Leak detector of vacuum system

A vacuum system and leak detection technology, which is applied in the direction of using liquid/vacuum to measure liquid tightness and detecting the appearance of fluid at the leakage point, can solve problems such as offset and affect the normal operation of the unit, and ensure personal safety , reduce loss and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

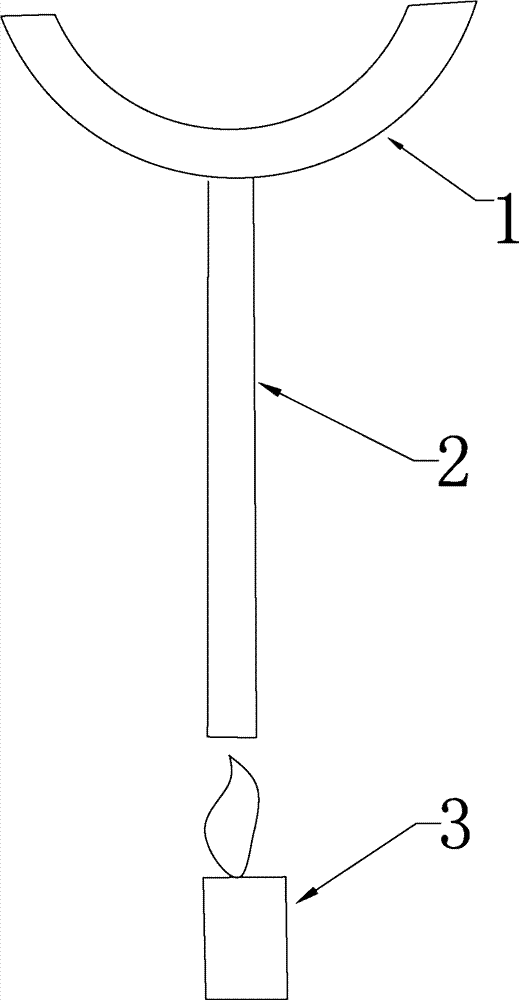

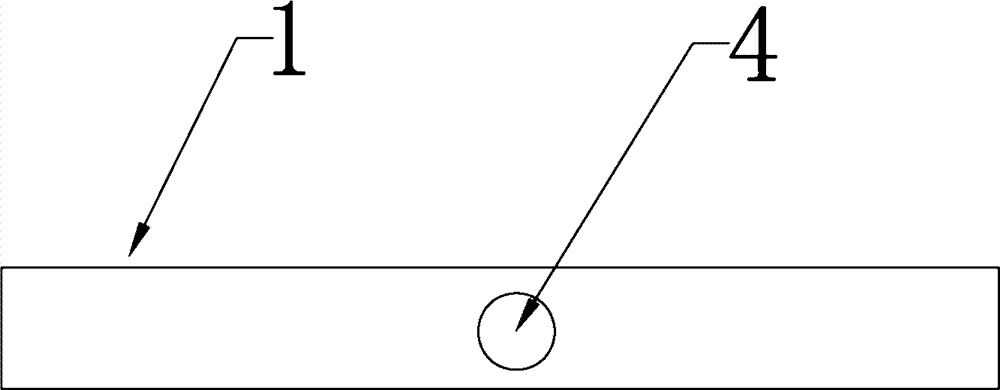

[0024] The vacuum system leak detector includes a detection part 1, a connection part 2 and an induction device 3, the connection part 2 is provided with a hollow tube, the detection part 1 is provided with a detection hole 4, and one end of the hollow tube is connected to the The detection hole 4 of the detection part 1 is connected, an air flow channel is formed between the detection hole 4 and the hollow tube, and the sensing device 3 is placed at the other end of the hollow tube. Especially for some spaces where the unit has high temperature and pipelines are densely covered, and the staff cannot approach the flange to check for leaks, the invention can be used for effective and convenient inspection. The detection part 1 is moved along the pipeline or the flange. When moving When reaching the leaking place, according to the principle of high and low pressure air flow, the detection hole 4 communicates with the hollow tube of the connecting part 2, and the air flow passes t...

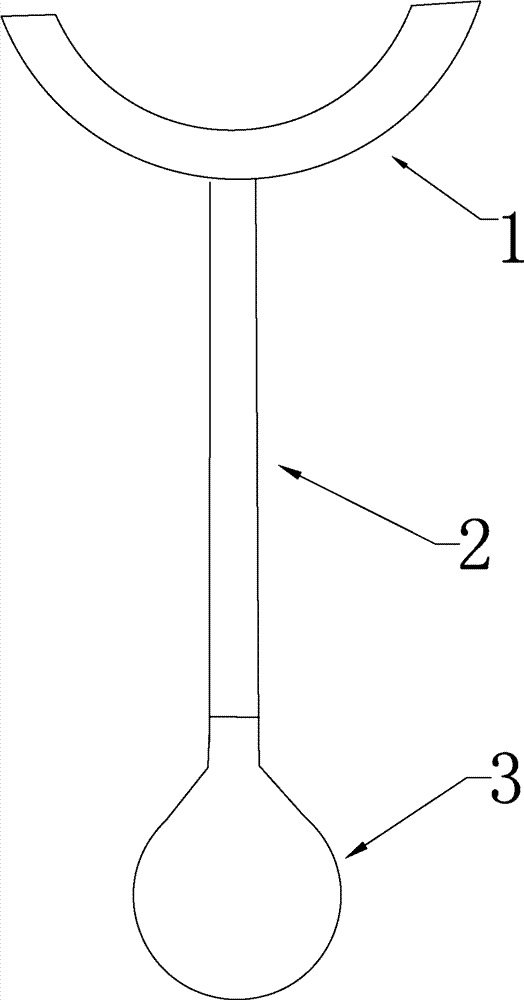

Embodiment 2

[0032] The difference between this embodiment and the first embodiment is that the connection part 2 is a telescopic tube. The connecting part 2 can be expanded and contracted, and the length of the connecting part 2 can be adjusted arbitrarily during detection, so as to adapt to the detection of pipes and flanges in different places.

[0033] The induction device 3 is a balloon, and the balloon is sheathed at the end of the hollow tube. In the power plant, there will be a large flammable hidden danger, so it is necessary to control the open flame. The sensing device 3 of the present embodiment is a balloon, and the balloon is an inflated soft leather balloon, which is spherical in normal state. When the air pressure is lower than the outside air pressure, the balloon will automatically inhale and deform. When testing, put the balloon on the end of the hollow tube at the connection part 2, and then approach the pipe or flange to be tested. When a leak is detected, the balloo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com