Patents

Literature

51results about How to "Deal with as soon as possible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Business request adjusting method and device

InactiveCN106470169ADeal with as soon as possibleTimely executionData switching networksResource utilizationDistributed computing

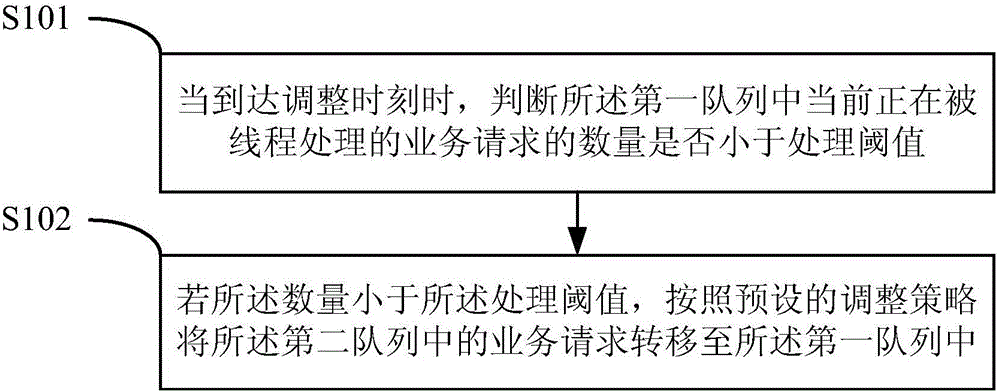

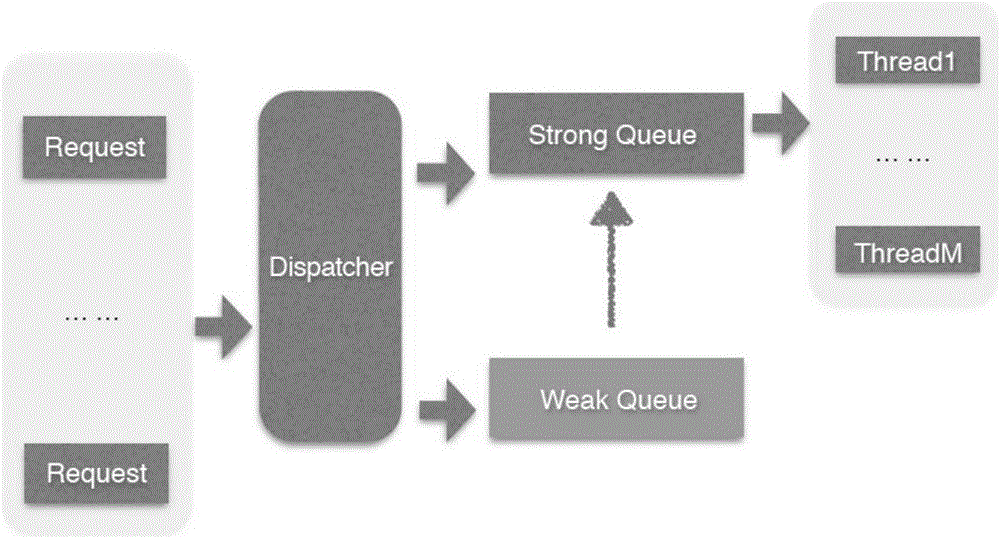

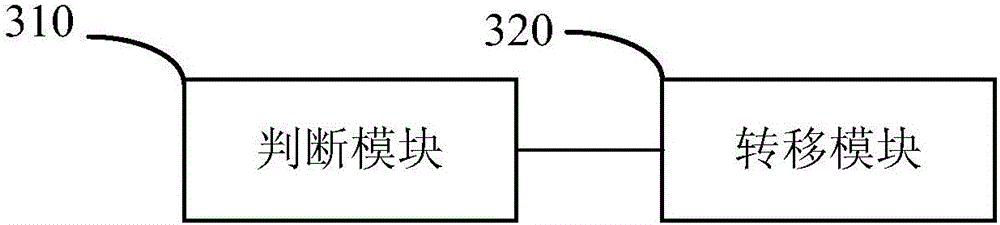

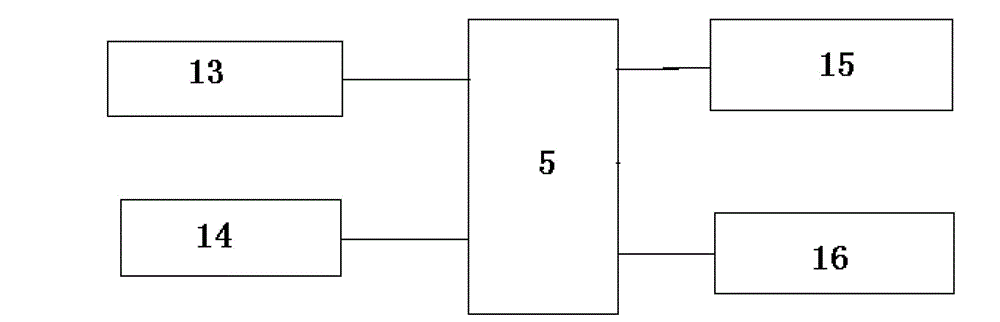

The invention discloses a business request adjusting method and device. In a business request processing system, a first queue and a second queue are pre-created. The number of threads opened by the first queue is higher than the number of threads opened by the second queue; and the priority of the business request in the first queue is higher than the priority of the business request in the second queue; when the adjustment time arrives, it is confirmed whether the number of business requests currently being threaded in the first queue is less than a processing threshold, and if so, the business requests in the second queue are transferred to the first queue according to a preset adjustment strategy so as to dynamically adjust the resources allocated to the service requests in the queues according to the usage of the resources, to ensure that the business requests with higher priority are executed in time, and to ensure that the business requests with lower priority are processed as quickly as possible when the resources are idle enough. Therefore, the resource utilization efficiency is increased.

Owner:ALIBABA GRP HLDG LTD

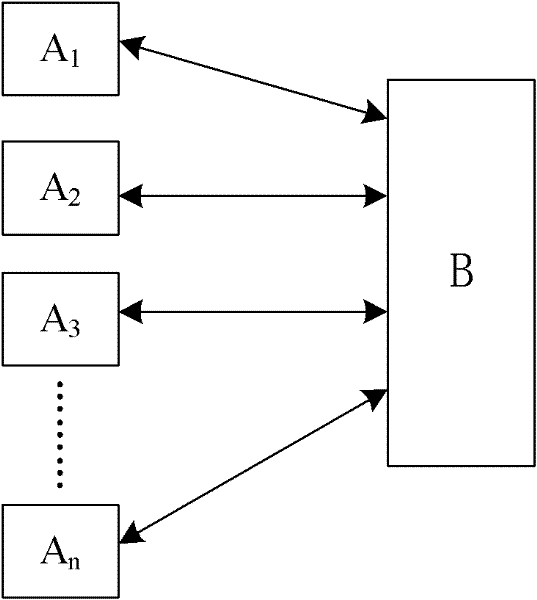

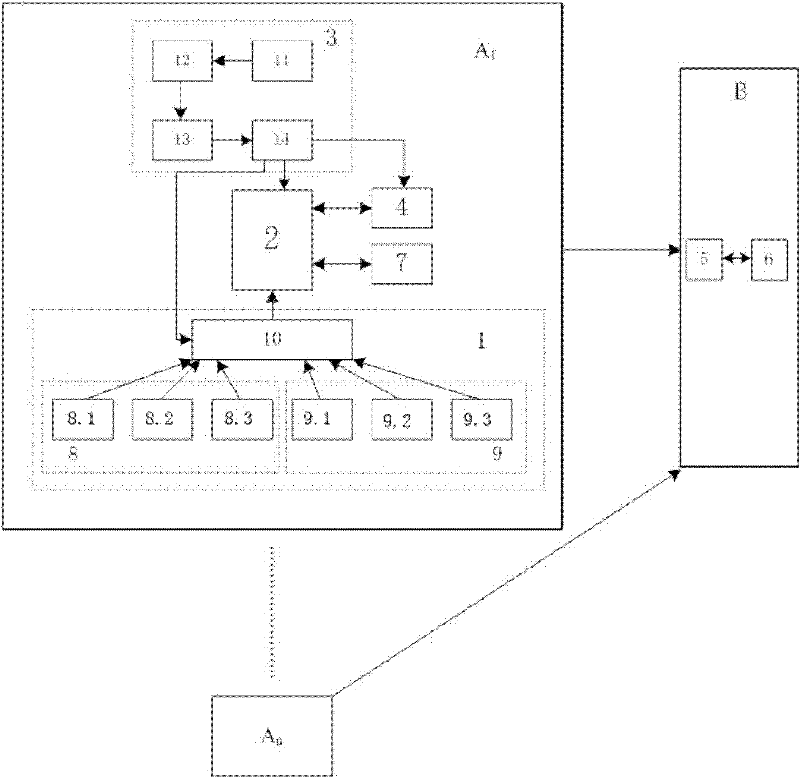

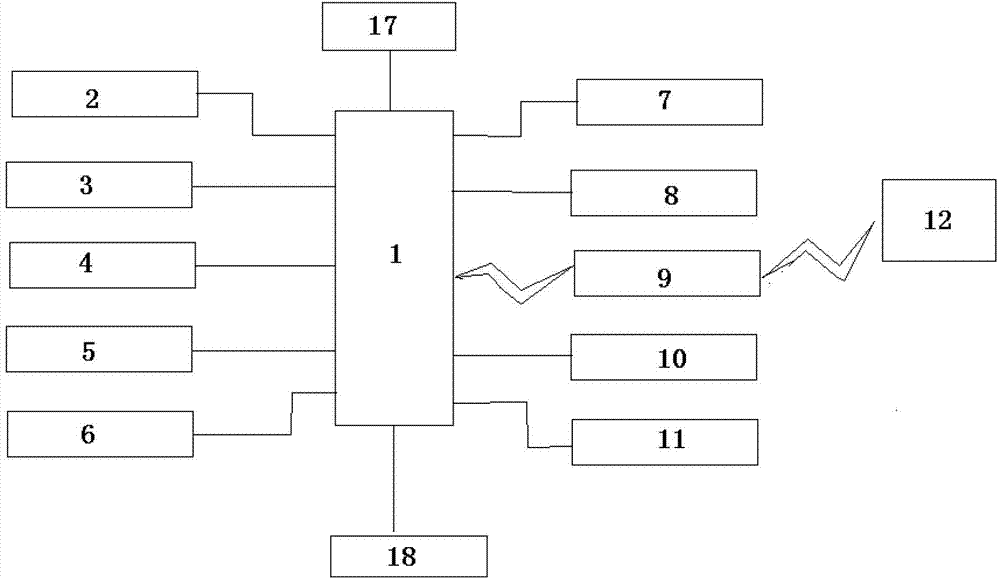

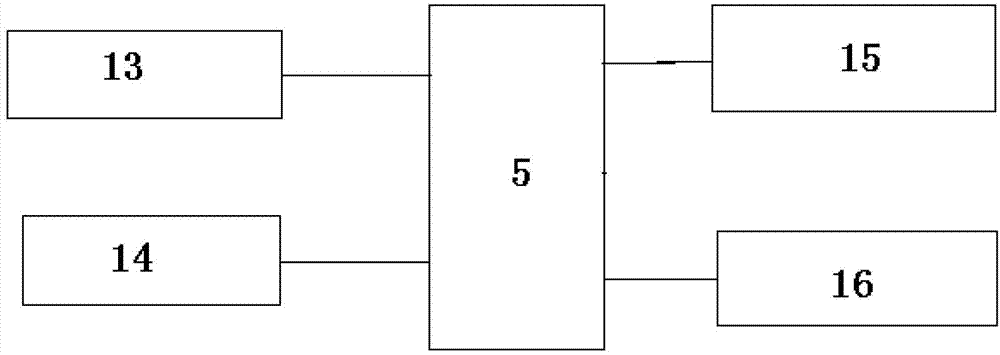

Intelligent home system

InactiveCN103149902AConvenience to followImprove life experienceProgramme total factory controlLife qualityControl system

