Patents

Literature

39results about How to "Quick leak detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for registering and measuring leaks and flows

InactiveUS20100268489A1High precisionQuick leak detectionDetection of fluid at leakage pointSurveyContinuous measurementSignal-to-noise ratio (imaging)

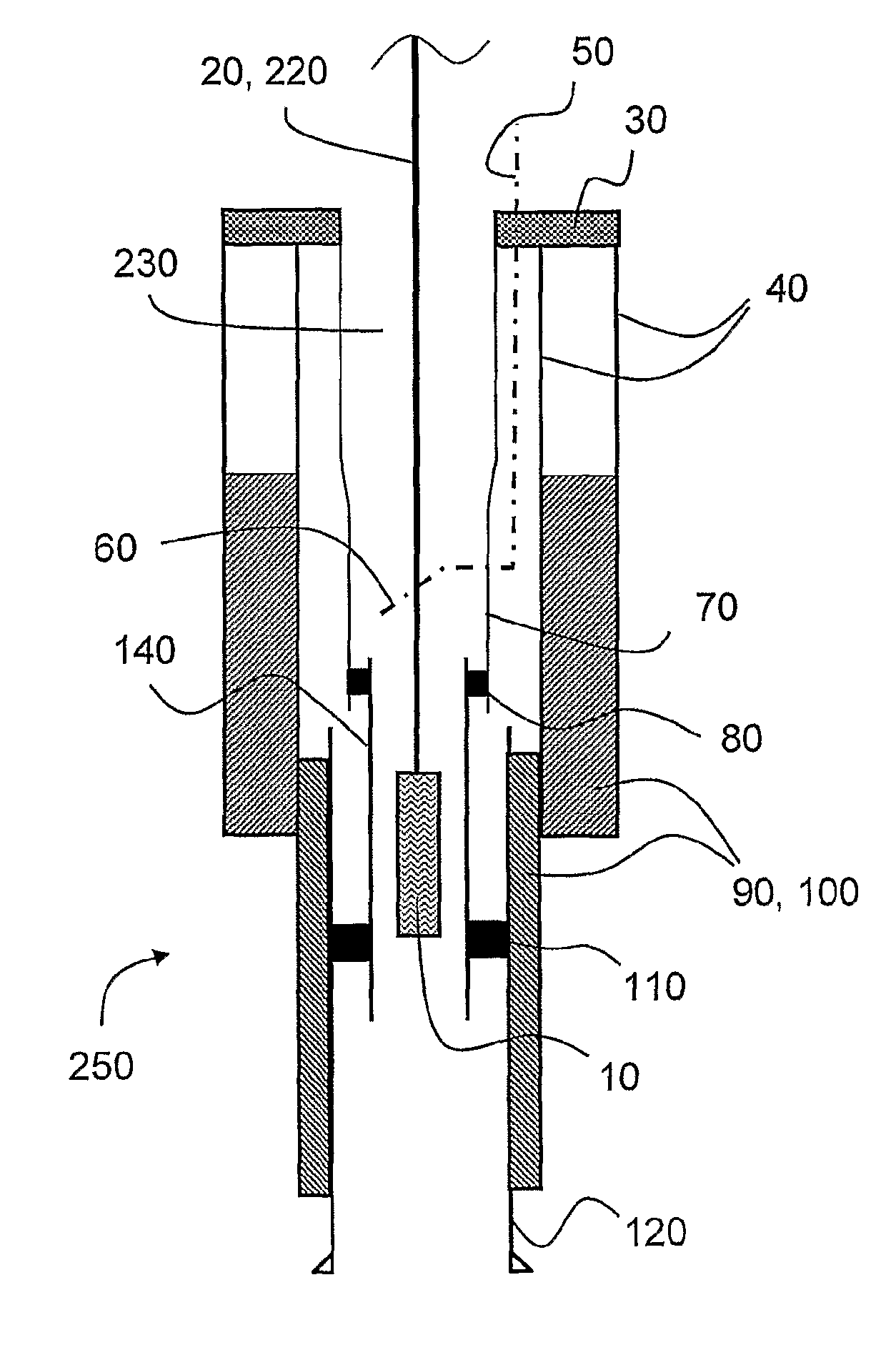

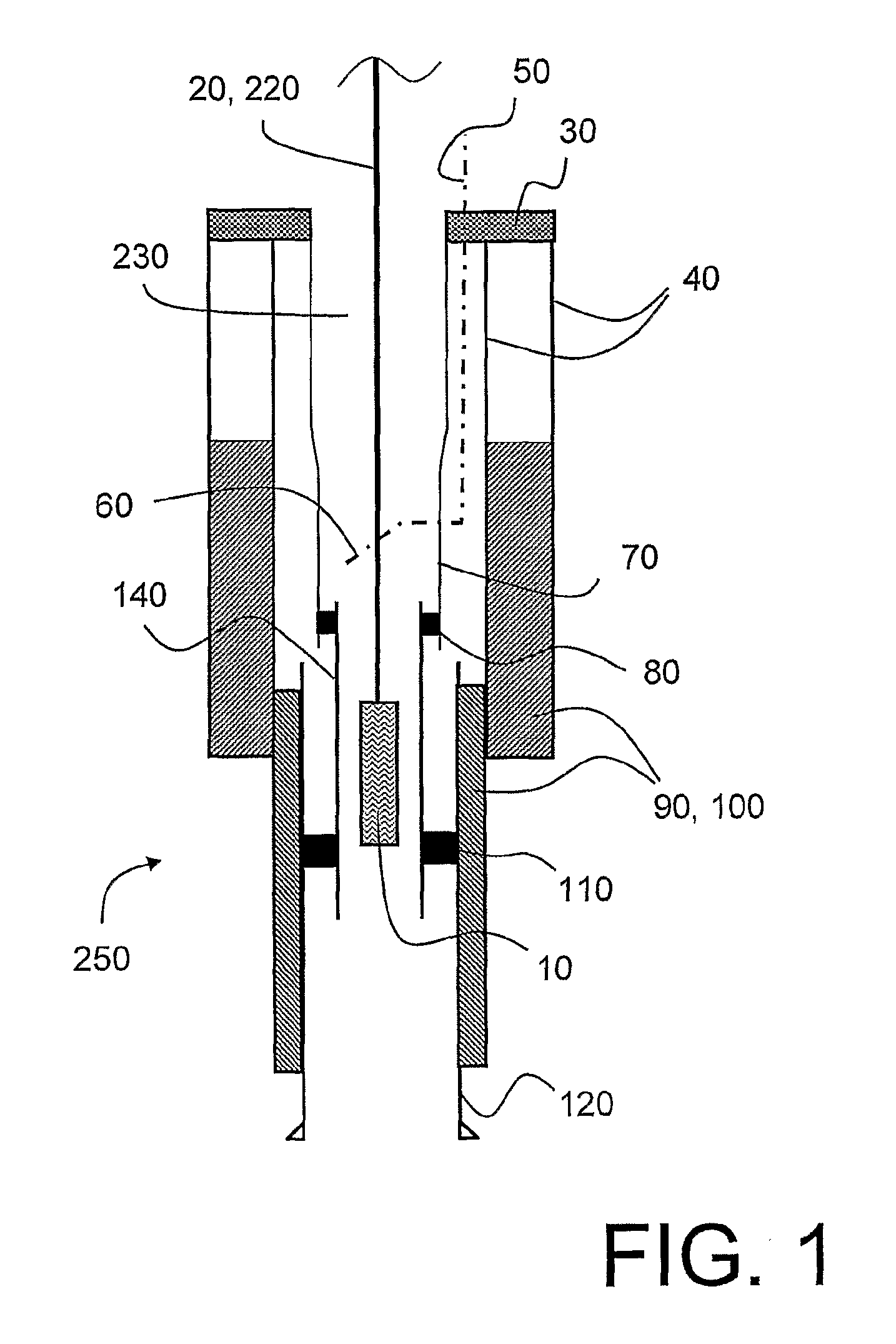

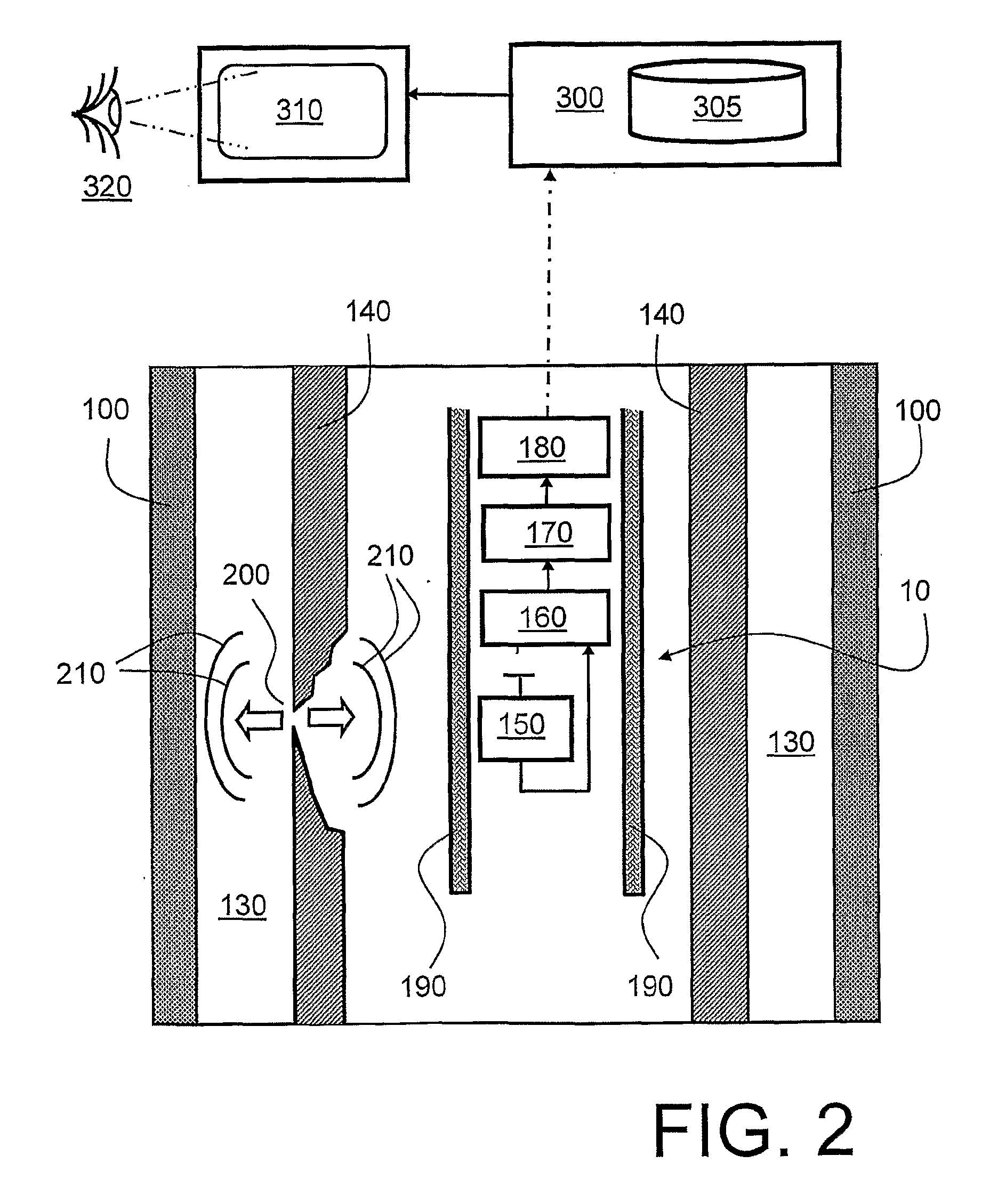

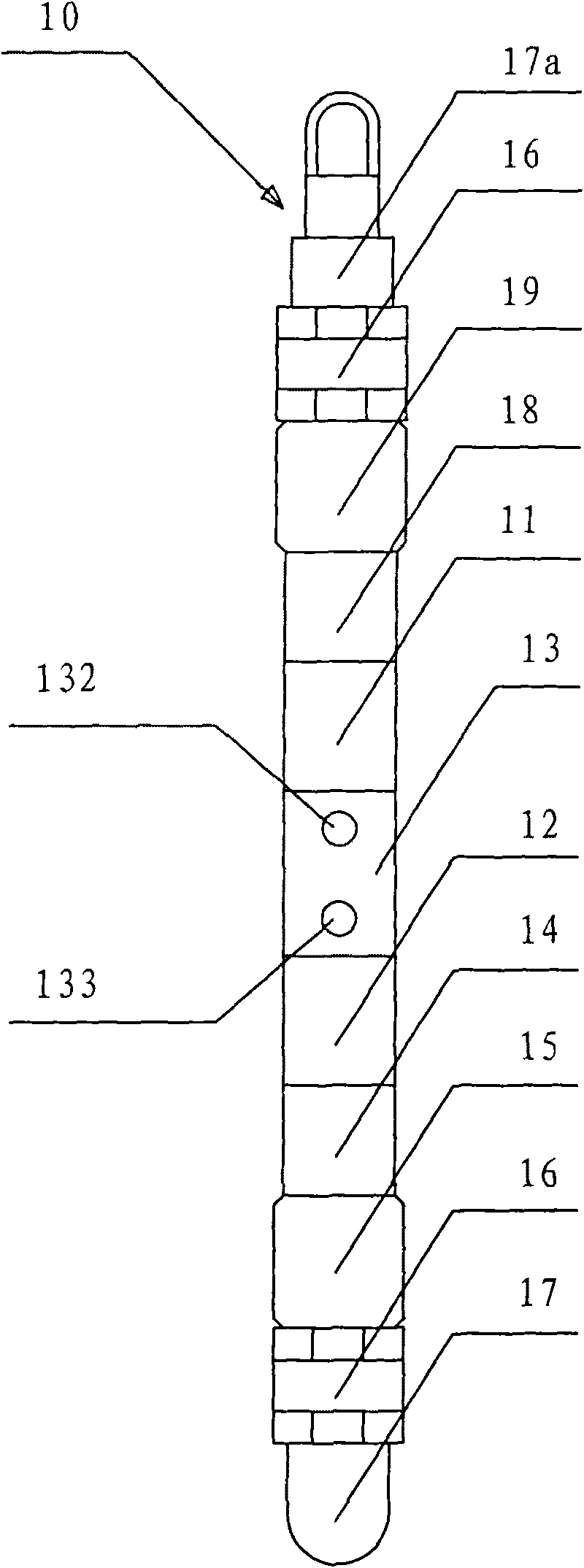

The present invention concerns a method of quantifying, detecting and localizing leaks or flows of liquid, gasses, or particles, in an oil or gas producing well (230). The method utilizes an acoustic transducer (150) arranged in the well (230). The method comprises steps of: (a) detecting signals (210) using the transducer (150), wherein the signals (210) are generated by acoustic noise from leaks (20) or flow of liquid, gasses, or particles in surroundings of the transducer (150); (b) amplifying the signals (210) to generate corresponding amplified signals for subsequent processing in a processing unit (170) disposed locally to the transducer (150); (c) filtering the amplified signals (210) over several frequency ranges using dynamic filtering for simultaneously detecting in these frequency ranges for better optimizing the signal-to-noise ratio by filtering away background noise in the amplified signals (210), and thereby generating corresponding processed data; and (d) sending the processed data from the processing unit (170) to a unit on the surface for storage and / or viewing of said data. The invention also comprises a corresponding system for implementing the method. The method and system are beneficially adapted for a continuous measurement up and / or down the oil or gas producing well. (230) in a non-stepwise manner.

Owner:ARCHER SA

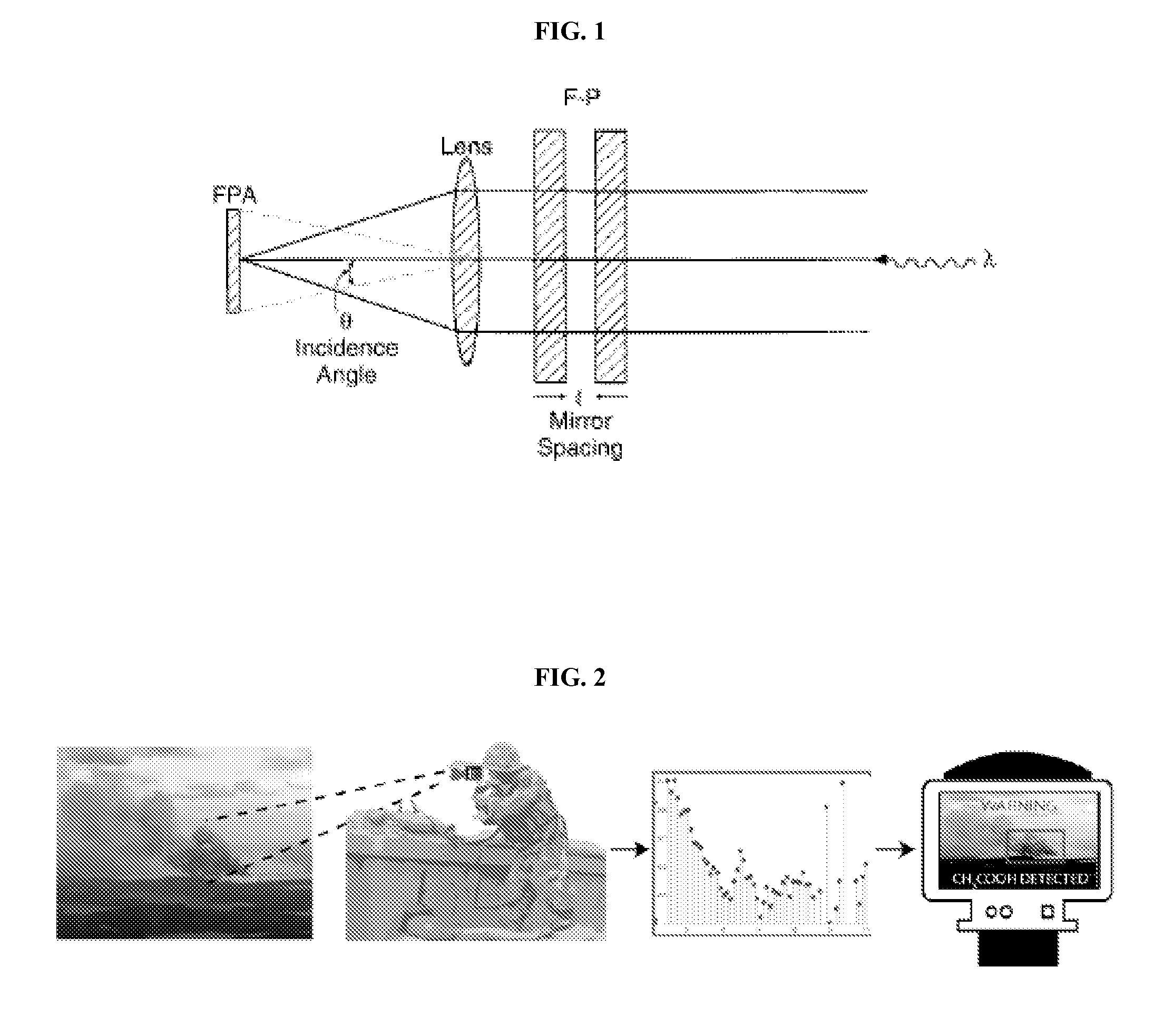

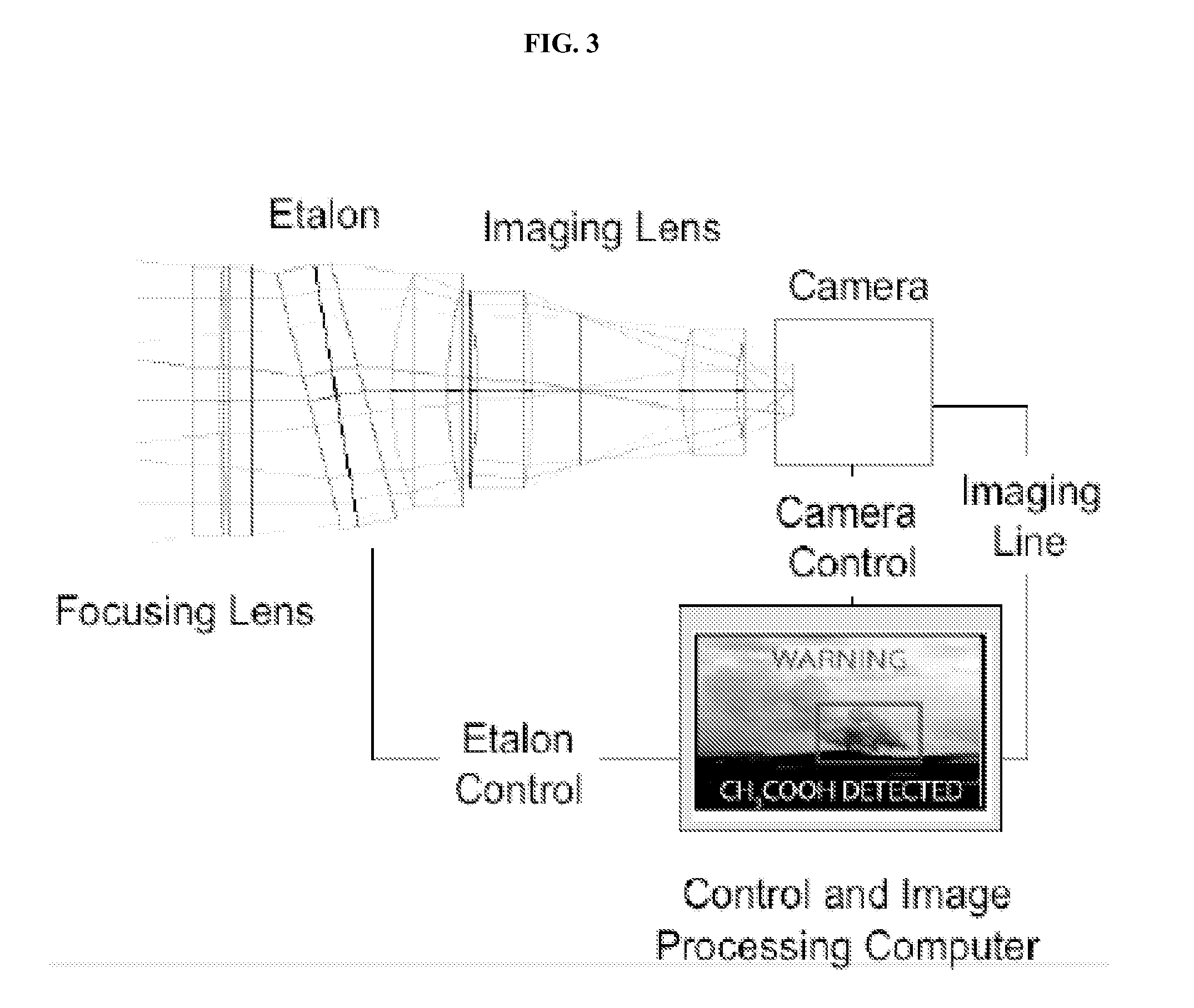

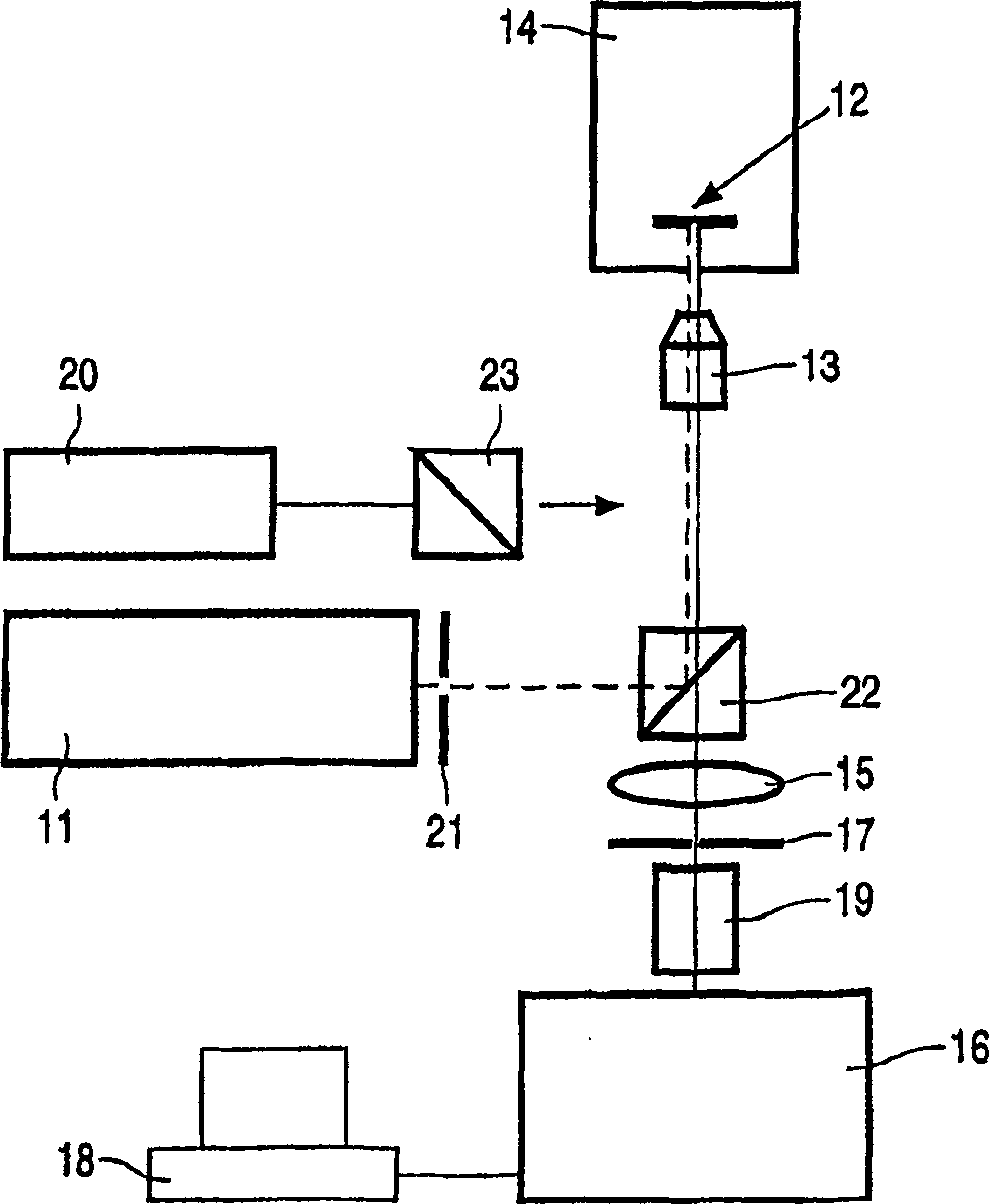

Leak Detection and Identification System

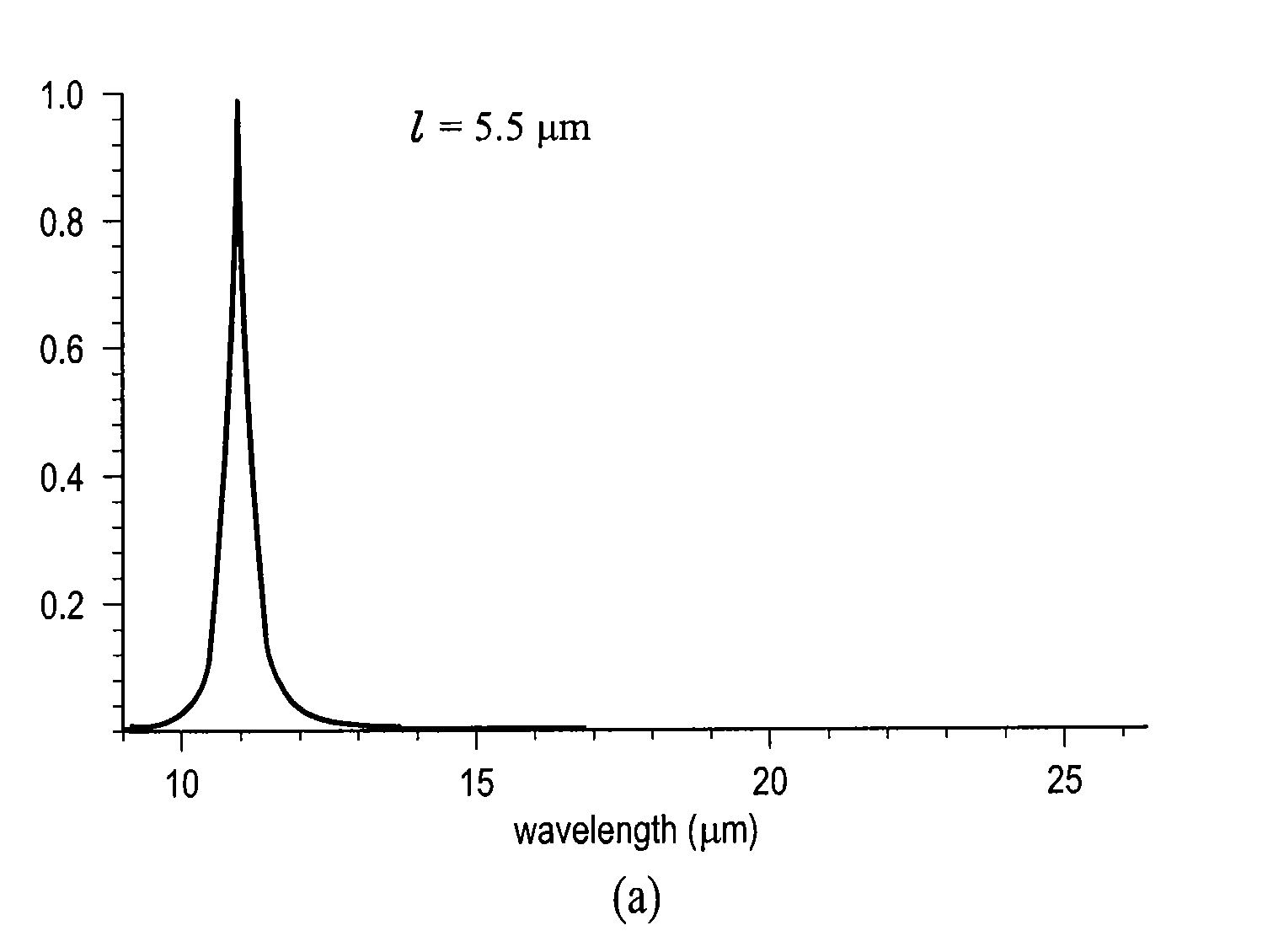

InactiveUS20100211333A1High sensitivityLight weightFlow propertiesMaterial analysis by optical meansBandpass filteringMicrobolometer

A leak detection and identification system a Fabry-Perot etalon, an imaging lens, a microbolometer camera, and a computer for spectral and image data post-processing, wherein the data peaks are deconvoluted for use thus avoiding the need for bandpass filters.

