Tram turnout switch structure

A technology for trams and point switches, which is applied to the upper structure of the track, point switches, tracks, etc., and can solve the problems of easy loosening of guide rails, high material consumption rate, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

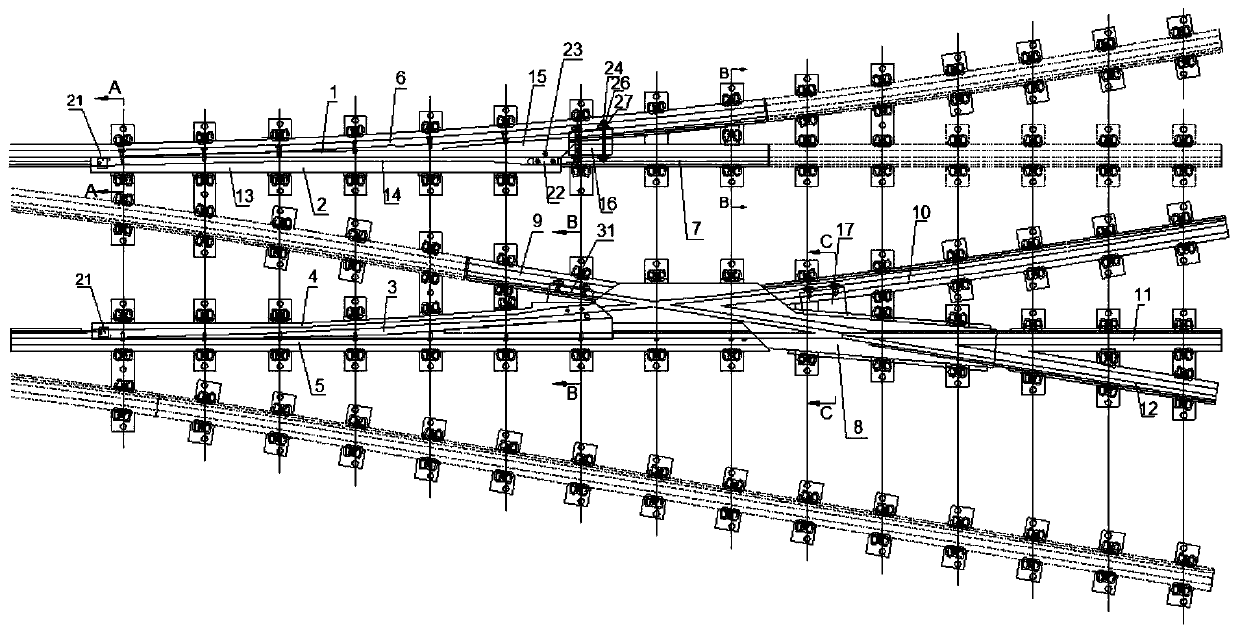

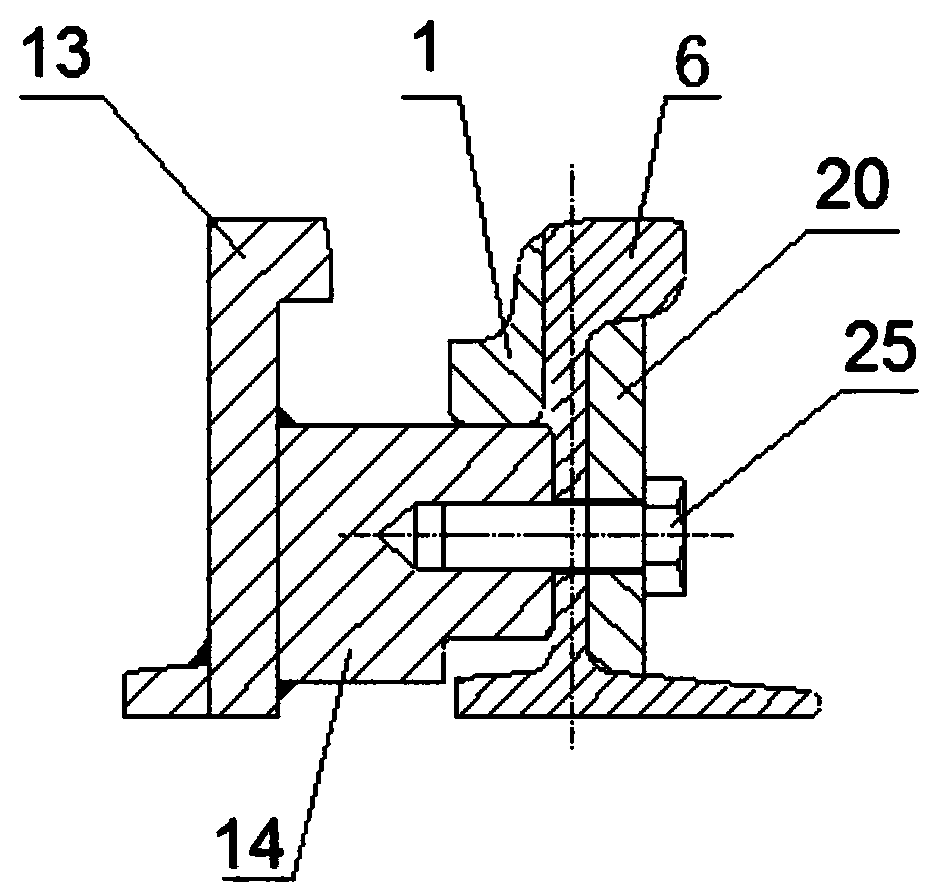

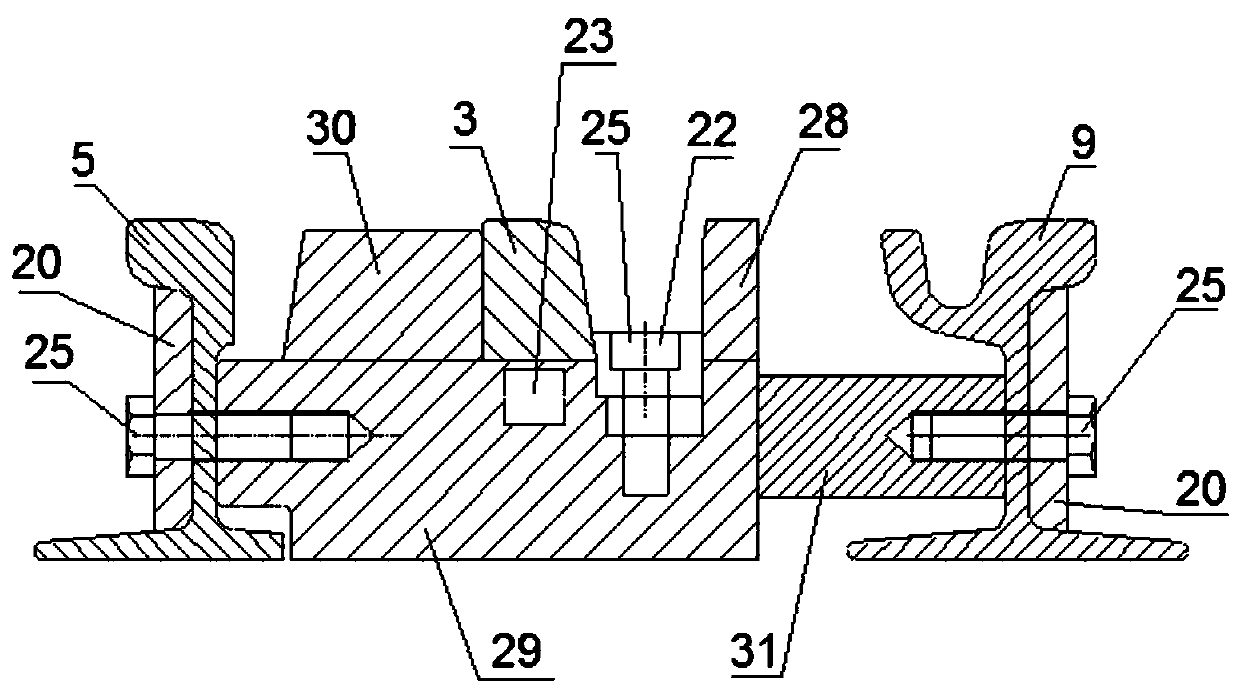

[0027] see figure 1 , figure 2 , image 3 , Figure 4 , a tramway turnout switch structure provided in an embodiment of the present invention, the structure includes a switch rail seat, a bottom support platform is provided on the top of the switch rail seat, and a switch rail is provided on the top of the bottom support platform, so A pin shaft is arranged on the lower part of the switch rail on the bottom support platform, and a wedge block is fixedly installed on the heel of the switch rail on the bottom support platform; a basic rail is connected to one side of the bottom support platform, and the bottom support platform The support platform is welded with stop rails, stop platforms and spacer irons;

[0028] Wherein, the switch rail is made of alloy steel plate.

[0029] In order to prevent jumping of the switch rail, an anti-jumping block is arranged on the switch rail seat at the front end of the switch rail.

[0030] Further, the switch rail seat is a straight sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com