High-pressure clamped sealing gas injection tool being used for leak detection of tube column and having function of trip prevention

An anti-jump and leak detection technology, applied in the directions of sealing/packing, valve device of wellbore/well, production fluid, etc. and other problems, to achieve the effect of high detection reliability, simple and easy operation, and prevention of potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

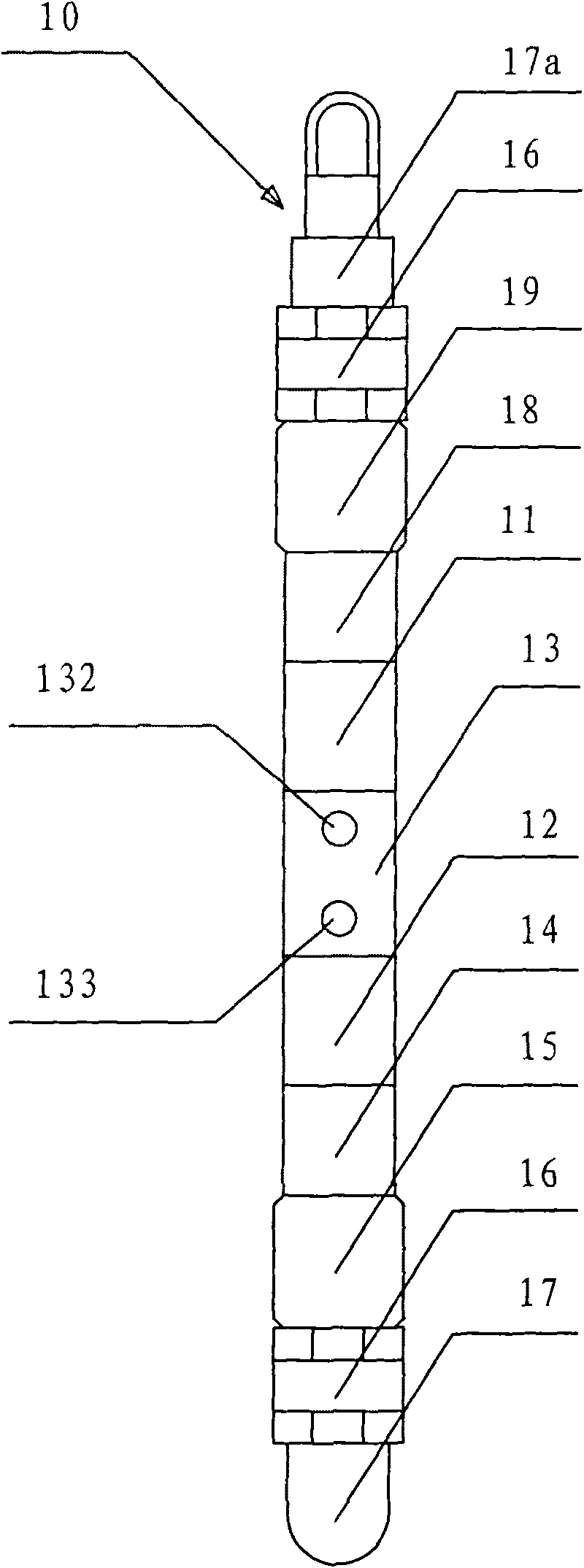

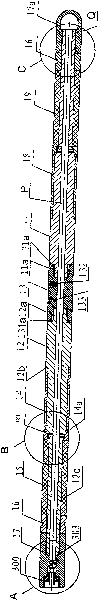

[0035] The high-pressure sealing and gas-injecting tool with anti-jump function for pipe string leak detection provided by the present invention comprises a sealing tool and a gas collecting sleeve,

[0036] like figure 1 , 2 , 4 and 5, the clamping tool includes two sets of clamping parts and a central column; the central column is a longitudinal hollow tube with a central lumen, and both ends of the hollow tube are provided with a sealing and sealing central tube Cavity; two sets of card seals are fitted on both sides of the rigid central column. Each set of clamps includes a rigid sliding sleeve and a packer made of elastic material, which is a rubber tube made of elastic material.

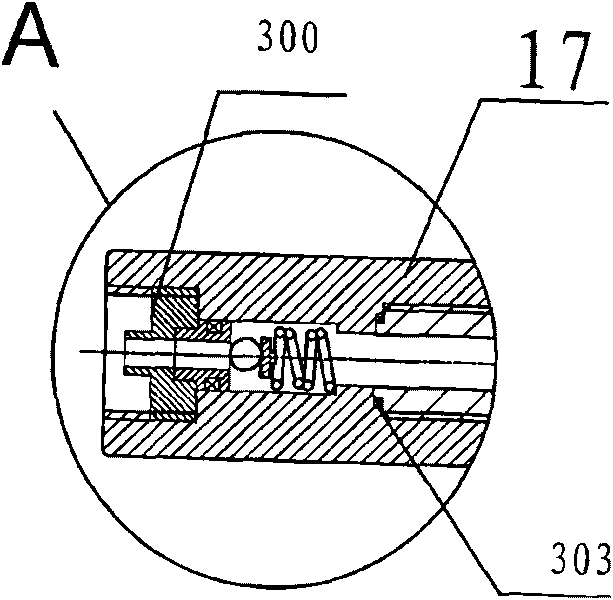

[0037] Specifically, as figure 1 , 2 As shown, the central column 10 is composed of an upper sliding sleeve rod 11, a lower sliding sleeve rod 12 and an air outlet short joint 13 connected to each other, and the air outlet short joint 13 is a hollow short tube, such as image 3 As shown, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com