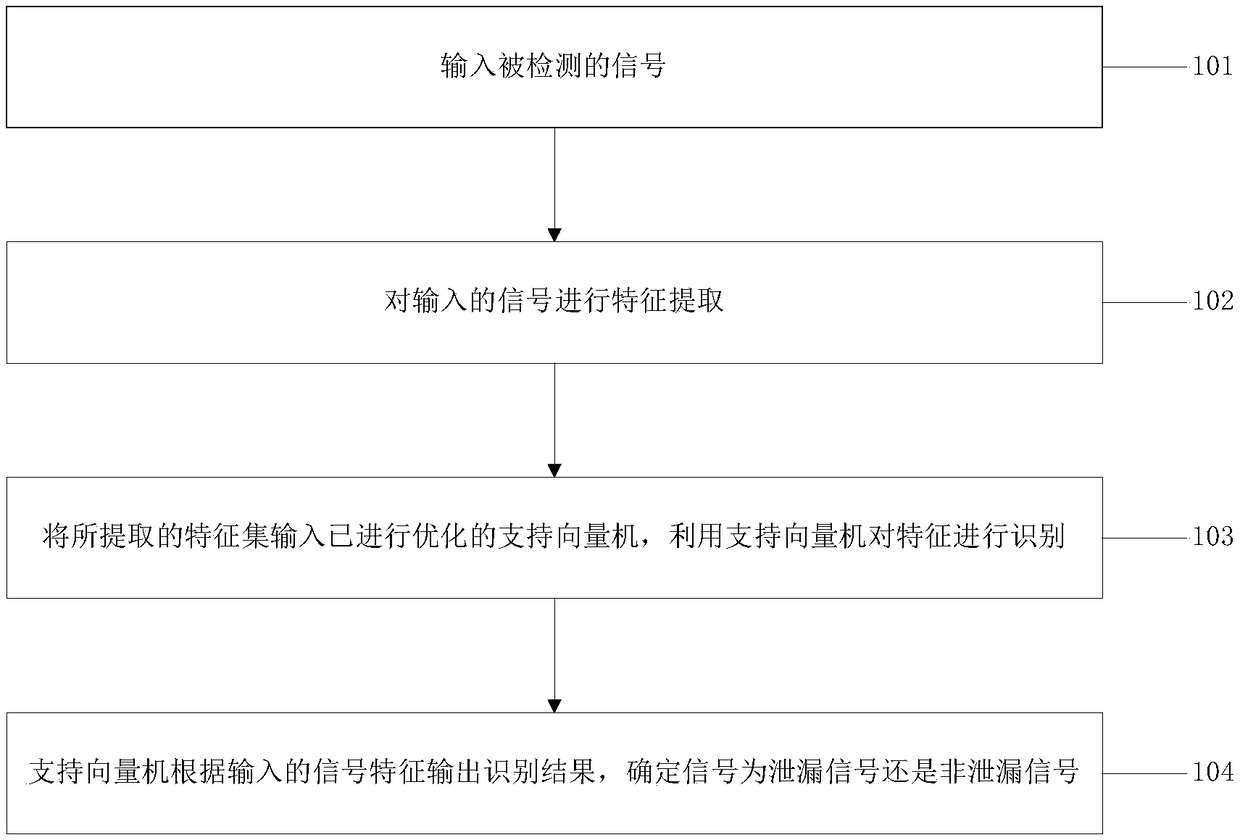

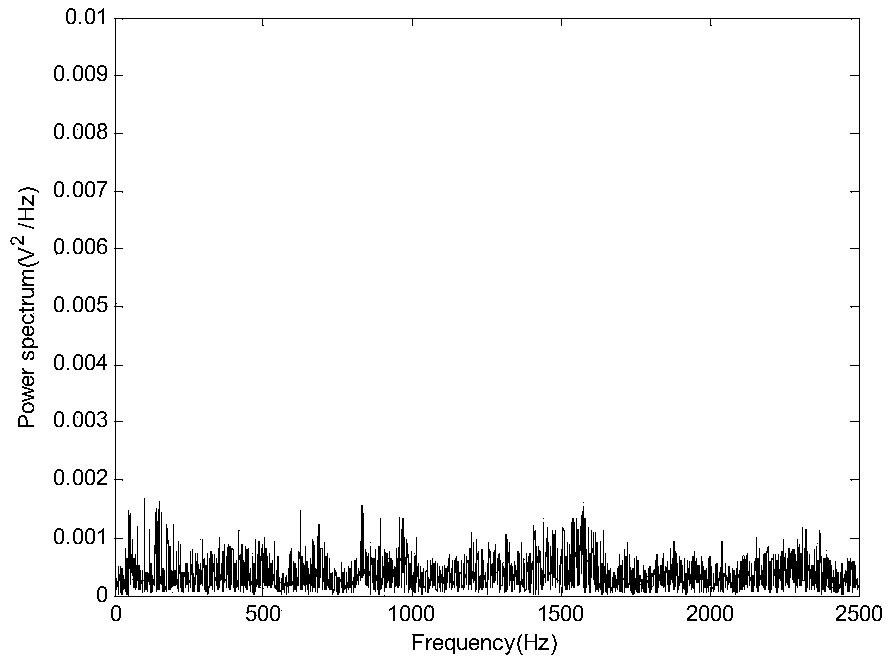

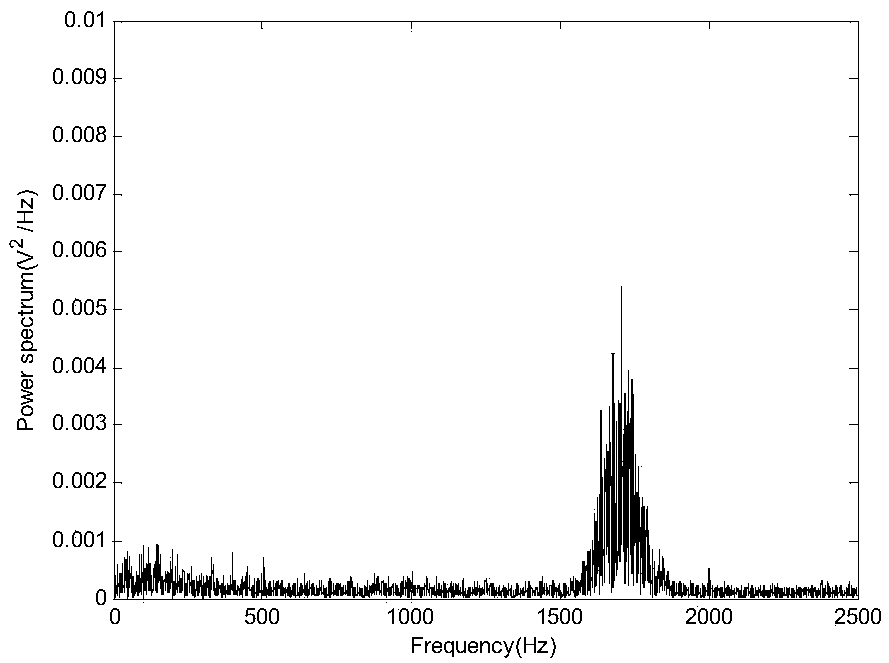

Water supply pipeline leakage identification method based on signal time-frequency characteristics and support vector machine

ActiveCN109284777AComprehensive detection effectAvoid problems with a high probability of misjudgmentCharacter and pattern recognitionSupport vector machineFeature set

The invention discloses a water supply pipeline leakage identification method based on signal time-frequency characteristics and support vector machine, belonging to the technical field of water leakage detection and positioning. The method includes: inputting a detected signal; performing feature extraction of the input signal; the extracted feature set is input to the optimized support vector machine, and the feature is recognized by the support vector machine. The support vector machine outputs a recognition result according to the input signal characteristics, and determines whether the signal is a leakage signal or a non-leakage signal. Based on the intrinsic mode function, approximate entropy and principal component analysis, three time-frequency characteristics of leakage signal areproposed by using its randomness and centralized frequency spectrum. Using these features to construct feature matrix as input of support vector machine, support vector machine is used as classifierto recognize the signal and output recognition results, thus solving the existing pipeline leak detection technology problems such as modeling difficulty coefficient is large, high misjudgment rate ishigh.