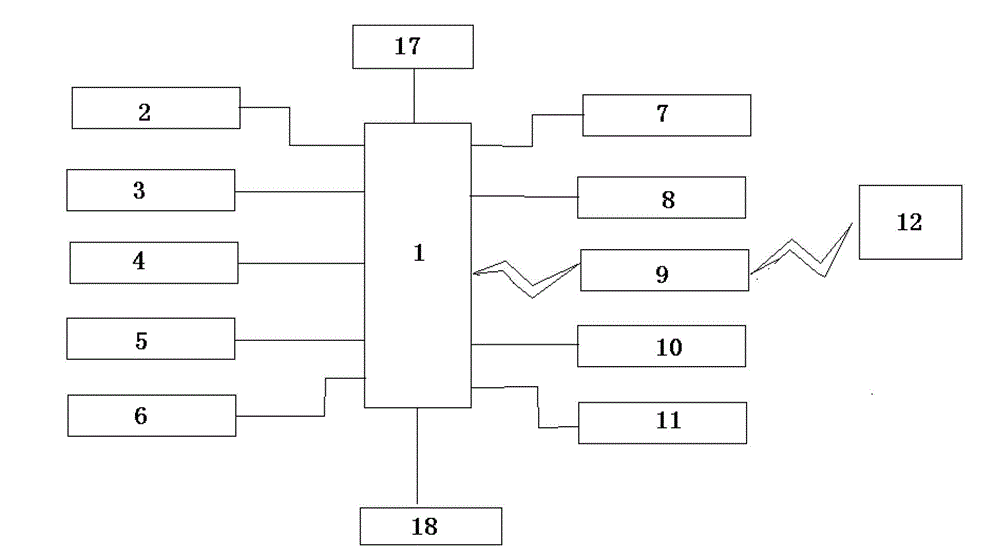

The invention discloses an intelligent home system comprising a central controller, an electric appliance control system, a damp-proof system, an information receiving module, a video collecting system, a crawler detecting system, an input circuit and an alarm apparatus, wherein the central controller is used for receiving a user demand instruction and information uploaded by each branch control system and controlling the operation of corresponding branch control systems, and is communicated with a cloud server; the electric appliance control system is used for controlling the state of each electric appliance in home; the damp-proof system is used for detecting the humidity and the temperature of the home; the information receiving module is used for receiving operation short messages sent by a user through a mobile terminal; the video collecting system is used for collecting home states; the crawler detecting system is used for detecting whether crawlers exist in corners of rooms according to the change of a magnetic field; the central controller is connected with the input circuit; and the central controller is further connected with the alarm apparatus. According to the intelligent home system disclosed by the invention, the user can conveniently pay close attention to the home states at any time when going out so that the intelligent home system is of convenience for the user, has wide applicability, can also achieve an active alarm effect; and through the intelligent home system, the user has excellent life experience and higher living quality at home.

Owner:孙凯祺

Intelligent transportation management method and system

InactiveCN108154683AReal-time feedbackReal-time integrationDetection of traffic movementInformation analysisThe Internet

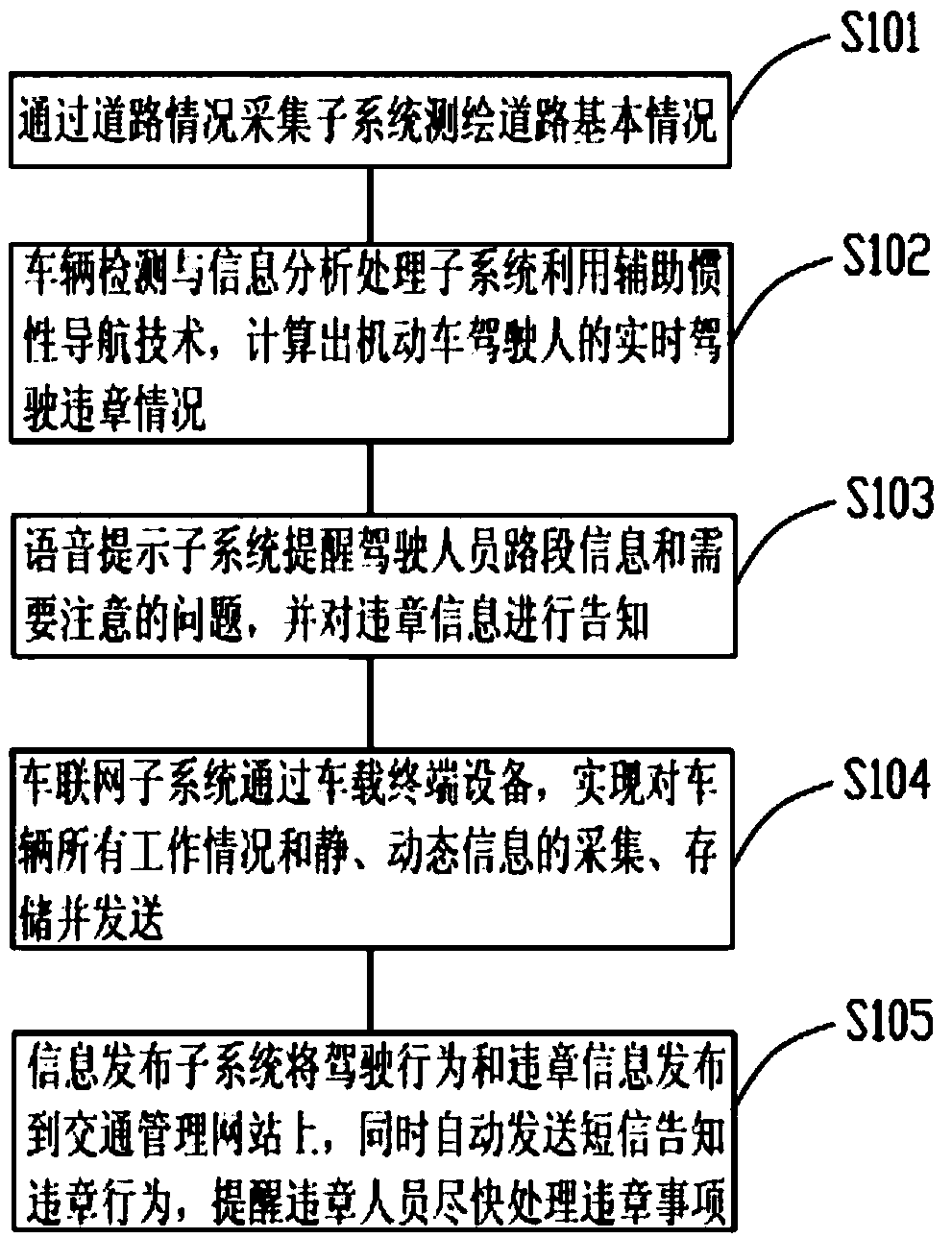

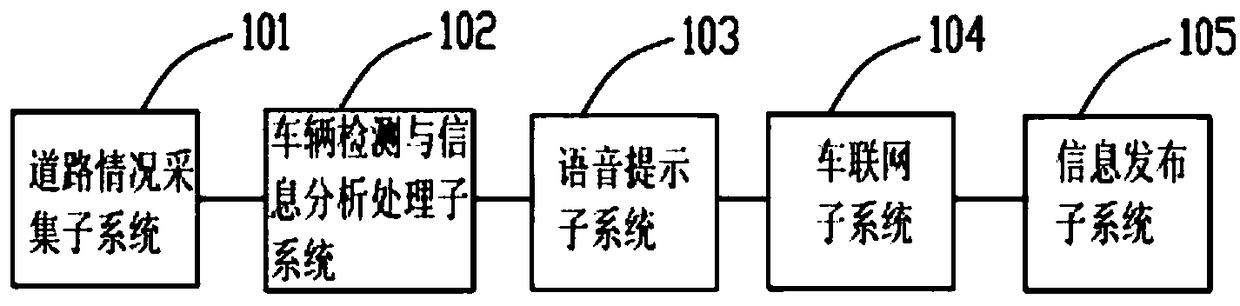

The invention discloses an intelligent transportation management method and system. The intelligent transportation management method includes the steps that the basic road condition is surveyed and mapped through a road condition collecting subsystem; a vehicle detection and information analysis processing subsystem calculates real-time driving violation conditions of motor vehicle drivers with the auxiliary inertial navigation technology; a voice reminding subsystem reminds the drivers of road section information and problems needing attention, and informs the drivers of violation information; an Internet of Vehicles subsystem achieves collection, storage and sending of all working conditions and static and dynamic information of vehicles through vehicle-mounted terminal equipment; an information issuing subsystem issues driving behaviors and the violation information to a traffic management website, automatically sends short messages at the same time to inform violation persons of violation behaviors, and reminds the violation persons to process violation items as soon as possible. According to the intelligent transportation management method and system, driving and traffic management are closely connected, the violation conditions of the drivers are comprehensively learnt about in real time, alarming and rescuing during the emergency condition can be carried out according toobtained information, and the road traffic security is guaranteed.

Owner:HEBEI AGRICULTURAL UNIV.

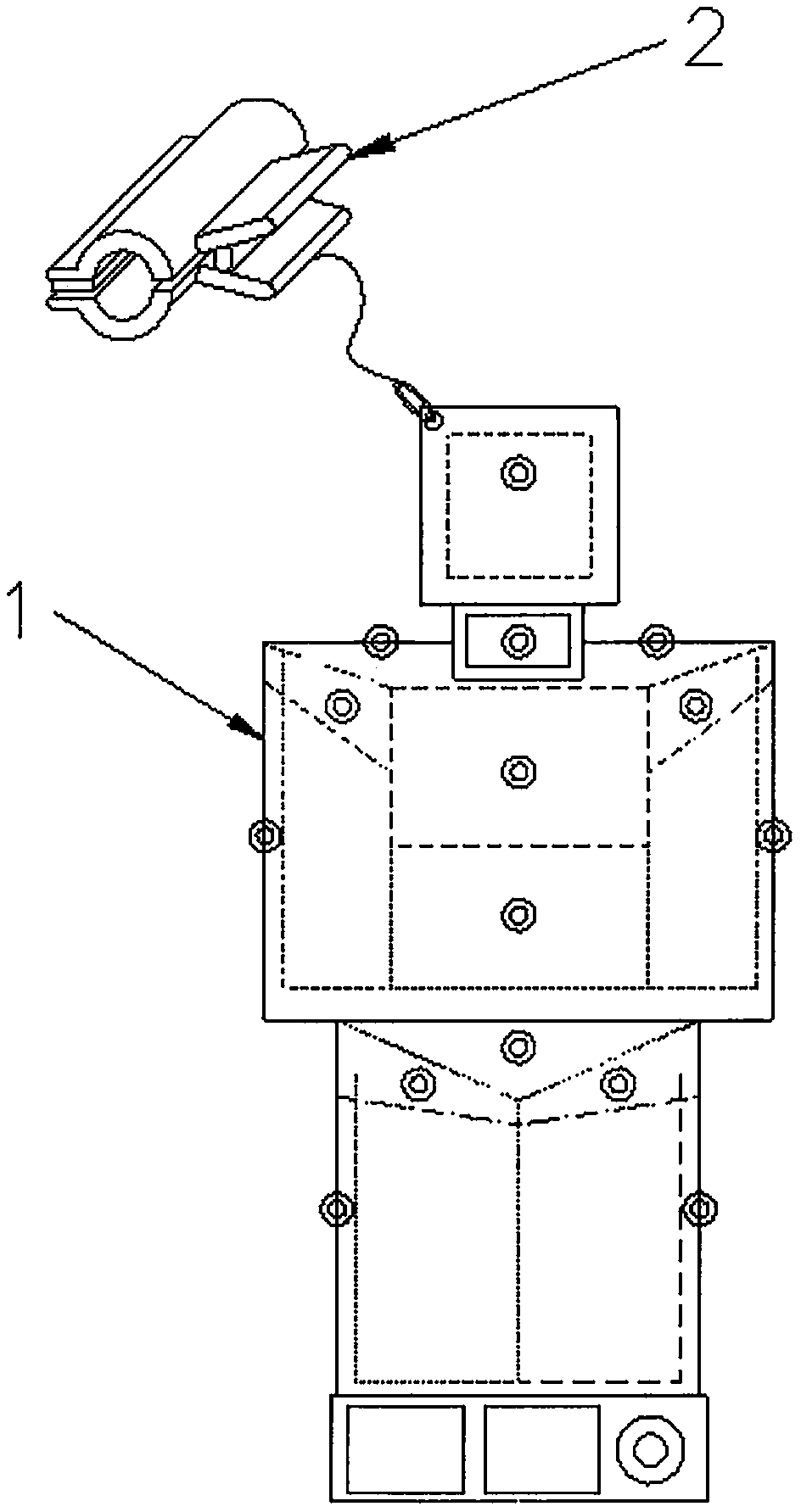

Multifunctional streetlamp

InactiveCN107726211ADeal with as soon as possibleTo gain timeMechanical apparatusElectric circuit arrangementsPower controllerVehicle detector

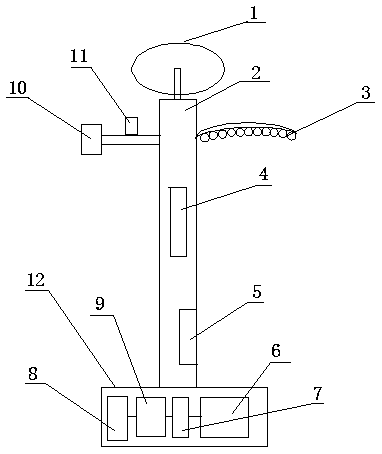

The invention discloses a multifunctional streetlamp. The multifunctional streetlamp is characterized by comprising a lamp body, a solar charging device and an intelligent alarm device; the lamp bodycomprises a lamp pole, an LED lamp and a lamp holder, the solar charging device comprises a solar cell panel, a power controller and a storage battery, and the intelligent alarm device comprises a CCDcamera, a warning lamp and a video vehicle detector; and the CCD camera and the warning lamp are arranged on a lamp support, the video vehicle detector is arranged in the lamp holder, the video vehicle detector is connected with the CCD camera and the warning lamp, a wireless communication device is arranged in the lamp holder, and the wireless communication device is connected with the video vehicle detector and meanwhile is connected with a background server. By the adoption of the multifunctional streetlamp, the efficient solar power generation function, the function of sheltering sun andrain and the intelligent alarm function can be provided.