Owner:INTEGRATED PROCESS RESOURCES

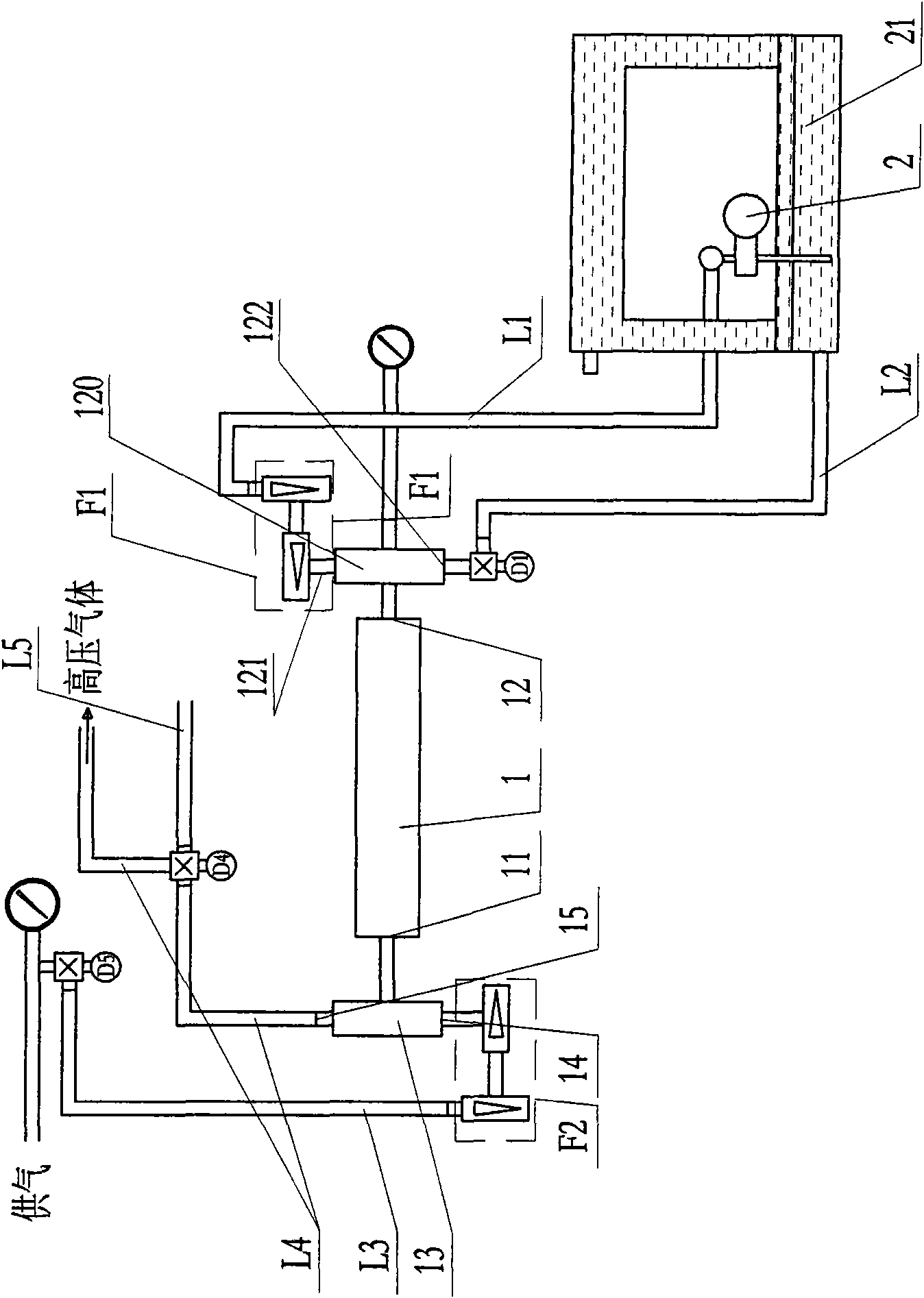

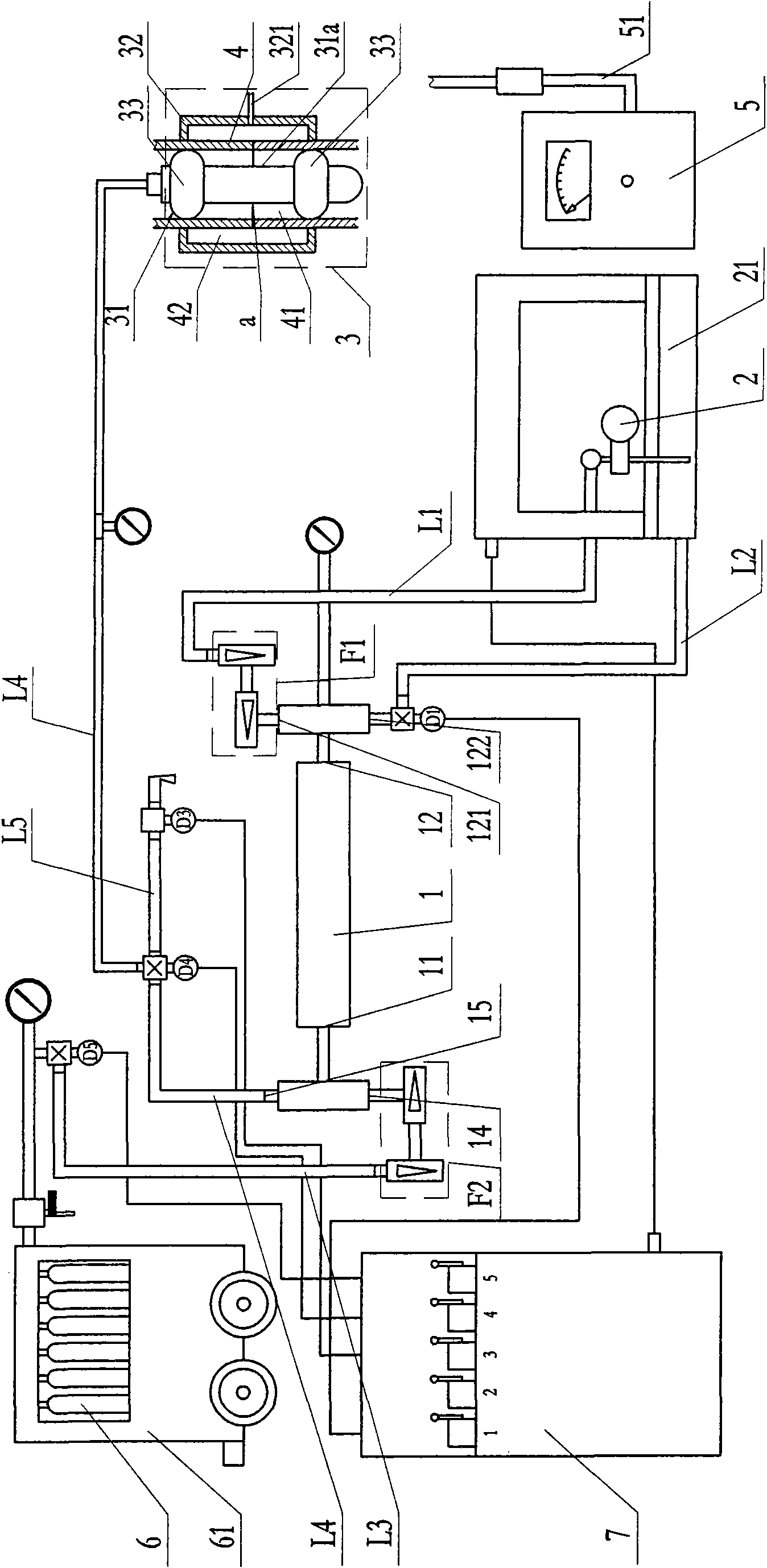

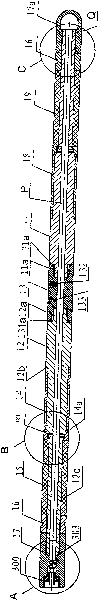

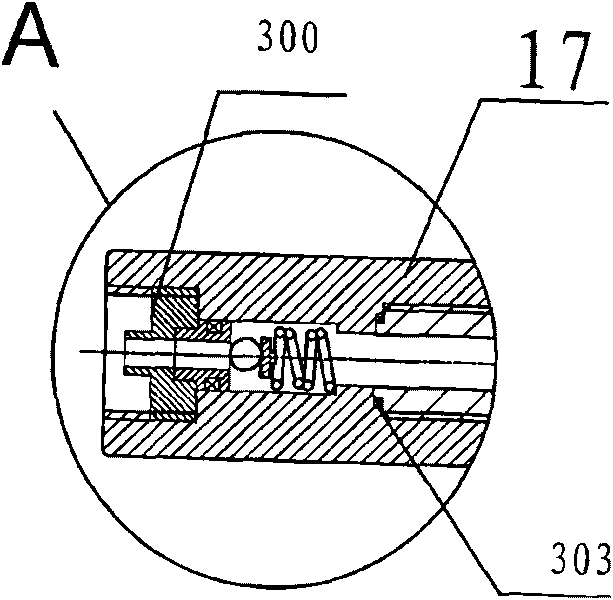

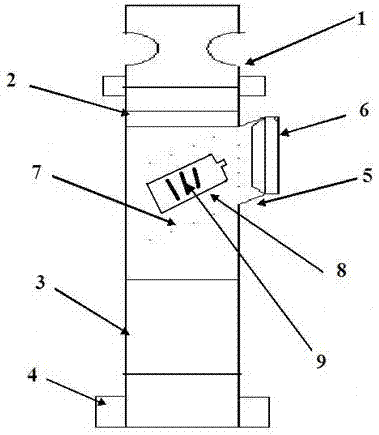

Leak detection tool applied to high pressure gas leak detection method

ActiveCN101598623AImprove detection reliabilitySimple structureDetection of fluid at leakage pointConfined spaceCasing string

A leak detection tool applied to a high pressure gas leak detection method, comprising a packer and a detection gas-collecting casing; the packer is arranged in an oil string to be detected or a casing string or an auxiliary tube, is located at two sides of a connecting thread buckle part to be detected and likely to leak, and is used for establishing inner confined space which is capable of filling with tracer gas and is otherwise called plenum space; the detection gas-collecting casing is arranged outside the oil string or the casing string or the auxiliary tube, is located in the connecting thread buckle part likely to leak, and covers the connecting thread buckle part to establish outer confined space which is capable of detecting leak and is otherwise called detection space; the plenum space is connected with a high pressure vent pipe on a pressurized container to facilitate high pressure tracer gas to enter. The detection space is connected with a detector of the tracer gas by being provided with a pipeline. The leak detection tool provided by the invention has simple structure, high detection reliability and convenient and practical field operation.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

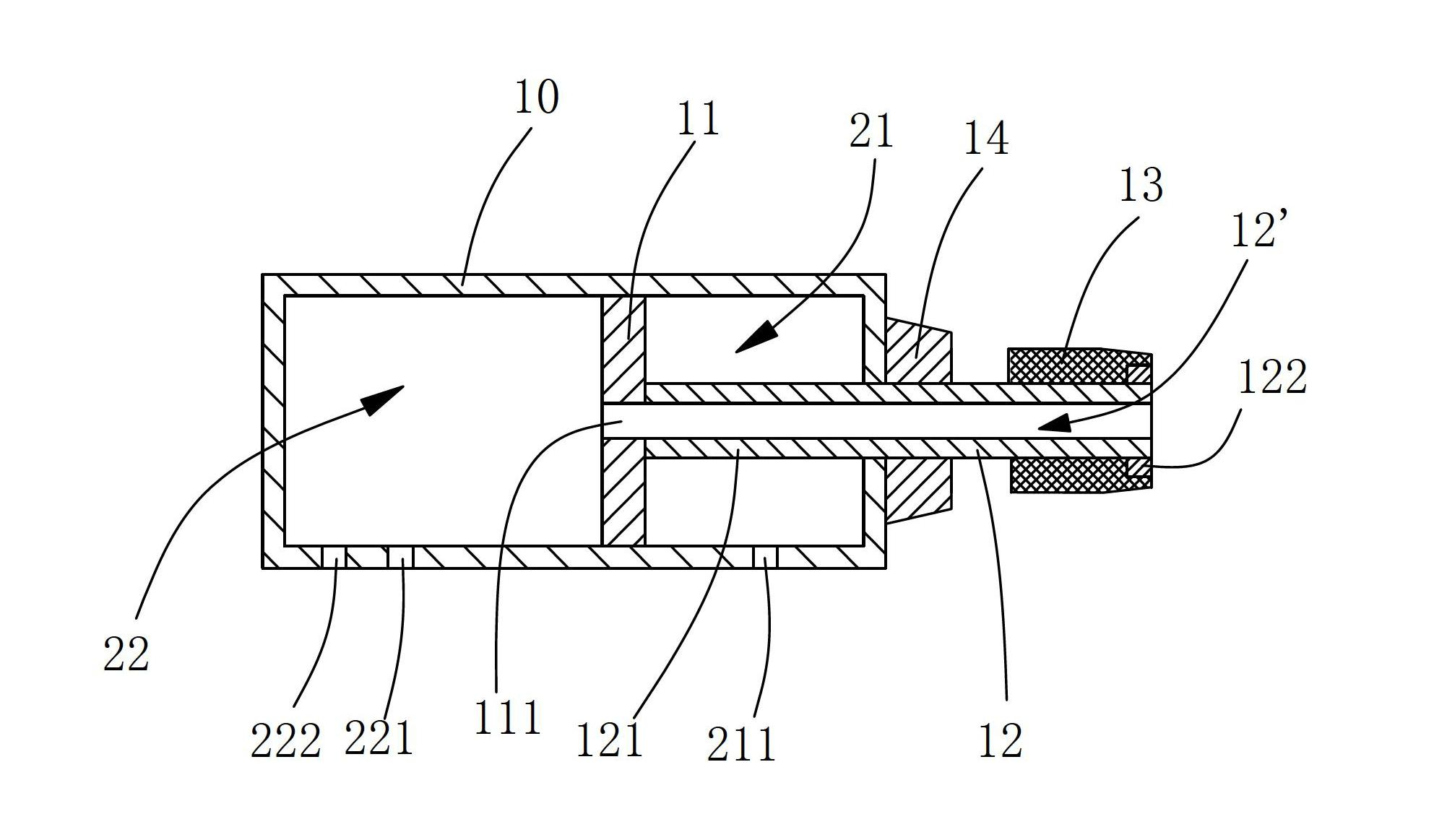

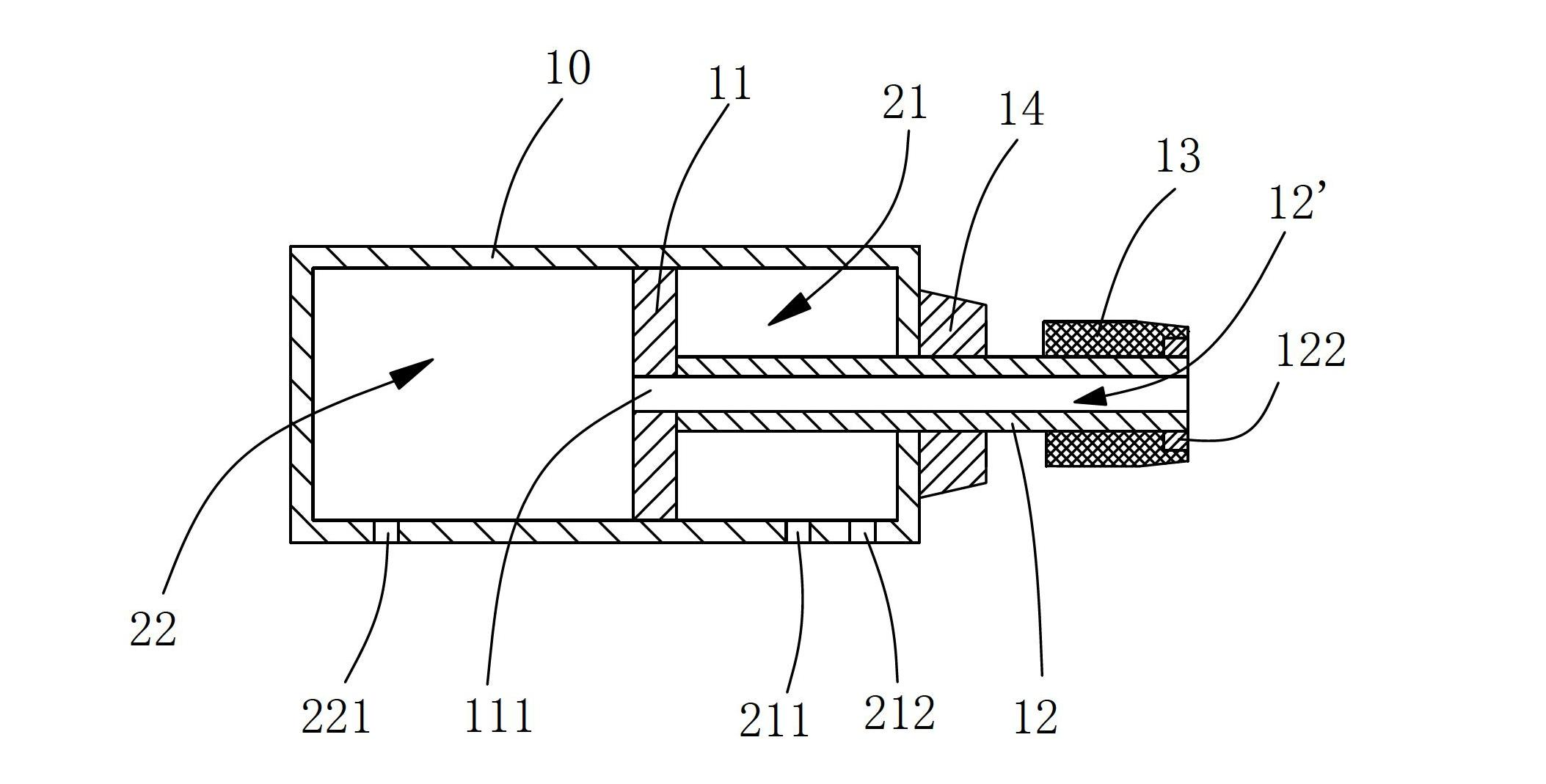

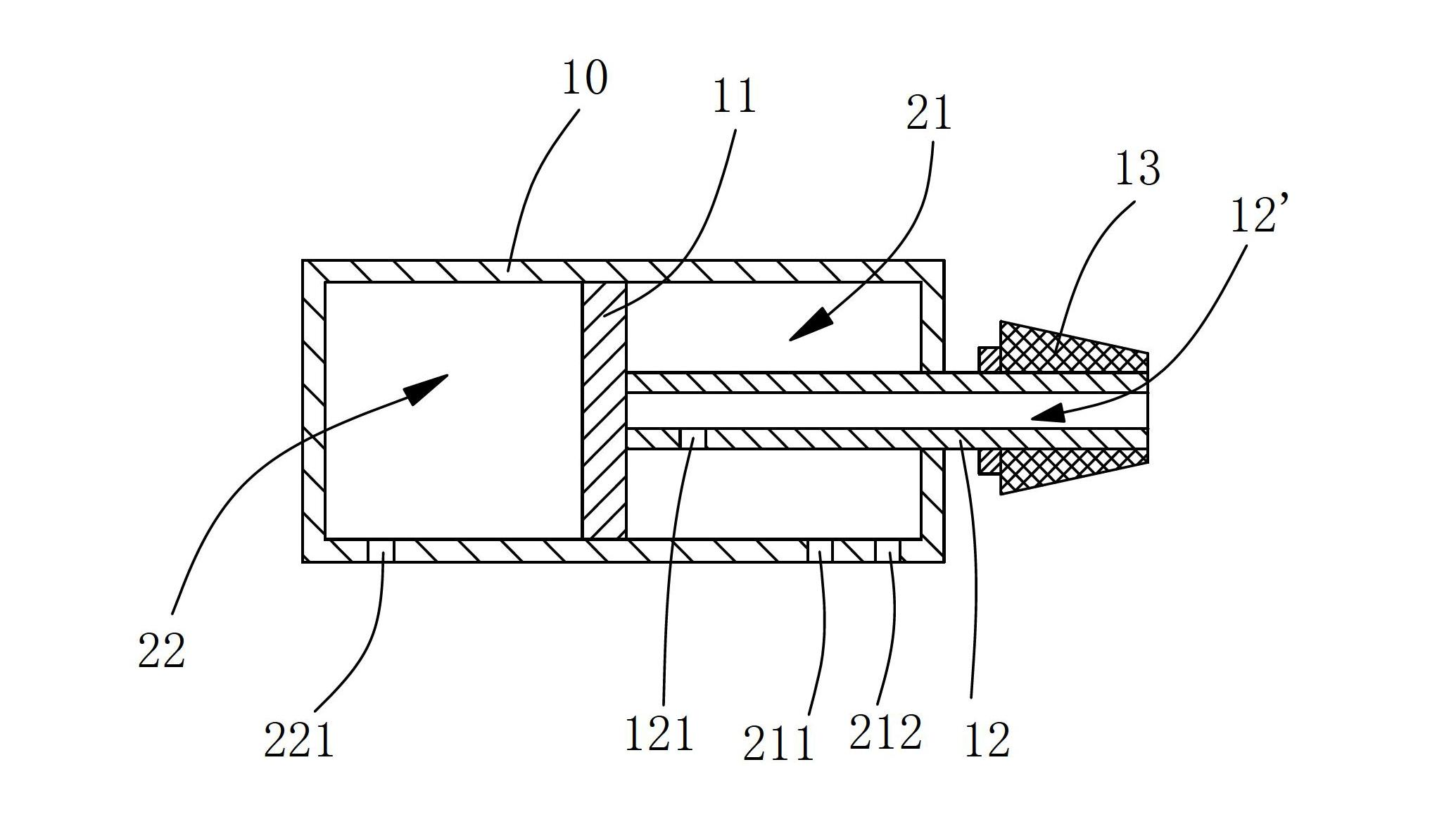

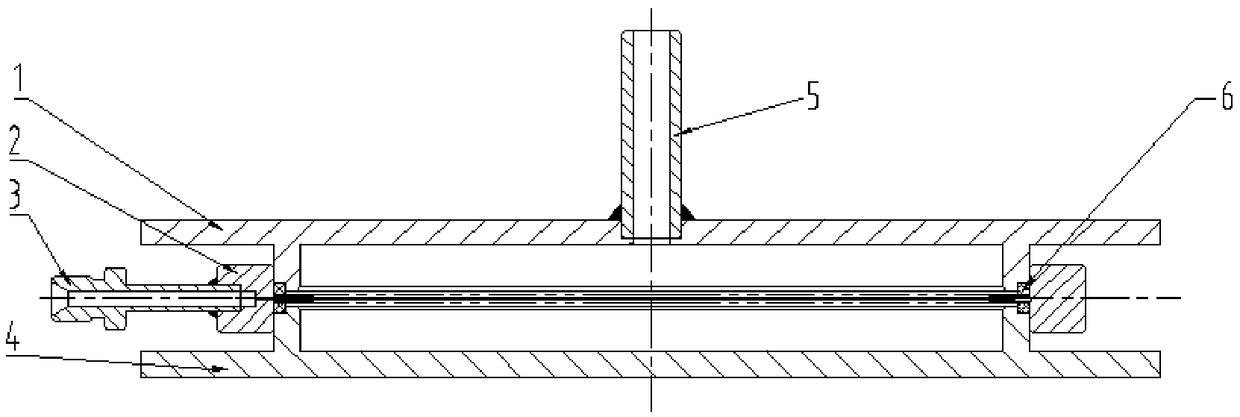

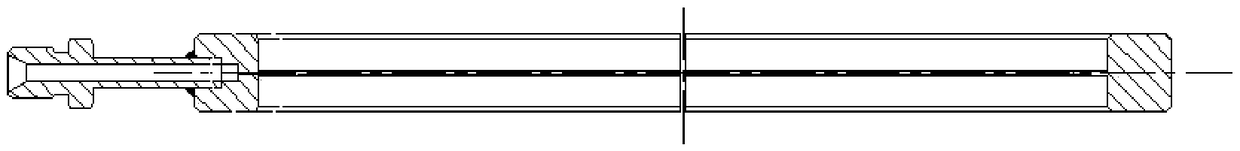

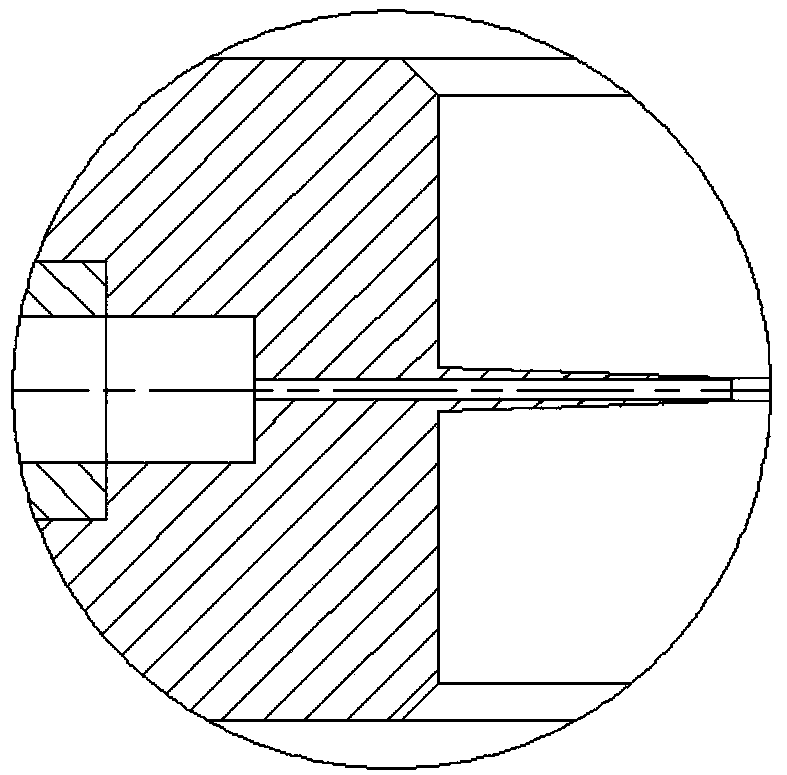

Leakage detecting device

InactiveCN102680189AQuick leak detectionFast clogMeasurement of fluid loss/gain rateEngineeringMechanical engineering

The invention discloses a leakage detecting device, comprising a cylinder body and a piston arranged in the cylinder body. A cavity inside the cylinder body is divided into a first cavity and a second cavity which are separated by the piston; a piston rod is arranged on the piston; a plug for blocking a pipeline opening of a workpiece is arranged on an end head extending outside the cylinder body of the piston rod; a first through hole and a second through hole, which are connected with a gas source, are respectively arranged in side walls of the first cavity and the second cavity; the piston rod is formed by a pipe body; and an air inflation channel formed in the pipe body is respectively communicated with a connection pipe and the first cavity / the second cavity. Gas is rapidly filled into the first cavity or the second cavity, which is separated from the air inflation channel, and the piston is pushed by the gas, so as to drive the plug to rapidly block the connection pipe. Meanwhile, the gas is filled into the other cavity, so that the gas is inflated into the workpiece through the air inflation channel, so as to realize the rapid leakage detection of the workpiece.