Owner:INNER MONGOLIA UNIVERSITY

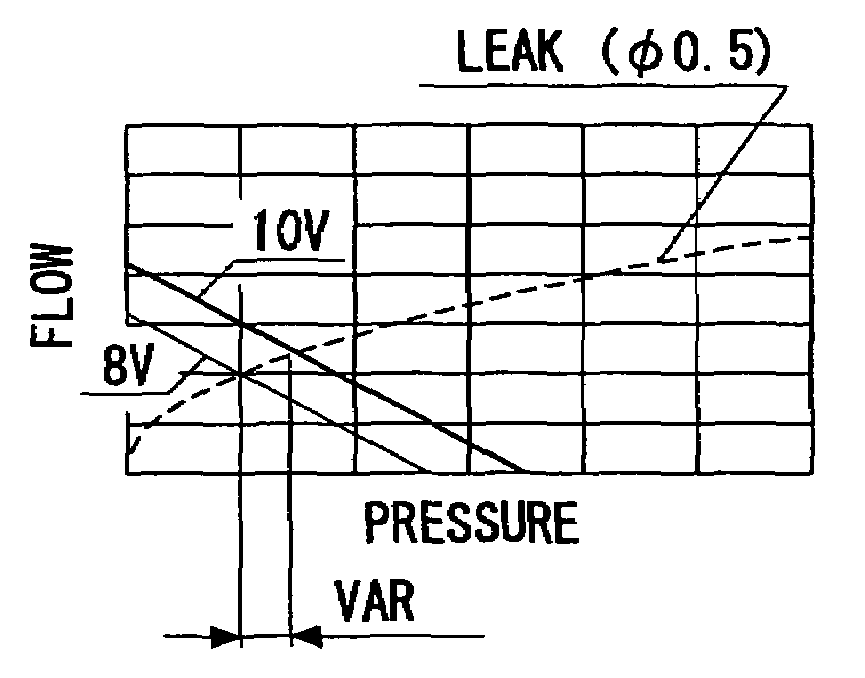

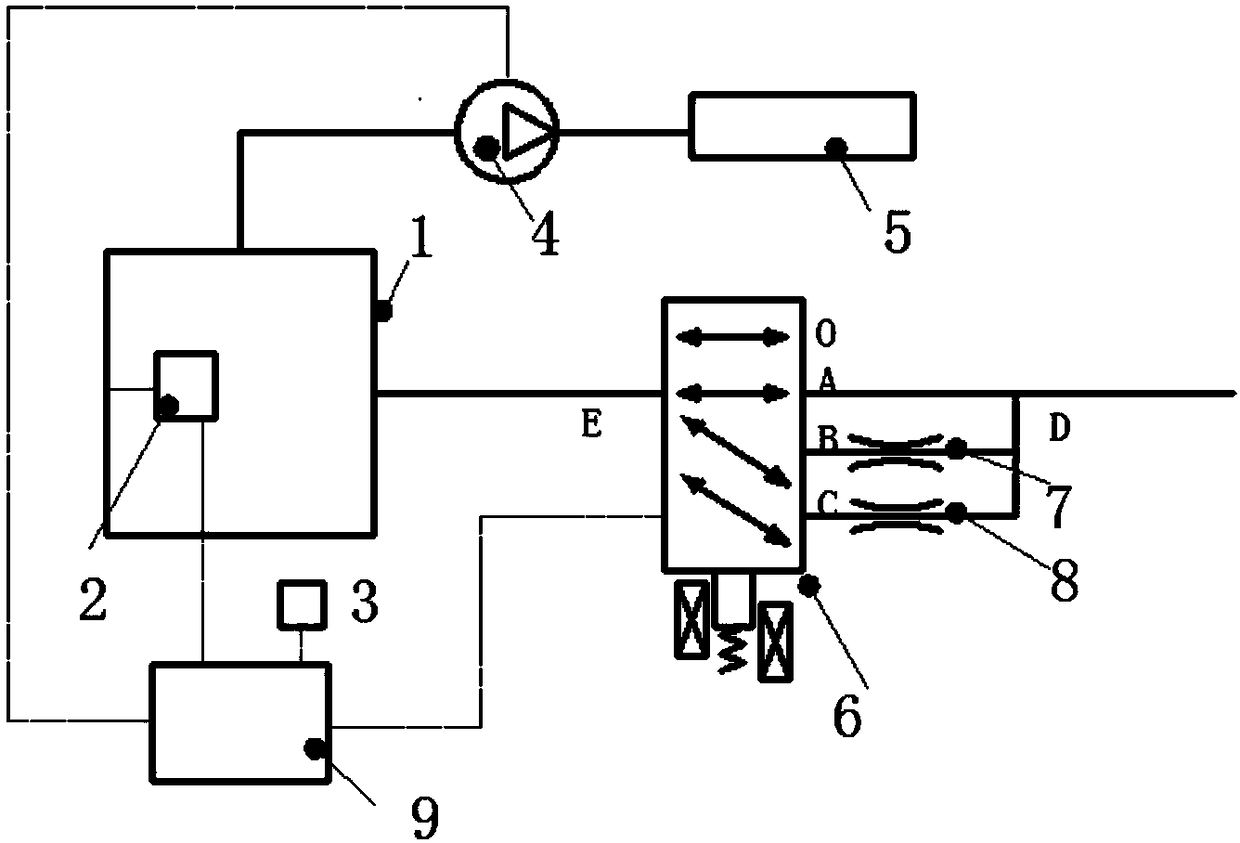

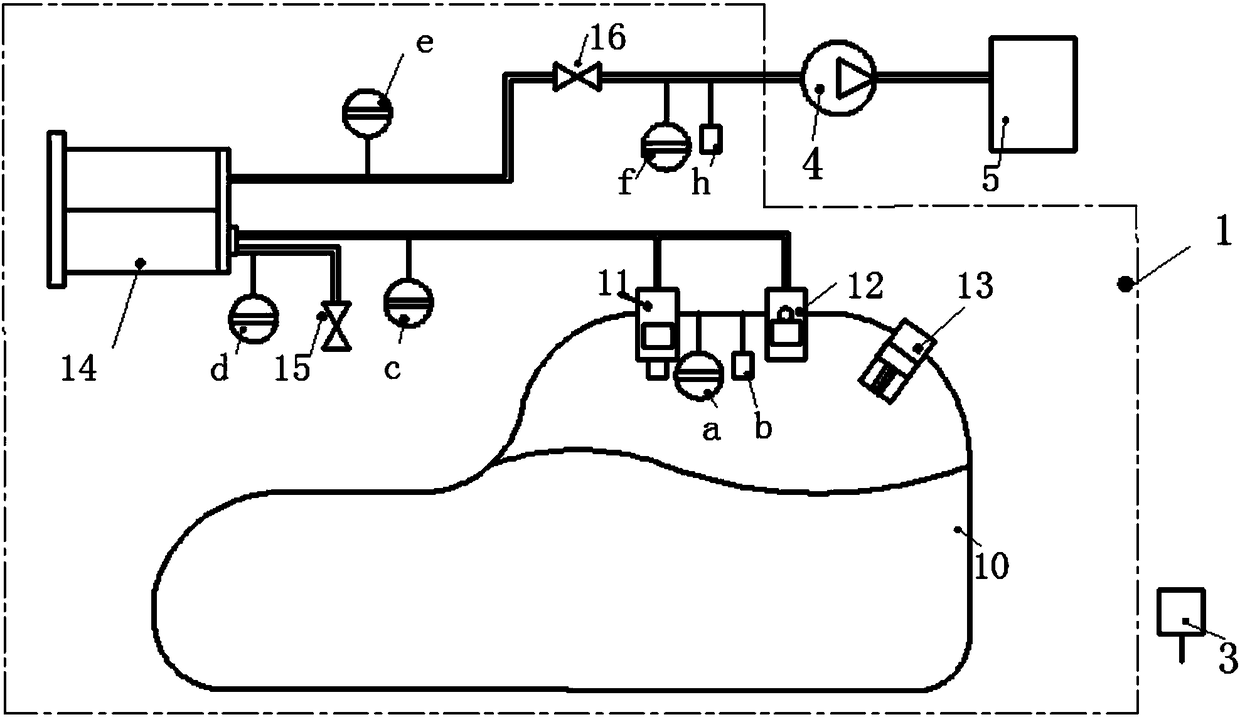

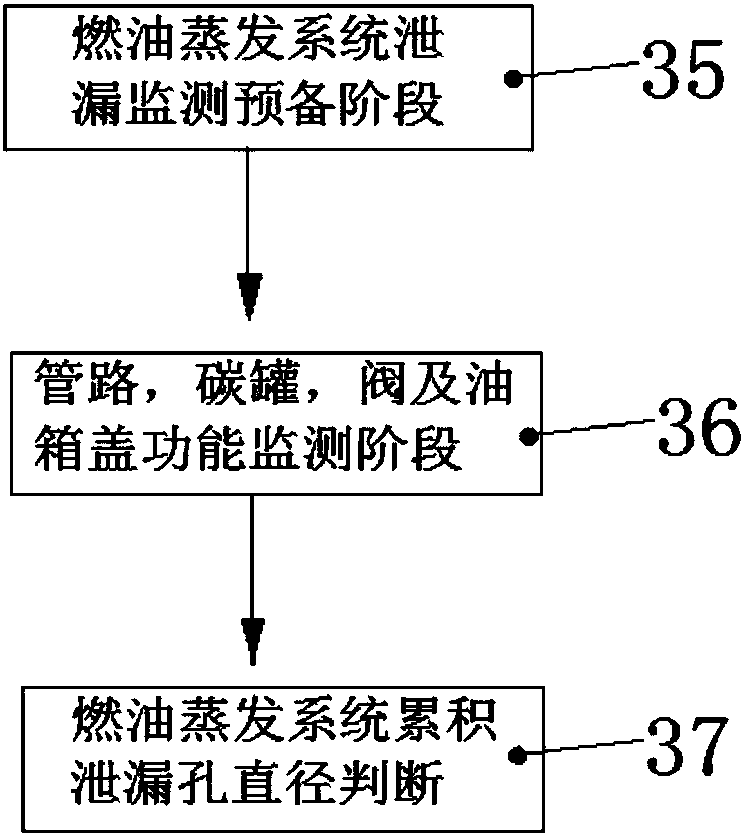

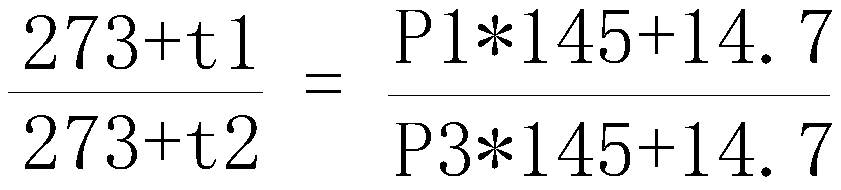

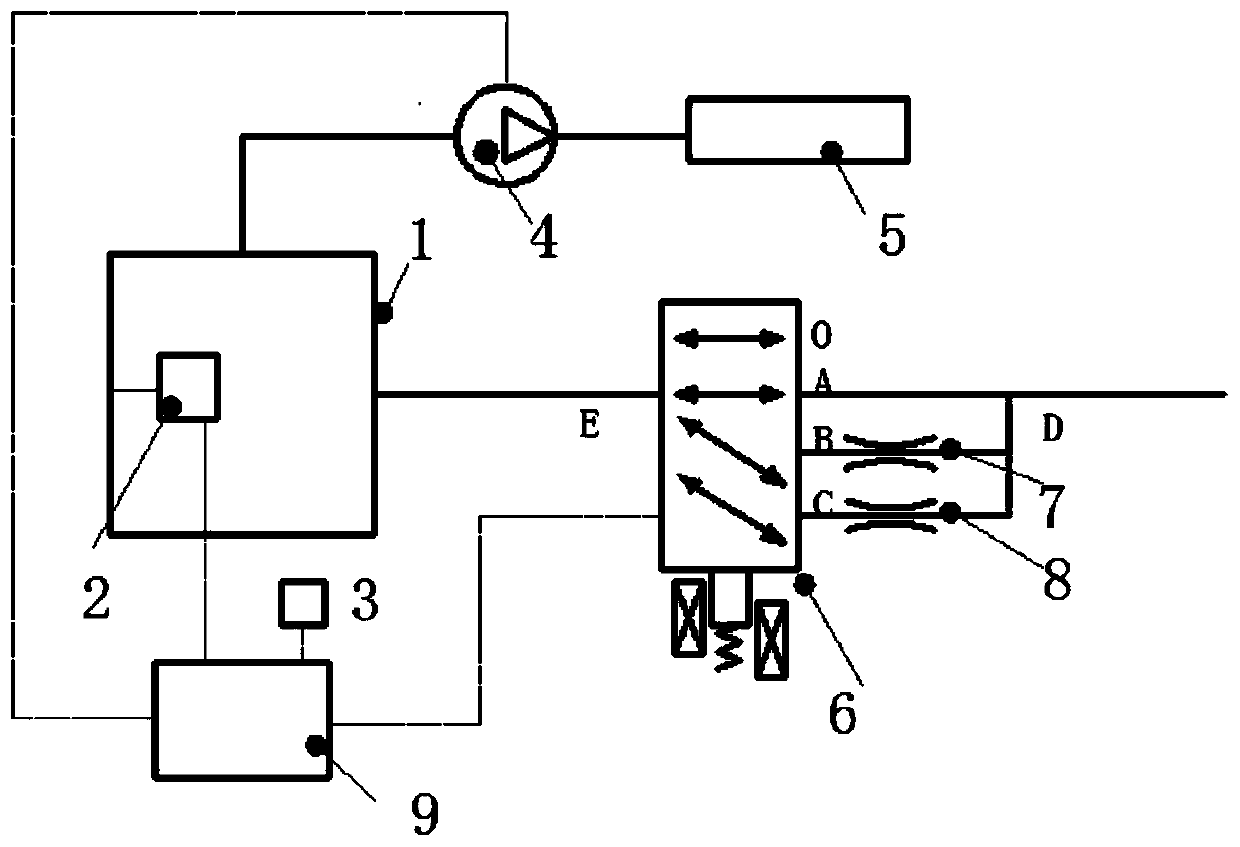

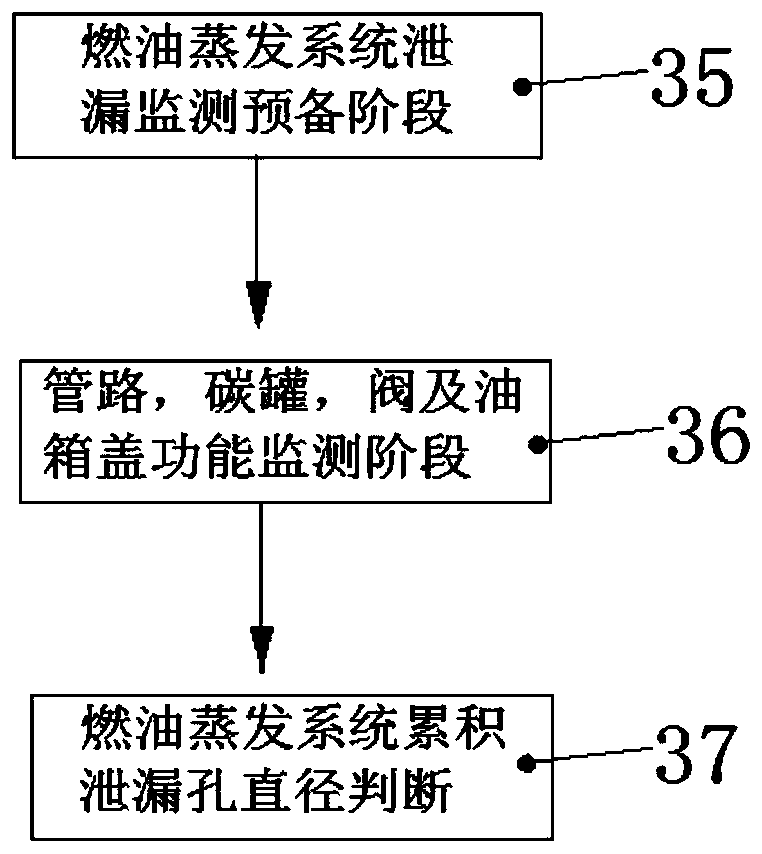

System and method for monitoring leakage of fuel evaporation system

ActiveCN108571401AImprove airtightnessReduce cloggingNon-fuel substance addition to fuelMachines/enginesFuel tankEvaporation

The invention discloses a system and a method for monitoring the leakage of a fuel evaporation system. The system for monitoring the leakage of the fuel evaporation system comprises a module used forjudging whether the diameter phi of an accumulative leakage hole is less than 0.5 mm, or more than 0.5 mm and less than 1 mm, or more than 1 mm; the judging module comprises a vacuum pump, a pressureand temperature sensor group installed in the evaporation system, a temperature sensor installed outside the evaporation system, a controller, and a reversing valve having a closing function, the reversing valve comprises a channel communicated with the fuel evaporation system, a channel provided with a 0.5 mm datum hole, and a channel provided with 1 mm datum hole. The method for monitoring the leakage of the fuel evaporation system comprises three monitoring stages: firstly, a preparatory stage for judging whether the leakage monitoring meets the molecular counting condition by the evaporation system; second, a monitoring stage used for judging whether a pipeline is disconnected, whether a carbon tank is blocked and whether an oil tank cover falls off; and thirdly, a judging stage used for judging the diameter of the accumulative leakage hole through the judging module and the equation.

Owner:扬州华光新材料股份有限公司

System for testing high-temperature pipeline flange under action of outer bending moment

InactiveCN104406751AMonitor stress levels in real timeHigh leak detection accuracyMachine part testingMeasurement of fluid loss/gain rateExhaust valveEngineering

Owner:WUHAN INSTITUTE OF TECHNOLOGY

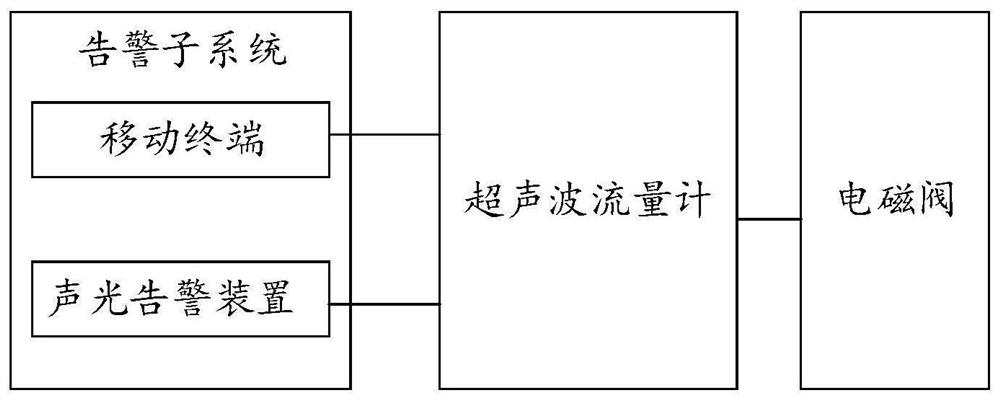

Gas leakage detection system

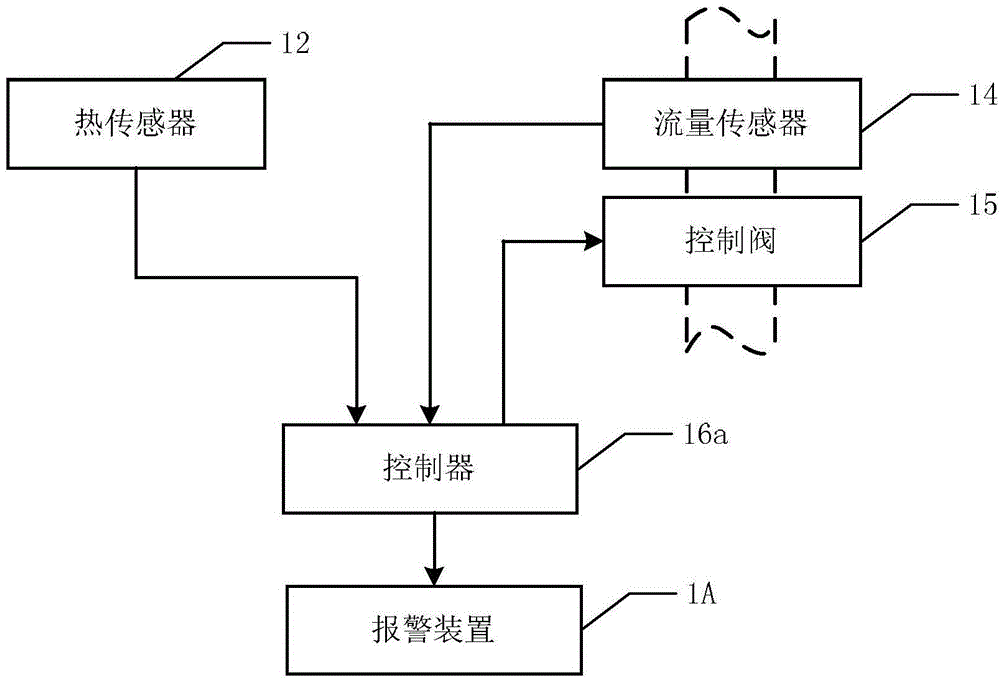

ActiveCN112197176AImprove leak detection accuracyNot affectedPipeline systemsAlarmsControl engineeringElectromagnetic valve

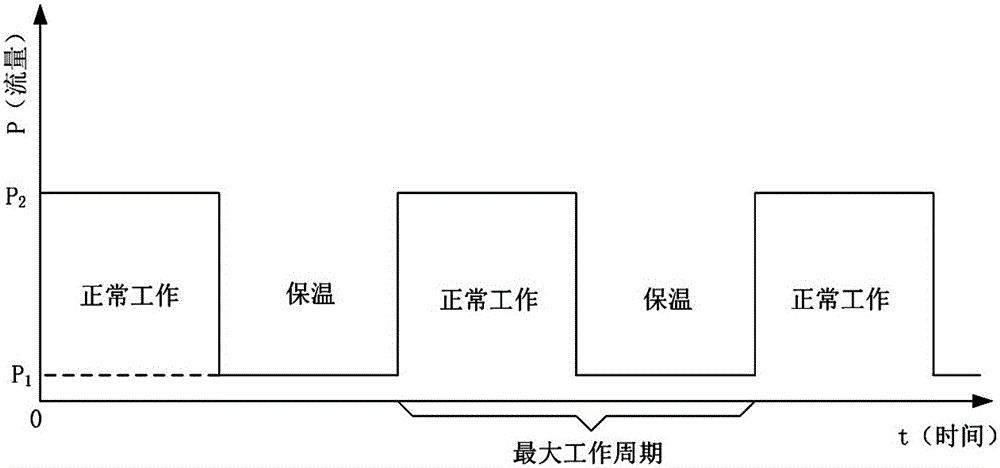

The invention discloses a gas leakage detection system. The gas leakage detection system comprises an ultrasonic flowmeter, an electromagnetic valve and an alarm subsystem, wherein the ultrasonic flowmeter and the electromagnetic valve are arranged in a gas pipeline; the ultrasonic flowmeter is used for collecting flow velocity data in the gas pipeline in real time, judging whether gas leakage happens to the gas pipeline or not and judging the gas leakage level when the gas leakage happens to the gas pipeline according to the flow velocity data and preset gas leakage conditions, and sending analarm command to the alarm subsystem and / or sending a valve closing command to the electromagnetic valve according to the gas leakage level when the gas leakage is determined to happen to the gas pipeline; the electromagnetic valve is used for closing the valve when the valve closing command is received; and the alarm subsystem is used for giving an alarm prompt when the alarm command prompt information is received. By implementing the embodiment of the invention, the accuracy of gas leakage detection can be improved.

