Device and method for accurate leak checking on blast furnace tuyere small sleeves

A small tuyere cover and leak detection technology, which is applied to inspection devices, cooling devices, etc., can solve the problems of inaccurate judgment, difficult to deal with water leakage in the small tuyere cover, unfavorable blast furnace production, etc., and achieve intuitive and accurate leak detection results and simple detection The device and method, the effect of accurate and reliable detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

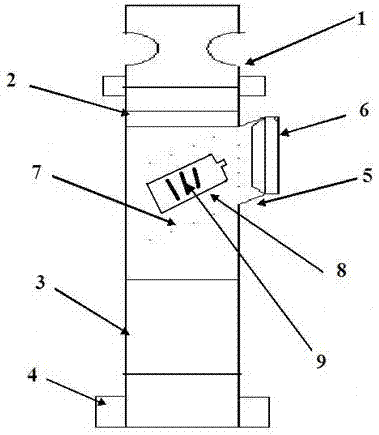

[0025] The leak detection device of the tuyere small sleeve of the present invention consists of a front connector 1 of the water inlet pipe chuck, a front pair of wires 2, a rear pair of wires 3, a rear connector 4 of the water inlet pipe chuck, a drain valve 5, a drain valve plug 6, a drain valve Valve filter screen 7, potassium permanganate reagent bottle 8 form.

[0026] As shown in the figure, the front connector 1 of the water inlet pipe clamp is connected to one end of the detached water inlet pipe clamp through the front pair of wires 2, and the rear connector 4 of the water inlet pipe clamp is connected to the detached water inlet pipe clamp through the rear pair of wires 3. The other end of the head is connected, and a drain valve 5 is installed between the front connector 1 of the water inlet pipe chuck and the rear connector 4 of the water inlet pipe chuck.

[0027] The figure shows that the trap 5 itself has an included angle of inclination, which is 45°. Adopting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com