Owner:HUANGSHAN KENENG AUTO RADIATOR

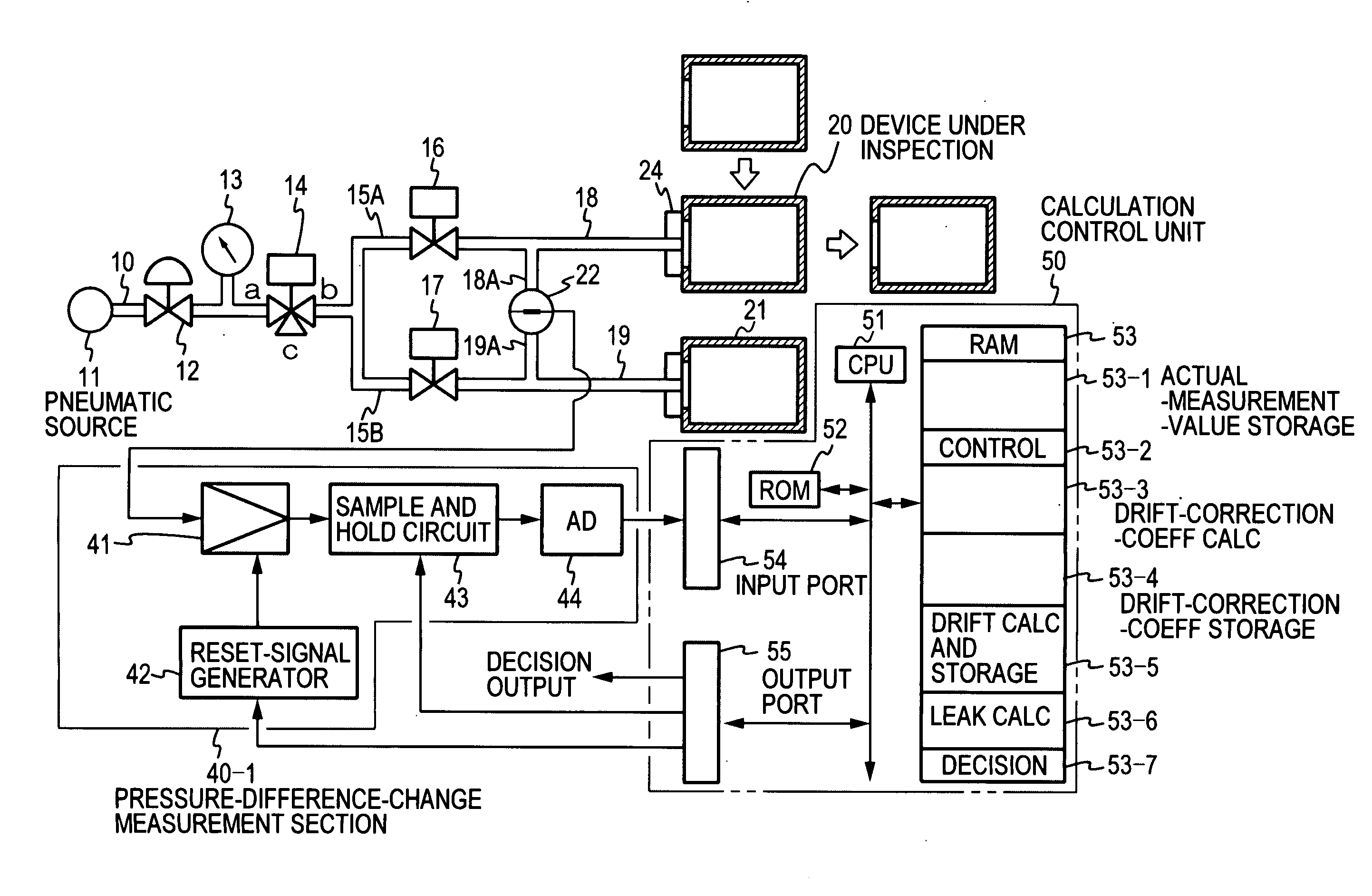

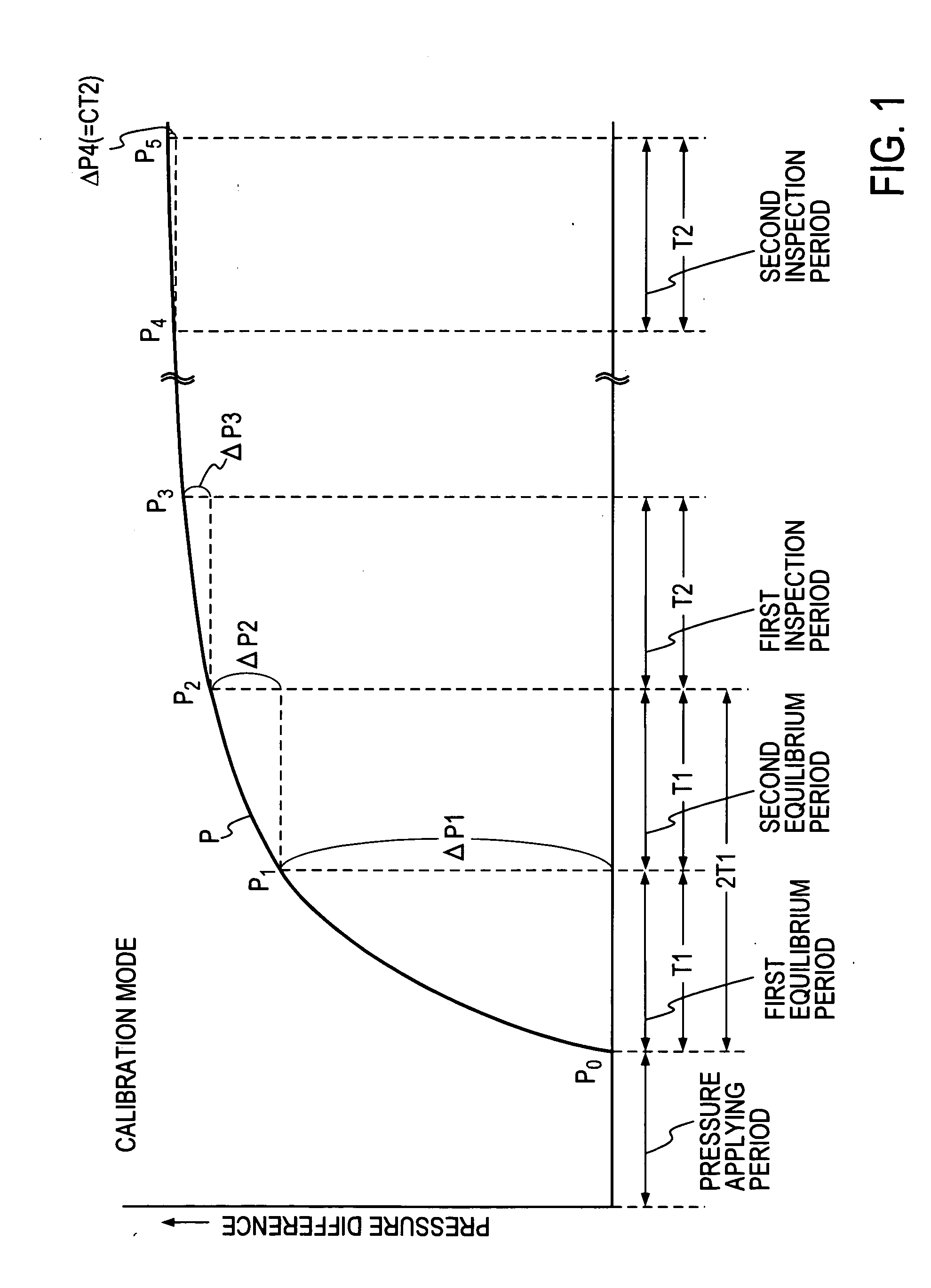

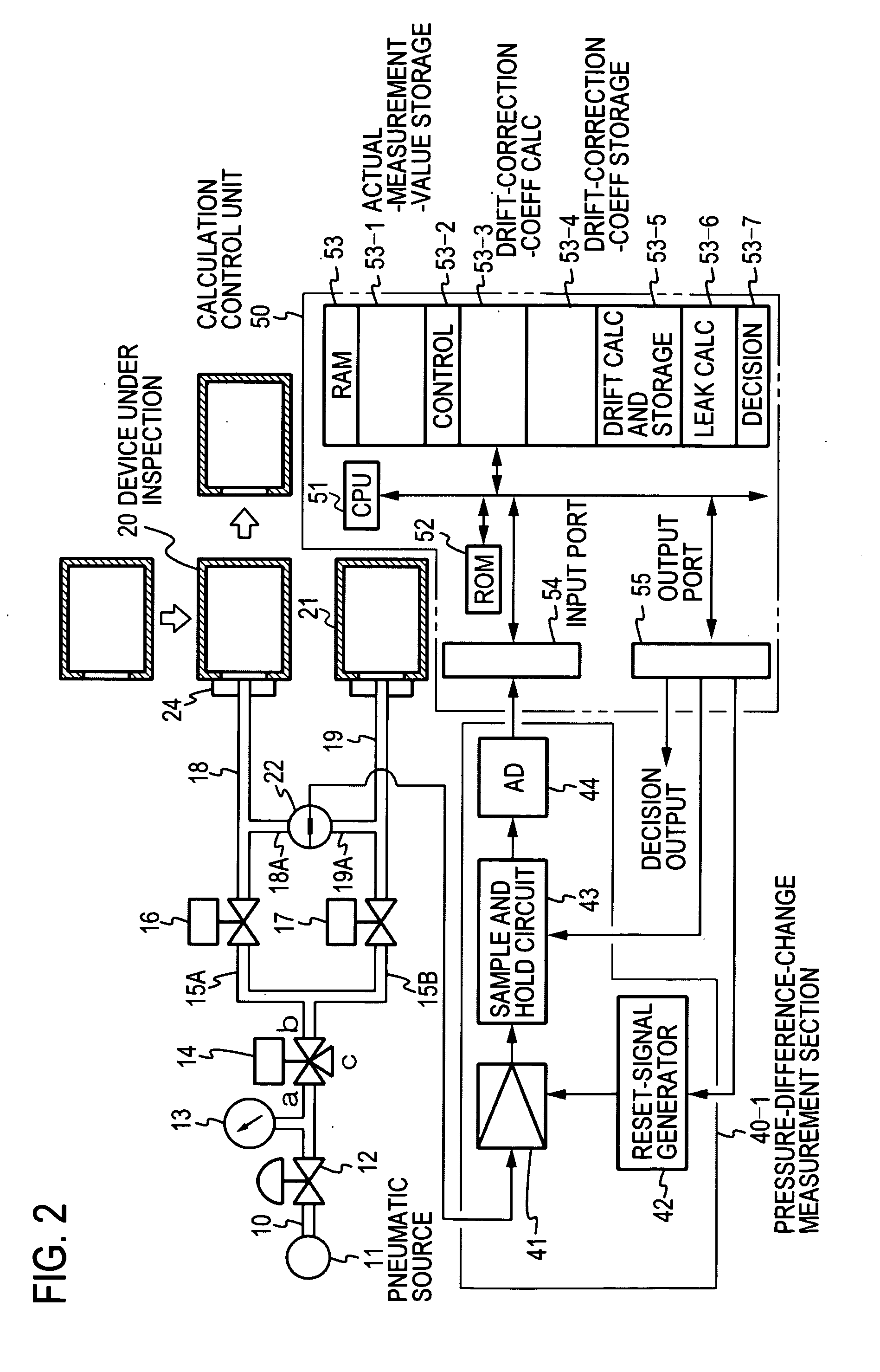

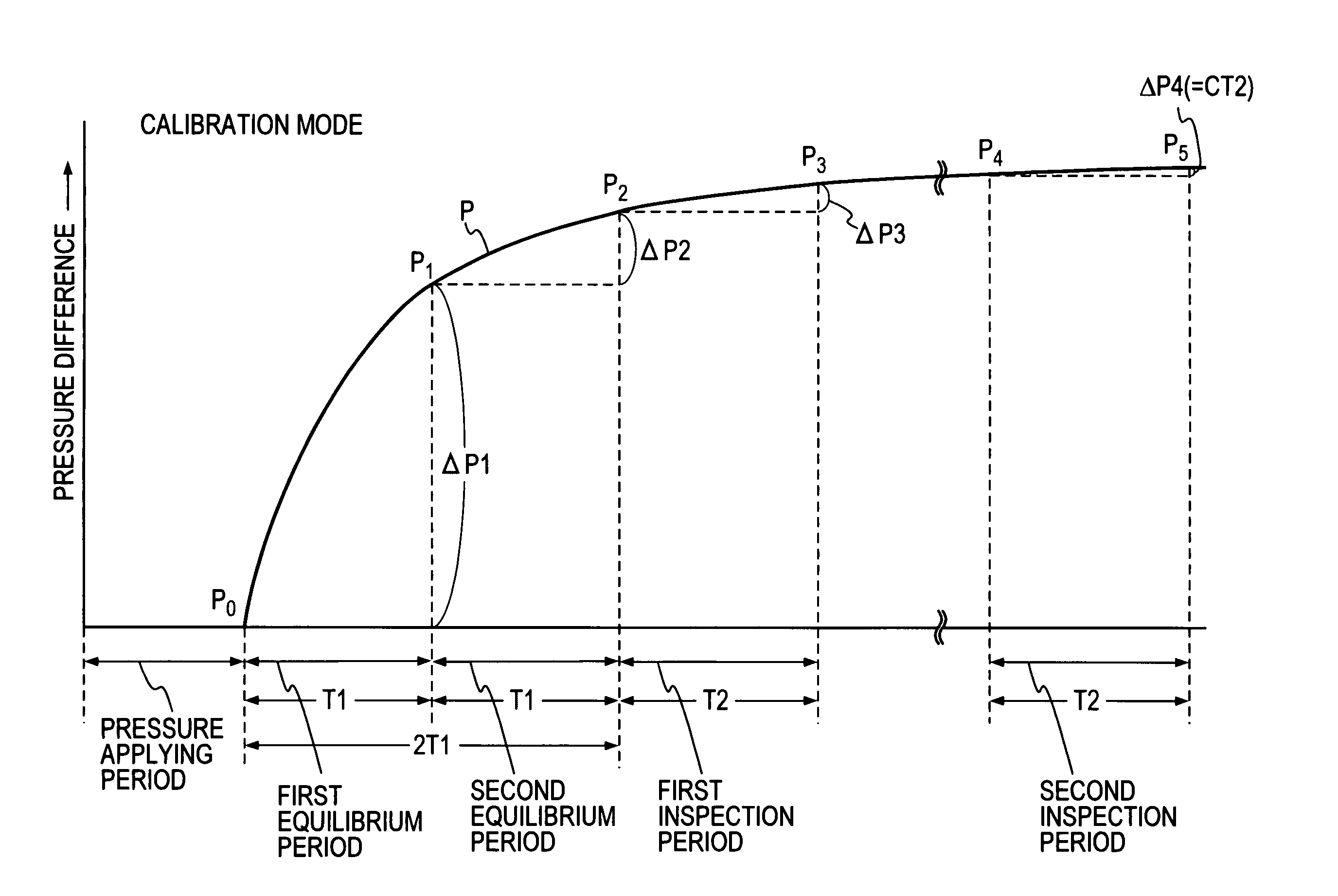

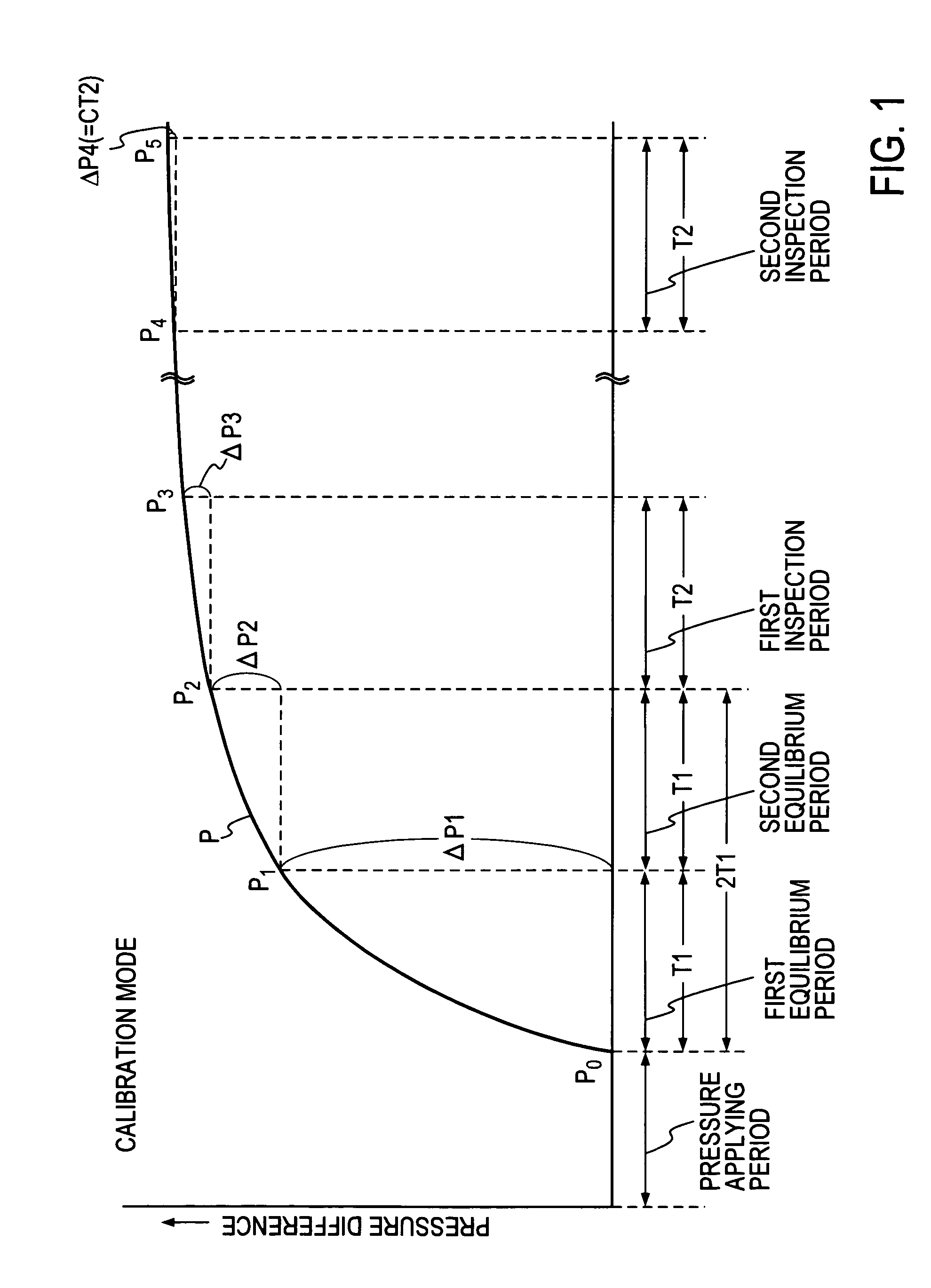

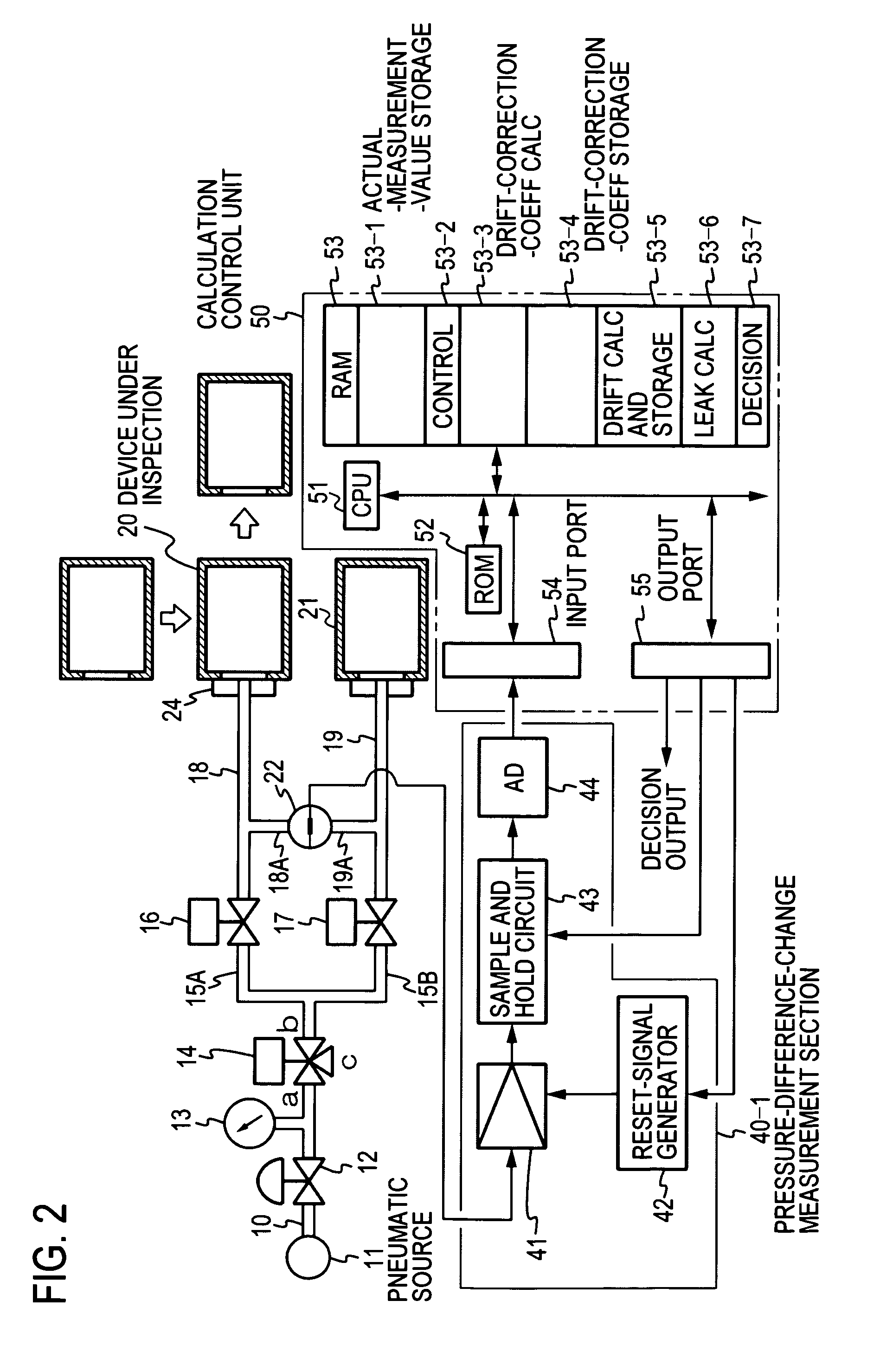

Leak Inspection Method and Leak Inspector

InactiveUS20090132185A1Precise drift correction coefficientQuick leak detectionDetection of fluid at leakage pointFlow propertiesEngineeringInspection method