Owner:GUANGZHOU EASTERN DEV GAS CO LTD

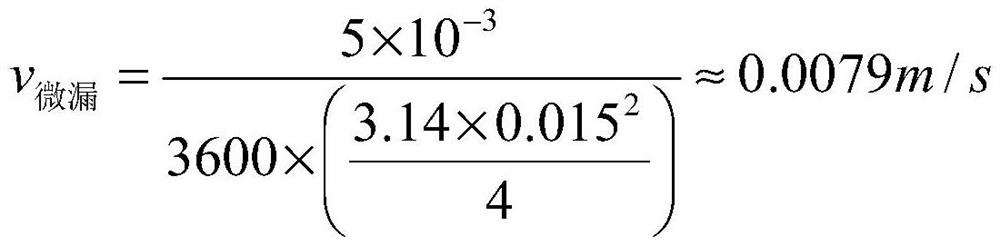

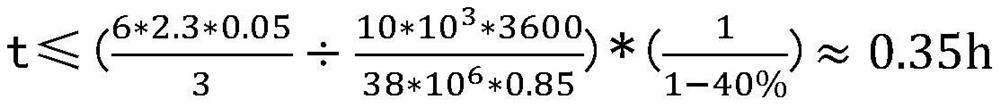

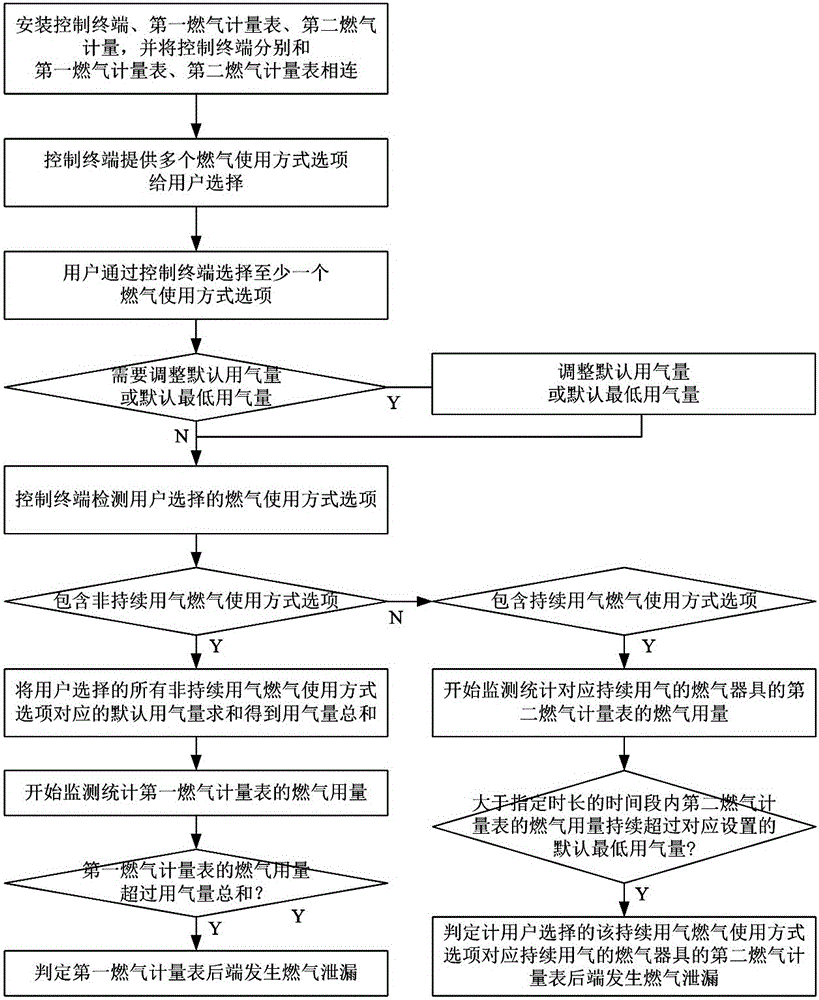

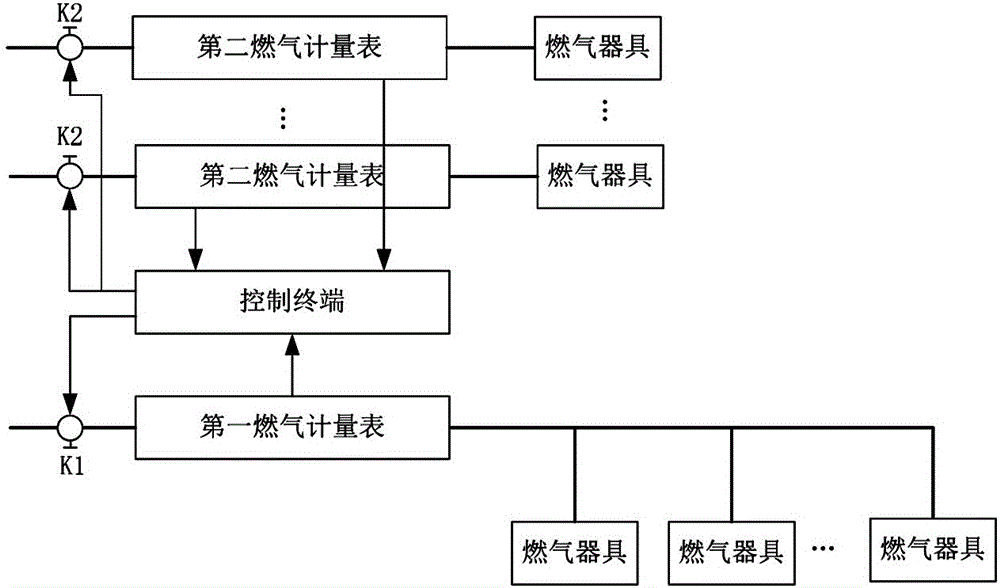

Gas leakage monitoring method and system based on gas metering

ActiveCN106052971ATimely maintenancePrecise screeningMeasurement of fluid loss/gain rateGas meterComputer terminal

The invention discloses a gas leakage monitoring method and system based on gas metering. The method comprises the following steps: a control terminal, a first gas meter and second gas meters are installed at a detected target area, the control terminal provides a plurality of gas usage mode options to a user to choose, the user chooses at least one gas usage mode option through the control terminal, each gas usage mode option corresponds one modifiable default gas consumed volume or default minimum gas consumed volume, and whether gas leakage occurs is determined according to gas metering values of the first and second gas meters and the default gas consumed volume or the default minimum gas consumed volume. The system comprises the control terminal, the first gas meter and the second gas meters, and the control terminal is connected with the first gas meter and the second gas meters. User's normal usage and the gas leakage can be accurately discriminated, leakage monitoring accuracy is high, a fault is convenient to timely handle by a user, occurrence of a vicious accident brought by the gas leakage is prevented, and a comprehensive disposal with a traditional gas leakage method is convenient.

Owner:谷振宇

Multi-feature and adaptive time delay estimation-based leakage detecting and locating method

ActiveCN107368799AImprove noise immunityImprove robustnessCharacter and pattern recognitionWater conservationAdaptive filterWater leakage

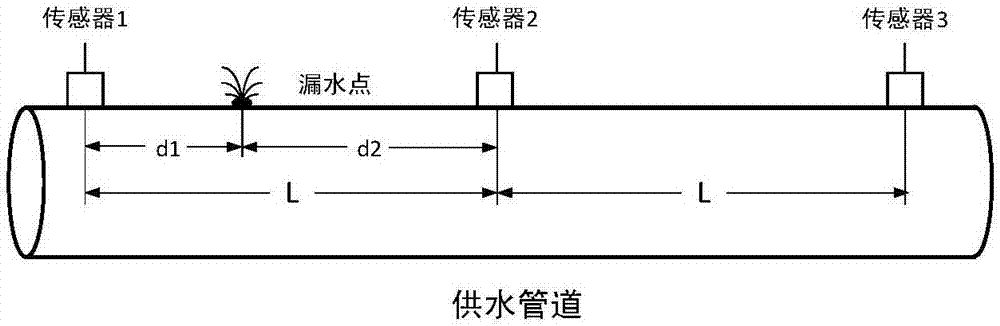

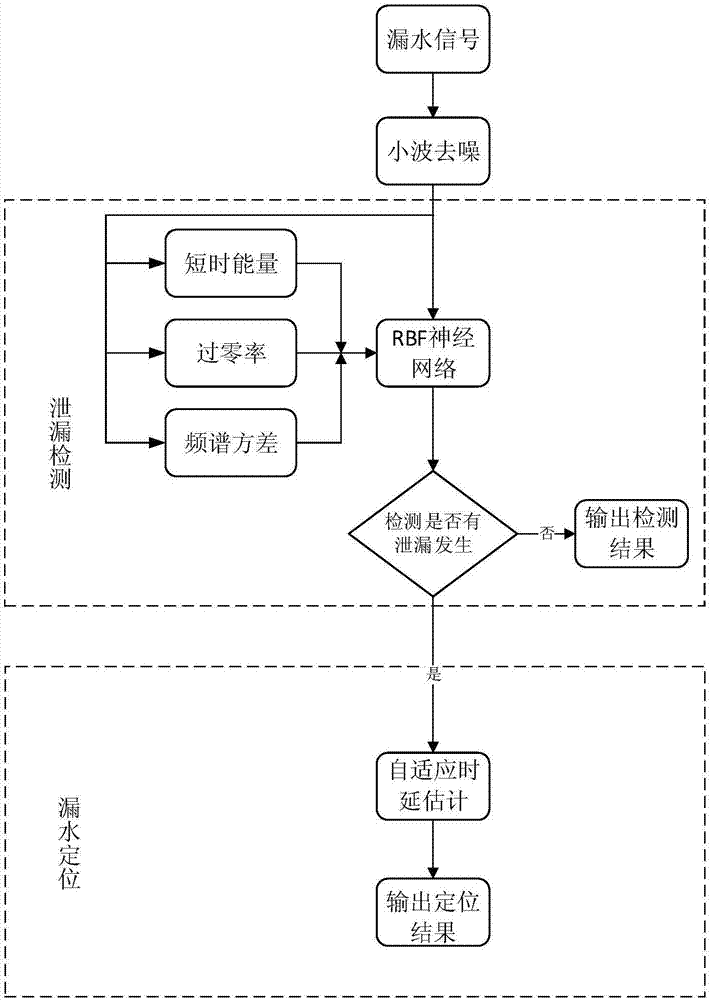

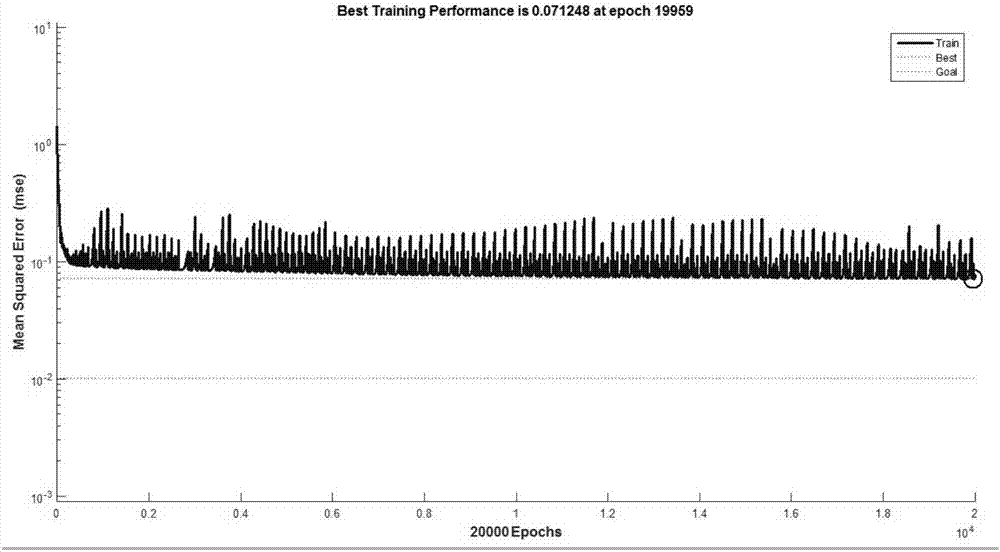

The invention provides a multi-feature and adaptive time delay estimation-based leakage detecting and locating method. The method comprises the steps of enhancing a water leakage signal by utilizing wavelet denoising; then taking a short-time energy feature, a short-time zero-crossing rate feature and a frequency spectrum variance of the water leakage signal as inputs of a neural network, training the neural network, and detecting whether leakage occurs or not; estimating time delay values of two sensors in receiving the leakage signal through an LMS (Least Mean Square Error) adaptive algorithm; and performing high-precision water leakage locating on pipeline leakage points through the time delay values. According to the method, time delay estimation is carried out by utilizing an LMS adaptive filter; the adaptive filter can perform adaptive dynamic adjustment, so that statistical features of signals and noises do not need to be pre-obtained; and the method is suitable for a water supply pipeline leakage detection environment.