Owner:杨佳友

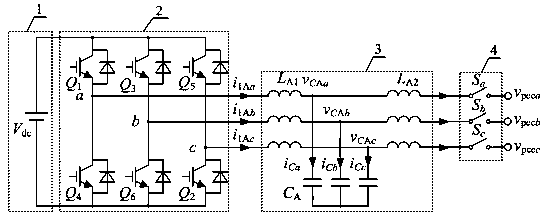

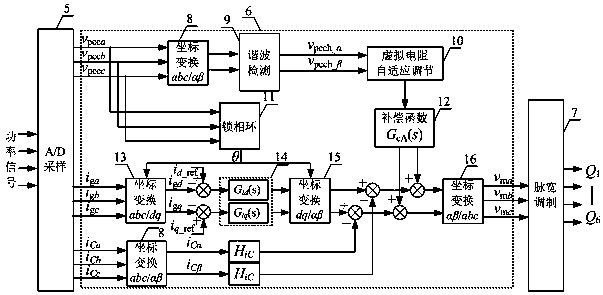

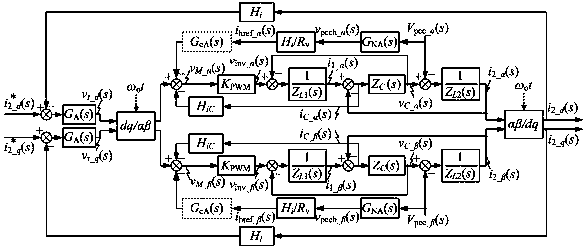

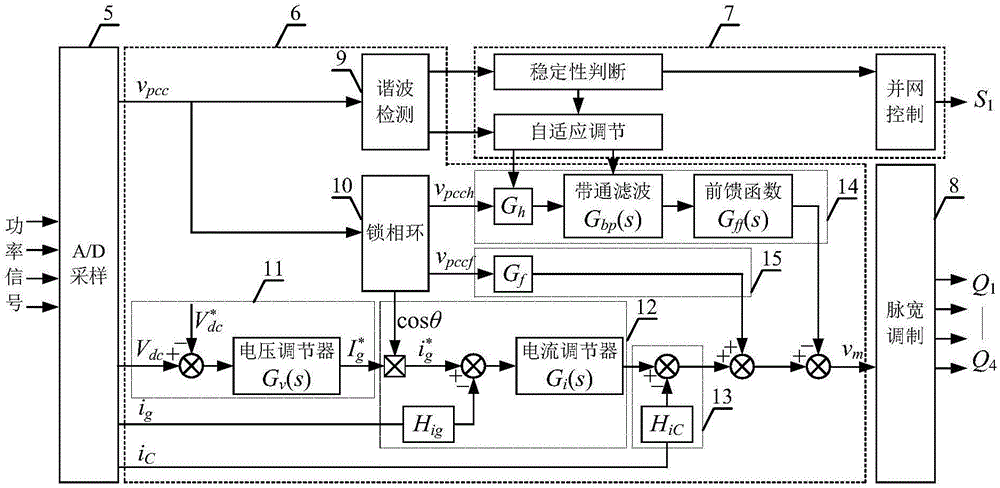

Active damper which can improve the stability of grid-connected inverter system and regulate the power

ActiveCN109149646AImprove stabilityIncrease computing loadSingle network parallel feeding arrangementsHarmonic reduction arrangementSynchronous coordinatesPower inverter

The invention provides an active damper which improves the stability of the inverter grid-connected system and can be adjusted in power, the active damper is connected in parallel with a plurality ofinverter grid-connected systems at a common coupling point, comprises a power output circuit and a control circuit, A power output circuit outputs a three-phase grid-connected current, the control circuit detects the three-phase PCC voltage, The harmonic content in the target frequency range is extracted, and the active damper is made to simulate the resistance characteristics in the control bandwidth by the feed-forward compensation unit in the static coordinate system, so as to damp the oscillation caused by the instability in the grid-connected inverter system and improve the stability of the whole system. At the same time, the active power and reactive power of the grid-connected current are controlled directly in the synchronous coordinate system. The active damper can stabilize the system quickly and effectively when the grid-connected system is unstable while the active power and reactive power are controlled, and it also has good damping effect for the case of multiple resonance points simultaneously.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

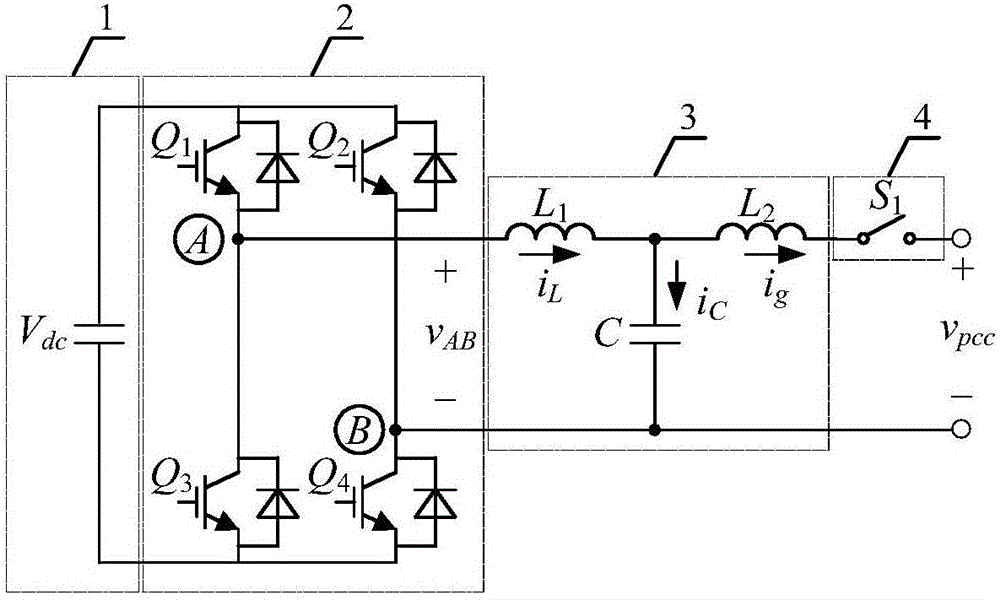

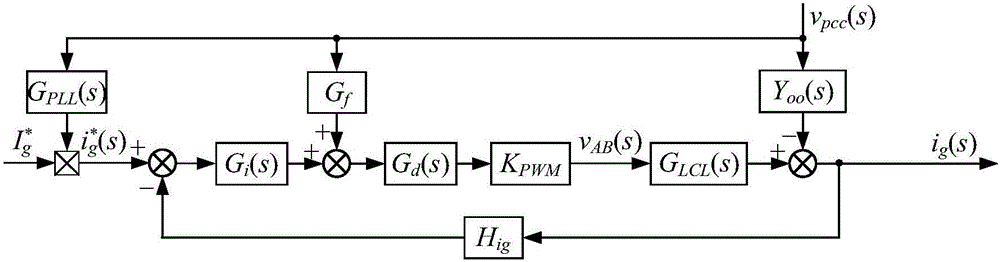

Impedance adapter used for stabilizing multiple inverter grid-connected system

ActiveCN106253337AReduce computing burdenDoes not affect normal workSingle network parallel feeding arrangementsClosed loopEngineering

The invention provides an impedance adapter used for stabilizing a multiple inverter grid-connected system. The impedance adapter is parallelly connected with the multiple inverter grid-connected system at a point of common coupling, and comprises a power output circuit and a control circuit, wherein the power output circuit outputs a DC side capacitance voltage V<dc> and a grid-connected current i<g>; and the control circuit detects a PCC voltage v<pcc>, acquires a phase position theta by means of a phase-locked loop unit, performs closed-loop control on the DC side capacitance voltage V<dc> by means of a voltage outer loop unit, performs closed-loop control on the grid-connected current i<g> by means of a current inner loop unit, and corrects output impedance characteristics of the impedance adapter by introducing a PCC voltage feedforward unit. The impedance adapter has the beneficial effects that the impedance adapter is less affected by digital control delay, can stabilize the system quickly and effectively, and has good stabilizing effect on the occurrence of a plurality of resonance points without changing control methods of each inverter in the system as well as software and hardware parameters.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