Owner:COSMO INSTR

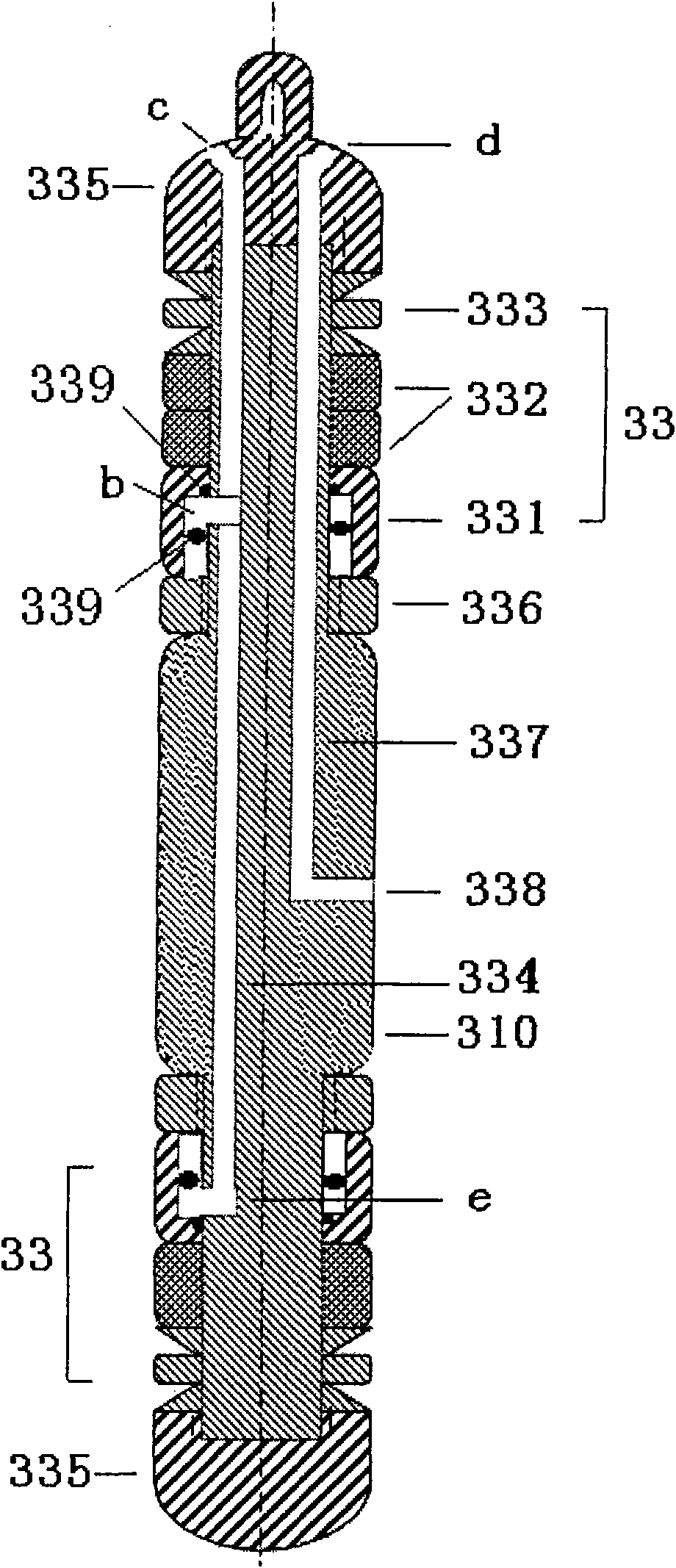

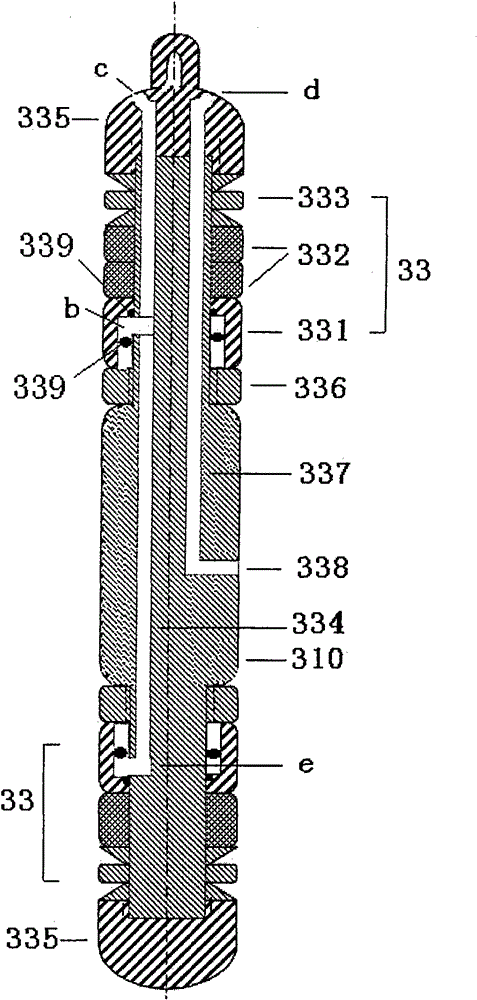

High-pressure clamped sealing gas injection tool being used for leak detection of tube column and having function of trip prevention

InactiveCN101699029AWith anti-jump functionImprove detection reliabilitySurveyFluid removalEngineeringTubes types

The invention provides a high-pressure clamped sealing gas injection tool being used for the leak detection of a tube column and having the function of trip prevention, which comprises two sets of clamped sealing components and a hollow tube type center column of which both ends are sealed; the two sets of clamped sealing components respectively comprise a sliding sleeve which can be sleeved on the center column in a slide way and a tubing sealer. A hollow cavity is arranged between the sliding sleeves and the center column and is sealed by a sealing ring; two through holes are arranged on the center column corresponding to the hollow cavity, are communicated with a center tube cavity and are communicated with the outside, wherein the through holes are respectively provided with a one-way valve, the disconnection and conduction directions of the one-way valves are opposite, and the conduction direction can be conducted at a set pressure difference, thereby forming a pressurization passage and a pressure relief passage. An input hole passage of a leak detection medium is arranged on a hollow tube wall. The lower end of the center column is also provided with a single-flow passage, and a single-flow valve which is outwards disconnected and inwards conducted is arranged in the single-flow passage. The leak detection tool provided by the invention has simple structure, high detection reliability and simple, convenient and easy site operation and can effectively prevent the potential safety hazard of tool trip during pressure relief after detection.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

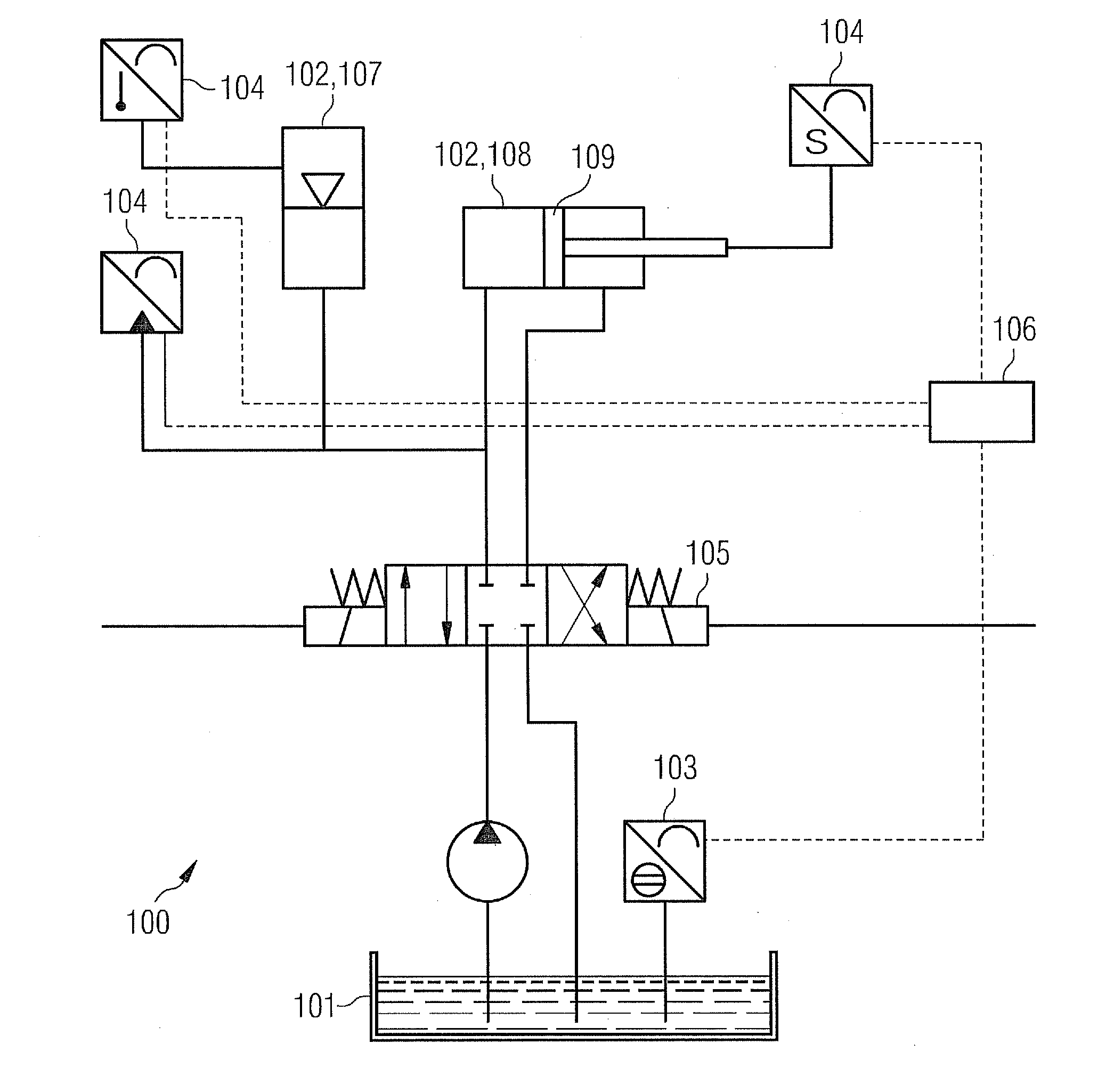

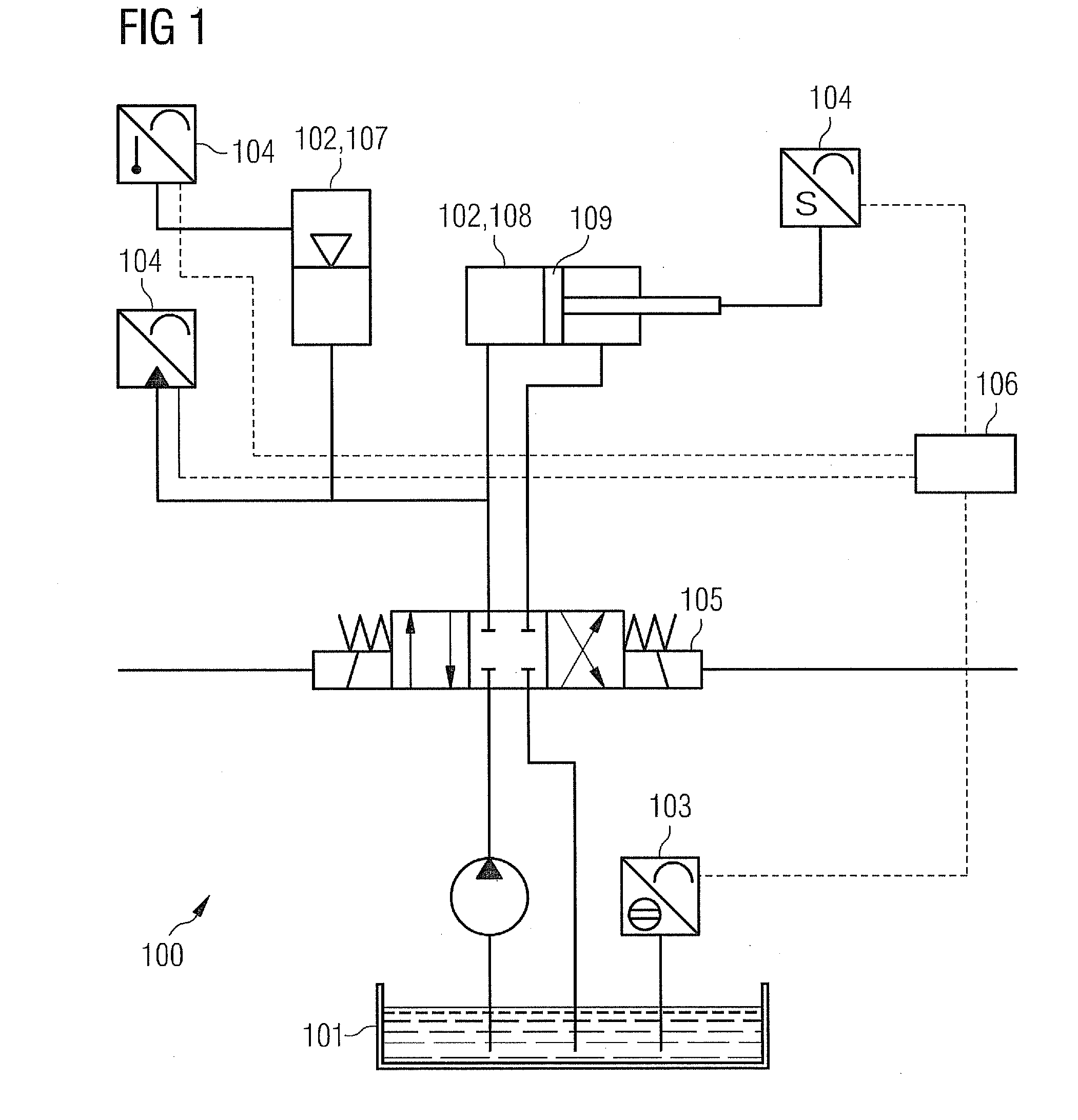

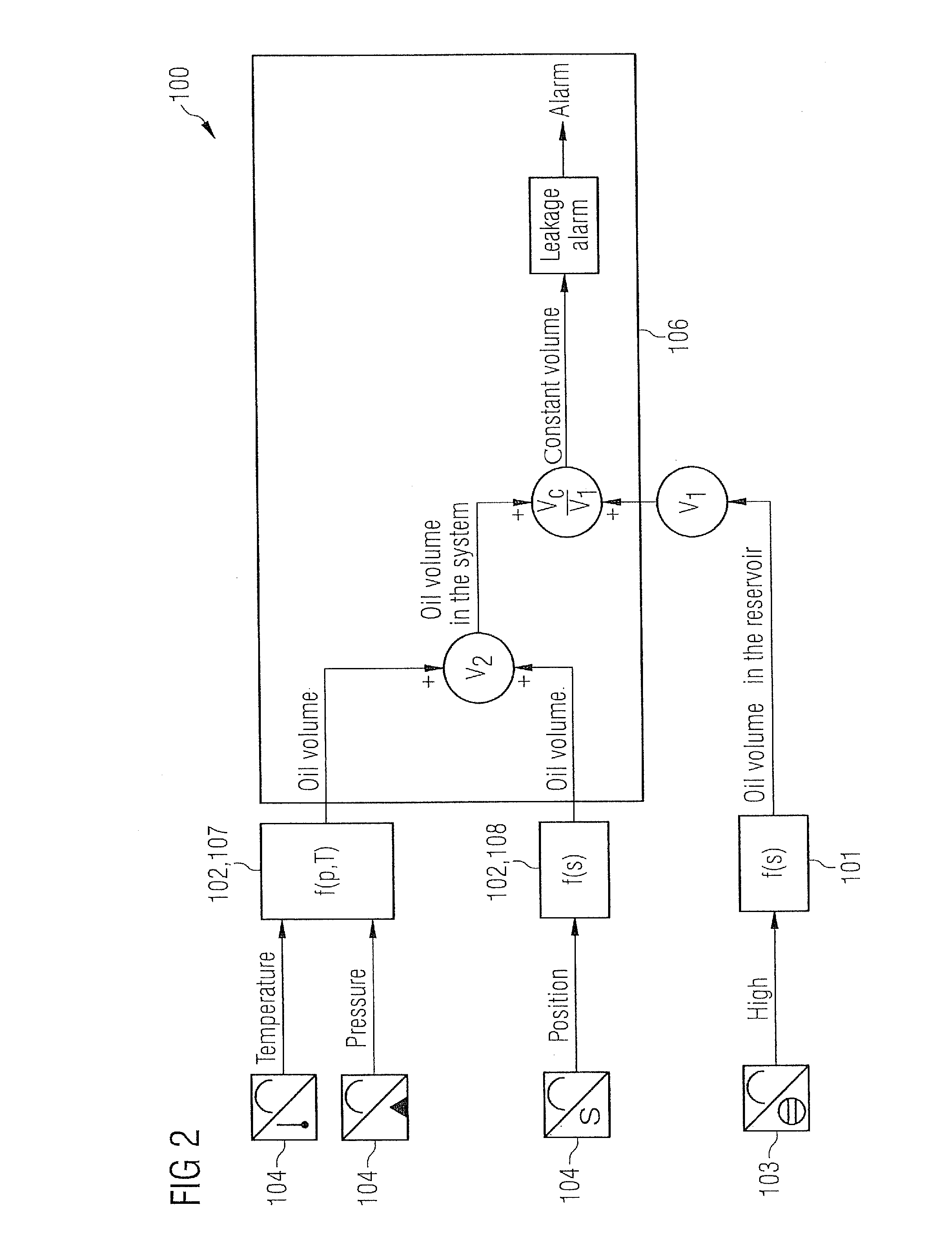

Leakage Detection System in a Wind Turbine

ActiveUS20100319336A1Quick leak detectionReduce the amount of solutionFluid-pressure actuator testingFluid couplingsEngineeringHydraulic fluid

In one aspect, a hydraulic system including a reservoir, a hydraulic device, a first sensor, a second sensor and a controller is described. The reservoir is connected to the hydraulic device for supplying hydraulic fluid to and from the hydraulic device. The first sensor is adapted for measuring a first volume of the hydraulic fluid in the reservoir. The second sensor is connected to the hydraulic device such that at least one parameter being indicative for a second volume of the hydraulic fluid in the hydraulic device is measurable. The controller is adapted for calculating the second volume of the hydraulic fluid based on the at least one parameter. The controller is adapted for determining a leakage of hydraulic fluid in the hydraulic system based on the first volume and the second volume.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

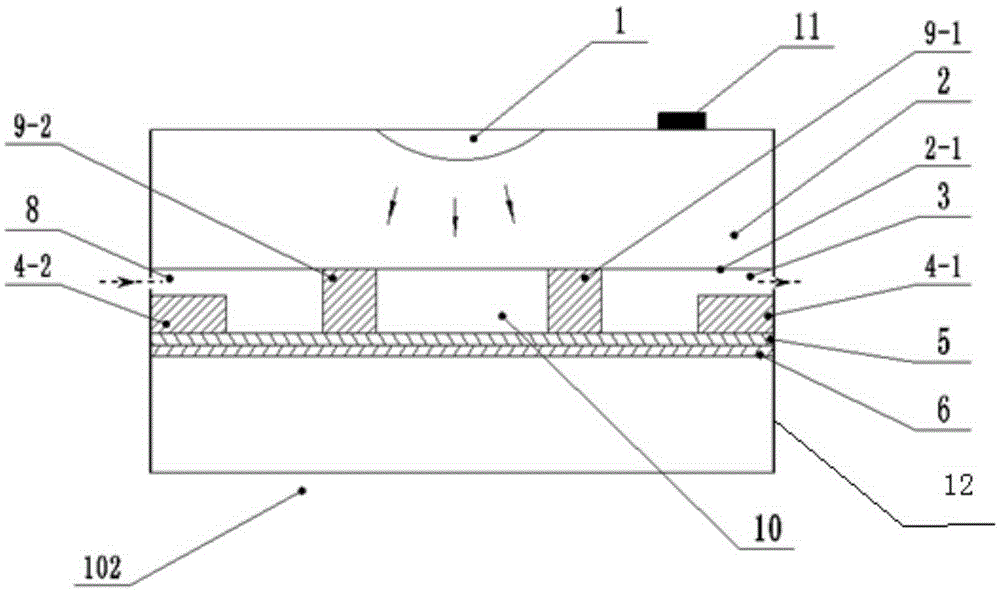

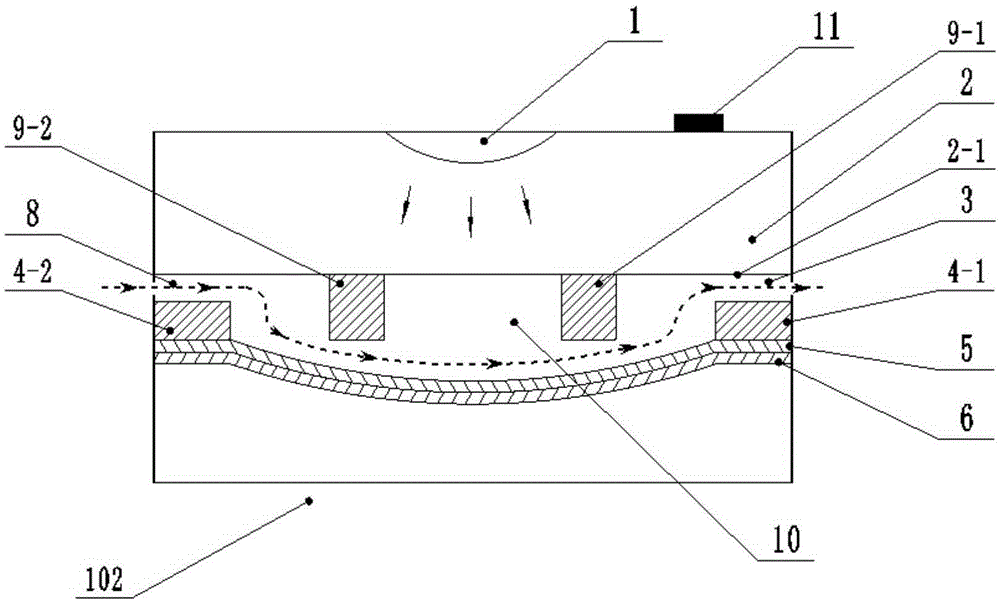

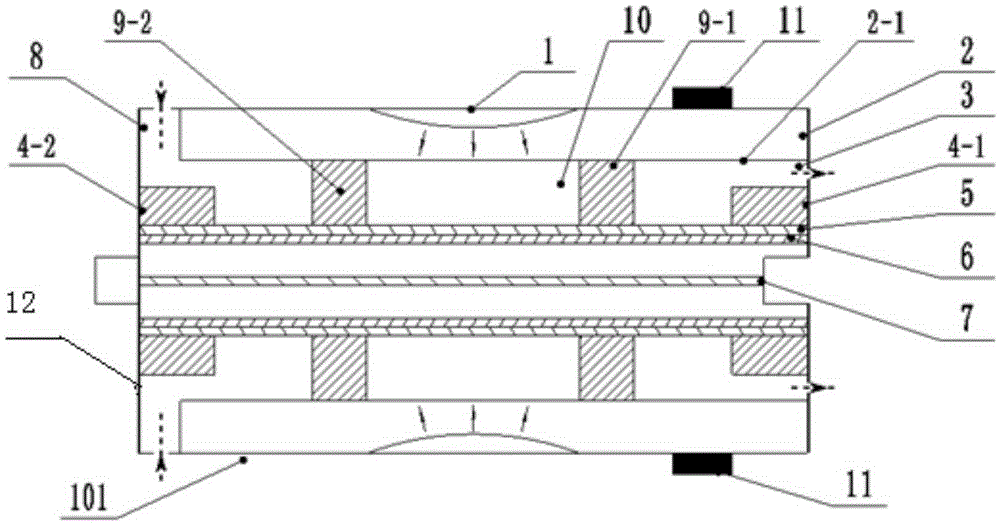

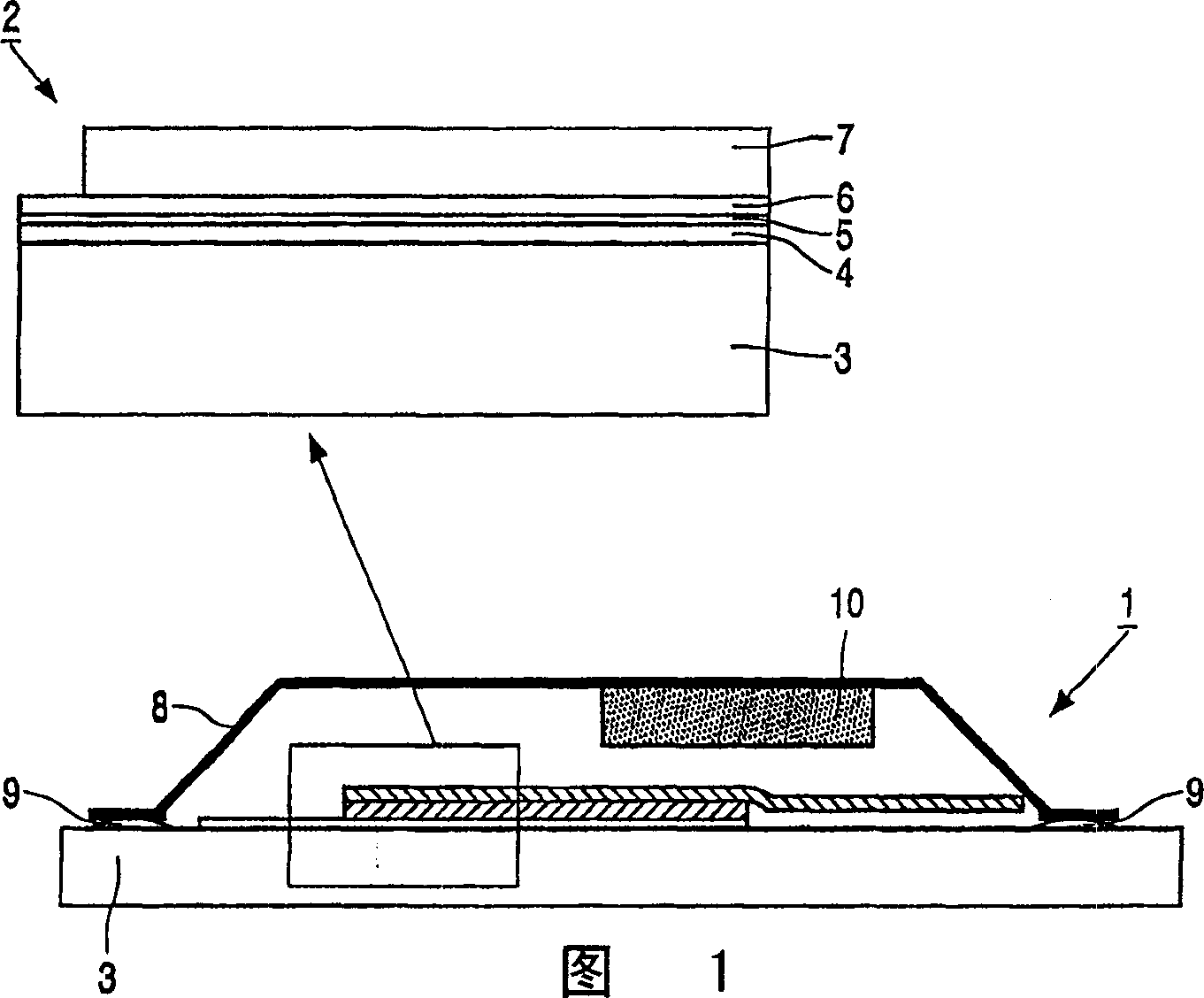

Electronic cigarette oil leakage preventing device adopting light-induced reversible deformation layer and oil leakage preventing method

ActiveCN105411010ASolve the oil spill problemSolve the problem of oil spillTobacco devicesEngineeringElectronic cigarette

The invention provides an electronic cigarette oil leakage preventing device adopting a light-induced reversible deformation layer. The electronic cigarette oil leakage preventing device comprises a housing (12), a light source accommodation cavity (2) provided with a light source (1) in the inside and provided with a transparent light outlet wall (2-1), a light-induced reversible deformation layer (5) provided with a lighted side surface and a back-lighted side surface, and an elastic layer (6) tightly attached to the back-lighted side surface of the light-induced reversible deformation layer (5), wherein the lighted side surface faces the light source (1), an airflow outlet channel is defined between the lighted side surface of the light-induced reversible deformation layer (5) and the light outlet wall (2-1) and the housing (12), and an air inlet hole (8) and an air outlet hole (3) of the airflow channel are respectively formed in the housing (12), one end of every one of the two holes is fixedly connected with the light outlet wall (2-1) or the housing (12), the other end of every one of the two holes is attached to the lighted side of the light-induced reversible deformation layer (5), and therefore blocking of the airflow channel is formed.