Owner:INNER MONGOLIA UNIVERSITY

Leakage detecting method of hydrogen system for coal-fired power generator

InactiveCN102539074AImprove securityHigh leak detection accuracyFluid-tightness measurement using fluid/vacuumSulfur hexafluorideDensity of air

The invention relates to a detecting method of a pressure container, in particular to a leakage detecting method of a hydrogen system for a coal-fired power generator. The leakage detecting method comprises the steps of replacing gas; vacuumizing; filling sulfur hexafluoride gas; detecting leakage of the hydrogen system for the generator by a sulfur hexafluoride gas leakage detector and marking the leakage points; and decompressing. The leakage detecting method of the hydrogen system for the coal-fired power generator is combined with the sulfur hexafluoride gas leakage detector to detect the leakage of the hydrogen system for the generator by means of the characteristics of sulfur hexafluoride gas, in particular the characteristic of inertia of the sulfur hexafluoride gas and density of the sulfur hexafluoride gas that is greater than the density of air. Compared with the prior art, the method of the invention is good in safety and has high leakage detection precision, and the sulfur hexafluoride gas after leakage detection can be recycled, thereby reducing the cost of leakage detection.

Owner:NINGXIA ELECTRIC POWER RES INST

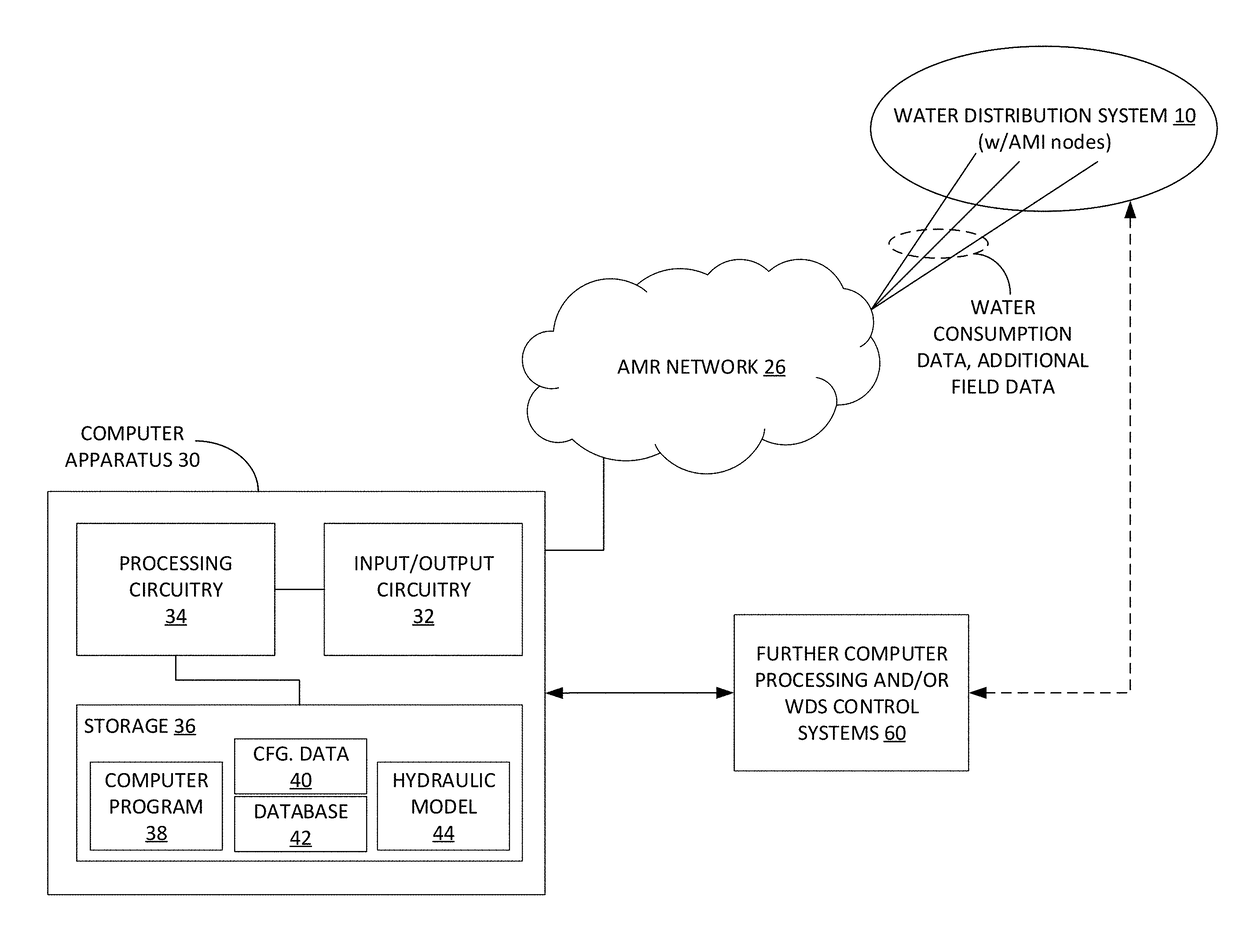

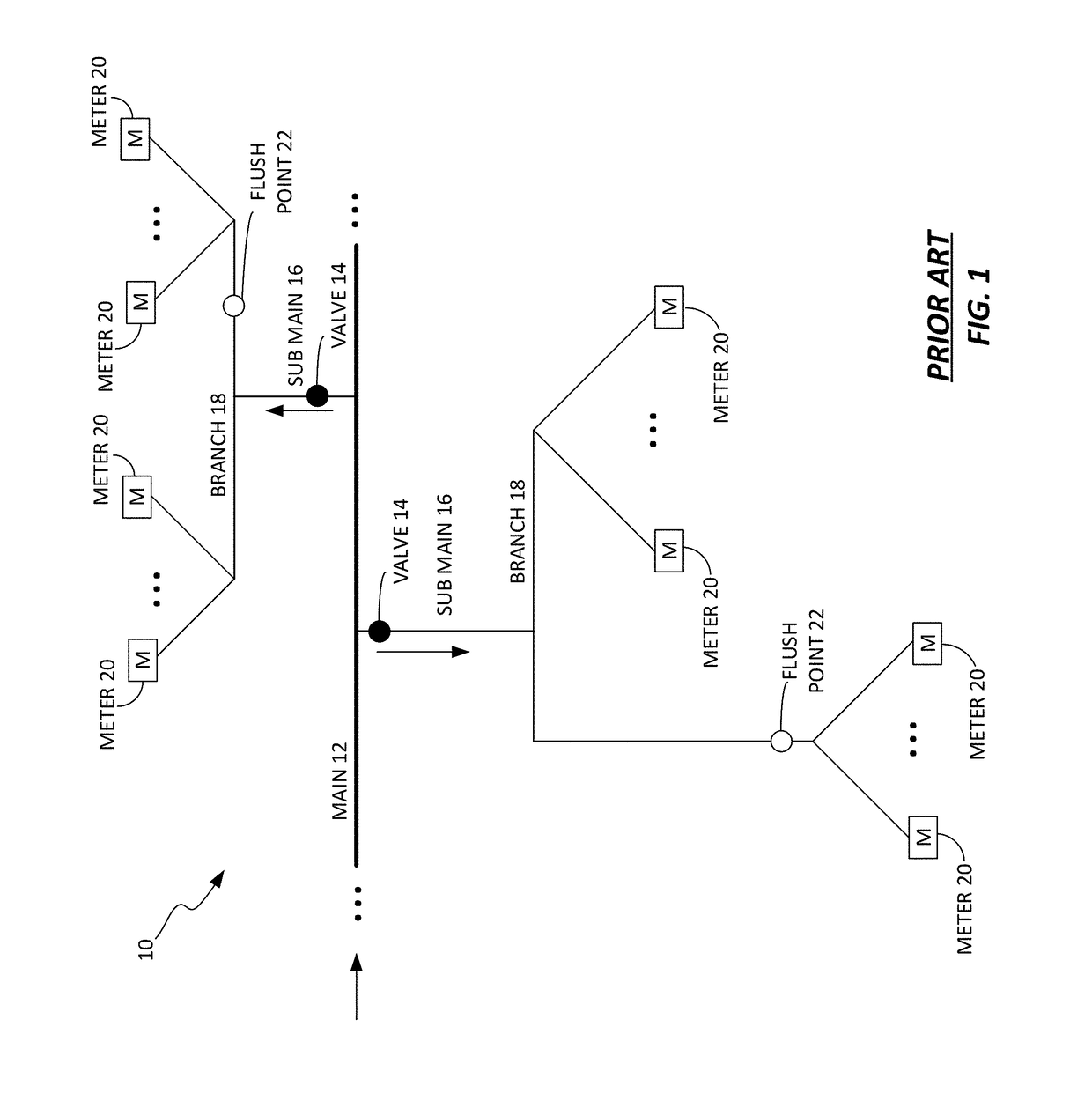

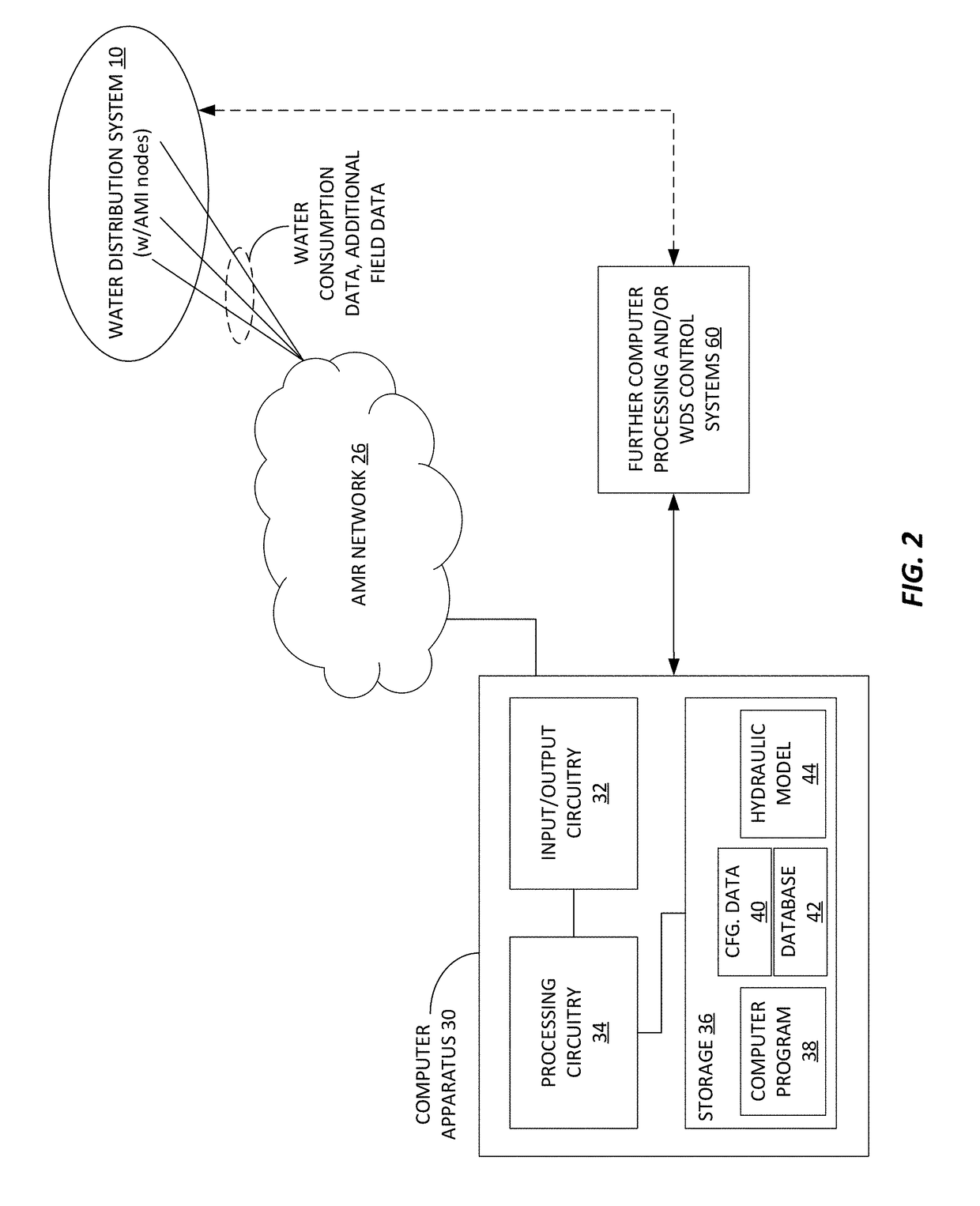

Method and apparatus for model-based leak detection of a pipe network

ActiveUS20180195926A1High leak detection accuracyReduce effortMeasurement of fluid loss/gain rateService pipe systemsPressure rangeEngineering

A method, apparatus, and system for leak detection in a distribution network having consumption meters. The distribution network is divided into zones having an upstream location and a downstream location. An upstream pressure sensor detects the upstream pressure at the upstream location and the downstream pressure sensor detects the detected downstream pressure at the downstream location. A downstream pressure lookup table is used to determine an expected pressure at each downstream location based on a range of hypothetical upstream pressures at the corresponding upstream location and consumption data from the consumption meters. The expected pressure and the detected downstream pressure at each downstream location are compared to determine if the calculated discrepancy exceeds a discrepancy threshold. If a discrepancy exceeds a discrepancy threshold, a leak location lookup table containing a set of potential leak locations based on a range of hypothetical discrepancies is used to determine a set of probable leak locations.

Owner:SENSUS SPECTRUM LLC

Leakage detection method for liquid packaging apparatus

ActiveCN106370365AHigh leak detection accuracyMeasurement of fluid loss/gain rateVacuum pumpBiomedical engineering

The invention discloses a leakage detection method for liquid packaging apparatus. The to-be-detected liquid packaging apparatus is filled with a liquid sample. The method comprises the following steps: sealing a sample room; using a vacuum pump device to have the sample room vacuumed continuously; and measuring the pressure value P1 of the sample room in the different times of T1; opening the sample room and placing the liquid packaging apparatus; then sealing the sample room again; and using the vacuum pump device to have the sample room vacuumed continuously; and measuring the pressure value P2 of the sample room in the different times of T2; and comparing the time T1 and time T2 and the pressure value P2 and the pressure value P1 respectively so as to determine whether leakage occurs in the liquid packaging apparatus or not. Through the comparing of time and pressure of the sample room with the liquid packaging apparatus and without the liquid packaging apparatus under the vacuumed condition, it is possible to determine whether leakage occurs in the liquid sample component or not, and the method is especially suitable for use on liquid containers with the least leakage and can achieve high accuracy in leakage detection.

