Anti-wire jumper sand-blasting device for multi-wire cutter

A kind of technology of multi-wire cutting machine and sandblasting device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

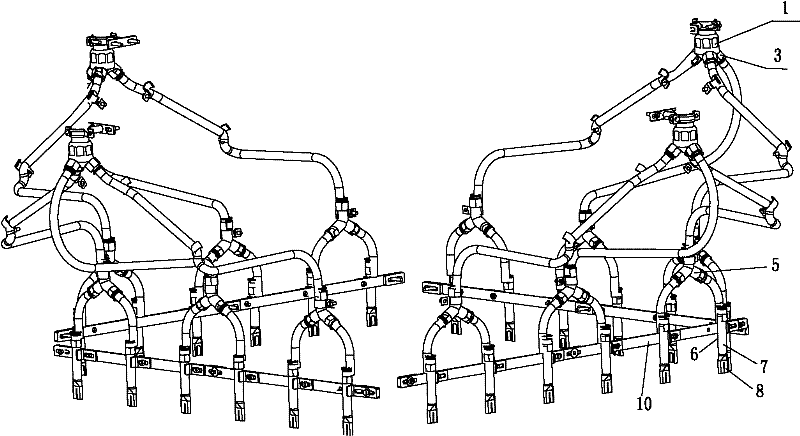

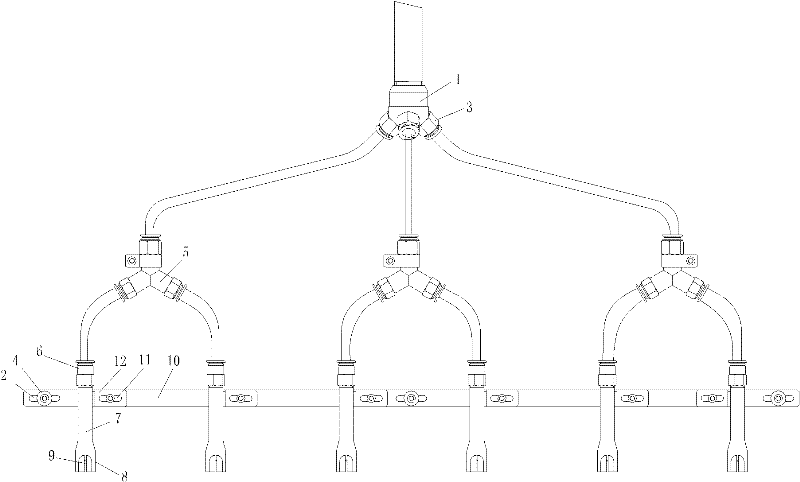

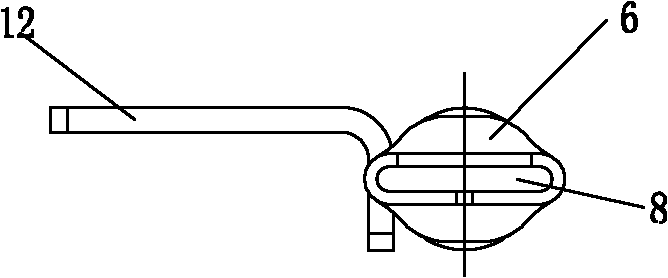

[0017] Such as figure 1 and figure 2 The shown anti-jumping sandblasting device for multi-wire cutting machine includes four sandblasting units arranged in a rectangle. The sandblasting unit includes a splitter head 1 and a plurality of sandblasters 6. Each outlet of the splitter head 1 is connected with The quick-plug connector 3 is also connected to the inlets of three tees 5 through flexible pipes, and the outlet of the three-way 5 is connected to the inlet of the sand blaster 6 through flexible pipes. One side of the sand blaster 6 forms a mounting plate 12 with a transverse waist groove 11, which is mounted on a horizontal plate 10 by fasteners. The horizontal plate 10 also has a lateral adjustment groove 2, which is fixed on the cutting head (omitted among the figures) by screws 4 . Such as image 3 and Figure 4 As shown, the sand blaster 6 includes a pipe body 7, the lower part of the pipe body 7 has an outwardly expanded nozzle 7, and the lower part of the pipe b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com