Owner:CHINA TOBACCO YUNNAN IND

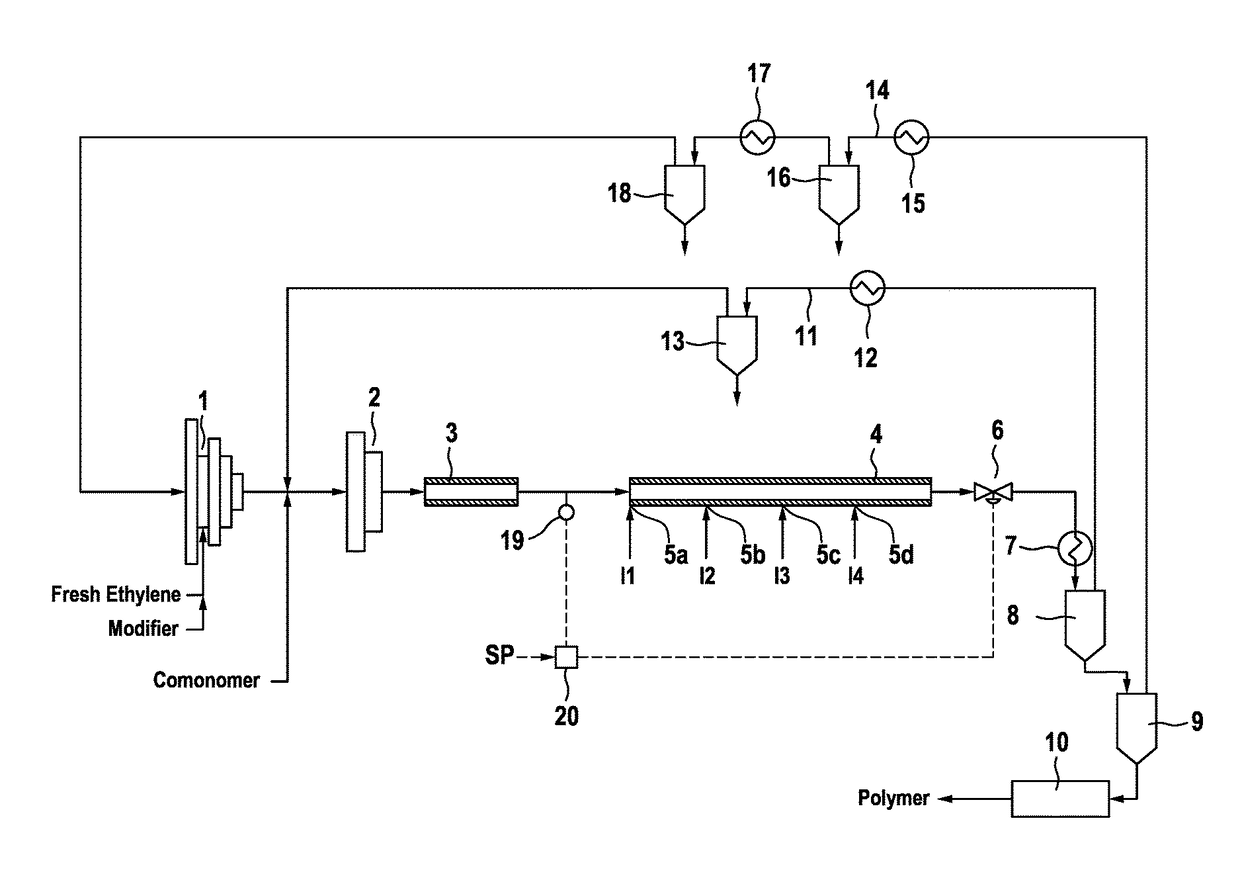

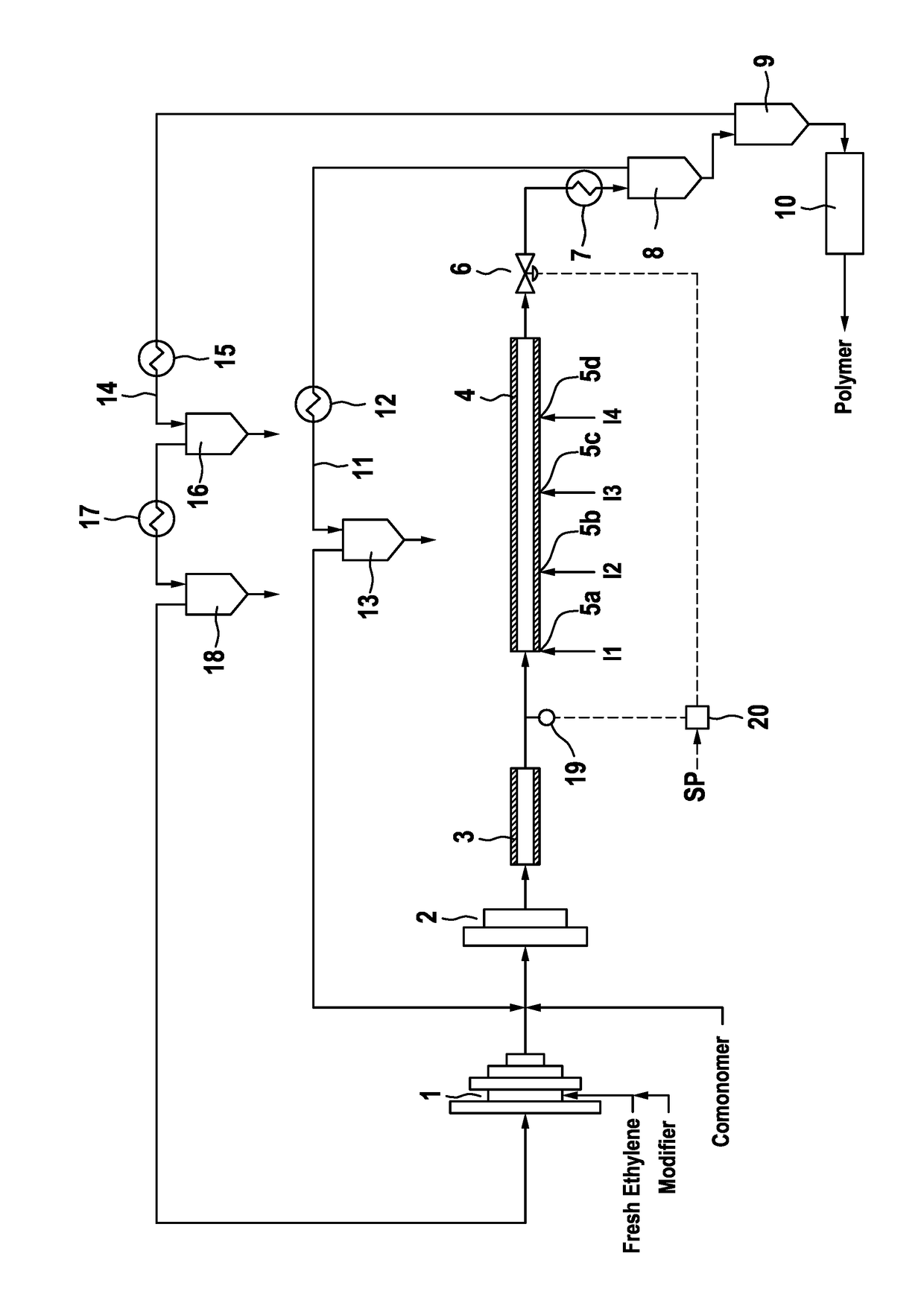

High-pressure polymerization process of ethylenically unsaturated monomers

ActiveUS9908950B2Quick leak detectionAvoid accumulationProcess control/regulationFluid pressure measurementDecreased pressureHigh pressure

Owner:BASELL POLYOLEFINE GMBH

Leak inspection method and leak inspector

InactiveUS7818133B2Correction coefficientQuick leak detectionDetection of fluid at leakage pointFlow propertiesEngineeringPressure difference

Owner:COSMO INSTR

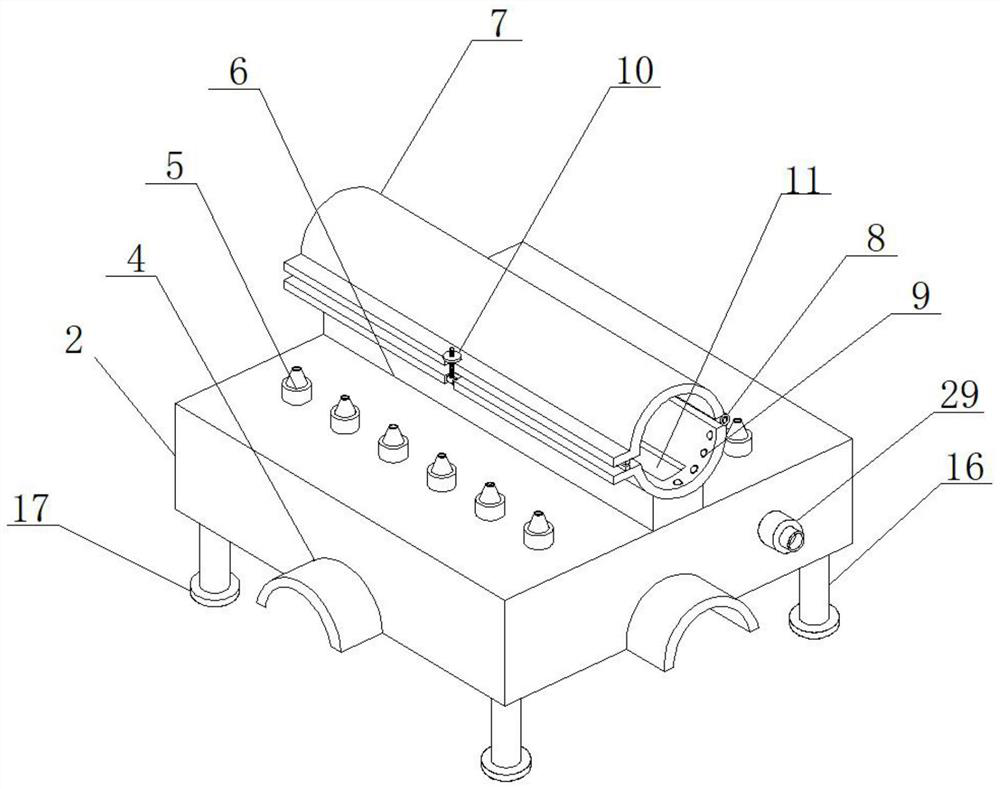

Novel pipeline rapid leak detection device capable of releasing colored gas

ActiveCN112284636AFunction increaseEasy to useDetection of fluid at leakage pointGas passingStructural engineering

The invention provides a novel pipeline rapid leak detection device capable of releasing colored gas, which comprises a leak detection device body. The leak detection device body comprises a lower boxbody and an upper box body, an upper arc-shaped plate is welded on the upper box body, a lower arc-shaped plate is welded on the lower box body, the upper arc-shaped plate is matched with the lower arc-shaped plate, spray heads are arranged on the outer wall of the upper box body and the outer wall of the lower box body correspondingly, rubber sealing nozzles are installed in the spray heads, connecting plates are welded to the upper box body and the lower box body, fixing frames are welded to the connecting plates, and rotating shafts are installed on the fixing frames. When the rapid pipeline leak detection device capable of releasing the colored gas is used, the tank body filled with the colored gas is matched with the connector through the pipeline, so that the required colored gas isinjected into the box body, and the colored gas in the box body is sprayed out from the interior of the nozzle through the change of internal air pressure in a pipeline leakage state, so that the leakage rate of the colored gas is improved. Therefore, the pipeline can be rapidly detected.

Owner:HUBEI LINGTAN ELECTROMECHANICAL EQUIP CO LTD +1

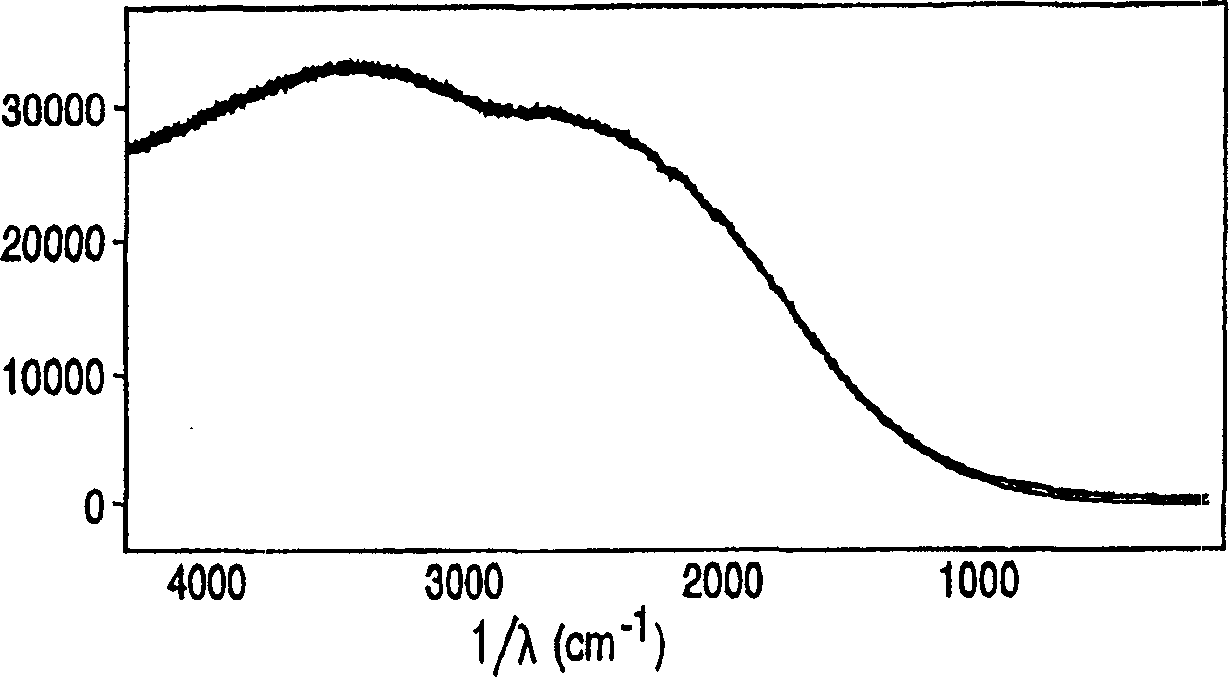

Method and apparatus for leak-testing electroluminescent device

InactiveCN1529820AQuick leak detectionNon-destructiveSemiconductor/solid-state device testing/measurementElectroluminescent light sourcesNon destructiveOrganic electroluminescence

A method of detecting the leak-in of oxygen in an organic electroluminescent device via the extent of photo-degradation of the electroluminescent organic material is described. The photo-degradation of the electroluminescent organic material is induced by the presence of oxygen, and can be detected by comparing the photo luminescence of the material, before and after illumination of the material with light (e.g. form a laser). Photo-degradation due to the presence of oxygen in an encapsulated organic electroluminescent device is evidence for a leak in the device, which leak will result in a shorter lifetime of the device. The invention provides a fast, non-destructive method of inspecting organic electroluminescent devices on leakage, immediately after their production. Leak devices can be identified and discarded, even on-line.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

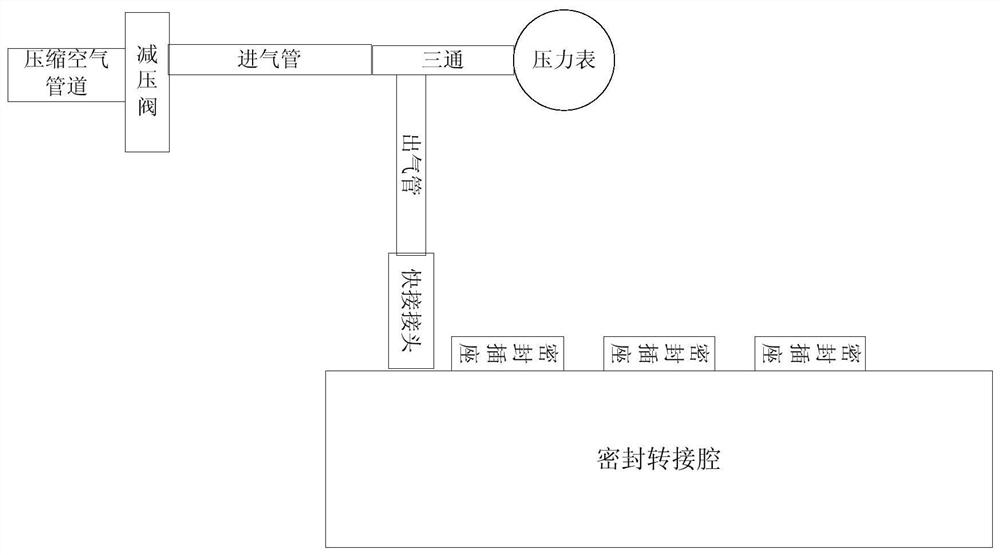

Method for testing sealing performance of crimping terminal assembly of crimping electric connector for cable network

ActiveCN111947846AImprove efficiencyQuick leak detectionDetection of fluid at leakage pointStopwatchWater storage tank

The invention discloses a method for testing the sealing performance of a crimping terminal assembly of a crimping electric connector for a cable network, and the method comprises the following steps:1) filling a water storage device with water, and putting a sealed switching cavity into the water storage device; (2) opening a compressed air pressure reducing valve, wherein it is required that noobvious bubbles leak out of a sealed through connection cavity placed in the water storage tank; 3) inserting the wire end of the crimping assembly to be detected into the mounting hole of the sealing socket on the sealing adapter cavity, and putting the sealed transfer cavity into a water storage device; 4) putting the processed contact pin or jack terminal of the crimping assembly to be detected into a test tube, inverting the opening of the test tube, emptying air in the test tube, fixing the test tube and the test tube fixing tool, and putting the test tube and the test tube fixing tool into a water storage device; 5) opening the compressed air valve again, and adjusting the pressure value of the compressed air outlet; 6) observing the plugging position of the sealing socket and the to-be-detected crimping assembly wire by naked eyes, wherein it is required that no obvious bubbles can be seen; 7) opening a stopwatch to start timing, and checking the sealing performance of the assembly; and 8) closing the compressed air pressure reducing valve, taking out the sealed adapter cavity and the test tube fixing tool from the water storage device, and pulling out the to-be-tested assembly from the sealed socket and the test tube, thereby completing the airtightness test.

Owner:BEIJING SATELLITE MFG FACTORY

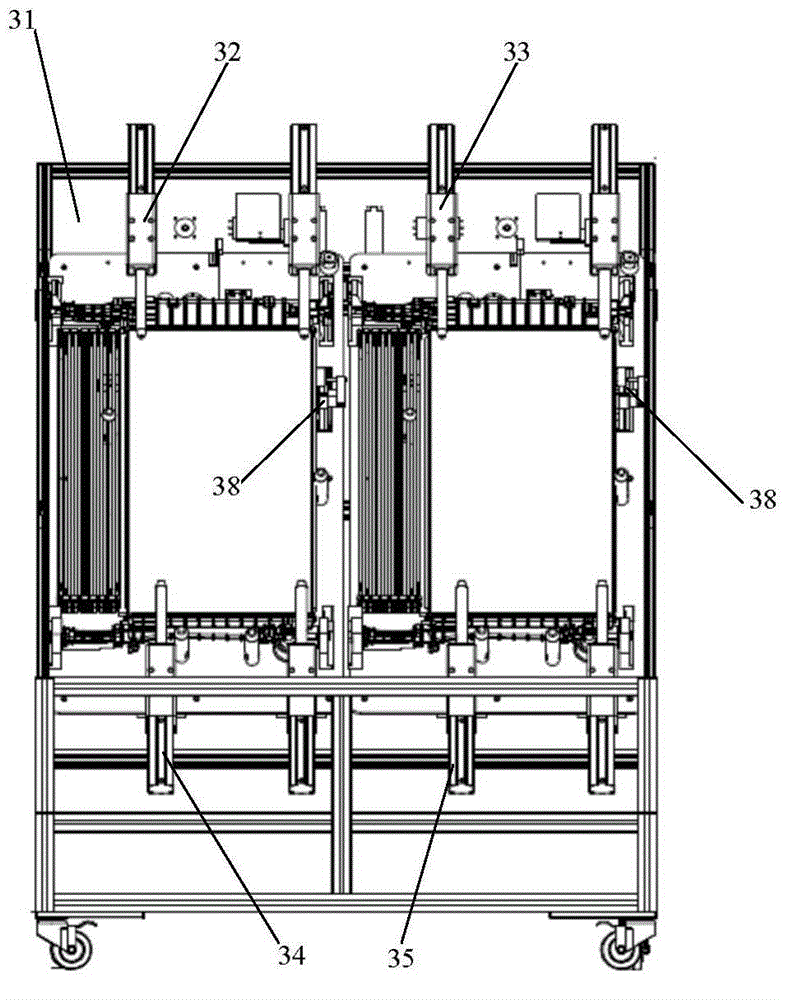

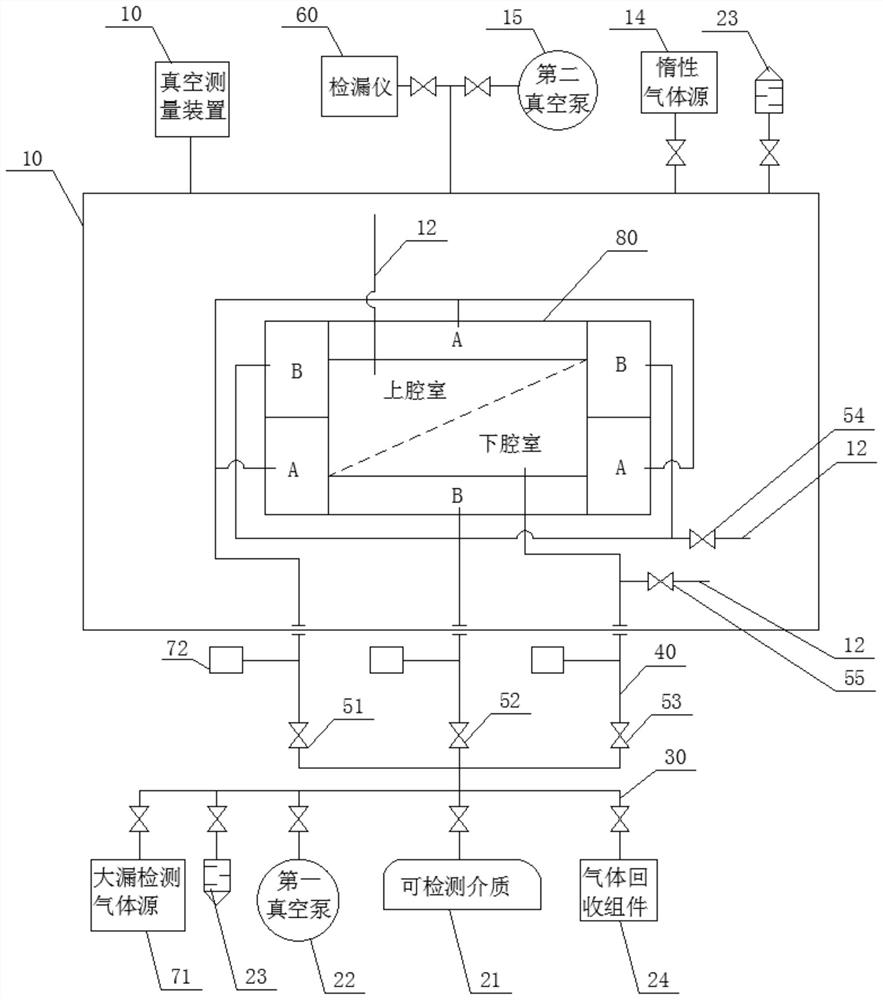

Double-station gastight dry-type leakage detecting method and double-station dry-type leakage detecting equipment

ActiveCN104677573AImprove stabilityImprove accuracyMeasurement of fluid loss/gain rateVacuum pumpingPositive pressure

The invention provides a double-station gastight dry-type leakage detecting method and double-station dry-type leakage detecting equipment. The method comprises the following steps: firstly, respectively placing two to-be-detected products on left and right stations of the double-station dry-type leakage detecting equipment, fixing and clamping the detected products, and extruding and sealing inlets, outlets and gas vents of the products; under a certain negative pressure condition, performing negative-pressure vacuum-pumping on the two products simultaneously to measure product leakage rate value under the negative pressure condition when the two products are in series connection, judging whether the two products have large leakages or not according to the detected leakage rate value, and ending the detection if the two products both have large leakages; otherwise, under a certain positive pressure condition, simultaneously charging dry gas with a certain pressure into the products and then detecting, detecting the leakage rate value obtained by comparing and detecting the two products under a positive pressure condition, and determining leakage conditions of the two products according to the compared and detected leakage rate value. The invention further provides corresponding leakage detecting equipment. The double-station dry-type leakage detecting equipment has the advantages of being stable in performance, quick to detect leakage, high in detection precision and wide in scope of application.

Owner:SDAAC AUTOMOTIVE AIR CONDITIONING SYST CO LTD SHANGHAI

Blast furnace cooling wall leakage detection device

ActiveCN104928423ALeak detection process is simpleEasy to check for leaksCooling devicesProcess efficiency improvementBlast furnace smeltingEngineering

The invention relates to the technical field of blast furnace smelting, aims to solve the technical problems of complex process and high time cost during leakage detection of a blast furnace cooling wall and provides a blast furnace cooling wall leakage detection device which comprises a blast furnace body, a water supply pipe, a water return pipe, multiple water incoming elbow flowmeters, multiple master water incoming pipes, multiple water outgoing elbow flowmeters and multiple master water outgoing pipes. The water supply pipe is arranged around the blast furnace body at a furnace base of the same, each water incoming elbow flowmeter is connected with one end of a cooling water pipe through one master water incoming pipe, the water return pipe is arranged around the blast furnace body at a furnace top of the same, each water outgoing elbow flowmeter is connected with the other end of the cooling water pipe through one master water outgoing pipe, and the water incoming elbow flowmeters and the water outgoing elbow flowmeters are in one-to-one correspondence. Whether the cooling water pipe on the cooling wall is damaged or not is judged by utilizing flow change of the water incoming elbow flowmeters and the water outgoing elbow flowmeters, so that the leakage detection process is simple and convenient, and quick leakage detection of the blast furnace cooling wall is realized.

Owner:武汉钢铁有限公司

Quick helium mass spectrum leakage detecting device for diaphragm inner circle welding joint

ActiveCN109297649AQuick leak detectionAccurate leak detectionDetection of fluid at leakage pointEngineeringHelium

The invention relates to a quick helium mass spectrum leakage detecting device for a diaphragm inner circle welding joint, solves the problem of difficulty in sealing caused by a small inner cavity formed due to a thin wall and welding of the inner circle welding joint, effectively avoids the problem the whole diaphragm box is scrapped due to leakage of inner circle welding joint, and improves theleak detection efficiency greatly. An inner supporting tool, an upper cover and a lower cover, a sealing ring and the like are used for sealing a narrow space formed after the diaphragm inner circlewelding joint is welded, so that quick and accurate helium mass spectrum leakage detecting is realized; compared with the prior art, the inner supporting tool, the upper cover and the lower cover, thesealing ring and the like are used for sealing the narrow space formed after the diaphragm inner circle welding joint is welded, so that diaphragm inner circle welding joint leakage detecting is realized, and the possibility that the whole diaphragm box is scrapped due to leakage of the weld joint of the diaphragm is reduced.