Owner:INST OF CHEM CHINESE ACAD OF SCI

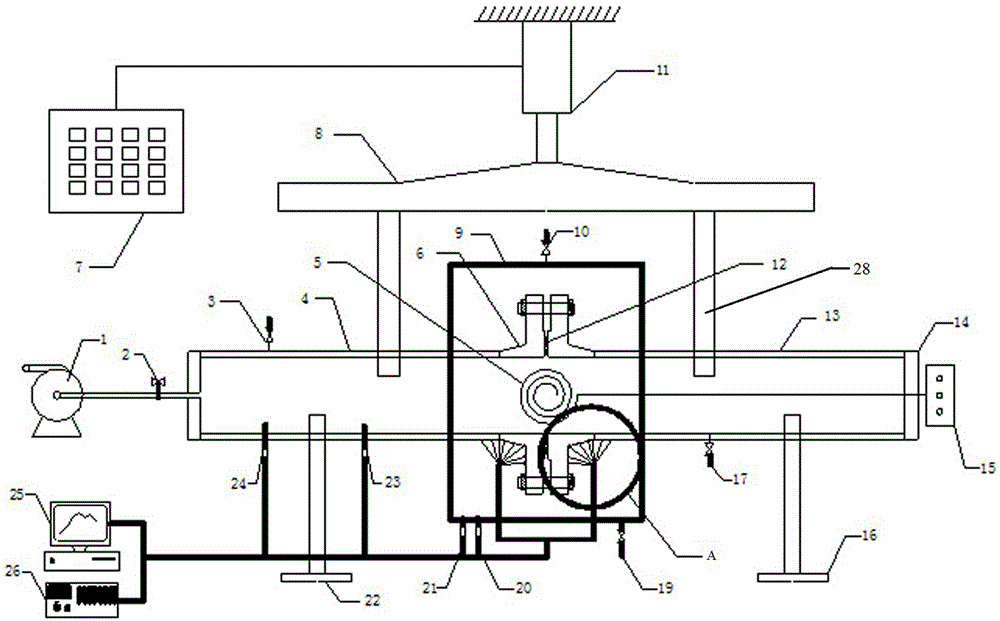

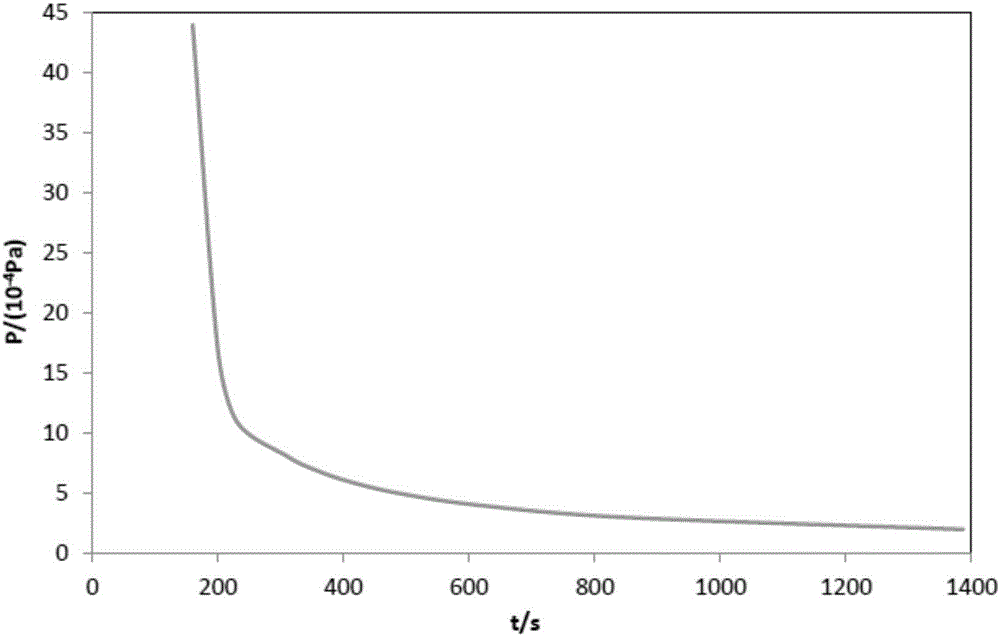

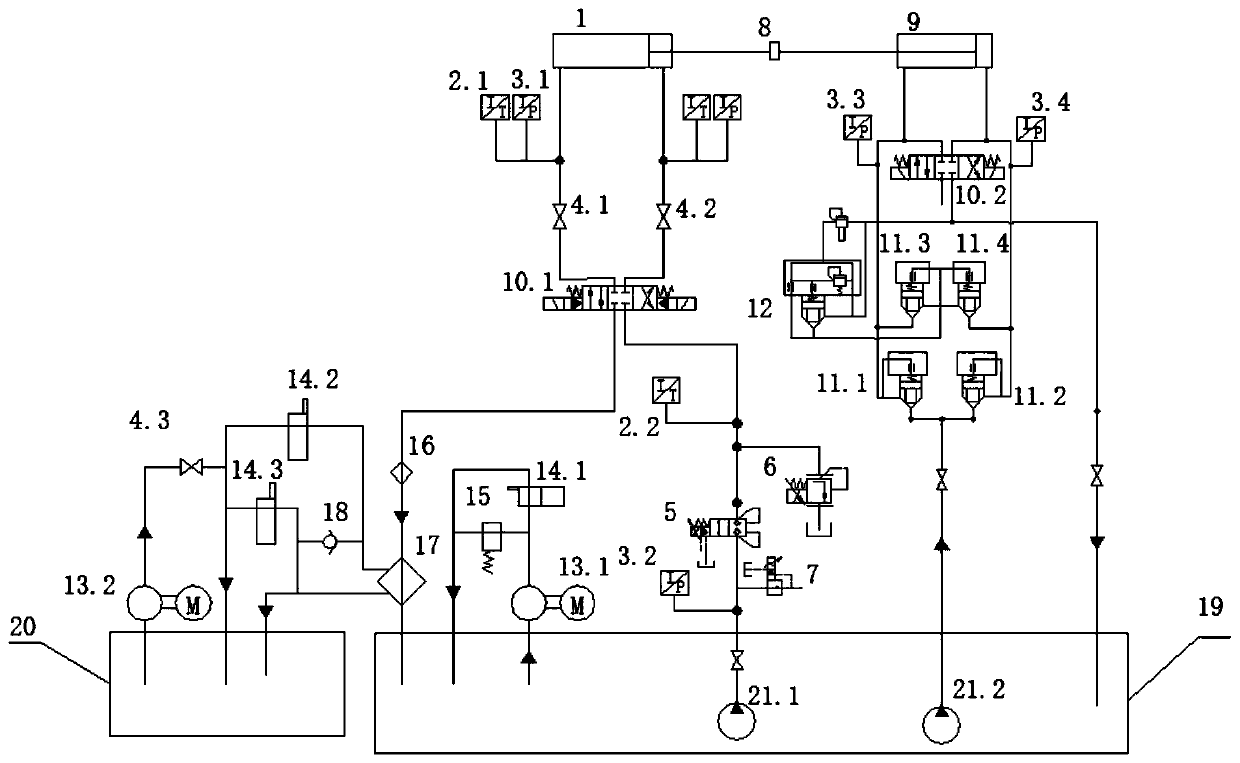

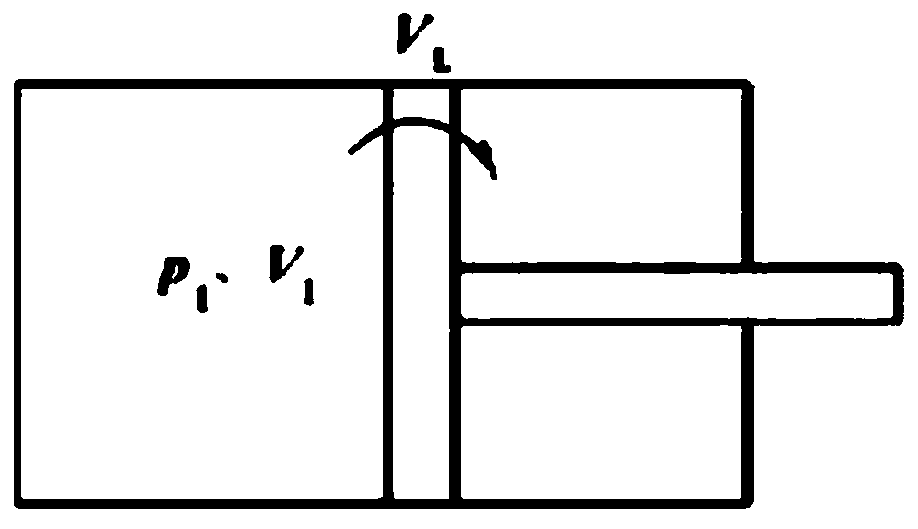

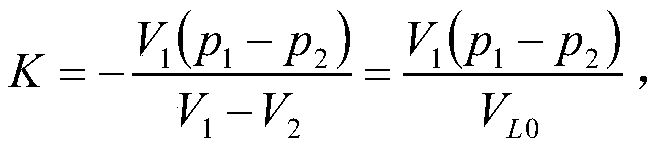

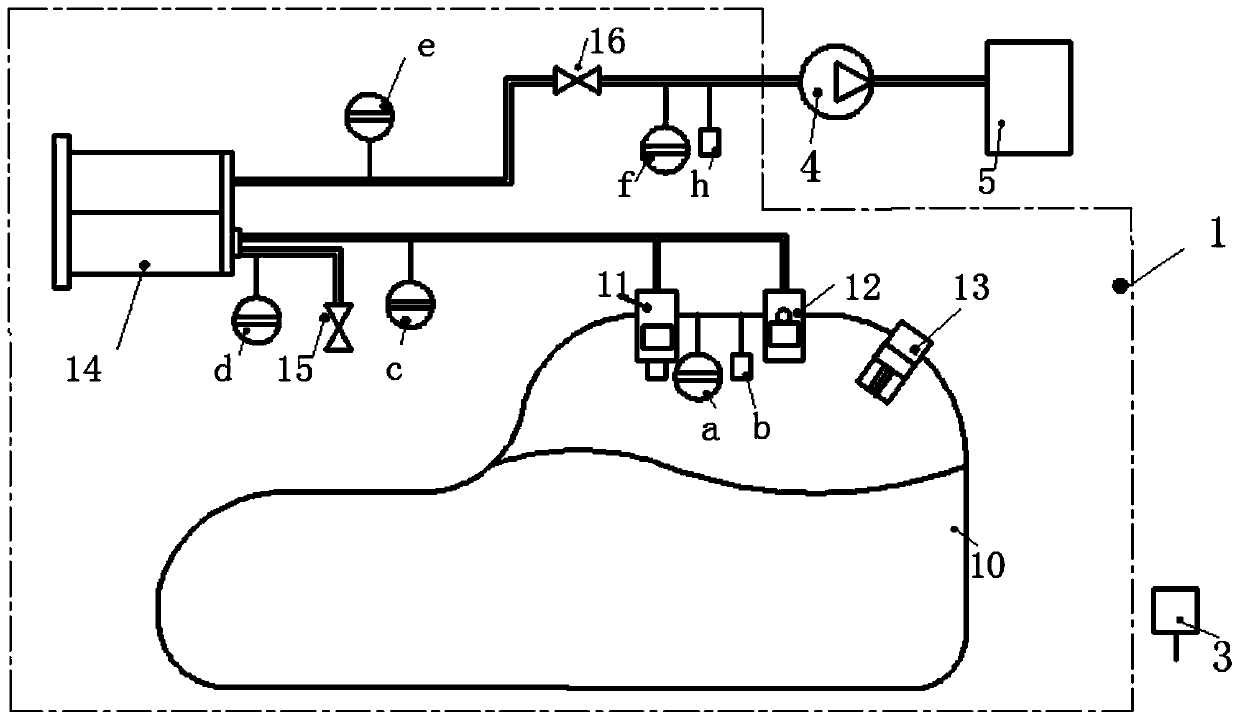

High-precision detection test stand for leakage in hydraulic cylinder

PendingCN111271341AHigh precisionImprove calibration accuracyFluid-pressure actuator testingServometer circuitsHydraulic cylinderControl system

The invention provides a high-precision detection test stand for leakage in a hydraulic cylinder. The high-precision detection test stand comprises a hydraulic cylinder loop, a hydraulic oil heating loop, a cooling water loop and a loading cylinder loop. A piston rod of the loading cylinder is connected with a piston rod of a hydraulic cylinder through a connecting tool. The hydraulic oil heatingloop comprises a heating oil pump, an electromagnetic valve A and a safety valve. An oil outlet of the heating oil pump communicates with an oil inlet of the electromagnetic valve A. An oil outlet ofthe electromagnetic valve A is used for returning oil to a hydraulic oil tank. The safety valve is arranged between the heating oil pump and the electromagnetic valve A. An oil temperature control system consisting of the hydraulic oil heating loop and the cooling water loop is adopted to control the temperature error at + / -2DEG C. A hydraulic oil volume elastic modulus K can be measured at different temperatures. The calibration precision of the hydraulic oil elastic modulus K and the detection precision of leakage in the hydraulic cylinder to be tested are improved. The loading cylinder loopis arranged to adjust the pressure of the hydraulic cylinder, so that the hydraulic oil volume elastic modulus K can be measured at different pressure.

