A mixer truck top loading and concrete mixer truck

A technology of mixer truck and mixing drum, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of disassembly and assembly trouble, restrictions, length and height restrictions of the whole vehicle, etc., and can reduce the height of the whole vehicle and The height of the center of gravity, the effect of enhancing road passability, and reducing the length of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

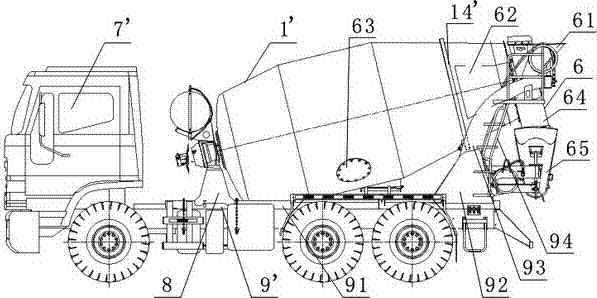

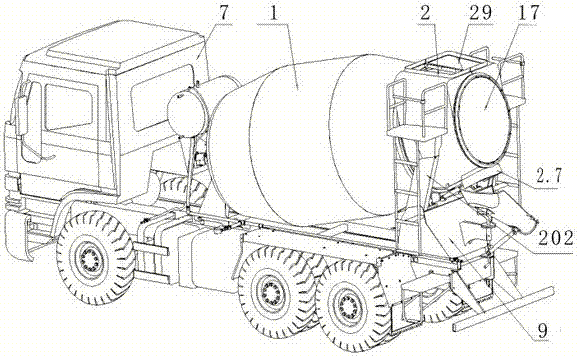

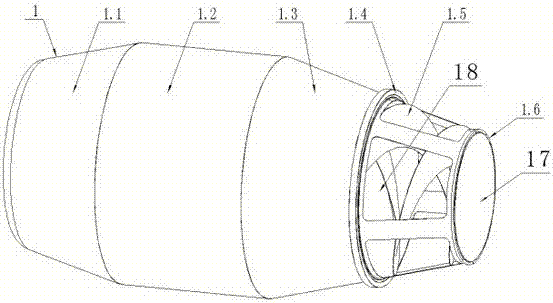

[0041] figure 2 Among them, the present invention consists of a chassis (7), a mixing drum (1), a sub-frame (9) and a feeding and discharging system, the tail of the mixing drum is closed by a circular plate (17), and the feeding and discharging system is improved to a fixed sleeve (2), The fixed sleeve realizes the integration of material feeding and discharging and ladder climbing. The upper part of the fixed sleeve (2) has a material inlet (29), the lower part of the fixed sleeve has a material outlet, and a sliding door (2.7) is installed at the material outlet, which is installed on the rear cone and short tail (202) of the mixing drum . Because the tail of the mixing drum is closed in the present invention, the possibility of material leakage is eliminated, so it no longer depends on the inclination angle of the mixing drum, but can also be placed horizontally, which greatly reduces the height of the center of gravity of the mixing drum, improves the stability of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com