Owner:CAPITAL AEROSPACE MACHINERY +1

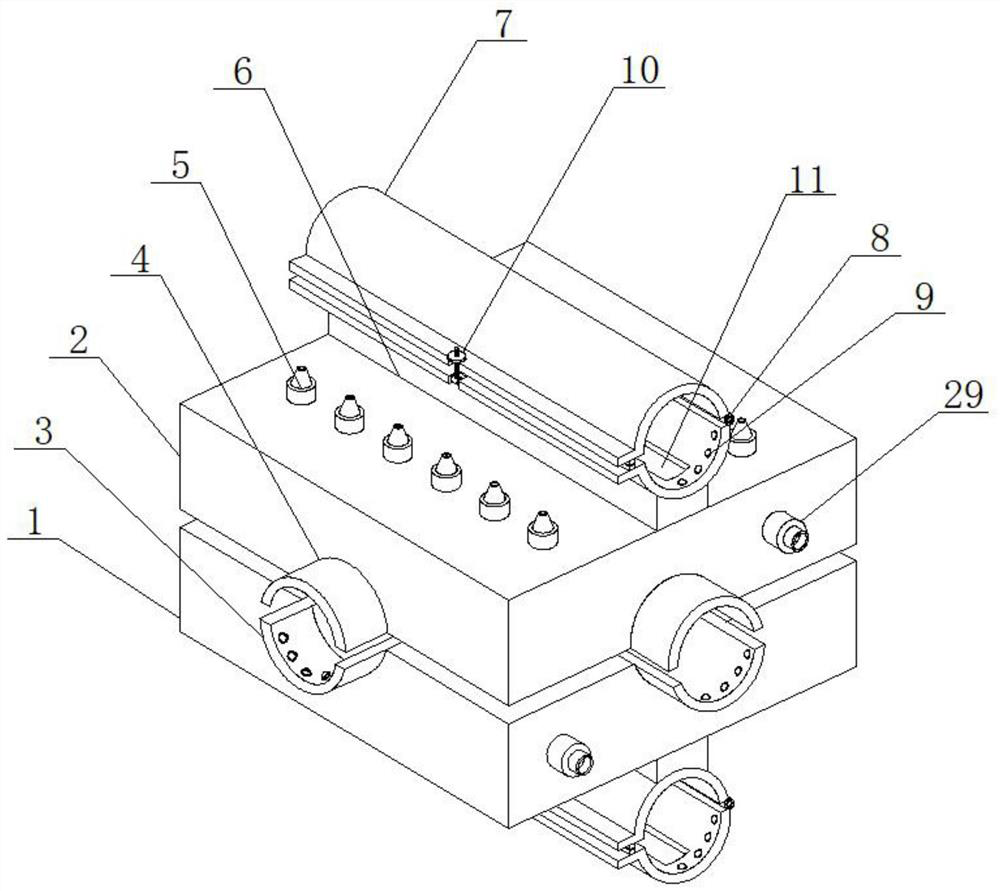

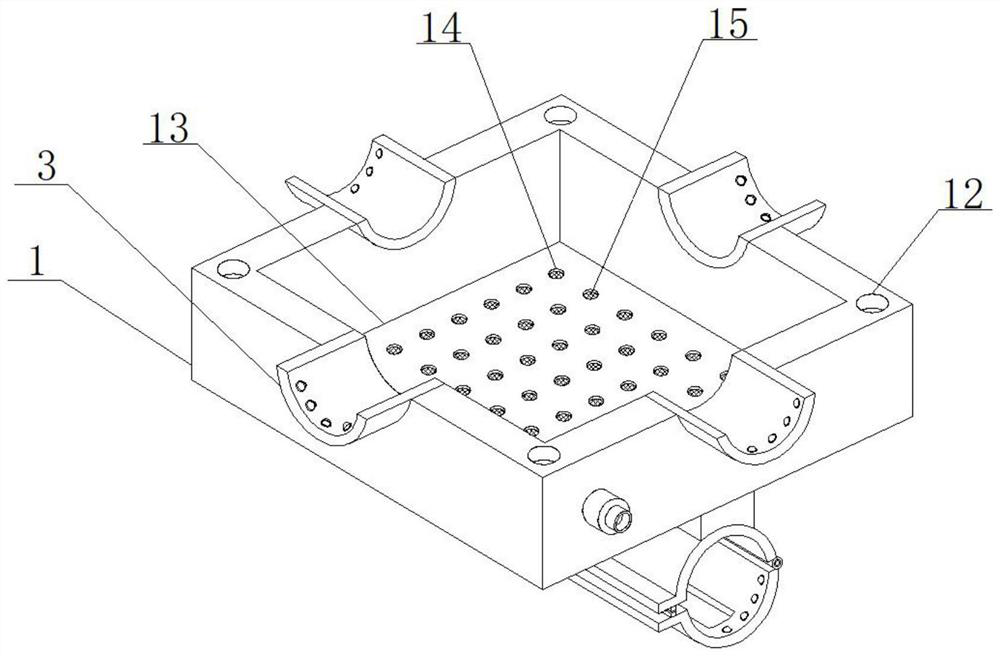

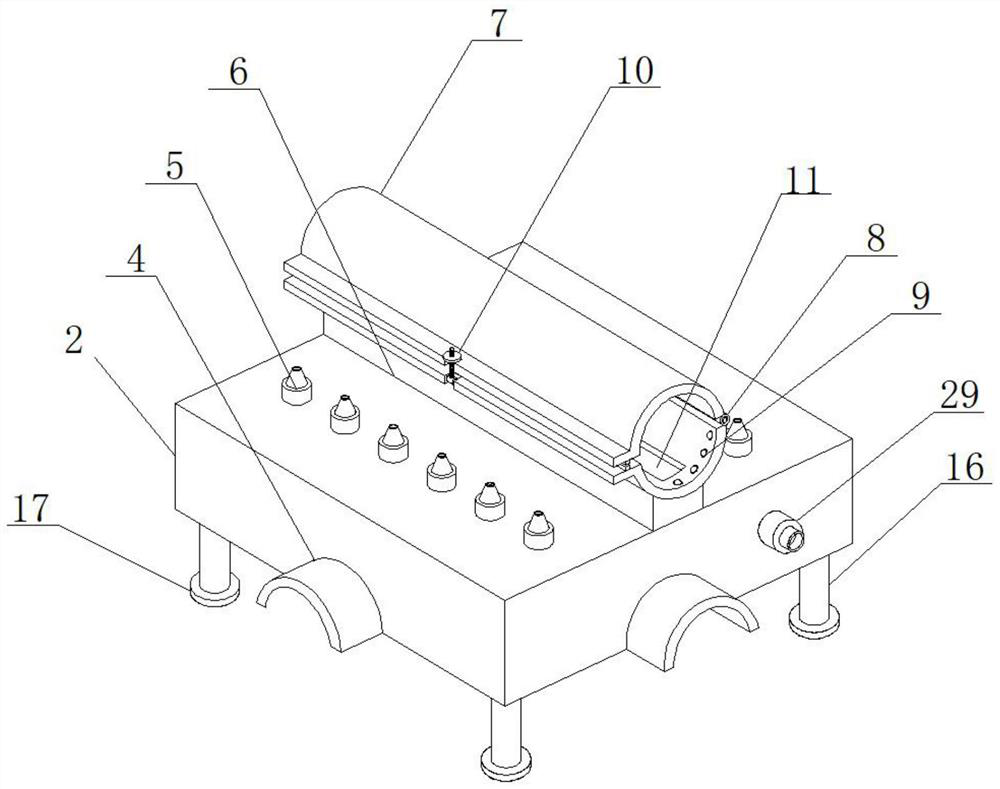

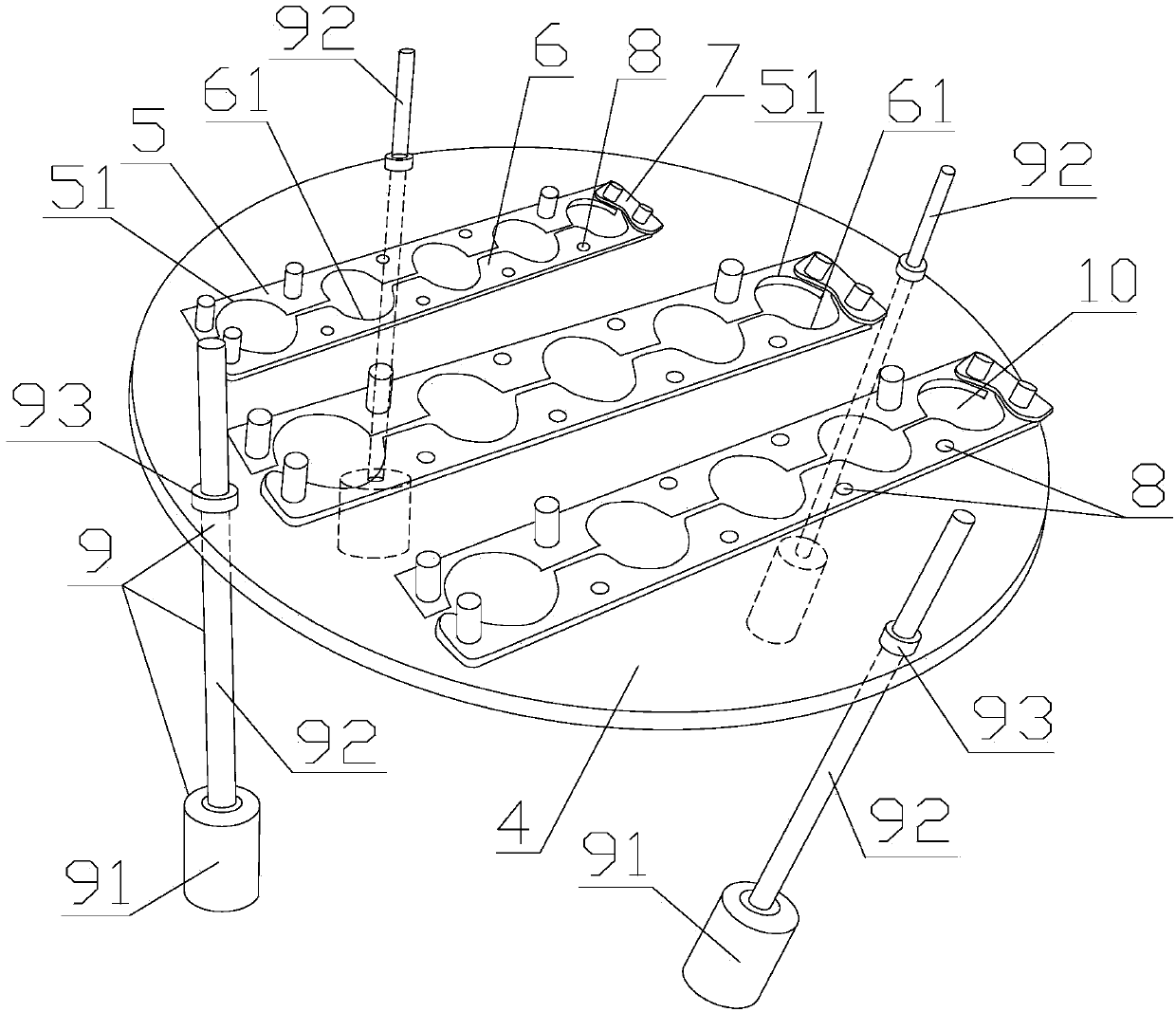

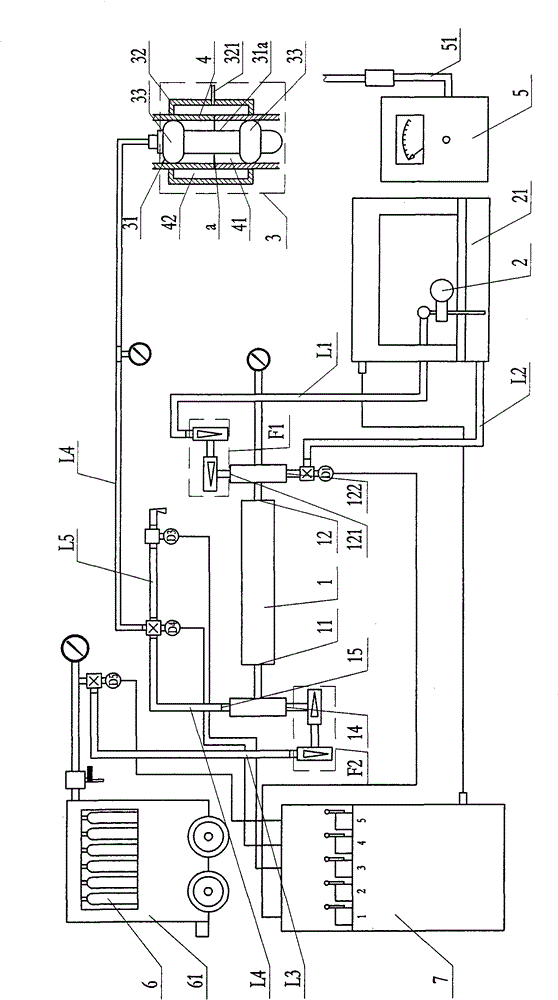

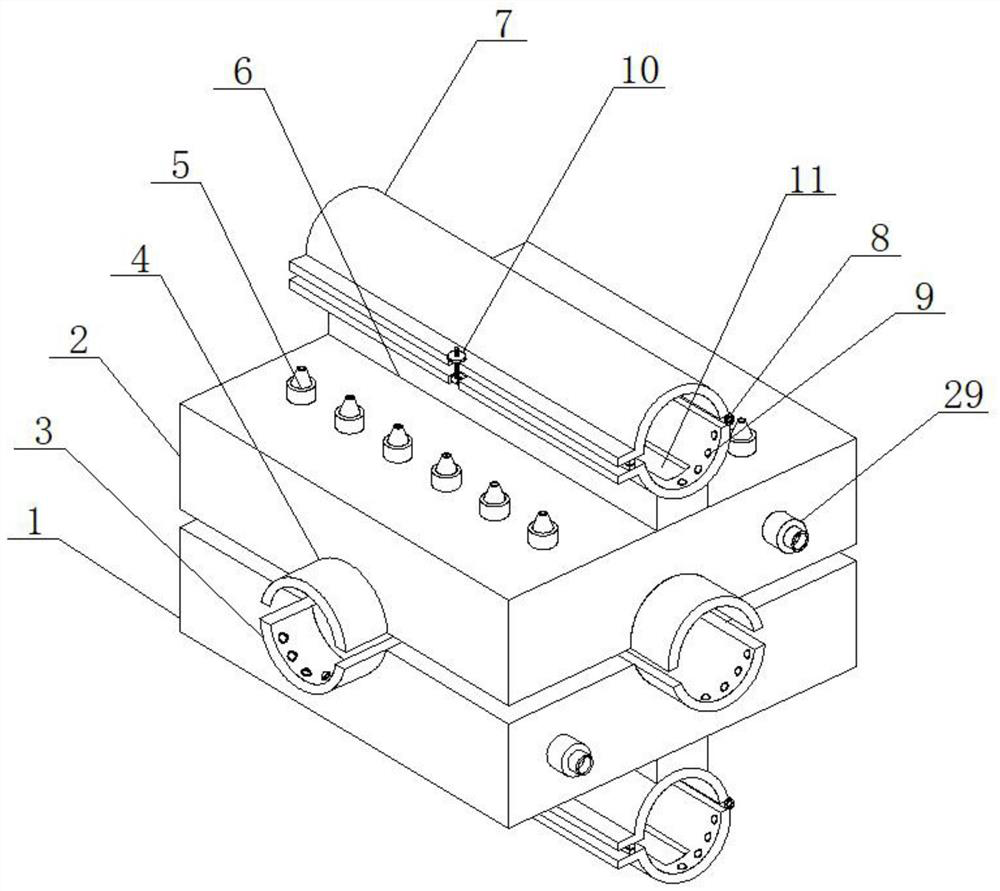

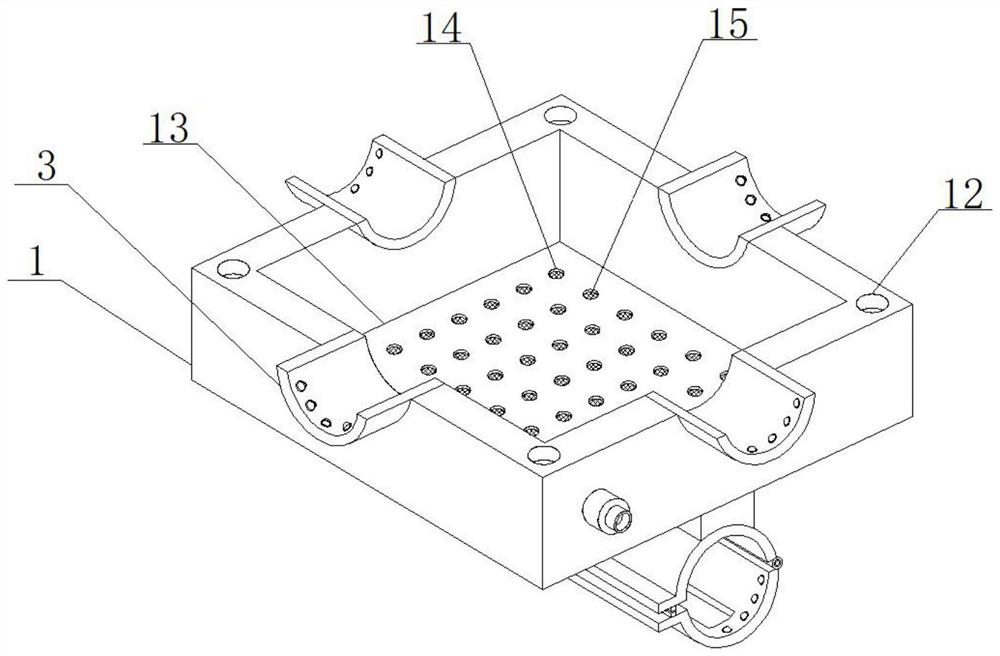

Galvanic pile membrane electrode leakage detection device

PendingCN111912583AQuick leak detectionImprove leak detection efficiencyMeasurement of fluid loss/gain ratePumping vacuumStructural engineering

The invention provides a galvanic pile membrane electrode leakage detection device which is used for detecting leakage of a galvanic pile membrane electrode plate, the galvanic pile membrane electrodeplate is provided with a first chamber and two groups of second chambers, the first chamber comprises an upper chamber and a lower chamber. The device comprises a vacuum box, a clamp, a leakage detection pipeline, a first connecting pipeline, a second connecting pipeline, a valve group, a leakage detector and a vacuum pump for vacuumizing a cavity, the leakage detection pipeline is used for communicating the interior of the vacuum box with one group of the second chamber, the upper chamber and the lower chamber; the second connecting pipeline respectively penetrates through the clamp and is communicated with the lower chamber and the two groups of second chambers; and the valve group comprises a plurality of valves for controlling the connection and disconnection of the first connecting pipeline, the second connecting pipeline and the leakage detection pipeline. The galvanic pile membrane electrode leakage detection device can simultaneously detect the inner micro leakage of a plurality of cavities relative to the plurality of cavities and the outer leakage of the plurality of cavities, and can quickly detect the leakage of the membrane electrode plate.

Owner:江门龙浩智能装备有限公司

Device and method for accurate leak checking on blast furnace tuyere small sleeves

ActiveCN106929620ASimple structureEasy to operateCooling devicesChecking devicesLeaking waterEngineering

The invention provides a device and method for accurate leak checking on blast furnace tuyere small sleeves, and belongs to the technical field of blast furnace inspection tools and methods. The device and method are used for leak checking on blast furnace tuyere small sleeves. According to the technical scheme, a water inlet pipe chuck front connecting part is connected with one end of an unfastened water inlet pipe chuck trough front threads, a water inlet pipe chuck rear connecting part is connected with the other end of the unfastened water inlet pipe chuck through rear threads, and a steam trap is installed between the water inlet pipe chuck front connecting part and the water inlet pipe chuck rear connecting part. According to the checking method, the characteristic that the potassium permanganate changes the color after dissolving in water is utilized, which sleeve is leaking water can be determined according to the changes of the color of leaking water, and the results of leak checking are visual and accurate. The device is simple in structure and convenient to operate. The device and the method are the pioneering technologies for checking leak of blast furnace tuyere small sleeves, the problem, which is not effectively solved for a long time, that whether water leak happens cannot be judged is solved with the simple checking device and method, the problem that in the prior art, the sleeve which is leaking cannot be accurately positioned is further solved, and therefore, the device and the method have completely positive practical effect on production.

Owner:HEBEI IRON AND STEEL

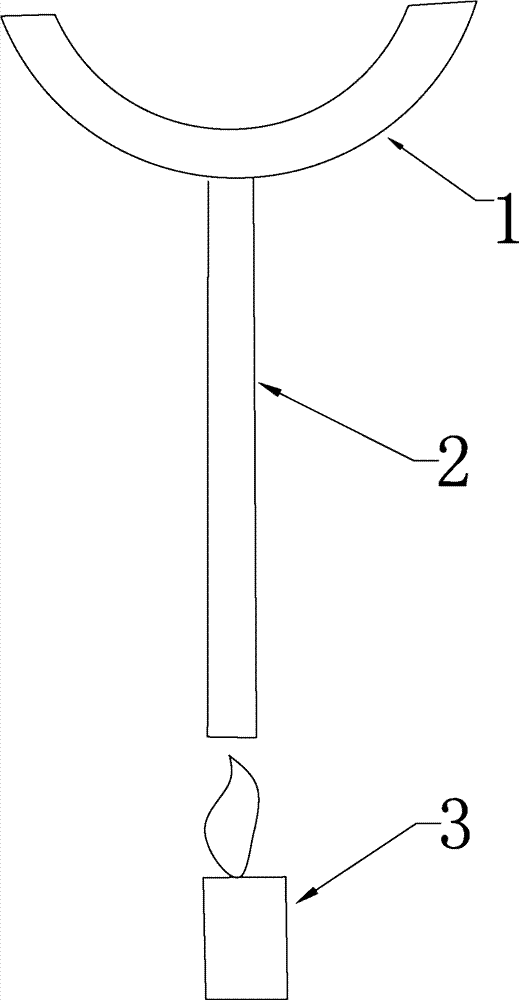

Leak detector of vacuum system

InactiveCN102759432AEnsure personal safetyConvenient and effective detectionDetection of fluid at leakage pointPipeMechanical engineering

The invention belongs to the technical field of leak detection for pipelines of vacuum systems and particularly relates to a leak detector of a vacuum system. The leak detector comprises a detection part, a connection part and a sensing device, wherein the connecting part is provided with a hollow pipe, the detection part is provided with a detection hole, one end of the hollow pipe is connected with the detection hole of the detection part, an air runner is formed between the detection hole and the hollow pipe, and the sensing device is arranged at the other end of the hollow pipe. When the leak detector is used, a unit is unnecessary to decelerate and stop and can be used under a normal operation state, not only is time consumption prevented, but also losses caused by continuous top can be reduced, the cost can be saved, furthermore, the personal safety of workers can be guaranteed and leaks can be rapidly detected and handled as soon as possible.

Owner:DONGGUAN NINE DRAGONS PAPER IND

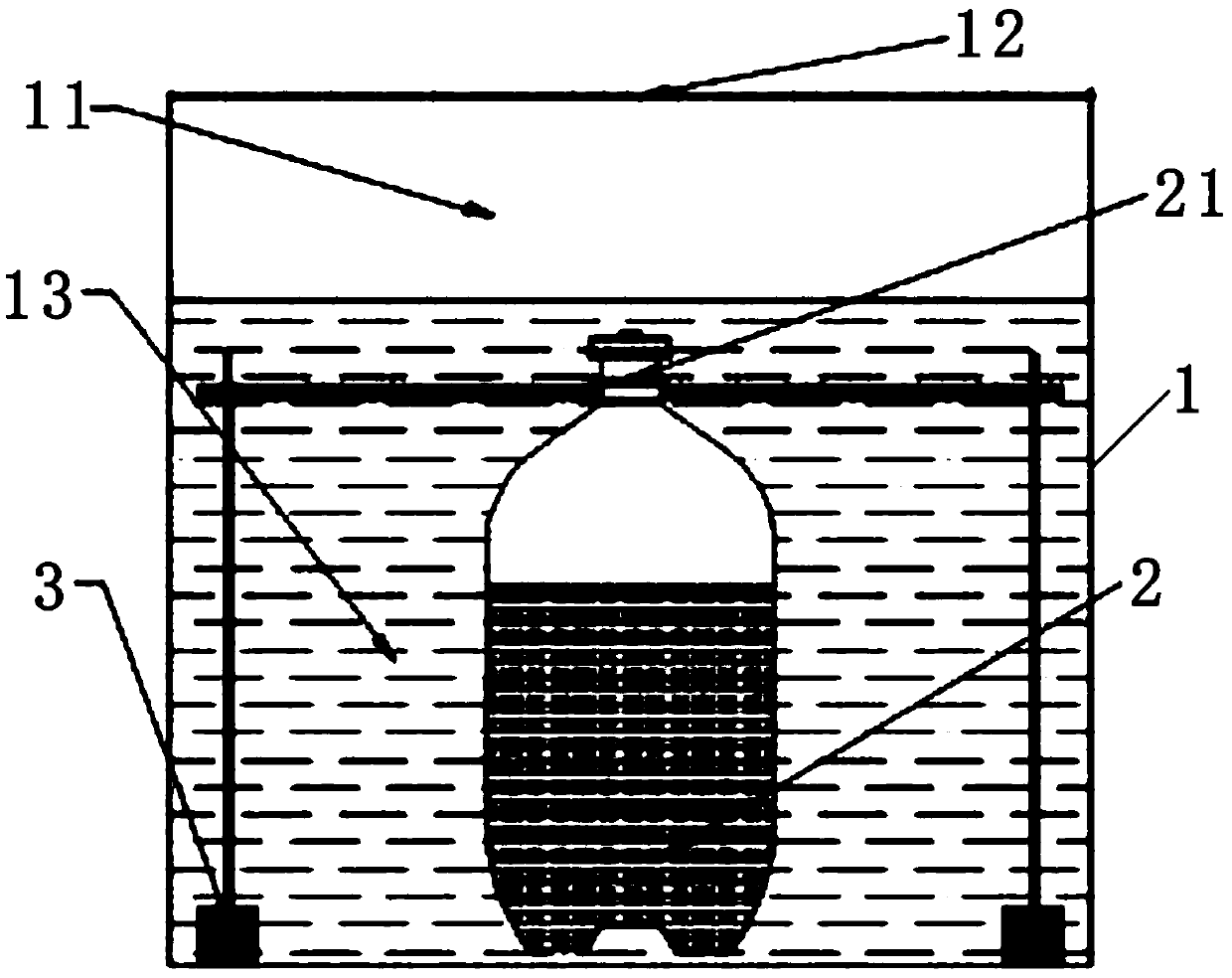

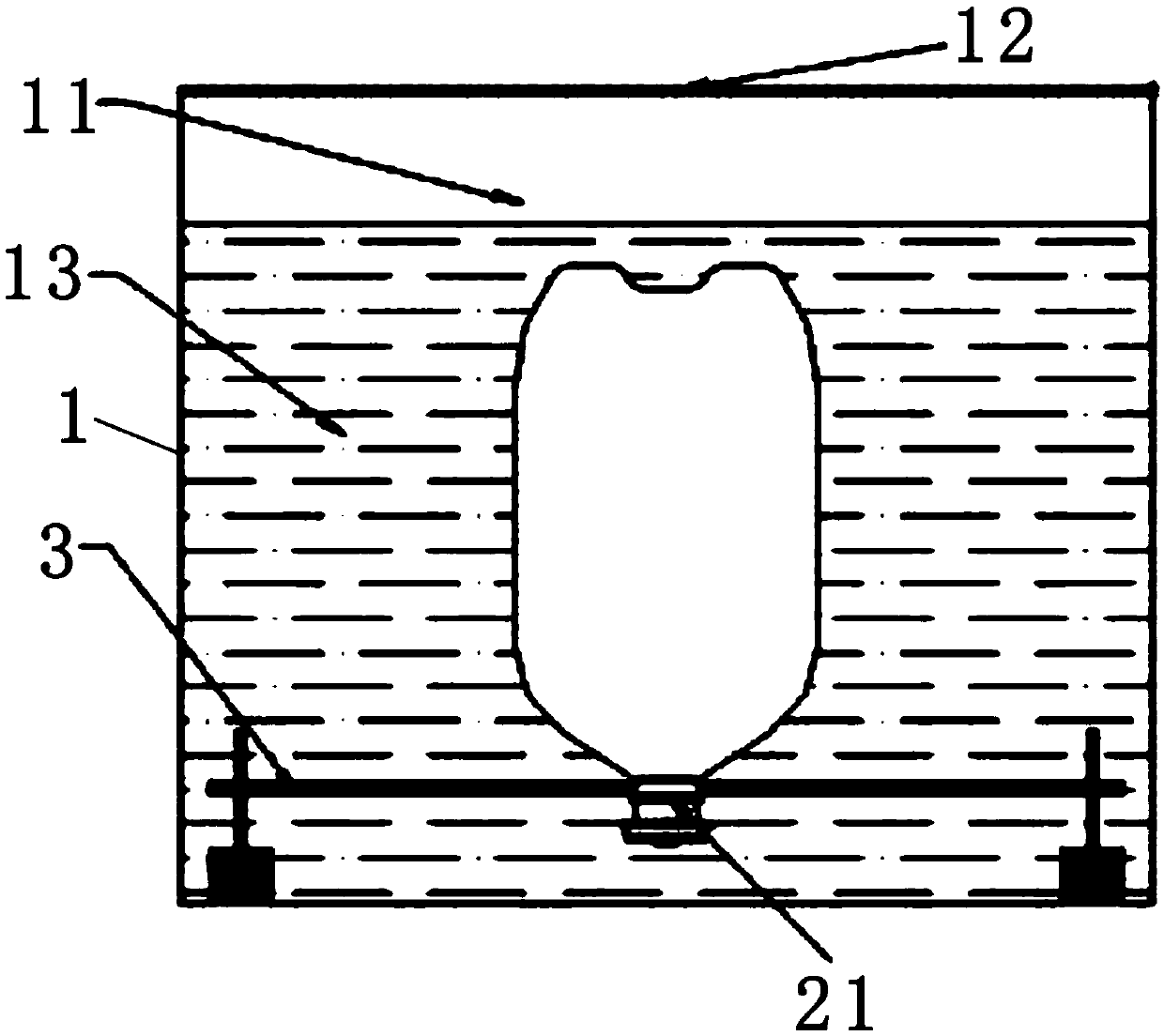

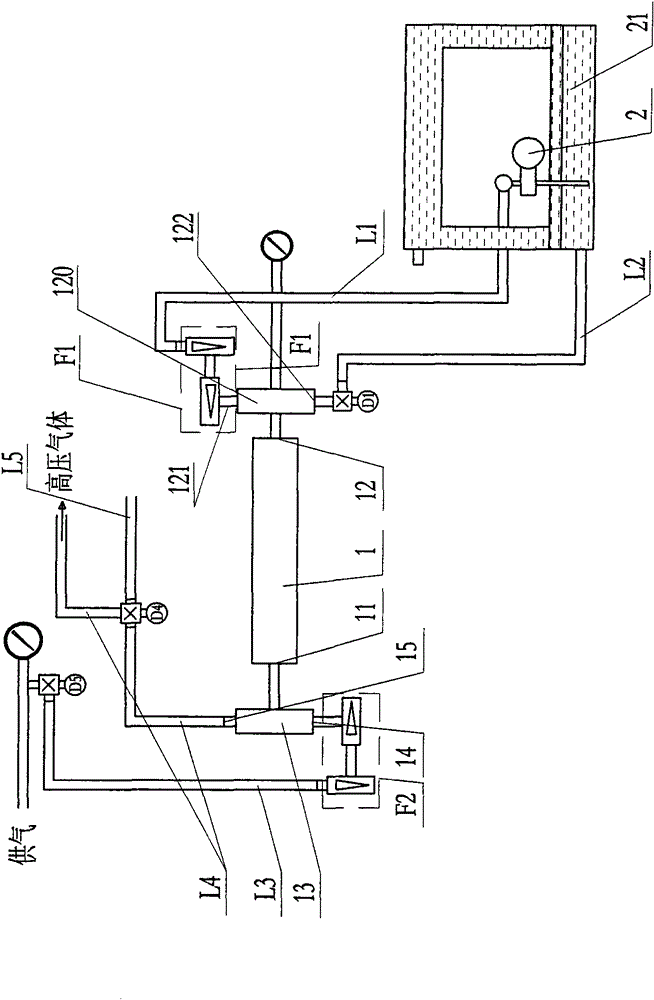

Infusion bottle leak detection device and leak detection method

ActiveCN107449558BEasy to operateQuick leak detectionDetection of fluid at leakage pointVacuum pumpingControl system