Owner:湖南省产商品质量监督检验研究院

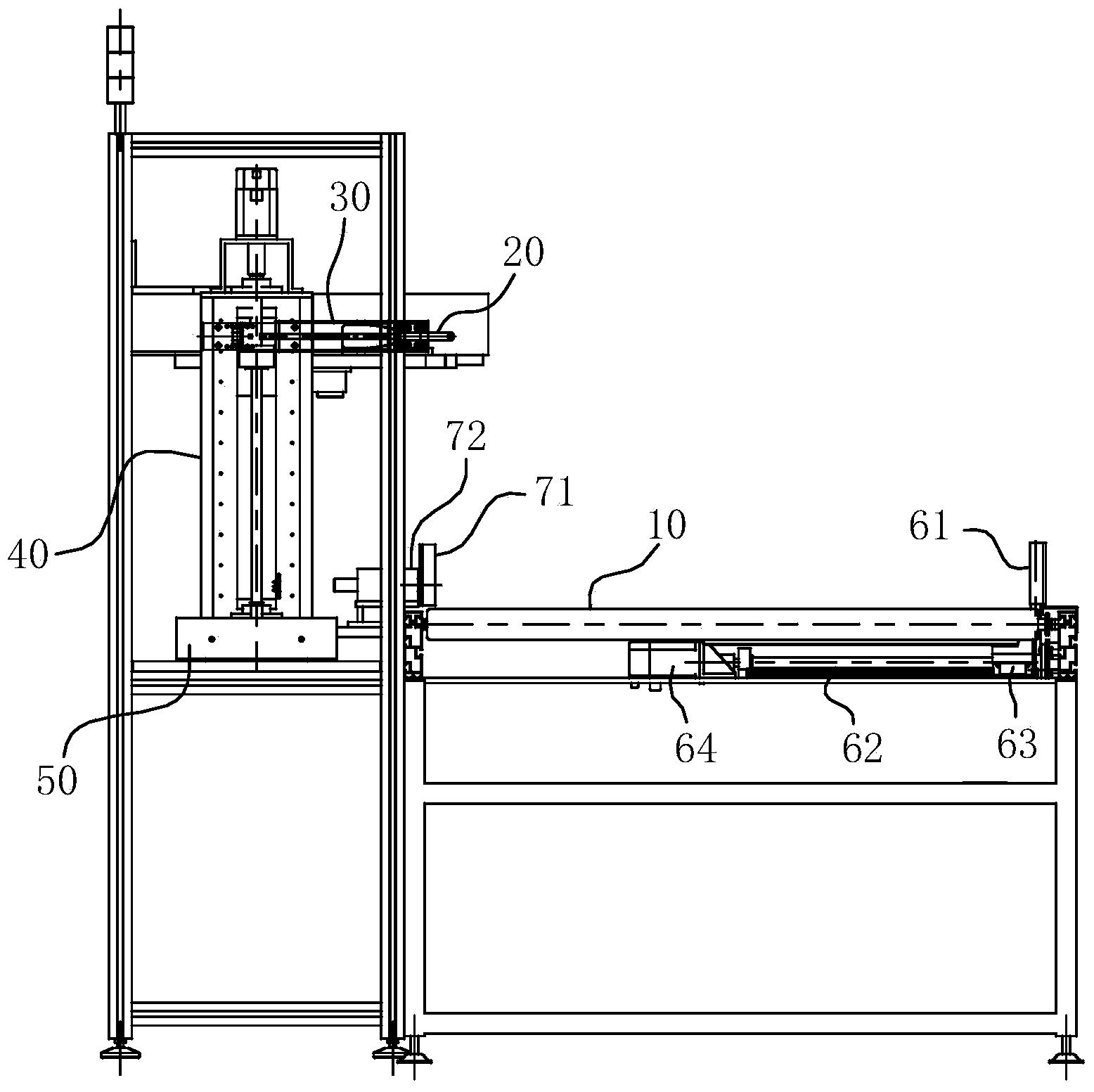

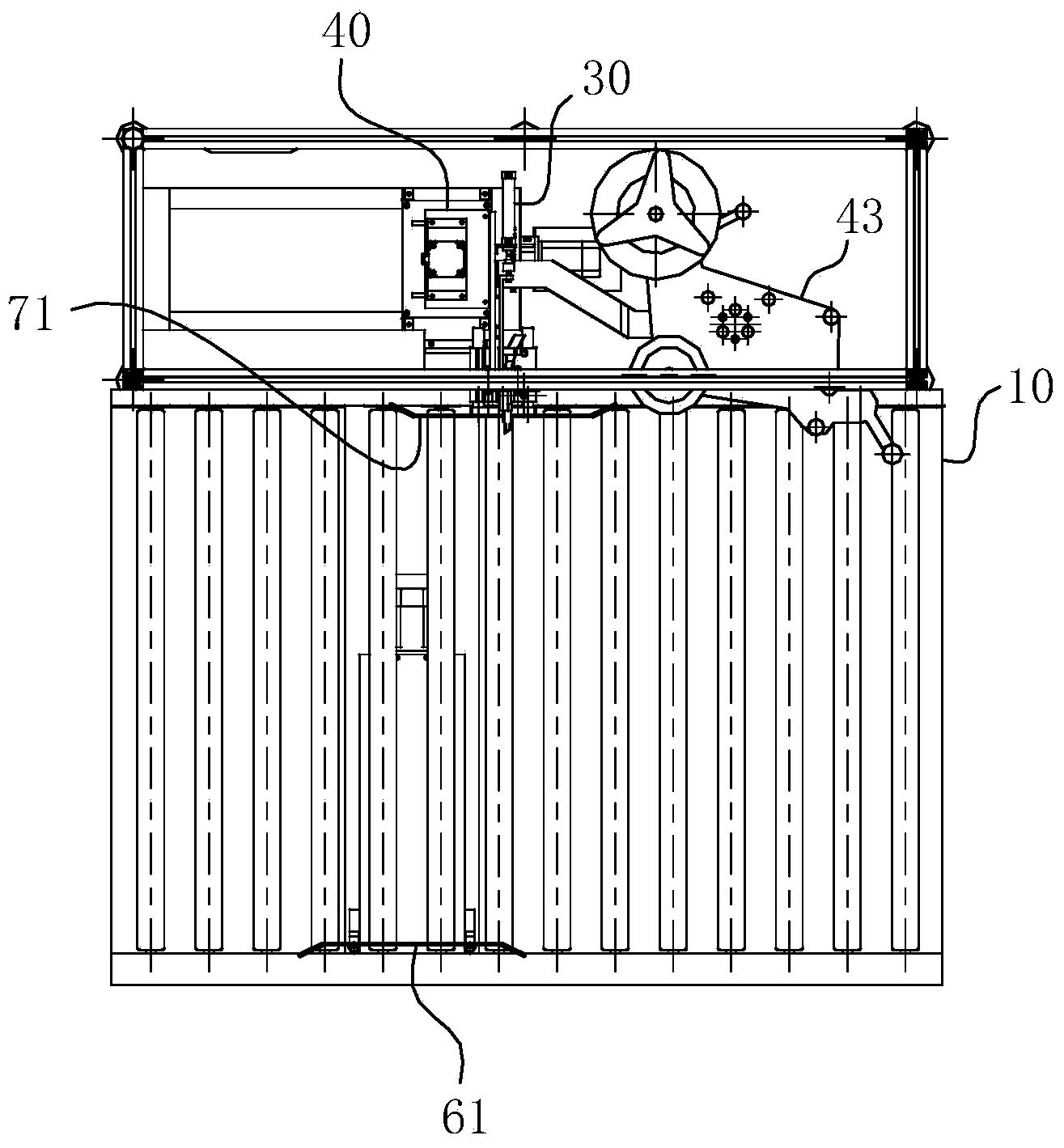

Automatic leakage detecting device for household air conditioner finished products

ActiveCN104215398ARealize the purpose of automatic sealing inspectionImprove factory qualityFluid-tightness measurementSensing by electromagnetic radiationIndustrial engineeringApplication actions

The invention relates to the field of sealability and leakage detecting equipment for household air conditioner finished products, in particular to an automatic leakage detecting device for household air conditioner finished products. The automatic leakage detecting device comprises a detection component, a retaining block component and a sensing component. The detection component is located on one side of the conveying direction of a conveying platform and comprises a leakage detection probe gun connected with a leakage detector probe suction gun and a pushing mechanism used for driving the leakage detection probe gun to perform reciprocating action along the specified direction. The retaining block component is located on the other side, relative to the side where the detection component is located, of the conveying platform, and the direction of force application action of the retaining block component on a to-be-detected packing box is opposite to that of acting force of the detection probe gun on the to-be-detected packing box. The sensing component comprises a sensing portion and a control portion, wherein the control portion receives signals of the sensing portion and controlling the pushing mechanism to act; the sensing portion detects in-place information of the to-be-detected packing box on the conveying platform; the control portion receives the signal and drives the pushing mechanism to perform specified pushing action. The automatic leakage detecting device is high in automation level, the requirements on sealability detection quality are met, and meanwhile, detection efficiency can be further improved.

Owner:HEFEI GENERAL MACHINERY RES INST +1

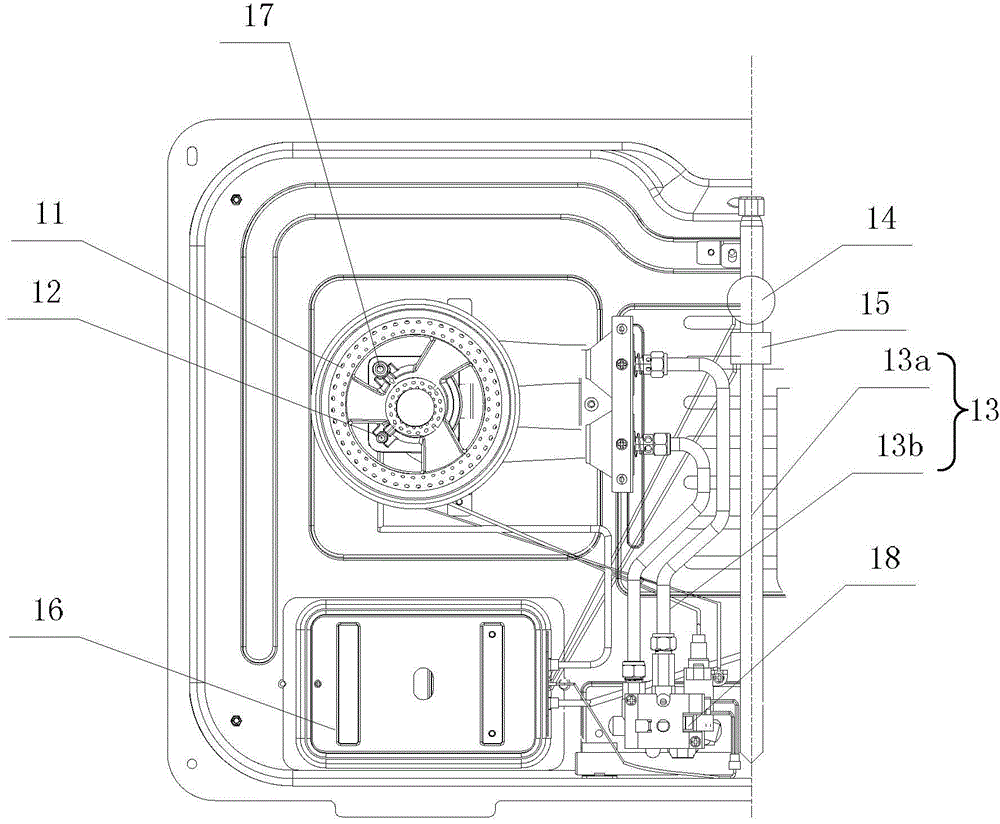

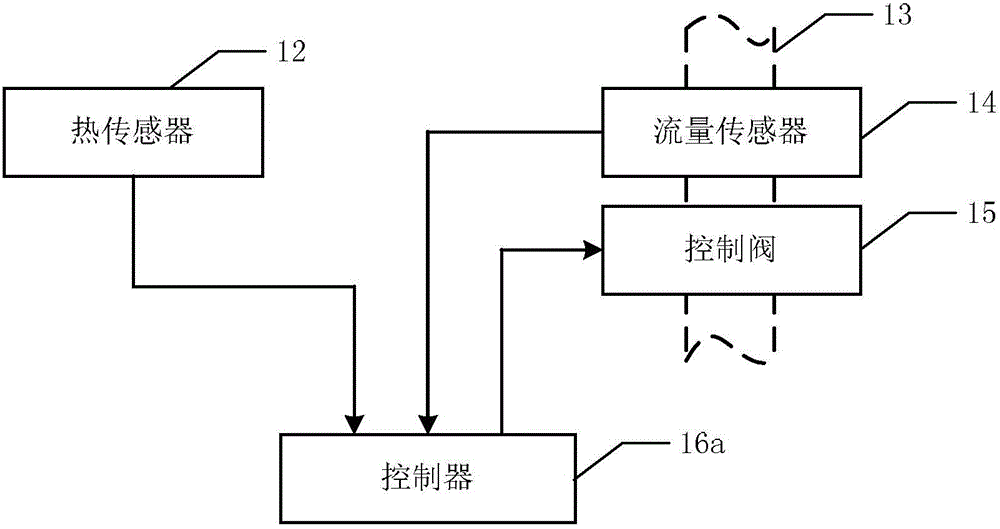

Gas stove and control method and device thereof

ActiveCN104930559APrevent leakagePrevent false detectionDomestic stoves or rangesLighting and heating apparatusCombustorProduct gas

The invention discloses a gas stove and control method and device thereof. The temperatures around burners and the gas flow of a gas inlet pipe are detected at the same time. If the temperatures around all the burners are not high and the gas intake flow is larger than zero and lasts for a preset time, it means that gas is leaked, and the gas inlet pipe is controlled to stop gas suction. In this way, gas leakage can be effectively avoided, detection errors can be avoided, and the leakage detection accuracy is improved.

Owner:GREE ELECTRIC APPLIANCES INC

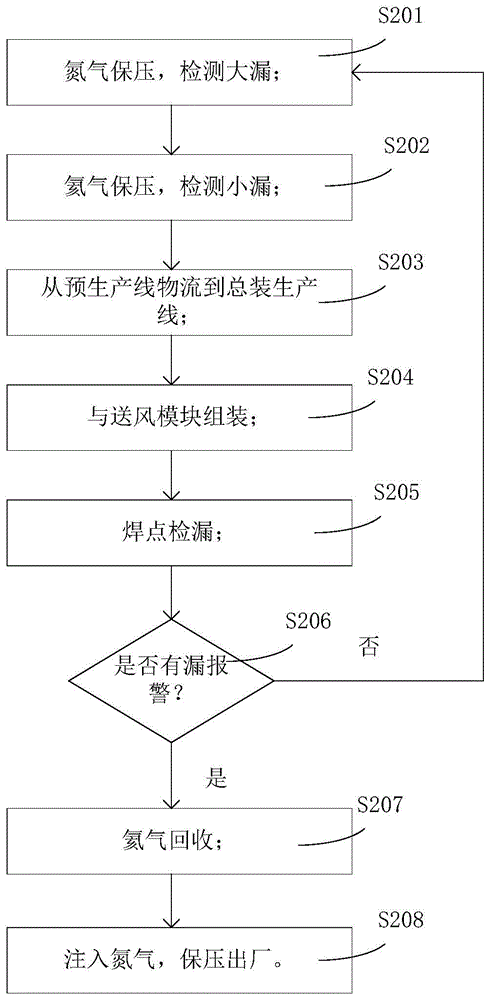

Leakage detection method for refrigeration system

ActiveCN110095237ALeak detection method is simple and practicalReduce testing costsMeasurement of fluid loss/gain rateHydrogenVacuum pressure

The invention relates to a detection method for a refrigeration system, in particular to a leakage detection method for a refrigeration system. The leakage detection method comprises the following steps that: the refrigeration system is vacuumized; vacuum pressure maintaining is carried out on the vacuumized refrigerating system, and if the pressure of the refrigerating system which has been subjected to vacuum pressure maintaining is qualified, the refrigerating system is filled with a detection nitrogen-hydrogen mixed gas; the pressure of the refrigerating system which has been filled with the mixed gas is detected, if the pressure is not lower than detection pressure, suction gun leakage detection is performed; a suction gun is adopted to perform air suction leakage detection on leakagepoints which are susceptible to leakage, if the leakage points are qualified, a pressure maintaining test is carried out; if the pressure of the refrigeration system which has been subjected to the pressure maintaining test is lower than pressure maintaining pressure, the refrigeration system is not qualified, and the method returns to a suction gun leakage detection process for re-detecting theleakage points; the nitrogen-hydrogen mixed gas in the refrigeration system which is qualified after pressure maintaining is discharged, and secondary vacuumizing is performed on the refrigeration system; and the refrigeration system is injected with nitrogen. The leakage detection method for the refrigeration system has the advantages of simplicity, practicability, low detection cost, high safety, high leakage point detection precision, fast leakage point detection, accurate and reliable detection results and high detection efficiency, and is suitable for the leakage detection of various refrigeration systems.