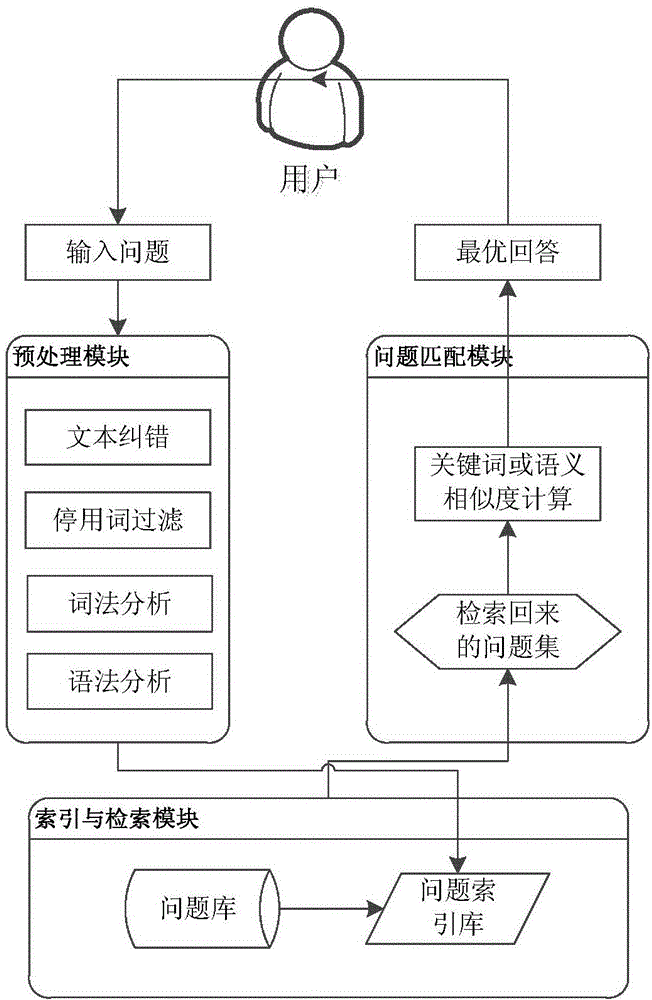

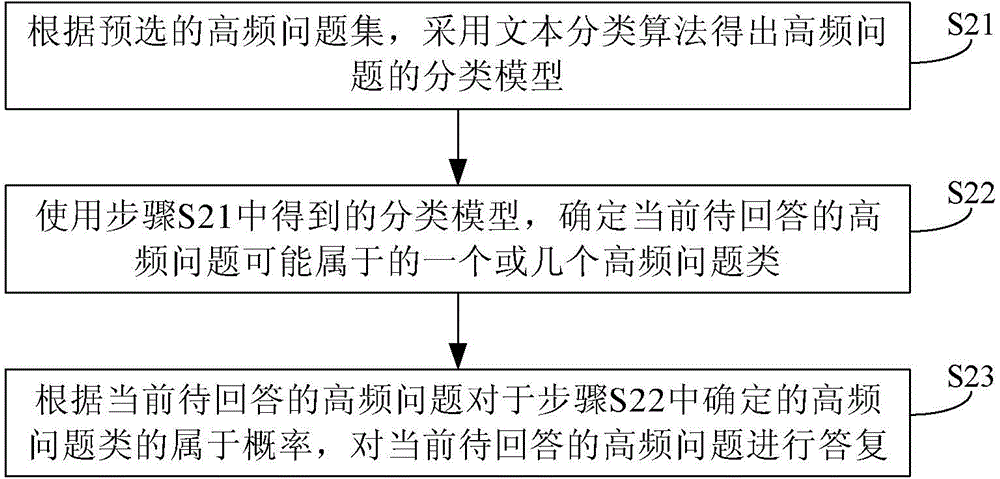

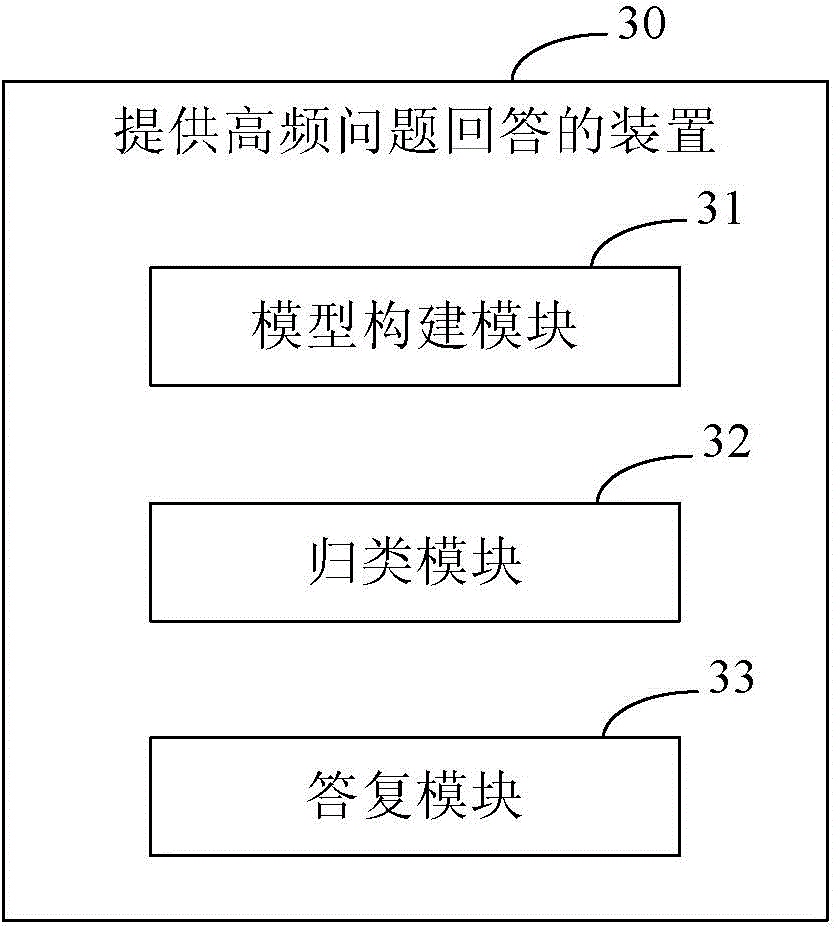

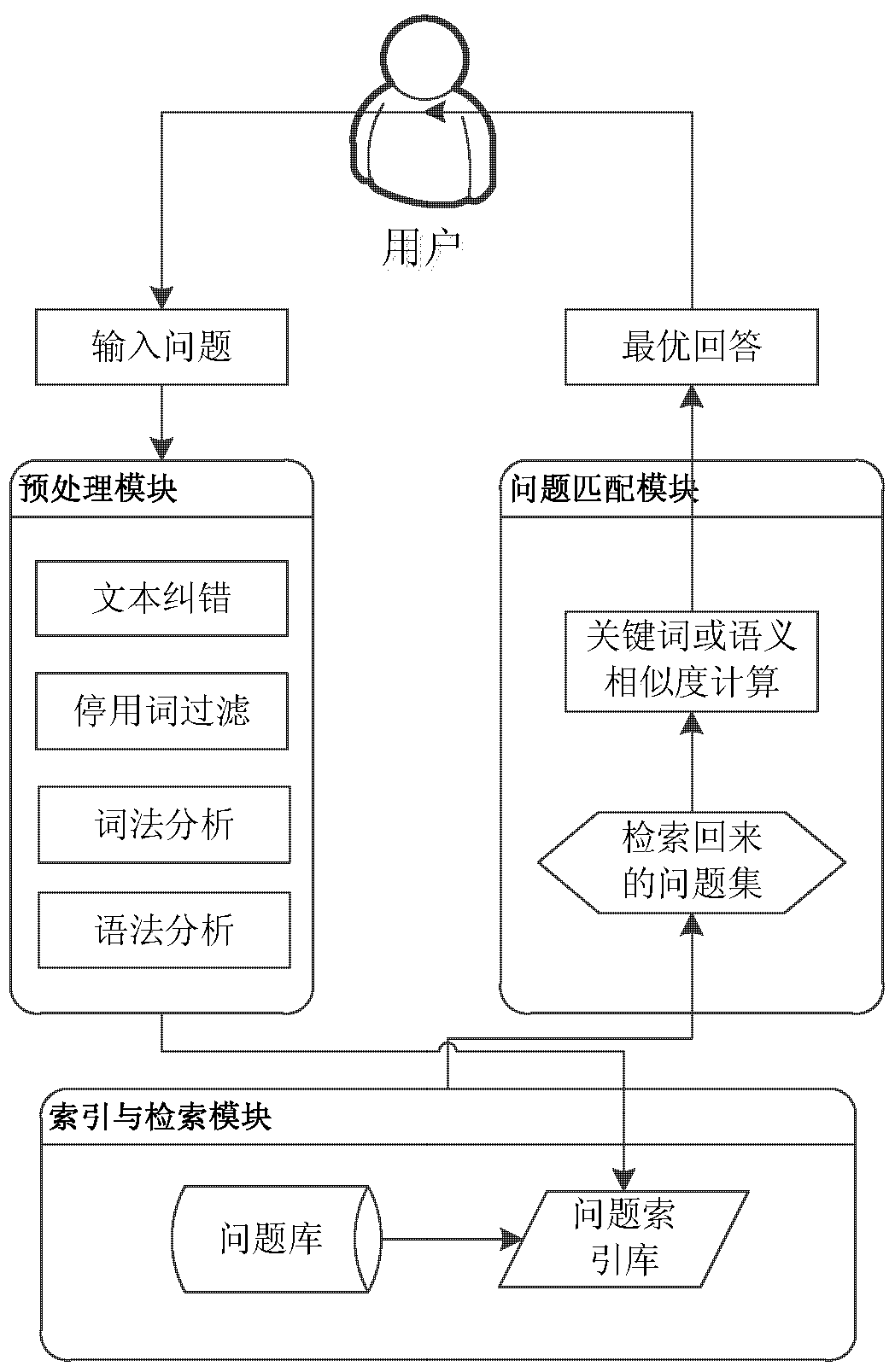

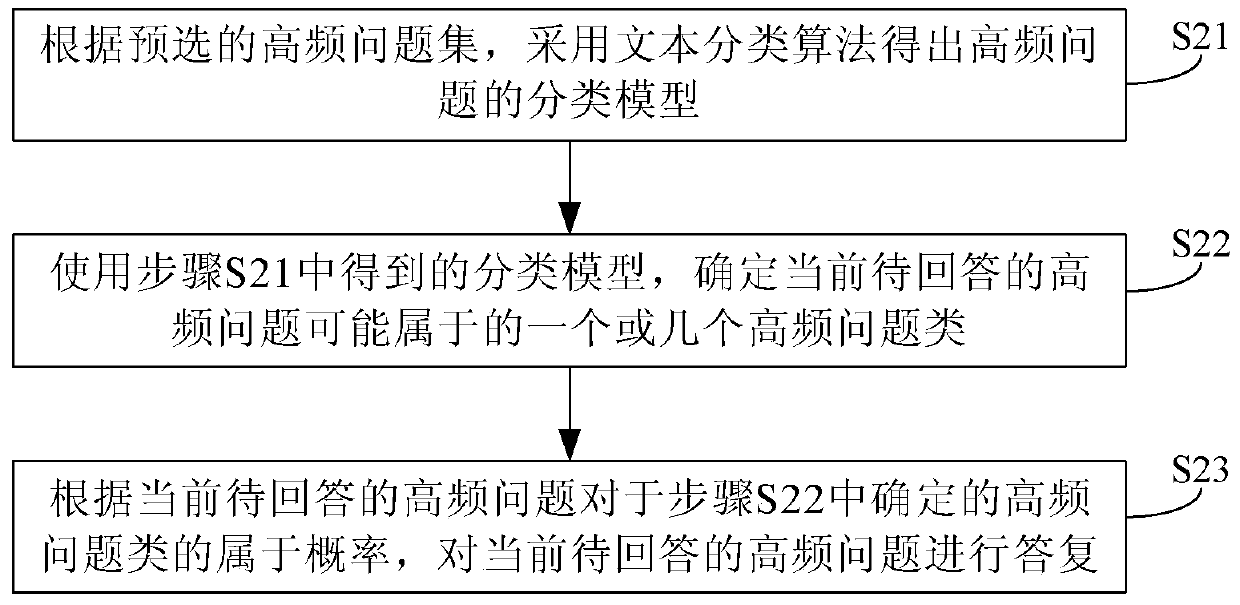

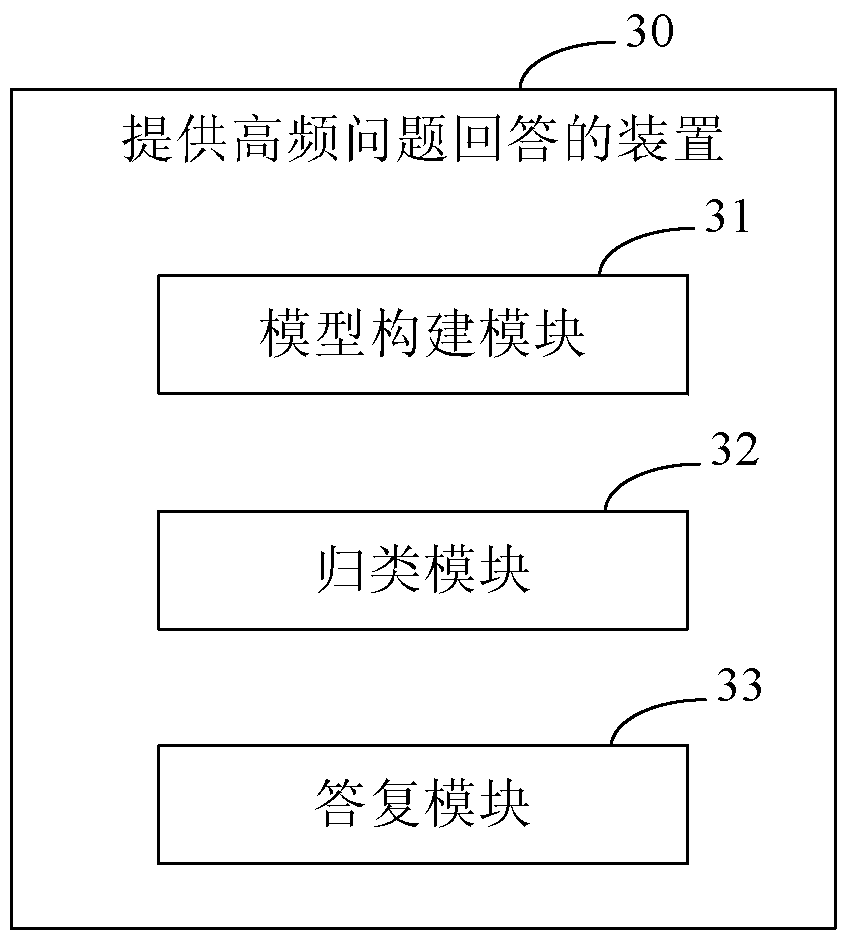

Method and apparatus for providing answers to frequently asked questions

ActiveCN104834651AImprove efficiencyImprove processing efficiencySpecial data processing applicationsLoad capacityFrequently asked questions

The present invention discloses a method and apparatus for providing answers to frequently asked questions, which can increase the load capacity of the system dealing with frequently asked questions and help to quickly respond to frequently asked questions. The method of providing answers to frequently asked questions disclosed in the present invention includes: according to the preselected set of frequently asked questions, obtaining the classification model of the high- frequently asked questions by a text classification algorithm, wherein the frequently asked questions with the same answers are classified into a same class; by using the classification model, determining the class or classes of the frequently asked questions which current to-be-answered frequently asked question may belong to; according to the possibility of the current to-be-answered frequently asked question belonging to the determined classes of the frequently asked questions, responding to current to-be-answered frequently asked question.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

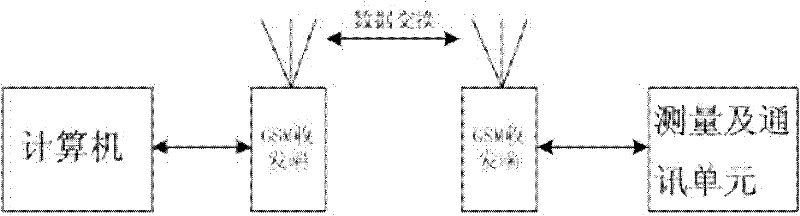

Fault Monitoring Device and Fault Judgment Method for Metering Electricity Fuses

InactiveCN102288908ADeal with as soon as possibleShorten the timeCircuit interrupters testingElectric power systemEngineering

The invention relates to a fuse fault monitoring system, which is mainly characterized in that: a data measurement element installed on a fuse measures voltage data and current data on the fuse; the voltage data and the current data are processed by a central processing unit; and a processing result is sent to a computer of an information center through a global system for mobile communication (GSM) module, so a monitor can timely find and handle a fuse fault. In the invention, geographic information of each fuse is recorded into a central processing unit corresponding to the fuse, a fault fuse can be quickly positioned, a fault type and corresponding measures can be provided, so the fuse fault can be reduced, the maintenance time is saved, the loss caused by the fuse fault is reduced, and the running stability of an electric power system is improved.