The invention discloses an infusion bottle leak detection device and a leak detection method thereof. The infusion bottle leak detection device comprises a vacuum tank, an infusion bottle fixation frame, a vacuum-pumping device and a control system. The vacuum tank is provided with a vacuum cavity, an opening of which is upward; the vacuum cavity of the vacuum tank is filled with purified water; the vacuum cavity of the vacuum tank is internally provided with a infusion bottle fixation frame arranged in the purified water; the vacuum-pumping device is communicated with the top portion of the vacuum cavity of the vacuum tank; the vacuum-pumping device is in electrical communication connection with the control system; and the upper opening of the vacuum cavity of the vacuum tank is sealed by a seal top plate. The infusion bottle fixation frame comprises a support disk, infusion bottle bottleneck clamps and support rods. The support disk is provided with the plurality of infusion bottle bottleneck clamps. The infusion bottle fixation frame clamping infusion bottles is placed in the vacuum tank filled with the purified water, so that by observing whether the bottleneck of each infusion bottle has bubbles, a rapid leak detection purpose can be realized.

Owner:SICHUAN KELUN PHARMA CO LTD

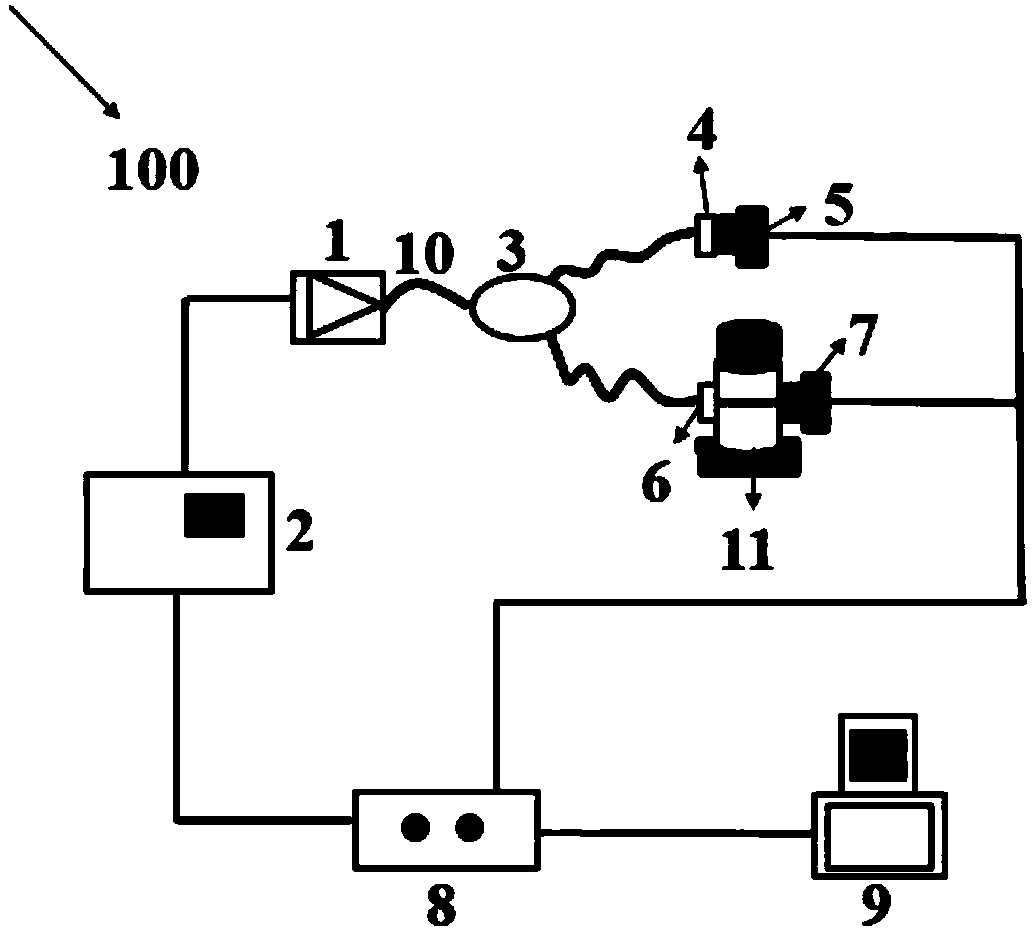

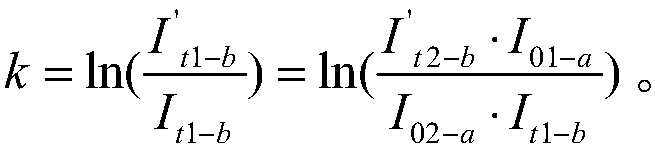

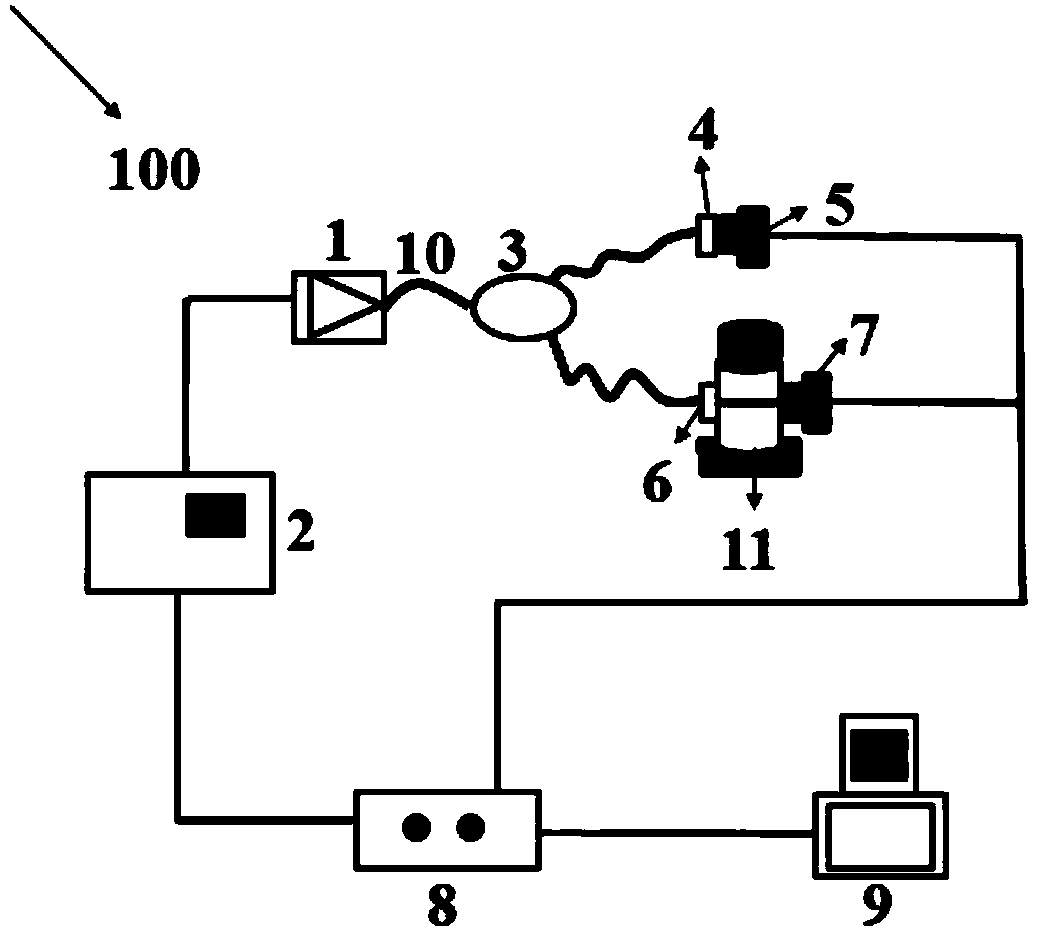

Penicillin bottle leakage detection device based on dual wavelength-TDLAS technology and measurement method thereof

ActiveCN108931346ASealing without interferenceQuick leak detectionFluid-tightness measurement using lightElectricityLight beam

The invention discloses a penicillin bottle leakage detection device based on a dual wavelength-TDLAS technology and a measurement method thereof. The device comprises a laser, a laser controller, anoptical fiber coupler, a first collimator, a first detector, a second collimator, a second detector, an acquisition card and a computer, wherein the laser controller is electrically connected with thelaser; the optical fiber coupler is connected with the laser; the first collimator is used for collimating laser beams with a laser intensity ratio to be a; the first detector is fixed on the first collimator; the second collimator and the second detector are fixed at two sides of the penicillin bottle body; the acquisition card is electrically connected with the first detector and the second detector; and the computer is electrically connected with the acquisition card. The method comprises the following steps: the laser is adopted to output two laser beams with different output wavelengths,the two laser beams are divided to two kinds of laser beams with the laser intensity ratios to be a and b by the optical fiber coupler, the collimators are adopted to collimate the split laser beams,the split laser beams are received by the detectors, the beams are acquired by the acquisition card after initial intensity and transmitting intensity are obtained, the optical signals are convertedto electric signals and are then transmitted to the computer for data processing, and the leakage coefficient of the penicillin bottle is obtained.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

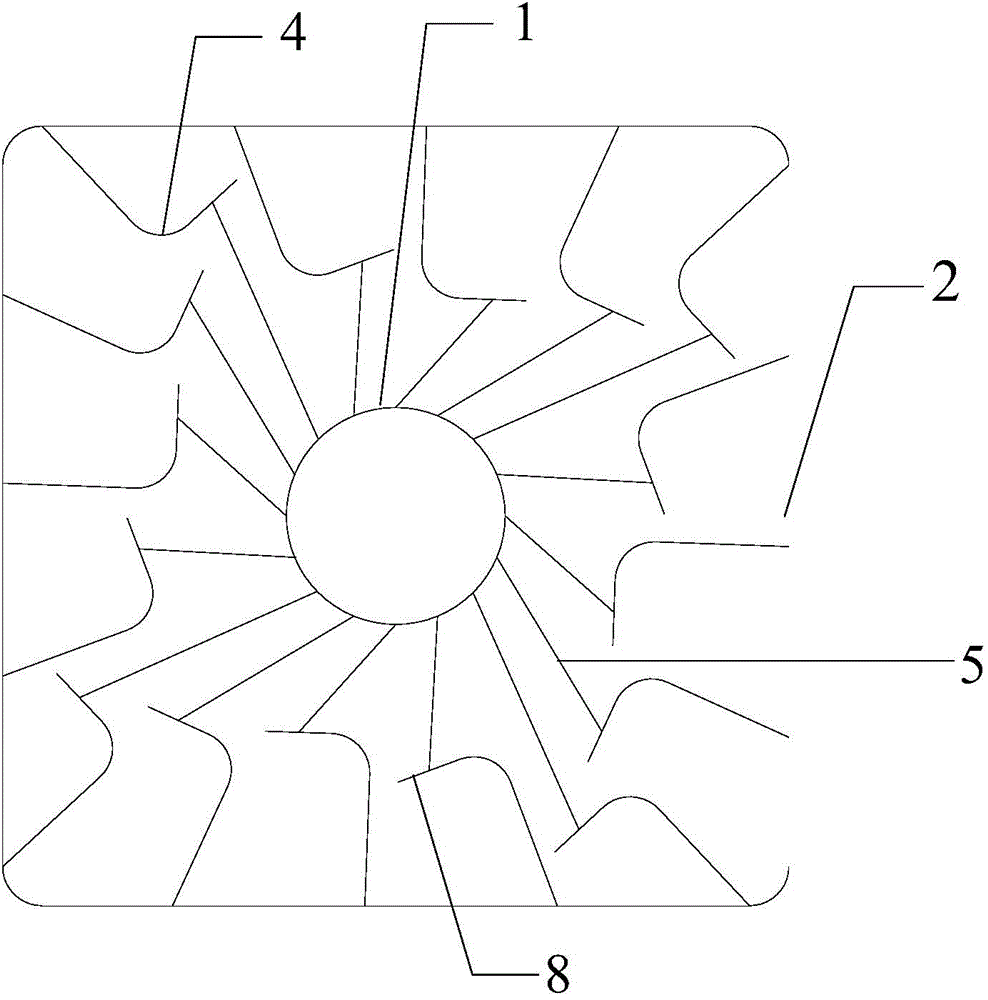

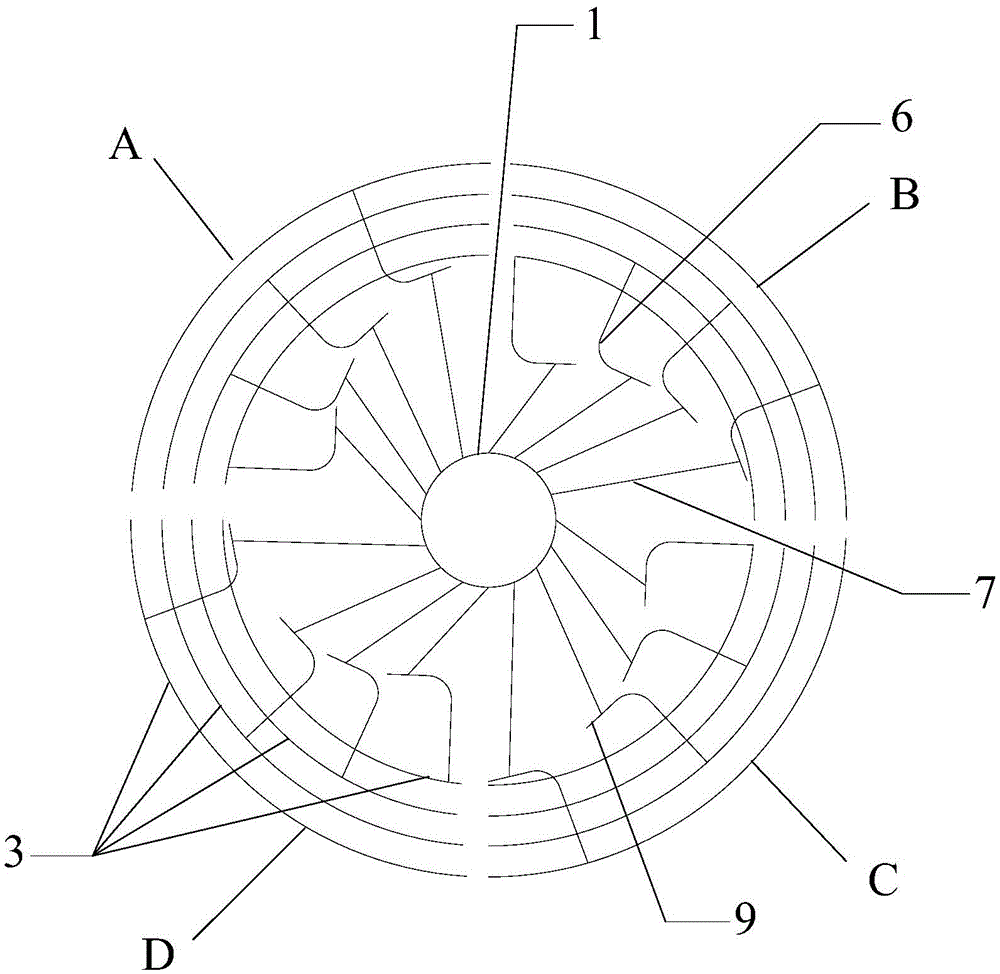

Machining method for condensation pipe of condenser

The invention provides a machining method for a condensation pipe of a condenser. The problems that an existing condensation pipe machining method is complicated and production cost is high can be solved. The method includes the following steps that first, a head is made, and then a stretcher is used for conducting multi-pass stretching on a copper alloy pipe blank; second, straightening is performed, and then a copper alloy pipe is subjected to saw cutting and deburring according to the required length; third, oil stains on the surface of the copper alloy pipe are scrubbed away, and copper cuttings inside the copper alloy pipe are blown down; fourth, annealing is conducted; fifth, internal threads and external fins of the copper alloy pipe are machined with a wire rolling mill and accordingly the condensation pipe can be prepared; sixth, straightening is performed again; seventh, total air tight testing is carried out, qualified products are put into an ultrasonic cleaning machine tobe cleaned and finally are aired or dried, and unqualified products are scraped; and eighth, finished product storage is conducted.

Owner:无锡市欣明换热新材料科技有限公司

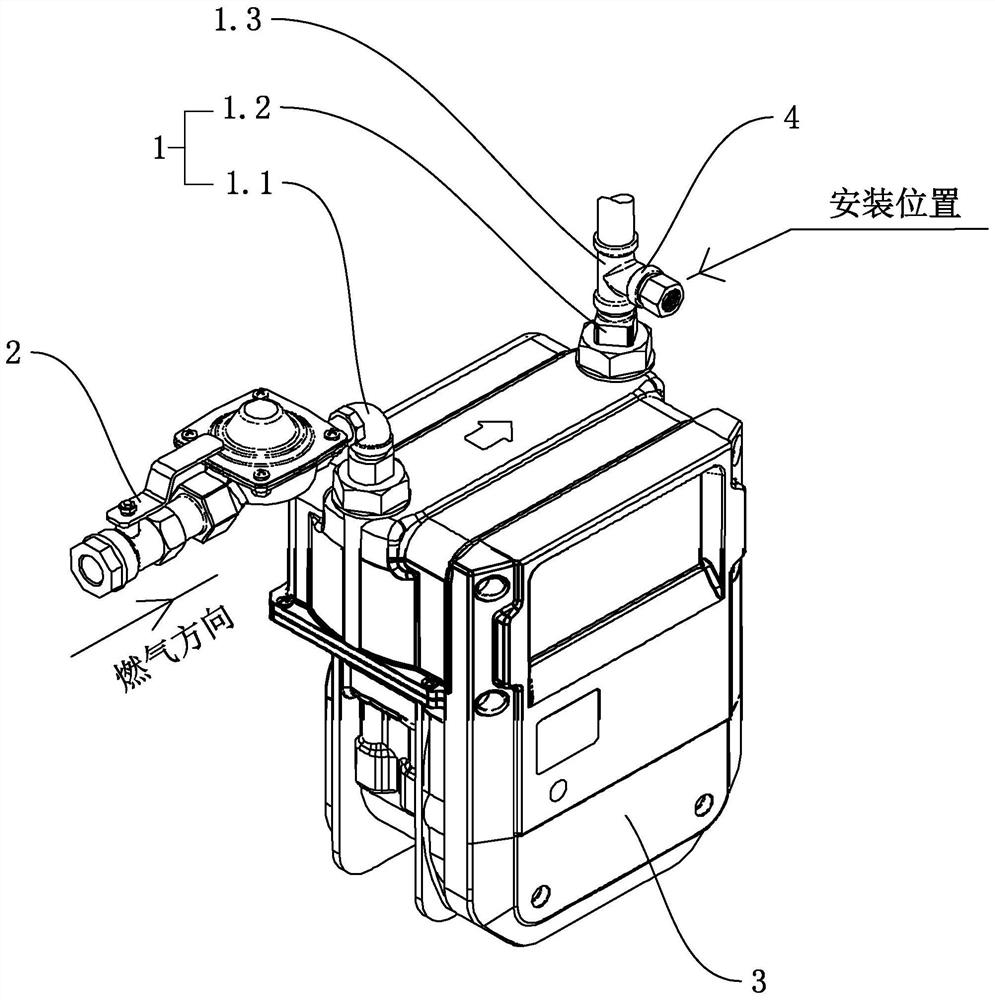

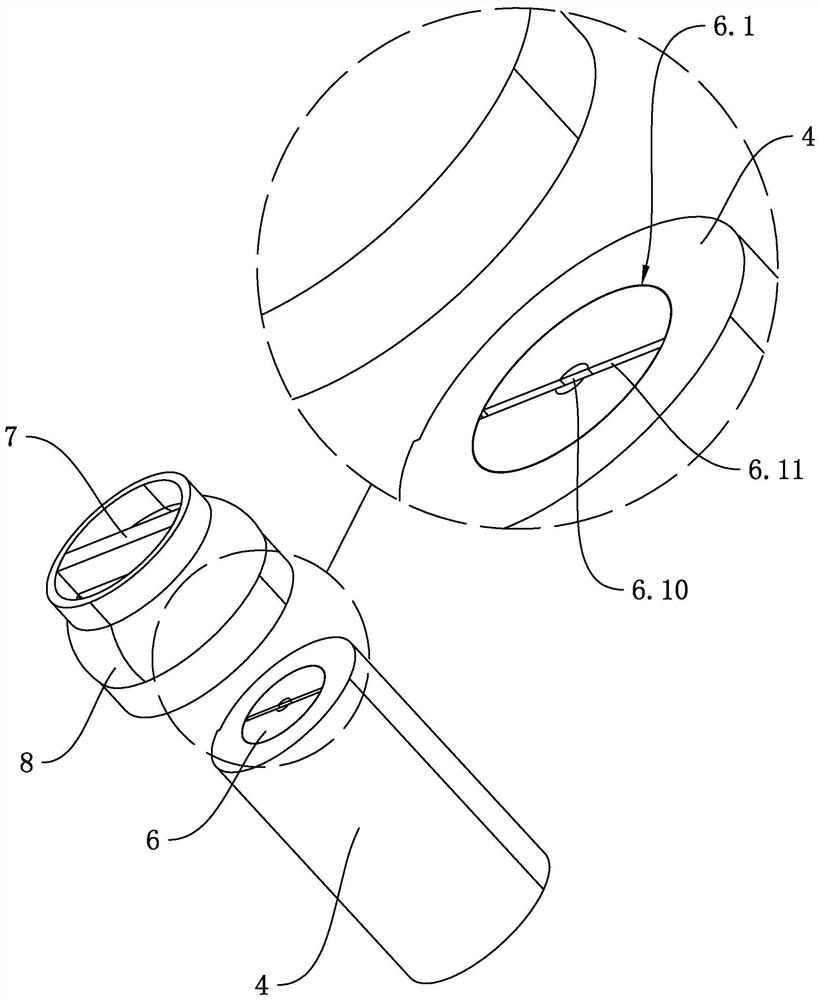

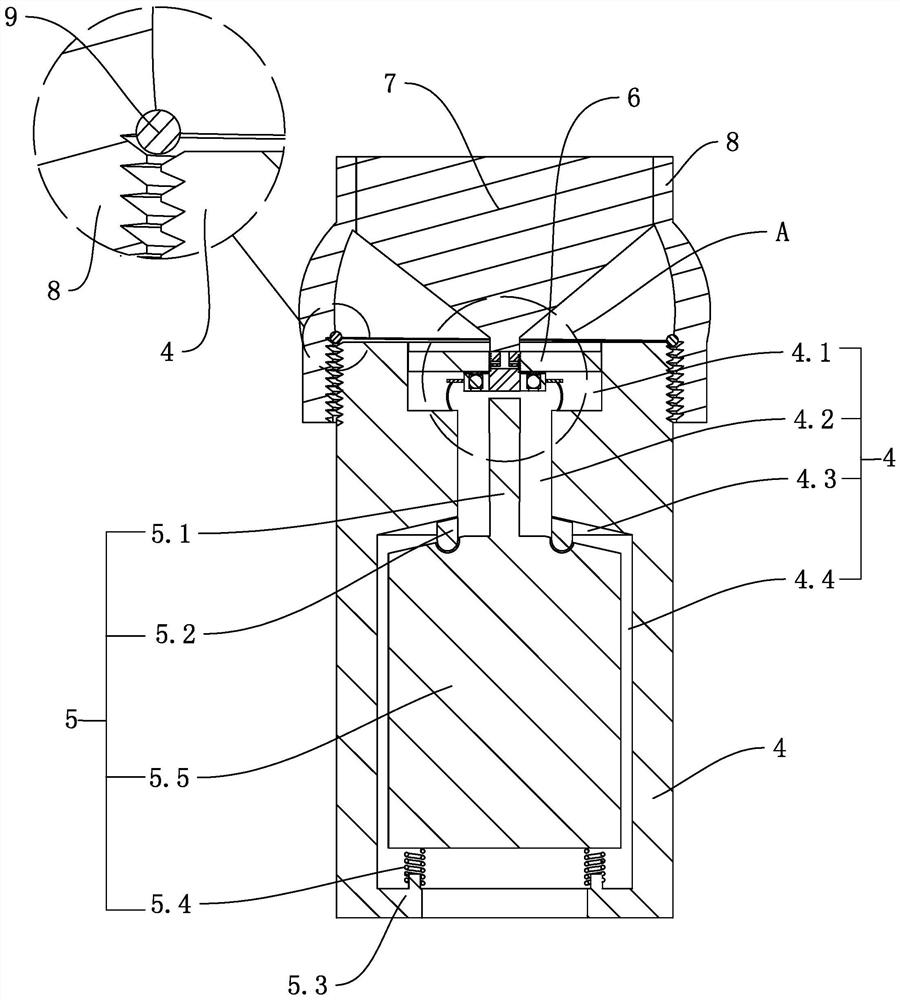

A natural gas rapid pressure measurement leak detection equipment and leak detection method

ActiveCN111473927BPlay a double blocking roleImprove detection efficiencyMeasurement of fluid loss/gain rateLine tubingCheck valve

The invention relates to a natural gas rapid pressure measurement leak detection device and a leak detection method, wherein the leak detection device includes a gas pipeline, the gas pipeline is provided with an opening and closing valve for opening and closing the gas pipeline, the gas pipeline is connected with a three-way pipe, and the three-way pipe One nozzle is a pressure measuring nozzle, and the pressure measuring nozzle is provided with a check valve for opening and closing the pressure measuring nozzle and a plug for blocking the pressure measuring nozzle, and the plug is provided with a plug penetrating from the outer surface of the plug to the inner surface. The threaded hole, the threaded push rod that matches the threaded hole, the threaded sleeve at the end of the pressure measuring pipe mouth is provided with a threaded plug, and the other end of the threaded plug connected with the pressure measuring pipe mouth is connected with a pressure gauge, and the threaded plug is provided with a As the threaded plug moves in the radial direction of the pressure measuring tube mouth, the threaded push rod moves the screw blade in the axial direction of the plug, and the threaded push rod pushes the valve stem on the check valve to move, opening the pressure measuring tube port, and the check valve has The elastic member that makes the check valve elastically return to close the pressure measuring tube port. Realize rapid leak detection, high efficiency, convenience, and resource saving.