Owner:百尔制冷(无锡)有限公司

Pipeline connecting pipe fitting seepage detection device and method

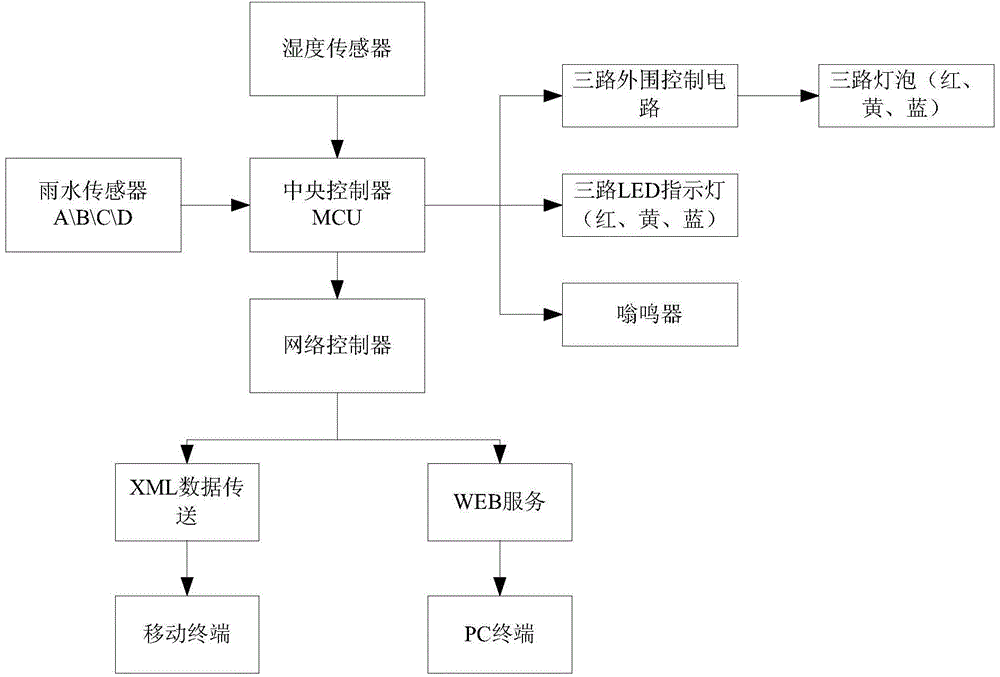

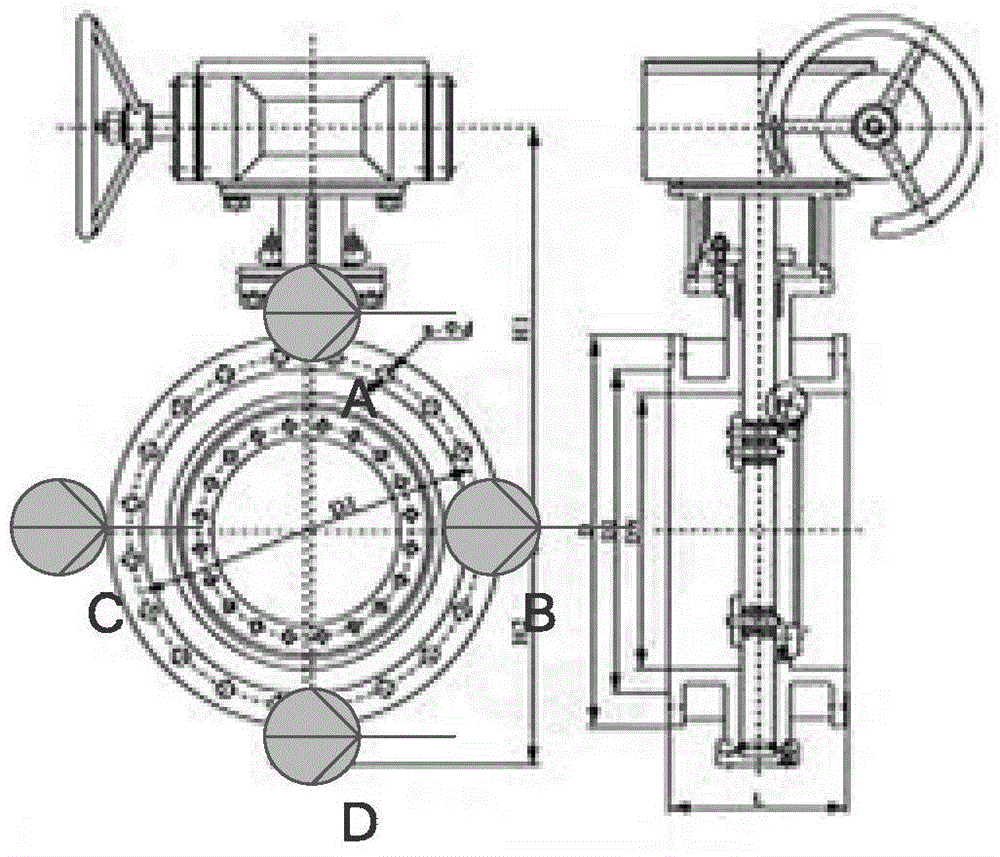

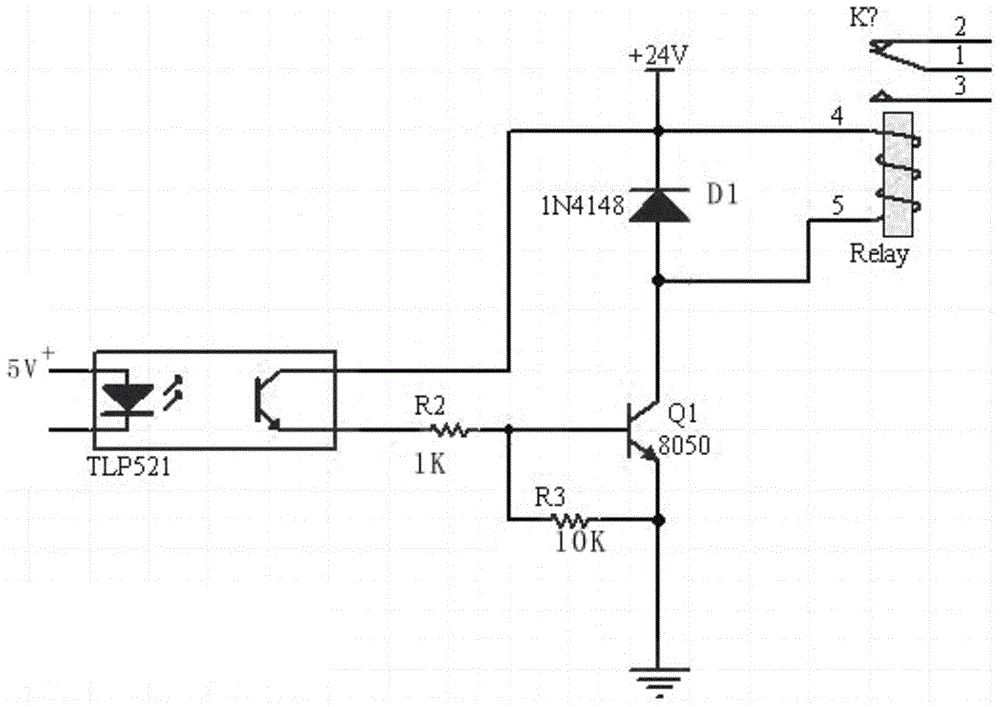

The invention discloses a pipeline connecting pipe fitting seepage detection device and method. The pipeline connecting pipe fitting seepage detection device comprises a central controller, four rainwater sensors and a warning unit, wherein the four rainwater sensors and the warning unit are connected with the central controller respectively, the four rainwater sensors are the rainwater sensor A, the rainwater sensor B, the rainwater sensor C and the rainwater sensor D, the rainwater sensor D is installed at the vertical-gravity bottommost position perpendicular of a pipeline connecting pipe fitting, and the rainwater sensor A, the rainwater sensor B and the rainwater sensor C are respectively installed above the pipeline connecting pipe fitting and the left-side position and the right-side position of the pipeline connecting pipe fitting. The analog signal output ends of the rainwater sensor A, the rainwater sensor B and the rainwater sensor C are respectively connected with an analog signal I / O port of the central controller, and the digital signal output end of the rainwater sensor D is connected with a digital signal I / O port of the central controller. The pipeline connecting pipe fitting is detected by combining the four rainwater sensors, the situation from humidity, water existing and water seepage of the pipeline connecting pipe fitting is judged to achieve a trend prediction warning function.

Owner:GUANGDONG GONGCHENG EQUIP PROPERTY SERVICE CO LTD

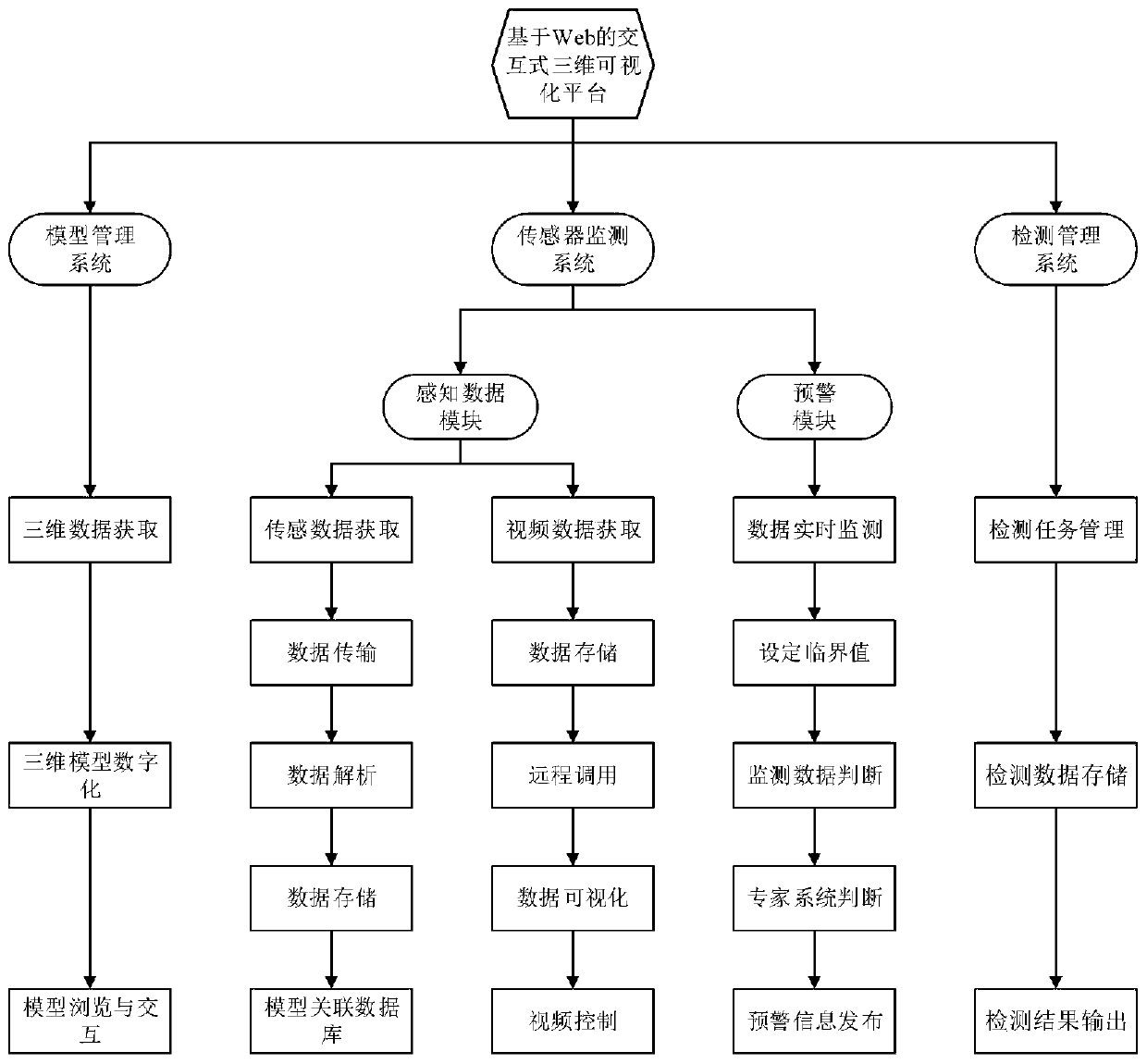

Interactive three-dimensional visualization platform based on web

InactiveCN111538297AAccurate Defect Prediction ResultsImprove Leak Detection AccuracyProgramme total factory controlAlgorithmEngineering