Owner:CHONGQING UNIV

Machine room inspection method and device

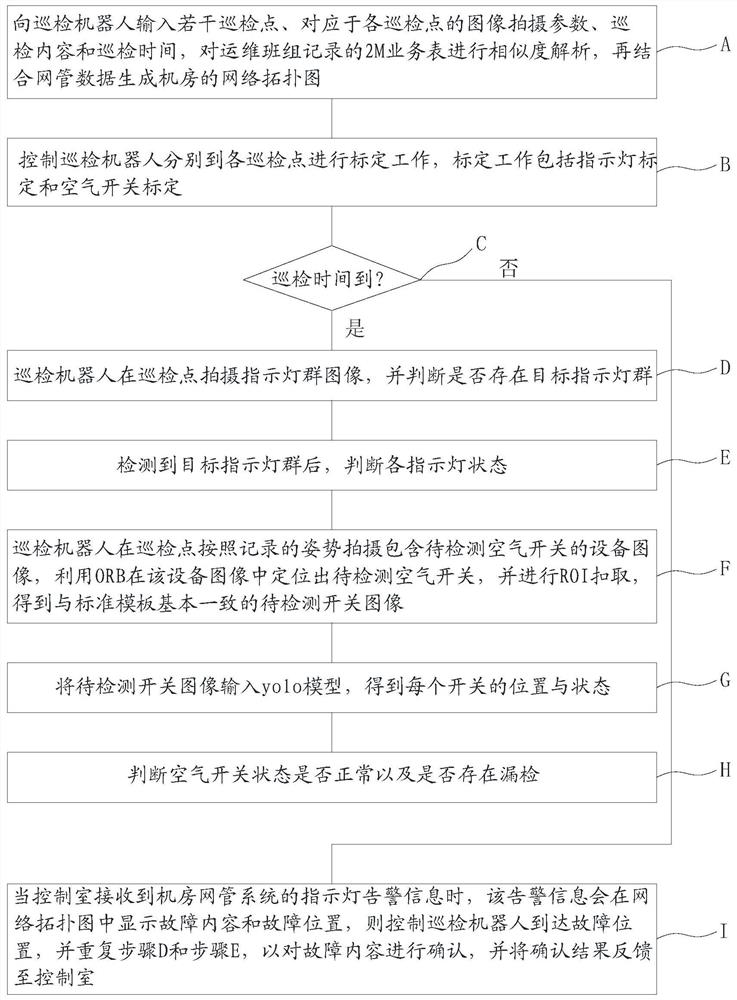

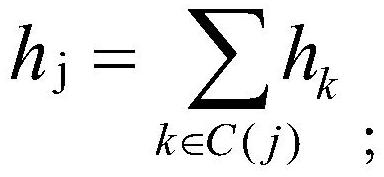

ActiveCN112766103APrevent overfittingImprove generalization abilityChecking time patrolsCharacter and pattern recognitionInformation controlImage detection

The invention provides a machine room inspection method, which comprises the following steps of: A, inputting a plurality of inspection points, image shooting parameters, inspection contents and the inspection time into an inspection robot, and generating a network topological graph; b, carrying out calibration work; c, performing routing inspection when the routing inspection time is up, otherwise, entering the step I; d, shooting an indicator lamp group image at the inspection point; e, detecting the state of an indicator lamp; f, shooting an equipment image containing the to-be-detected air switch, and positioning the to-be-detected air switch; g, inputting the to-be-detected switch image into the yolo model to obtain the position and the state of each switch; h, judging whether the air switch state is abnormal or not and whether leak detection exists or not; and I, receiving alarm information of the network management system, controlling the inspection robot to arrive at the fault position, and repeating the step D and the step E. The invention further provides a machine room inspection device. According to the invention, an accurate network topological graph can be generated, the detection with strong anti-interference performance, low false detection rate and high accuracy is achieved, and the inspection of the machine room is more comprehensive.

Owner:QUANZHOU POWER SUPPLY COMPANY OF STATE GRID FUJIAN ELECTRIC POWER +2

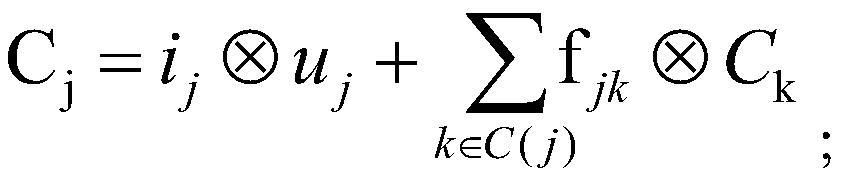

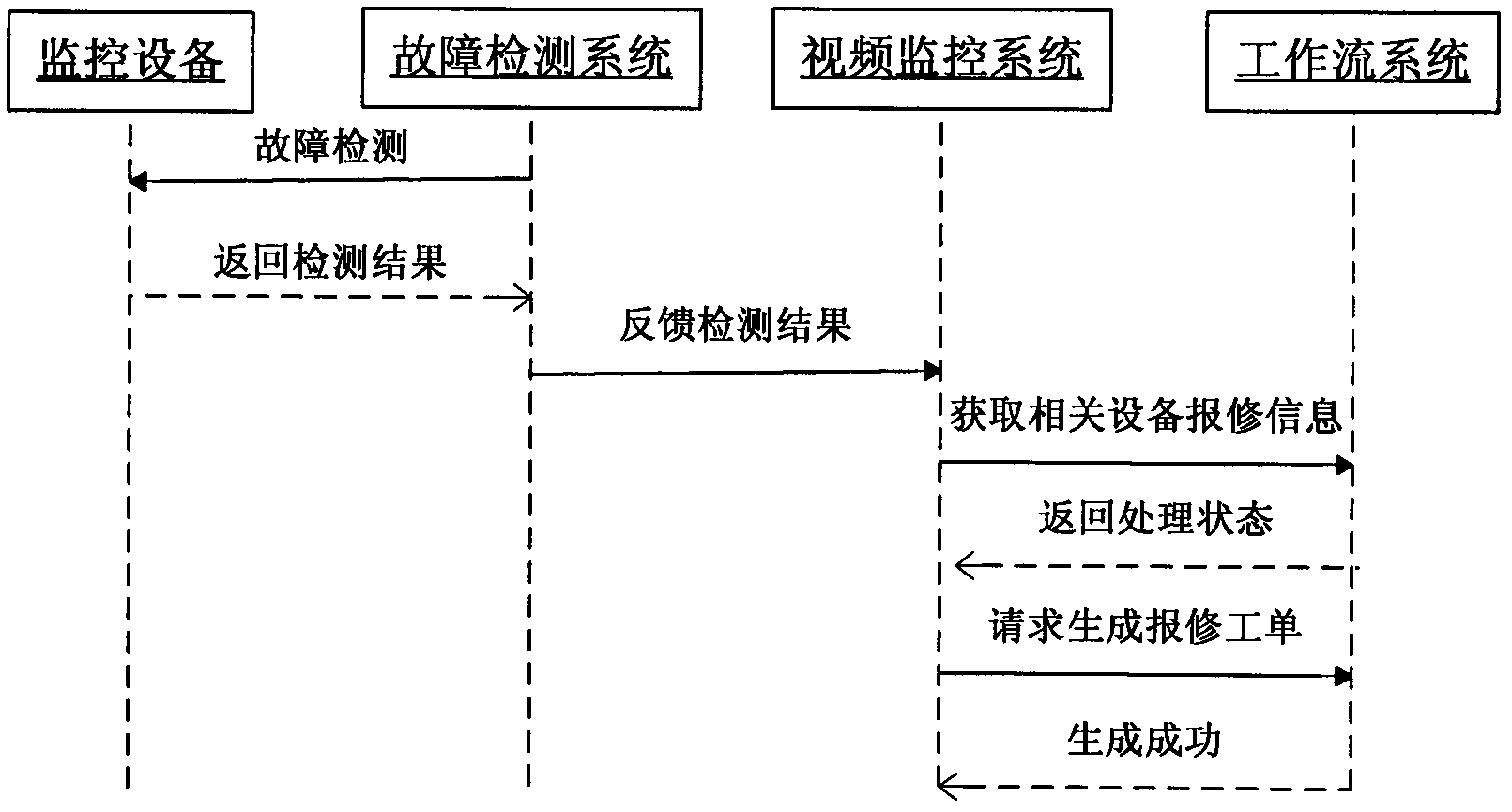

New method of intelligent repair monitoring equipment combining fault detection and workflow

InactiveCN103024425AAvoid duplication of formsDeal with as soon as possibleTelevision systemsResourcesDigital videoWorkflow

The invention discloses a new method of intelligent repair monitoring equipment combining fault detection and workflow. The new method comprises a fault detecting system, a video monitoring system and a workflow system, wherein the fault detecting system is used for detecting faults of monitoring equipment such as a vidicon, and a digital video record (DVR), collecting fault information and feeding the fault information to a video monitoring platform; the video monitoring system is used for implementing unified management on the monitoring equipment such as the vidicon and the DVR, collecting and processing detection results of the fault detecting system simultaneously, and requiring the workflow system to automatically generate a repair worksheet according to circumstances; and the workflow system is used for automatically generating a repair worksheet in different circumstances and different ranks according to the types of the fault equipment, the generated fault types and the fault situations as well as the fault detection information collected by the video monitoring system combining with a pre-customized repair procedure, and entering repair procedure flow. Meanwhile, the video monitoring system can also acquire the latest processing situation of the repair worksheet of certain monitoring equipment in real time through the workflow system, so as to avoid repeated sheet filling.