Owner:伊藤未来能源设备(上海)有限公司

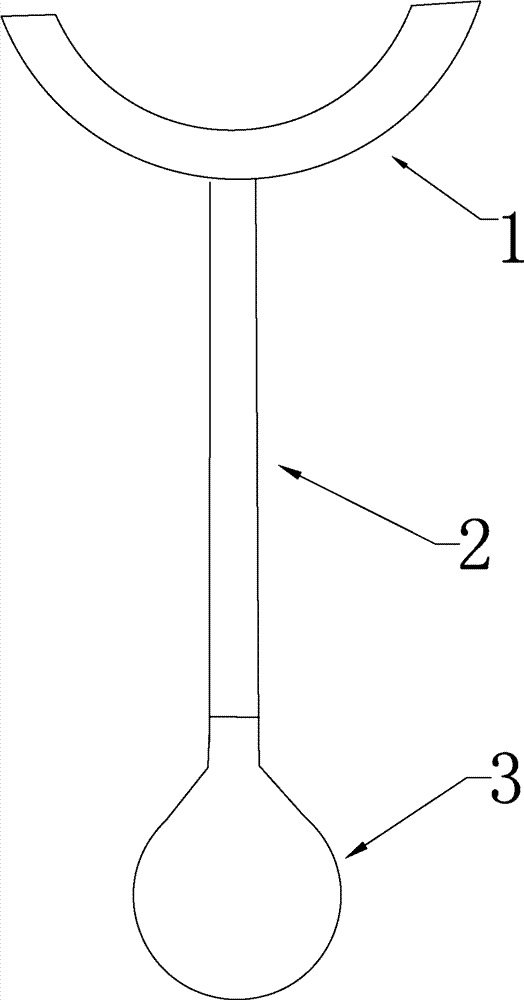

A fluorescent leak detection method

InactiveCN105675223BThe detection structure is accurateQuick leak detectionDetection of fluid at leakage pointFluorescenceEngineering

The invention discloses a fluorescence leak detection method. Detection is completed by the following steps that fluorescent glue is filled into a syringe needle tubing, and the syringe needle tubing is prepared for further use; a proper perforation position is searched in a sample for leak detection; a dye in the syringe needle tubing is extruded out of the internal of the sample under certain pressure at the searched perforation position; a camera or pick-up head is used to record the leak position of the sample; and the searched leak position of the sample is observed via a micro slice, gap in the assembling process of an electronic produce is found, and the leak detection process of the electronic product is realized. The fluorescence leak detection method has the advantages that the leak position can be found accurately, significant basis is provided for improvement of the product assembly process, the leak detection process is rapid, a detection structure is correct, operation is simple, the working efficiency is high, and the waterproof performance of the electronic product can be developed.

Owner:FLEXTRONICS MFG ZHUHAI

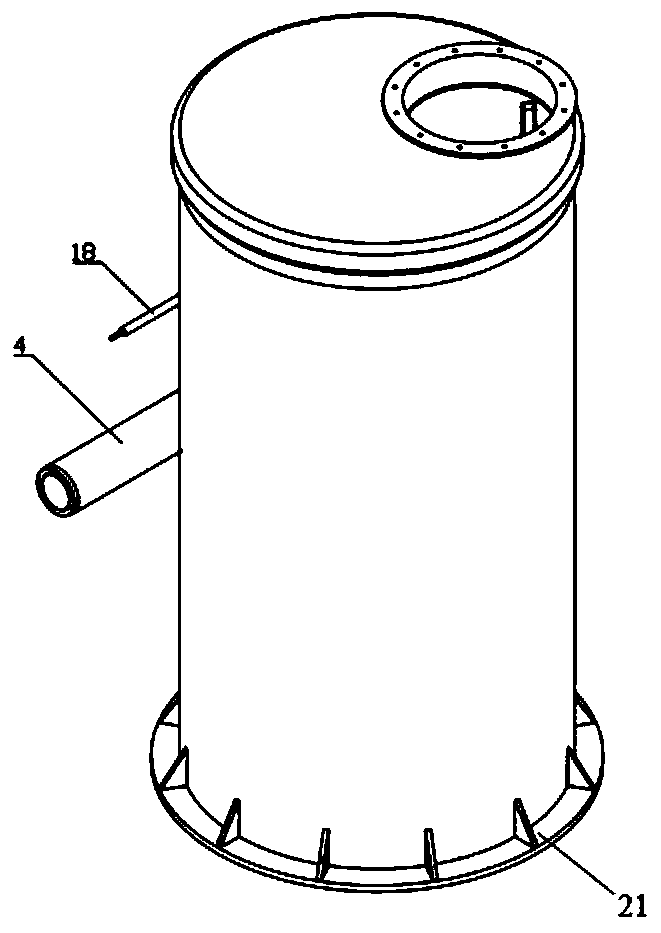

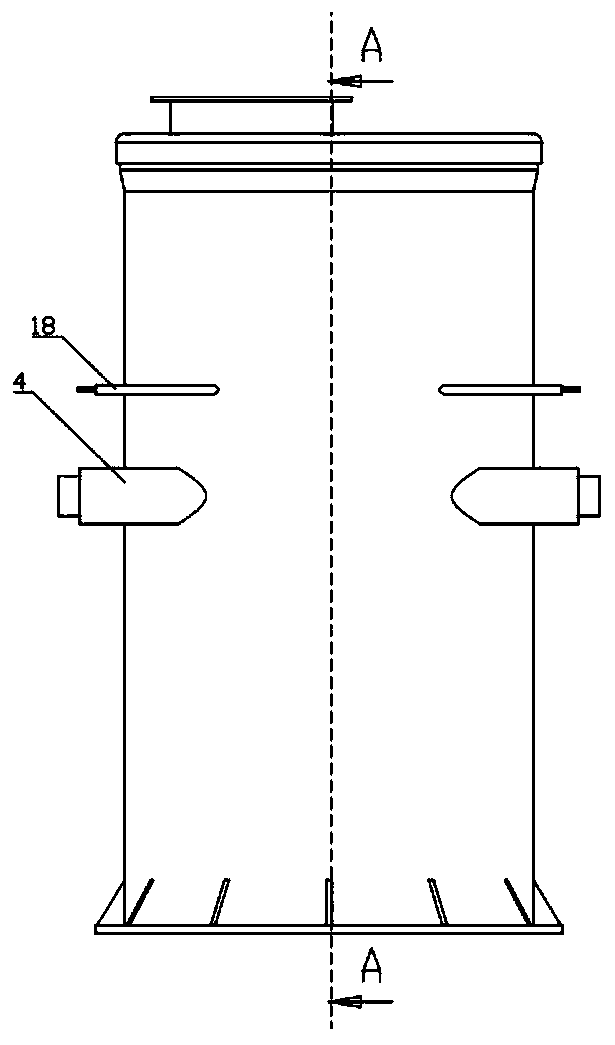

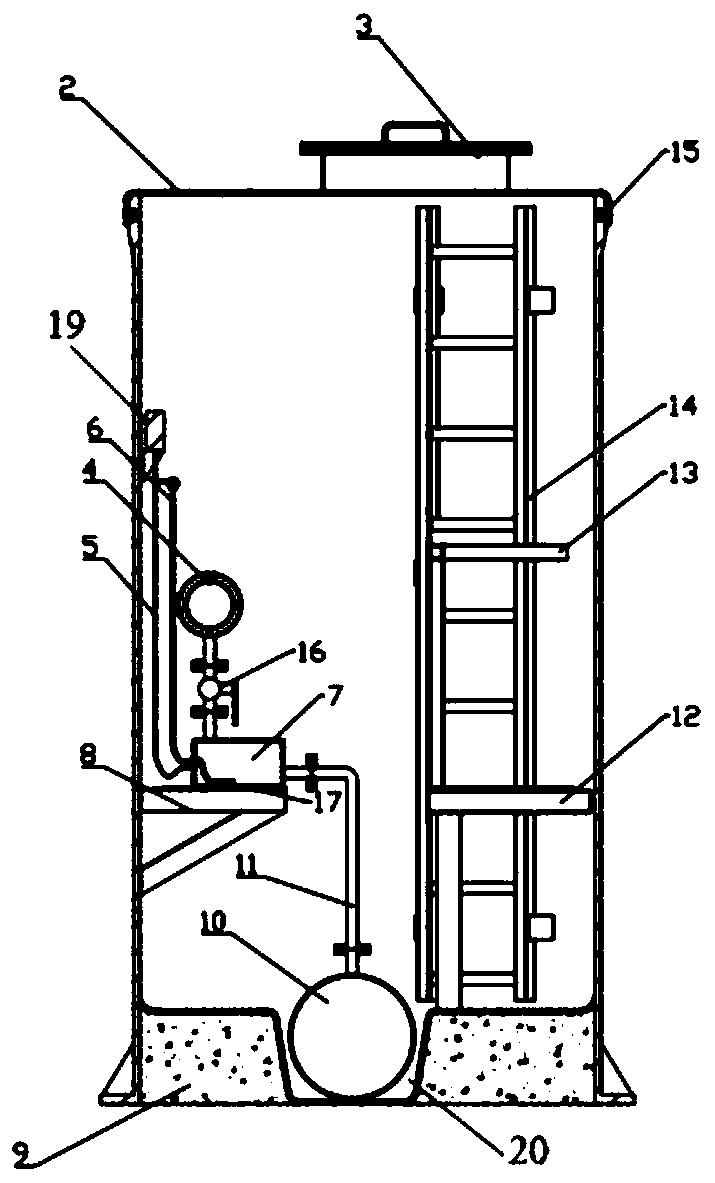

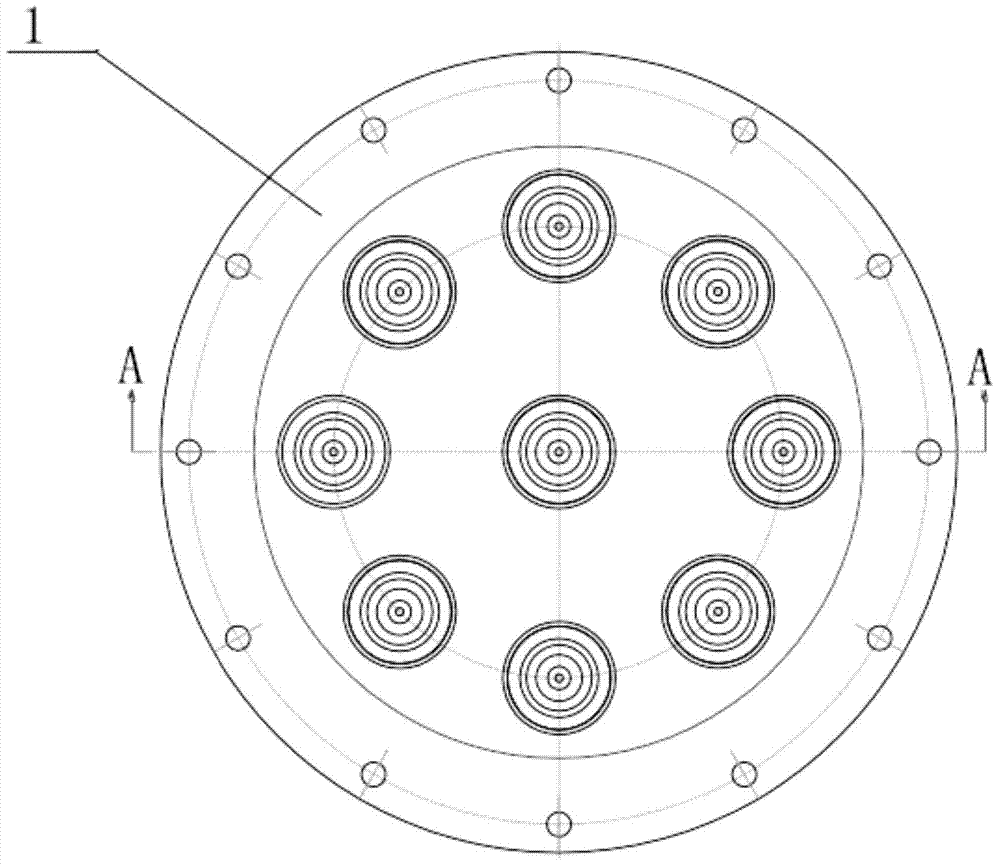

Multifunctional glass fiber-reinforced plastic liquid collecting well

PendingCN110689989AAvoid pollutionAvoid leakage expansionNuclear energy generationNuclear monitoringGlass fiberElectronic component

The invention discloses a multifunctional glass fiber-reinforced plastic liquid collecting well. The multifunctional glass fiber-reinforced plastic liquid collecting well includes a cylinder body, wherein a hole for allowing a conveying pipe to penetrate through is formed in the cylinder body, and a collection tank for collecting a leakage liquid and a hose for connecting the collection tank and the conveying pipe are arranged in the cylinder body. According to the liquid collecting well, multiple functions including waste liquid collecting, online monitoring, system power supplying, electronic component replacing and inspection and maintenance are integrated, and safety and high efficiency are achieved.

Owner:NANJING XINHE COMPOSITES CO LTD +1

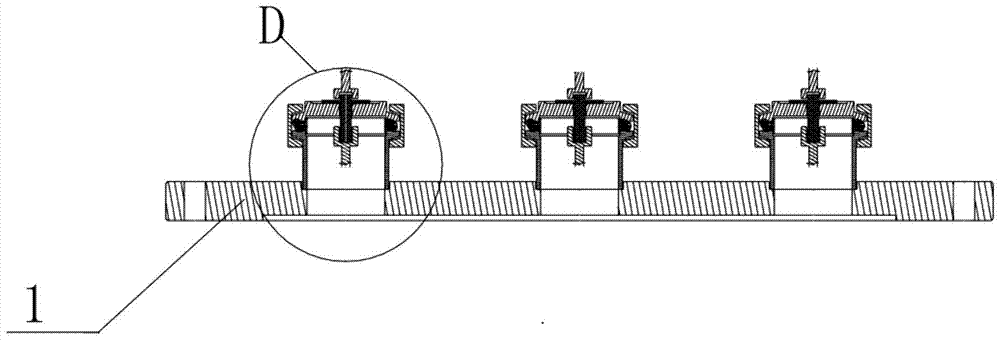

Vacuum tank wall connector flange and installation method

ActiveCN105292821BHigh reuse rateLow processing and production costsLarge containersMetal working apparatusEngineeringMechanical engineering

The invention provides a novel vacuum tank wall connector flange, including a vacuum tank wall flange blind plate, a tank wall connector blind plate assembly, a quick-release flange sealing assembly and a quick-release flange connector; wherein the vacuum tank A plurality of quick-release flange connectors are arranged on the wall flange blind plate; the tank wall connector blind plate component is sealed and connected with the quick-release flange connector through the quick-release flange sealing component. The tank wall connector blind plate assembly includes the tank wall connector, the connector sealing ring and the quick-release flange blind plate; wherein, the quick-release flange blind plate is provided with a through hole; one end of the tank wall connector enters the quick-release flange through the through hole. The inner side of the flange connector; the connector sealing ring is set between the tank wall connector and the end surface of the quick release flange blind plate. In the present invention, the blind plate assembly of the tank wall connector is sealed and connected with the quick release flange connector through the quick release flange sealing assembly, which is suitable for connectors of various specifications and sizes, can improve the reuse rate of tank wall flanges, and reduce processing and production costs .

Owner:SHANGHAI INST OF SATELLITE EQUIP

Leak detection tool applied to high pressure gas leak detection method

ActiveCN101598623BImprove detection reliabilitySimple structureDetection of fluid at leakage pointConfined spaceEngineering

A leak detection tool applied to a high pressure gas leak detection method, comprising a packer and a detection gas-collecting casing; the packer is arranged in an oil string to be detected or a casing string or an auxiliary tube, is located at two sides of a connecting thread buckle part to be detected and likely to leak, and is used for establishing inner confined space which is capable of filling with tracer gas and is otherwise called plenum space; the detection gas-collecting casing is arranged outside the oil string or the casing string or the auxiliary tube, is located in the connecting thread buckle part likely to leak, and covers the connecting thread buckle part to establish outer confined space which is capable of detecting leak and is otherwise called detection space; the plenum space is connected with a high pressure vent pipe on a pressurized container to facilitate high pressure tracer gas to enter. The detection space is connected with a detector of the tracer gas by being provided with a pipeline. The leak detection tool provided by the invention has simple structure, high detection reliability and convenient and practical field operation.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

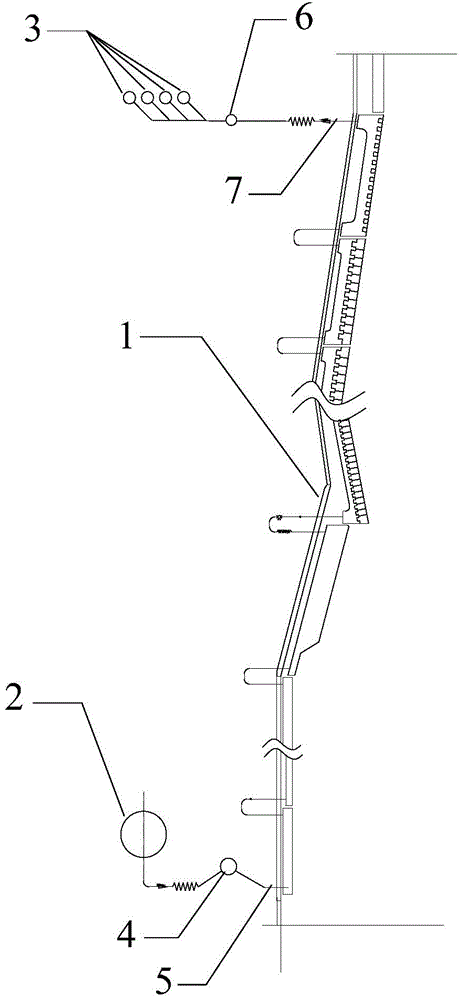

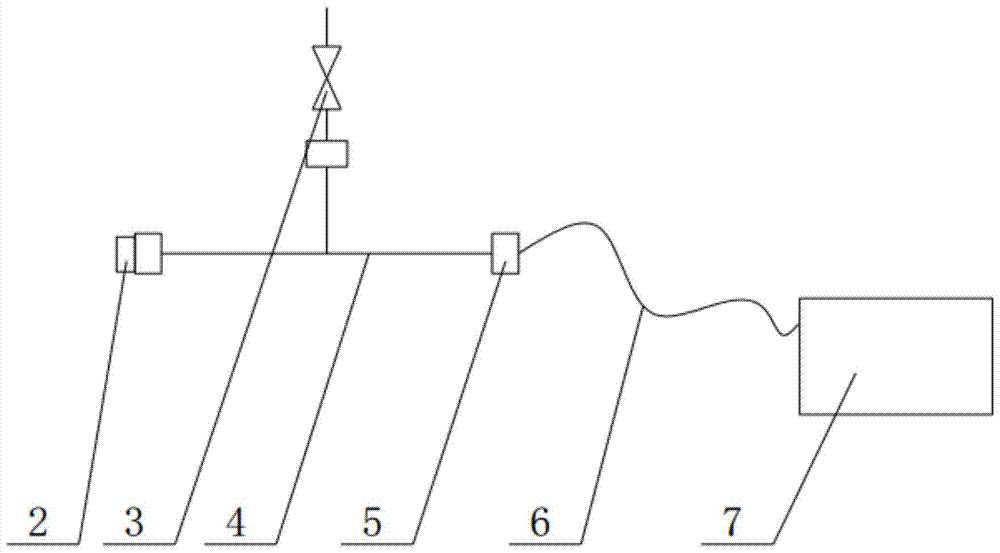

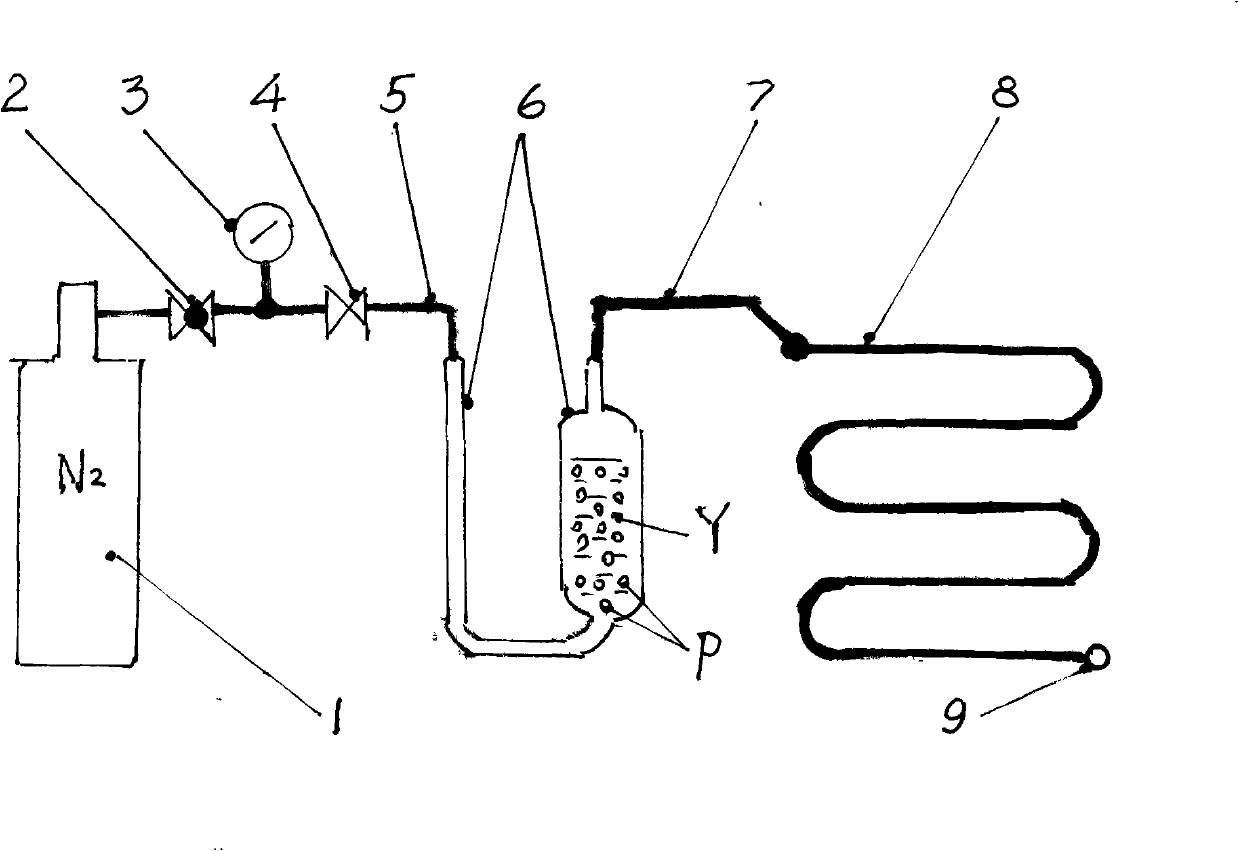

Simple leakage detection instrument for liquid container and using method thereof

InactiveCN102052996BQuick leak detectionExpand the range of applicationsFluid-tightness measurement using fluid/vacuumEngineeringHigh pressure

The invention relates to a simple leakage detection instrument for a liquid container and a using method thereof. The instrument comprises a high-pressure gas source (1) and a U-shaped tube (6), wherein the two sides of the U-shaped tube (6) have different tube wall thicknesses and are filled with liquid (Y); the high-pressure gas source (1) is connected with a thin tube inlet in the U-shaped tube (6) through a gas inlet guide tube (5) in which a pressure-stabilizing valve (2) and a stop valve (4) are connected in series; the U-shaped tube (6) is vertically arranged and provided with an upward orifice; and a gas outlet guide tube (7) is connected to a thick tube outlet of the U-shaped tube (6). The using method of the instrument is simple and comprises the following steps that: the gas outlet guide tube (7) is communicated with a detected container device (8), and the stop valve (4) is opened to perform high-pressure gas transmission, wherein the sealing property of the detected container device (8) (such as a container piece, or a pipeline piece with volume) is unqualified if continuous rising bubbles (P) are generated in the liquid (Y) in the thick tube section of the U-shaped tube (6), and the sealing property of the detected container device (8) is qualified if the continuous rising bubbles (P) are not generated in the liquid (Y).

Owner:CHINA JILIANG UNIV

A leak detection device and measurement method for vials based on dual-wavelength-tdlas technology

ActiveCN108931346BSealing without interferenceQuick leak detectionFluid-tightness measurement using lightPenicillinLaser intensity

Owner:UNIV OF SHANGHAI FOR SCI & TECH

A new type of rapid leak detection device for pipelines that can release colored gases

ActiveCN112284636BQuick leak detectionFunction increaseDetection of fluid at leakage pointGas passingEngineering

The invention provides a new type of quick leak detection device for pipelines that can release colored gas, including a leak detection device body, the leak detection device body includes a lower box body and an upper box body, and an upper arc-shaped plate is welded on the upper box body , the lower box body is welded with a lower arc-shaped plate, the upper arc-shaped plate matches the lower arc-shaped plate, the outer walls of the upper box body and the lower box body are provided with nozzles, and the inside of the nozzle head A rubber sealing nozzle is installed, a connecting plate is welded on the upper box body and the lower box body, a fixing frame is welded on the connecting plate, a rotating shaft is installed on the fixing frame, and the quick inspection of the pipeline that can release colored gas When the leakage device is in use, the tank with the colored gas is matched with the interface through the pipeline, so as to inject the required colored gas into the inside of the box. In the state of leakage through the pipeline, the internal air pressure changes, and the inside of the box is released. A colored gas is ejected from the inside of the spout, allowing a quick inspection of the pipe.

Owner:HUBEI LINGTAN ELECTROMECHANICAL EQUIP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com