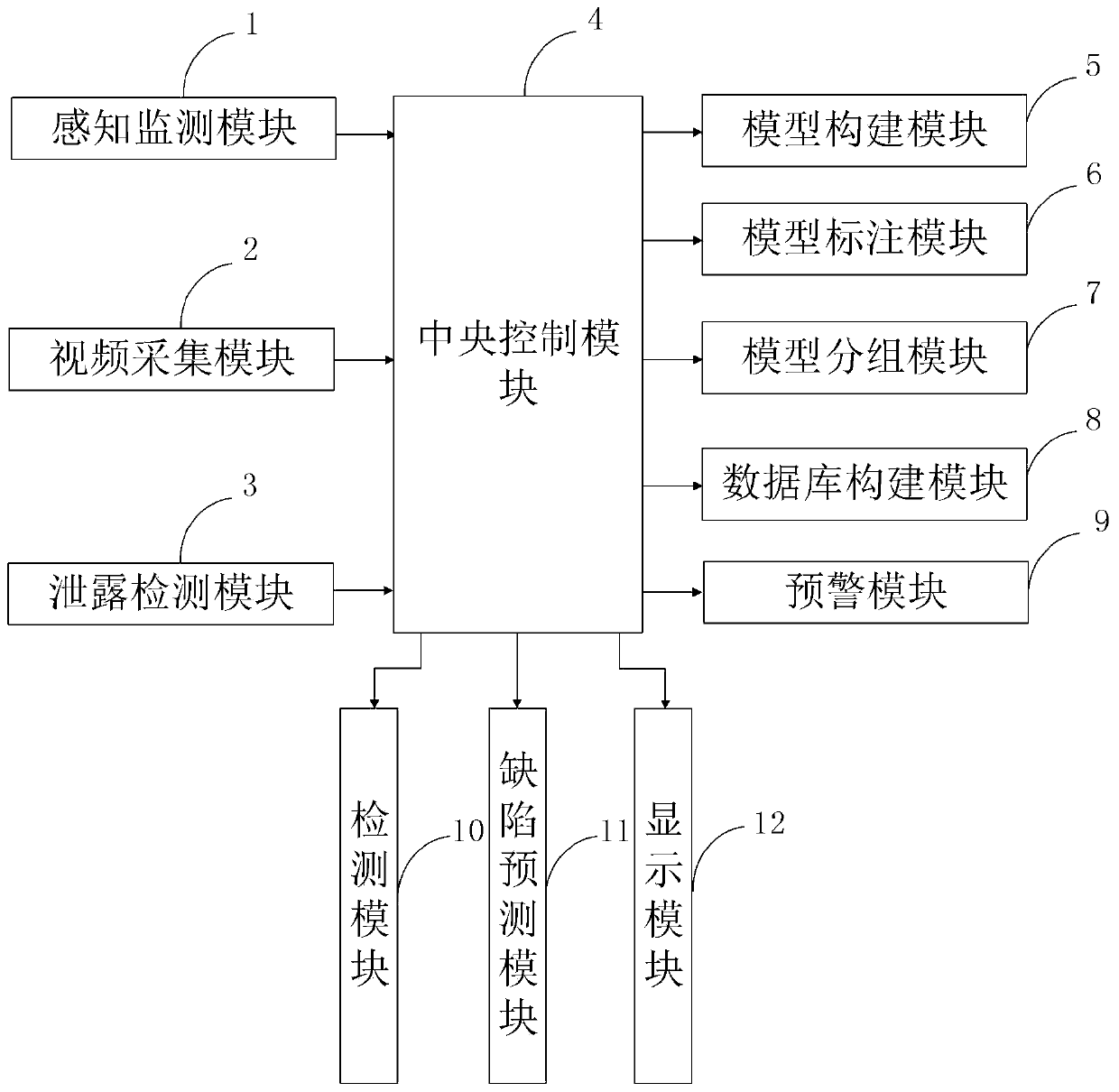

The invention belongs to the technical field of web-based interactive three-dimensional visualization, and discloses an interactive three-dimensional visualization platform based on web. The web-basedinteractive three-dimensional visualization platform comprises a perception monitoring module, a video acquisition module, a leakage detection module, a central control module, a model construction module, a model labeling module, a model grouping module, a database construction module, an early warning module, a detection module, a defect prediction module and a display module. According to theinvention, the technical effect of effectively improving the pipeline leakage detection precision is achieved through the leakage detection module; the feature data of the to-be-predicted pipeline areobtained through the defect prediction module; and the feature data of the to-be-predicted pipeline is input into a random forest model, the defect grade of the to-be-predicted pipeline is predicted,and the accurate pipeline defect prediction result is obtained due to the fact that the random forest model is generated by training according to the feature data influencing the defect grade of thepipeline.

Owner:浙江网标物联有限公司

A system and method for leak monitoring of fuel evaporation system

ActiveCN108571401BImprove airtightnessReduce cloggingNon-fuel substance addition to fuelMachines/enginesFuel tankEvaporation

The invention discloses a system and a method for monitoring the leakage of a fuel evaporation system. The system for monitoring the leakage of the fuel evaporation system comprises a module used forjudging whether the diameter phi of an accumulative leakage hole is less than 0.5 mm, or more than 0.5 mm and less than 1 mm, or more than 1 mm; the judging module comprises a vacuum pump, a pressureand temperature sensor group installed in the evaporation system, a temperature sensor installed outside the evaporation system, a controller, and a reversing valve having a closing function, the reversing valve comprises a channel communicated with the fuel evaporation system, a channel provided with a 0.5 mm datum hole, and a channel provided with 1 mm datum hole. The method for monitoring the leakage of the fuel evaporation system comprises three monitoring stages: firstly, a preparatory stage for judging whether the leakage monitoring meets the molecular counting condition by the evaporation system; second, a monitoring stage used for judging whether a pipeline is disconnected, whether a carbon tank is blocked and whether an oil tank cover falls off; and thirdly, a judging stage used for judging the diameter of the accumulative leakage hole through the judging module and the equation.

Owner:扬州华光新材料股份有限公司

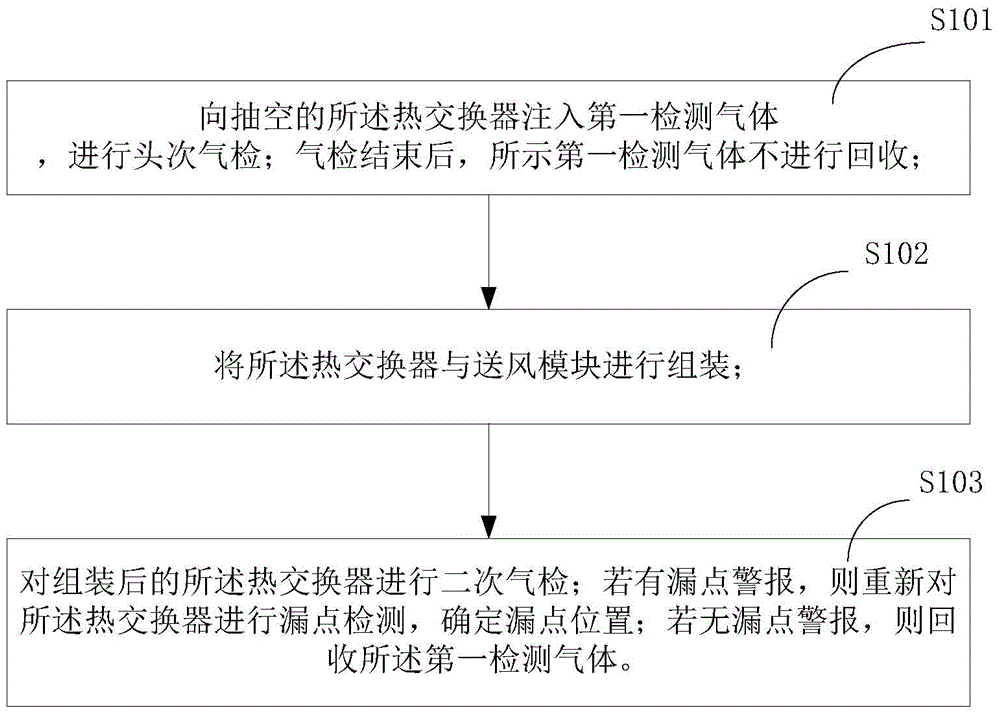

Air-conditioning heat exchanger leakage point detection method and detection platform

InactiveCN105675217AImprovement of leak detection abilityHigh leak detection accuracyFluid-tightness measurement using fluid/vacuumEngineeringAir conditioning

An air-conditioning heat exchanger leakage point detection method includes the following steps: first detection gas is injected into a vacuumized heat exchanger to perform primary gas detection; after the gas detection is finished, the first detection gas is recycled; the heat exchanger and an air supplying module are assembled; secondary gas detection is performed on the assembled heat exchanger; if a leakage point alarm is given, leakage point detection is performed on the heat exchanger again to determine a leakage point position; and if no leakage point alarm is given, the first detection gas is recycled. In addition, the invention also discloses a heat exchanger leakage point detection platform using the abovementioned method. Through the method and platform provided by the invention, a leakage point detection capability is improved by 100 times than an existing technology, and the method does not need to add any medium; leakage point detection precision of the heat exchanger is improved, the problem of air conditioner internal unit microleakage is fundamentally eliminated; and the method and platform are environment-friendly, can replace an original technology, and are optimized in technology and system.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

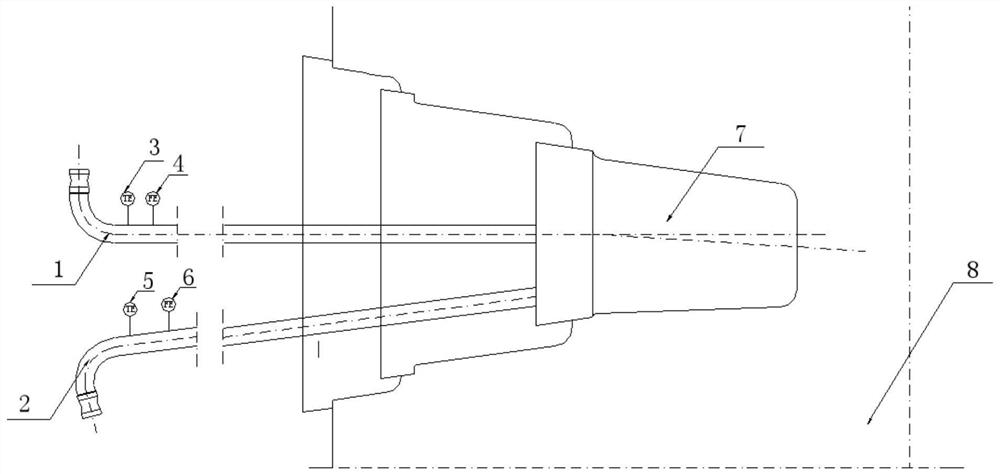

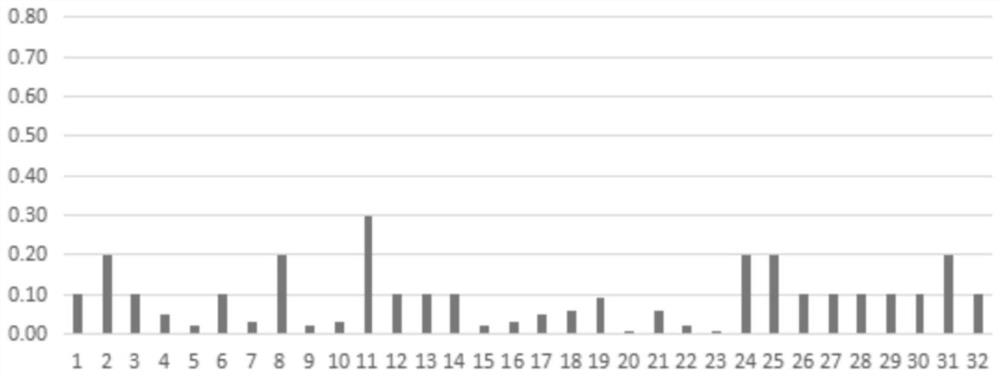

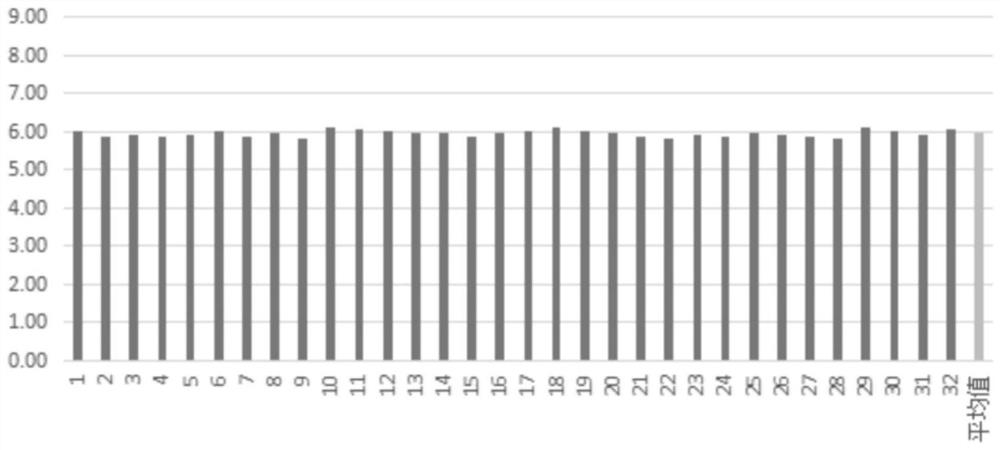

Blast furnace tuyere small sleeve leak detection device and leak detection method

InactiveCN112458222AQuick leak detectionAccurate leak detectionTuyeresCooling devicesEnvironmental engineeringWater leak

The invention relates to a blast furnace tuyere small sleeve leak detection device and a leak detection method, and belongs to the technical field of blast furnace maintenance tools. The blast furnacetuyere small sleeve leak detection device comprises a water outlet pipe and a water inlet pipe, wherein one end of the water outlet pipe and one end of the water inlet pipe respectively communicate with tuyere small sleeves; a water inlet thermometer and a water inlet flowmeter are arranged at the other end of the water inlet pipe; and a water outlet thermometer and a water outlet flowmeter are respectively arranged at the other end of the water outlet pipe. The leak detection method comprises the following steps: acquiring the temperature difference and the flow difference of cooling water of each tuyere small sleeve; comparing the temperature difference and the flow difference of the cooling water of any tuyere small sleeve with the temperature difference and the flow difference of thecooling water of other tuyere small sleeves; and if the temperature difference of the cooling water of one tuyere small sleeve is greater than the average value of the temperature difference of the cooling water of other tuyere small sleeves and the flow difference of the cooling water of the tuyere small sleeve is greater than 0.5m<3> / h, judging that a tuyere is damaged and leaks water. The blastfurnace tuyere small sleeve leak detection device is simple in structure, can quickly detect the leak of the tuyere small sleeves, and can accurately judge whether the blast furnace tuyere small sleeves are damaged or not, so that the leak detection accuracy is improved, and the leak detection workload is reduced.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Leakage detection method for special electronic gas transmission pipeline

InactiveCN109443651AEasy to check for leaksHigh leak detection accuracyDetection of fluid at leakage pointLiquid stateEngineering

The invention provides a leakage detection method for a special electronic gas transmission pipeline, and belongs to the technical field of machines. The method solves the problem in the prior art that the stability is poor. The leakage detection method for the special electronic gas transmission pipeline comprises the following steps of A, pipeline blocking, wherein the pipeline is erected, and the lower end of the pipeline is blocked; B, coating of a covering layer, wherein the outer side of the pipeline is uniformly coated with a coating medium in a viscous state, the covering layer uniformly covering the outer side of the pipeline is formed on the outer side of the pipeline; C, injection of leakage detection liquid, the leakage detection liquid in the liquid state is injected into thepipeline from the upper end of the pipeline; D, visual measuring for the covering layer, wherein the covering layer is naturally solidified to form a shell matched with the outer side of the pipeline,and whether or not obvious air holes exist on the shell is detected visually. The leakage detection method for the special electronic gas transmission pipeline is high in stability.

Owner:浙江英德赛半导体材料股份有限公司

Fuel system diagnostics

ActiveUS9322366B2Average power consumptionReduced fuel economyInternal-combustion engine testingMeasurement of fluid loss/gain ratePositive pressureVacuum pump

Methods and systems are provided for detecting a fuel system leak. While a system vacuum pump is operated to supply vacuum to a vacuum consumption device, air exhausted from the vacuum pump is routed to a fuel system to apply positive pressure thereon. A fuel system leak is identified based on a rate of decay of the pressure applied from the vacuum pump.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com