Owner:PCI TECH GRP CO LTD

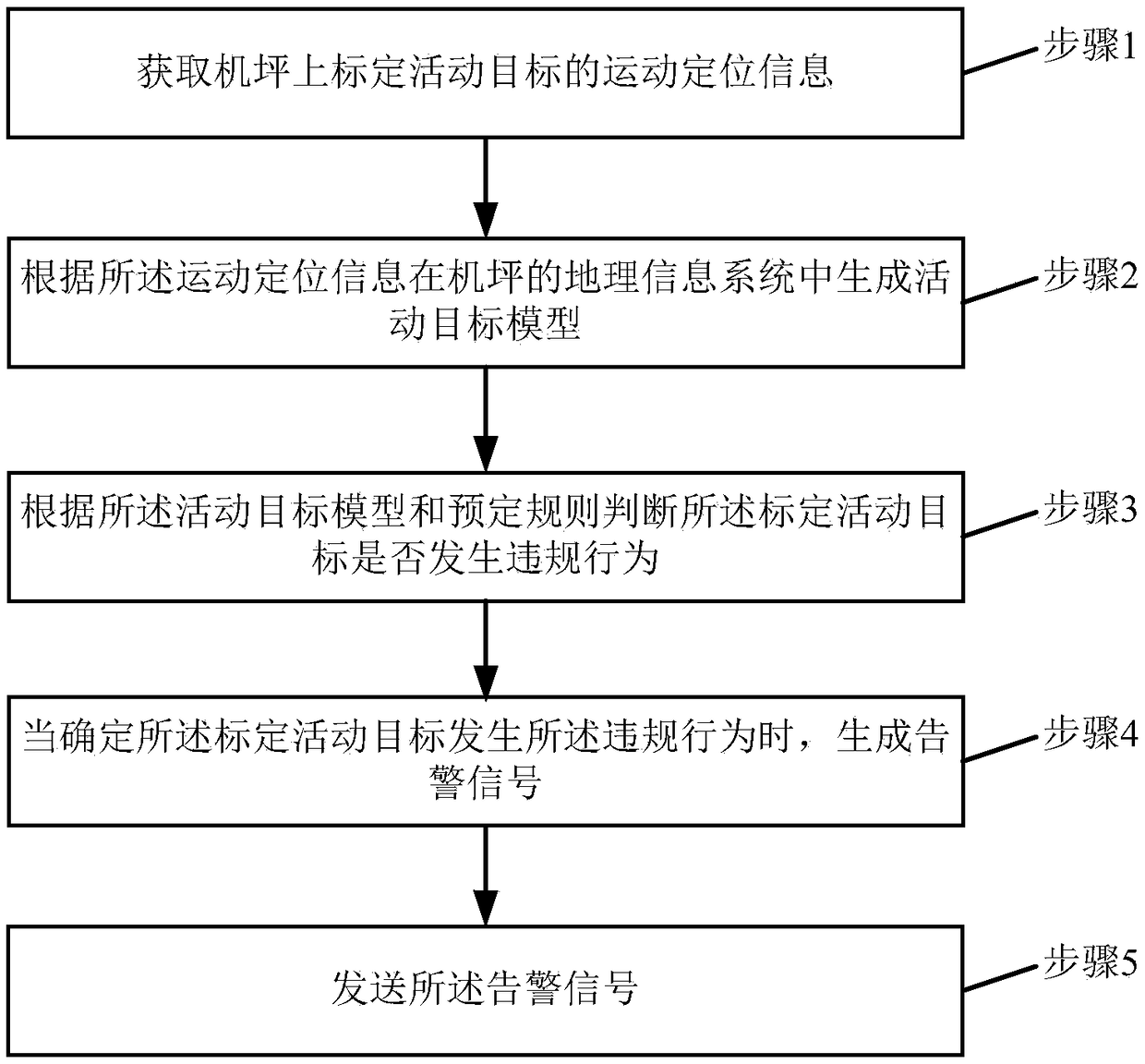

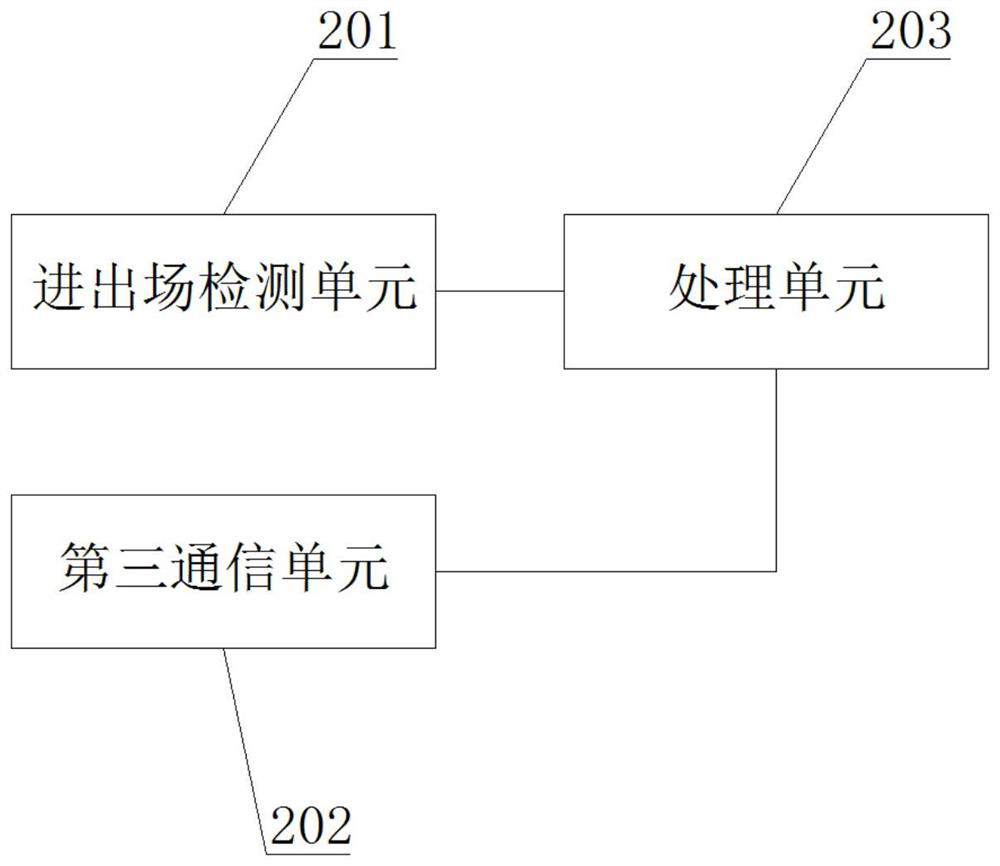

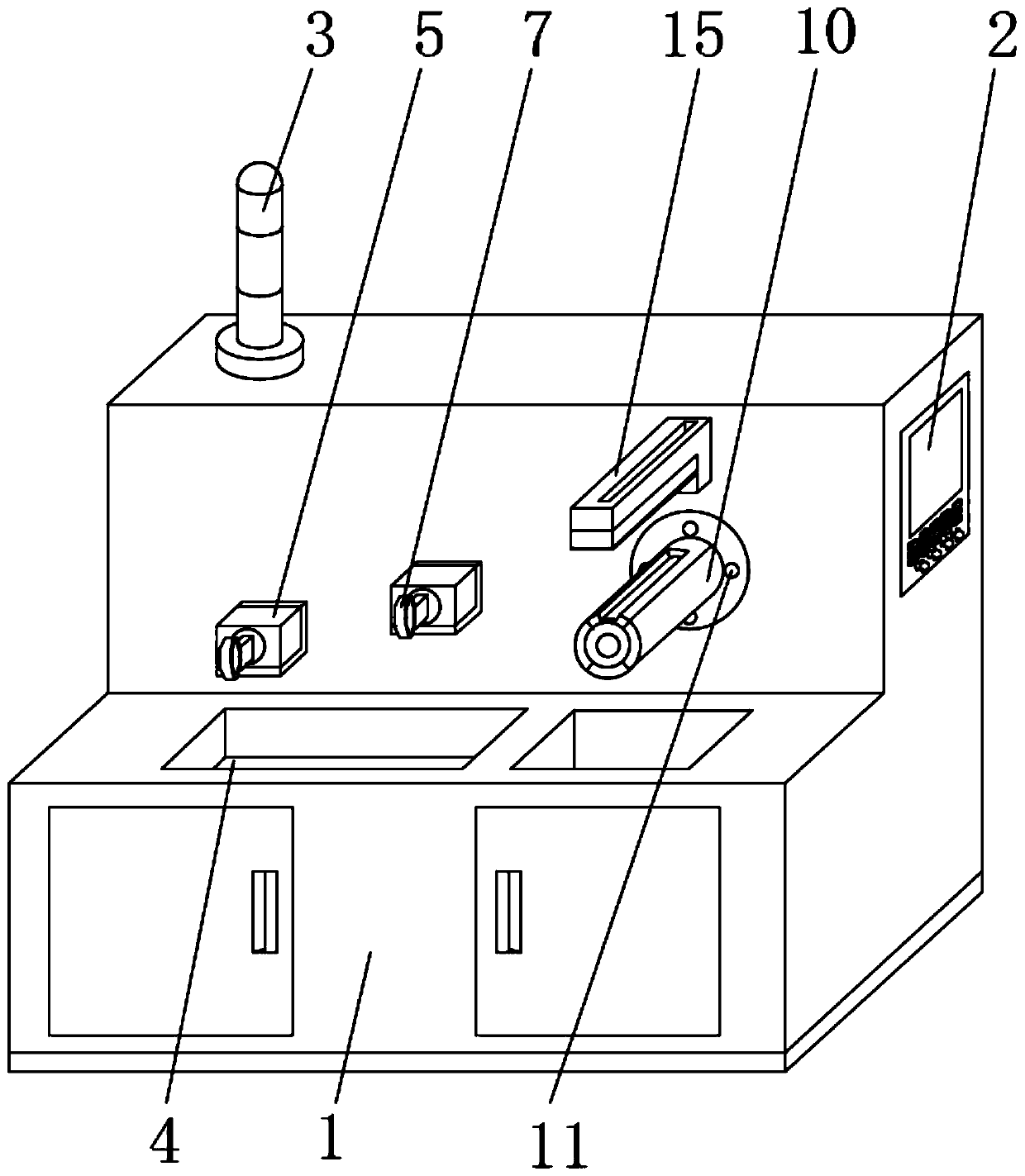

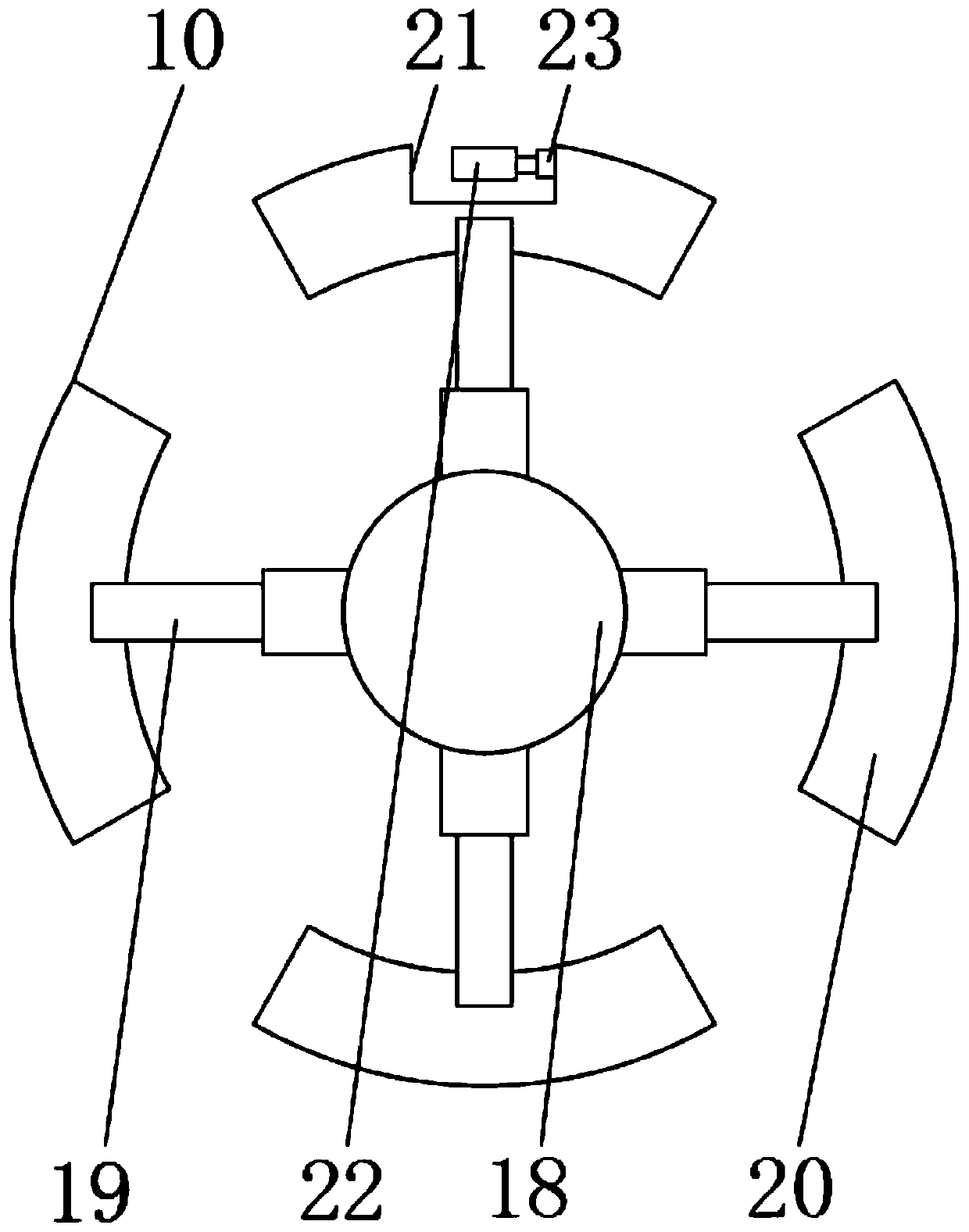

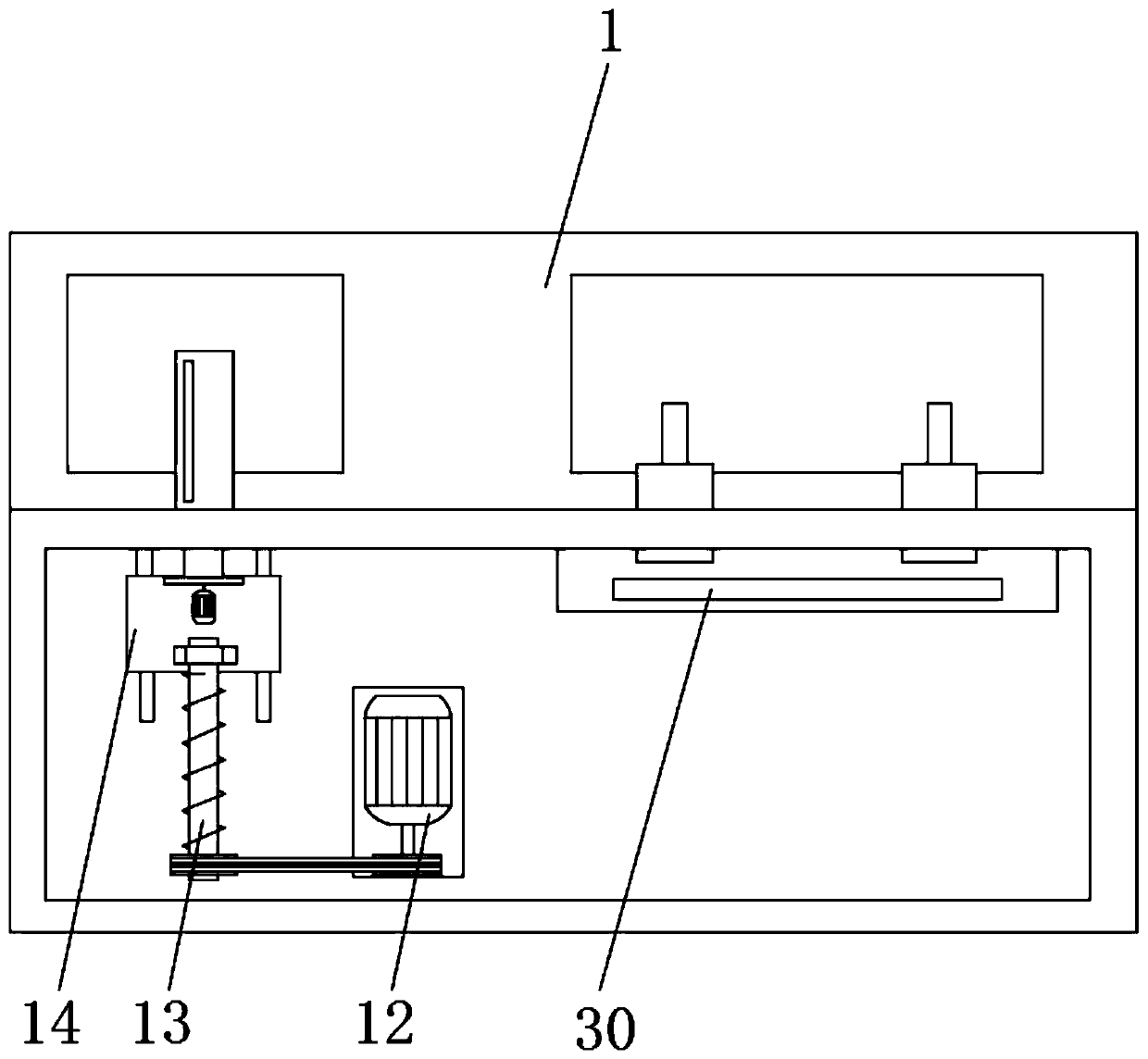

Comprehensive control method and system for airport apron

InactiveCN108428370AReduce the likelihood of accidentsReduce job hazardsAircraft ground controlGeographic information systemAirplane

The invention relates to a comprehensive control method and system for an airport apron. The method includes the following steps that: step 1, the motion positioning information of a calibration mobile target on the airport apron is acquired; step 2, a mobile target model is generated in the geographic information system of the airport apron according to the motion positioning information; step 3,whether the calibration mobile target conducts regulation violation behaviors is judged according to the mobile target model and predetermined rules; step 4, when it is determined that the calibration mobile target conducts regulation violation behaviors, alarm signals are generated; and step 5, the alarm signals are sent. With the comprehensive control method and system for the airport apron provided by the technical schemes of the invention adopted, the safety and timeliness of the control of mobile objects such as automobiles and airplanes on the airport apron can be improved, and the possibility of accidents on the airport apron can be reduced.

Owner:北京司拓民航科技有限责任公司

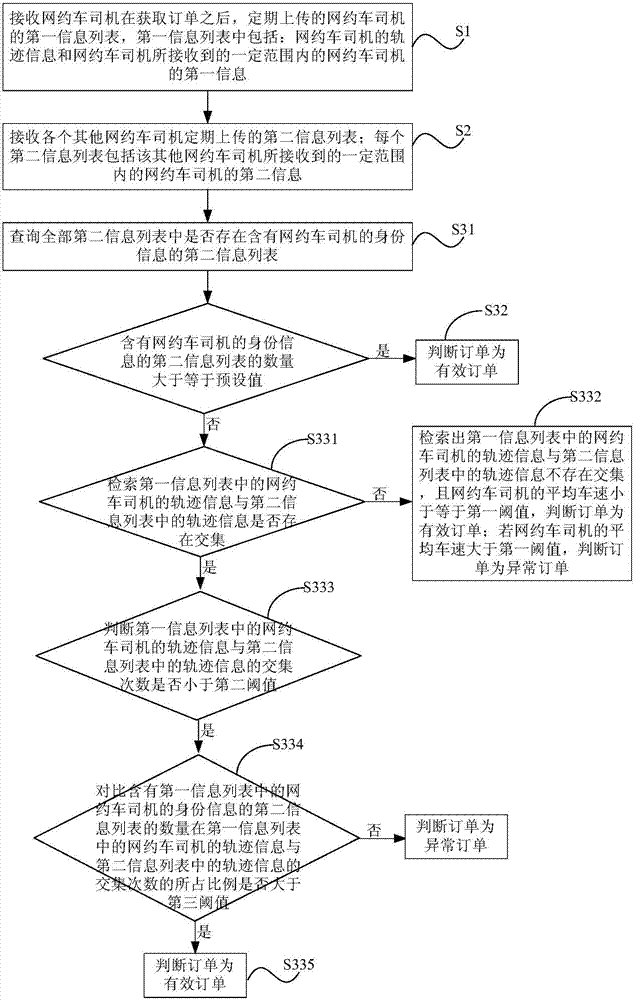

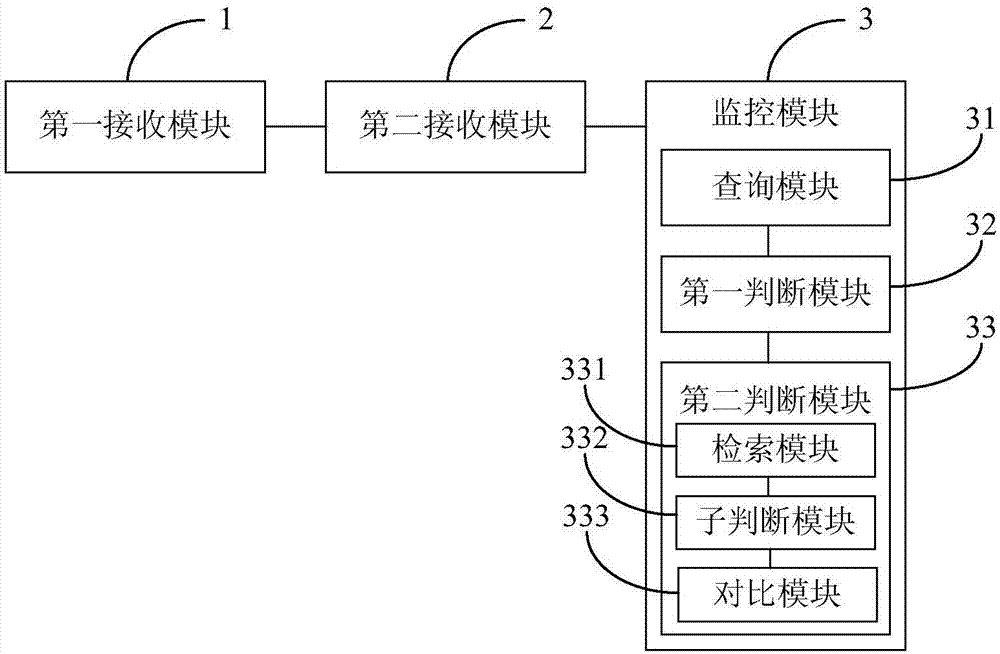

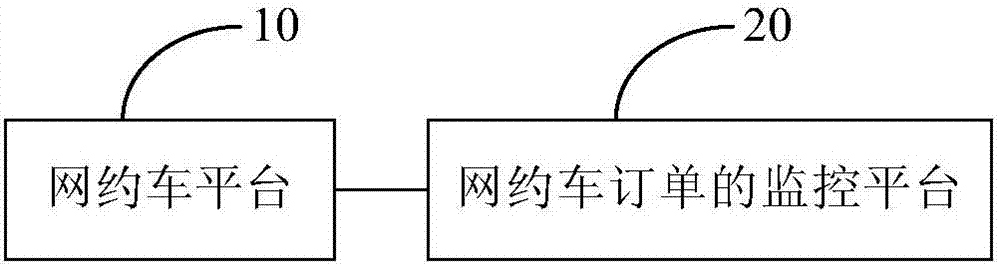

Method, platform and system for monitoring online taxi-hailing orders

ActiveCN106980904ASwiping behavior to eliminateDeal with as soon as possibleReservationsBuying/selling/leasing transactionsComputer scienceData science

The invention provides a method, a platform and a system for monitoring online taxi-hailing orders and belongs to the technical field of communication. According to the invention, the problem in the prior art that existing scalping behaviors for online taxi-hailing orders cannot be timely found out and effectively treated through conventional means can be solved. The method for monitoring online taxi-hailing orders comprises the steps of after an online taxi-hailing driver receives an order, periodically uploading a first information list of the online taxi-hailing driver, wherein the first information list comprises the trajectory information of the online taxi-hailing driver and the first information of the online taxi-hailing driver within a certain range; receiving a second information list periodically uploaded by each of other online taxi-hailing drivers, wherein each second information list contains the second information of online taxi-hailing drivers within a certain range from the other online taxi-hailing drivers; according to the first information of online taxi-hailing drivers within the certain range and received by the online taxi-hailing driver and the second information of online taxi-hailing drivers within the certain range and received by each of all the other online taxi-hailing drivers, monitoring the validity of the order.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

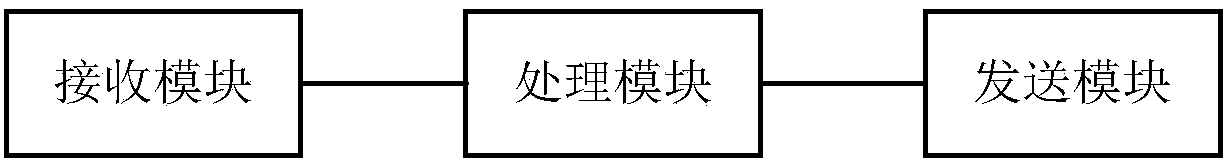

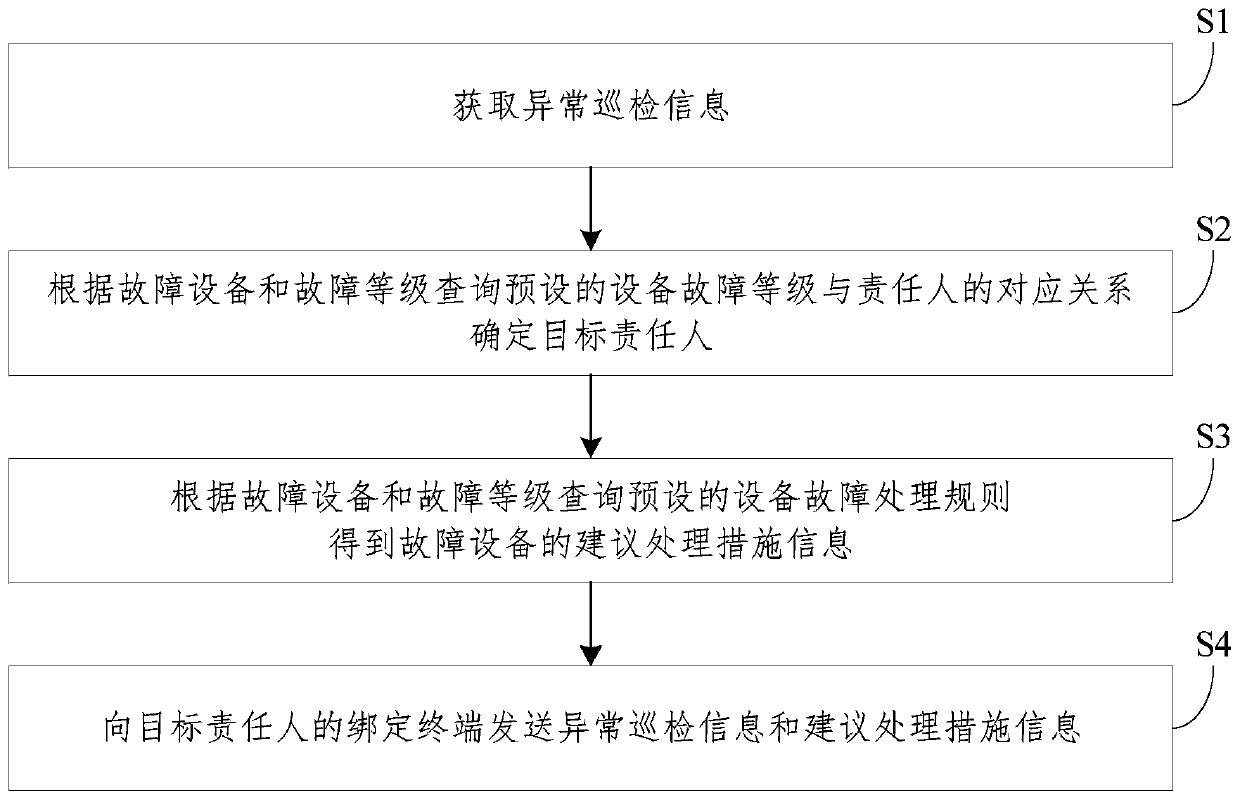

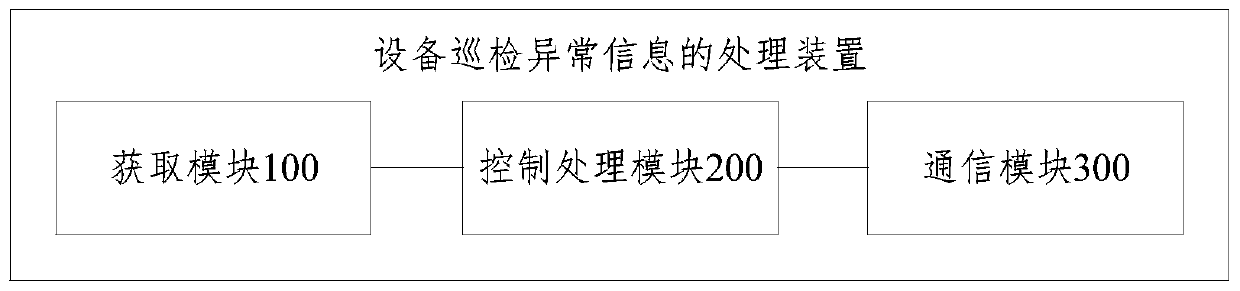

Equipment inspection abnormal information processing method and device and electronic equipment

InactiveCN111027800ADeal with as soon as possibleGuaranteed uptimeResourcesInformation processingReliability engineering

The embodiment of the invention discloses an equipment inspection abnormal information processing method and device and electronic equipment, and relates to the field of engineering equipment management. The processing method comprises: obtaining abnormal inspection information, wherein the abnormal inspection information comprises fault equipment, fault description information and a fault level;querying a preset corresponding relationship between the equipment fault level and a responsible person according to the fault equipment and the fault level to determine a target responsible person; querying a preset equipment fault processing rule according to the fault equipment and the fault level to obtain suggested processing measure information of the fault equipment; and sending the abnormal inspection information and the suggested processing measure information to a binding terminal of the target responsible person. According to the invention, the fault equipment, the fault descriptioninformation and the fault level can be automatically sent to the related responsible person, and the corresponding suggested processing measures can be sent to the related responsible person, so thatthe related responsible person can process the equipment fault as soon as possible, and the normal operation of the equipment is ensured.

Owner:南昌轨道交通集团有限公司 +2

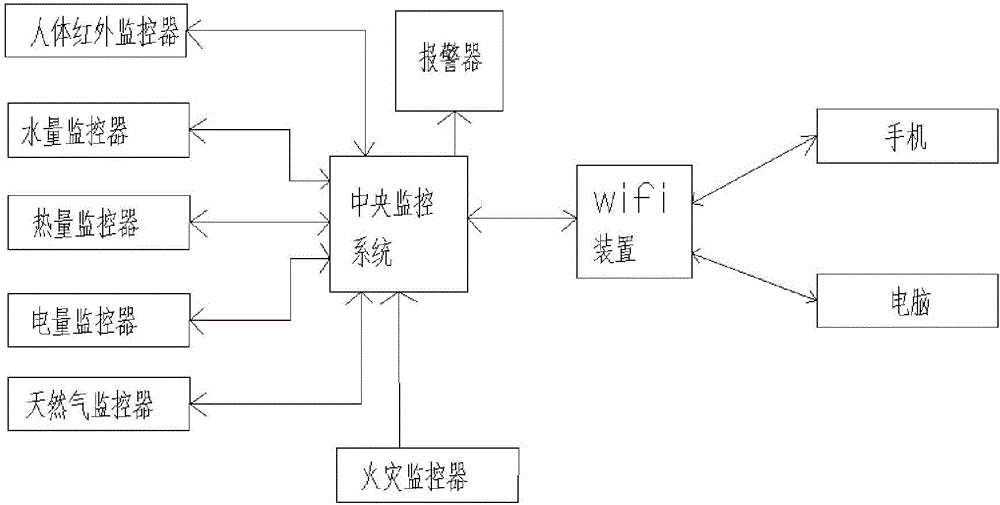

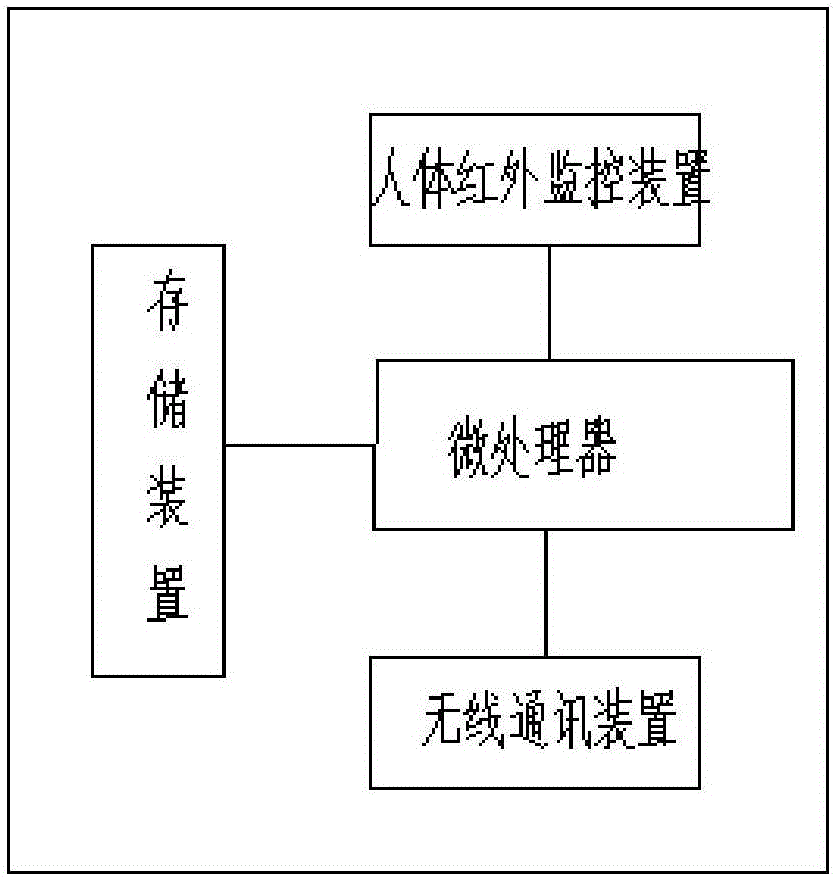

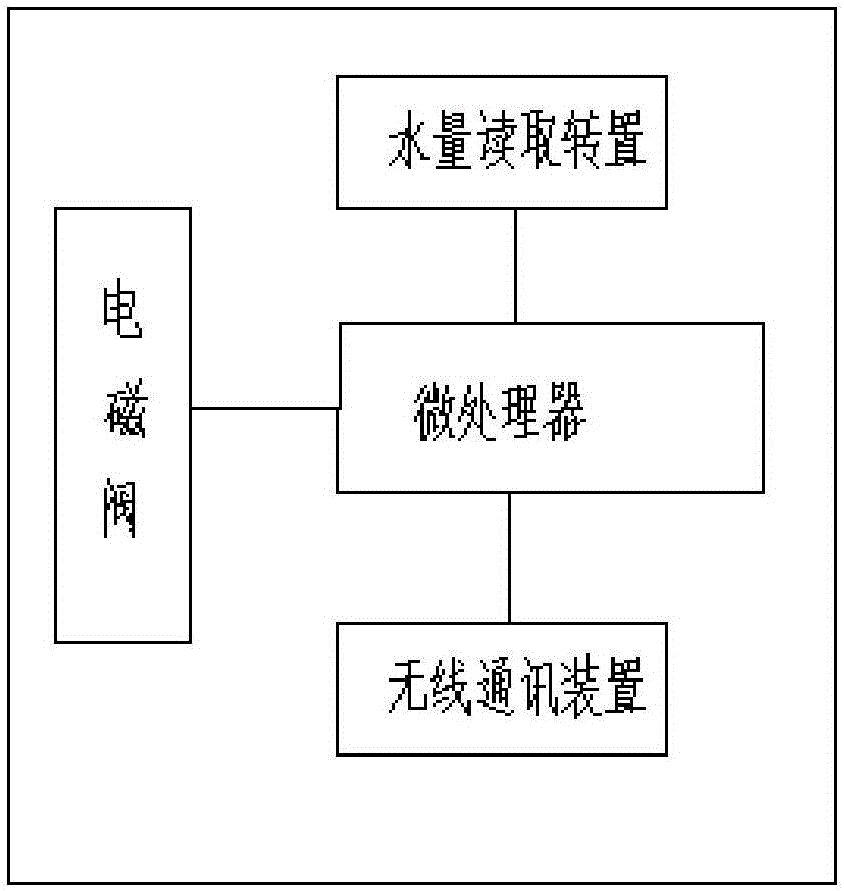

Intelligent monitoring system

InactiveCN106327784AInhibit deteriorationDeal with as soon as possibleProgramme controlComputer controlIntelligent lightingHuman body

The invention provides an intelligent monitoring system which comprises a monitoring device, a central monitoring system, a WiFi (wireless fidelity) device and an alarm device. The central monitoring system comprises a central processing unit, a memory and a wireless gateway, the memory and the wireless gateway are respectively connected with the central processing unit, the alarm device is connected with the central processing unit, the monitoring device comprises a wireless human body infrared monitor, the wireless human body infrared monitor comprises a microprocessor, a human body infrared monitoring device, a memory device and a wireless communication device, the human body infrared monitoring device, the memory device and the wireless communication device are respectively connected with the microprocessor, and data transmission is achieved between the microprocessor and the central processing unit by the wireless communication device. According to the intelligent monitoring system, people can comprehensively monitor family conditions through mobile phones or computers, potential safety hazards of families can be early discovered and treated and can early give an alarm, and deterioration is prevented.

Owner:TIANJIN YIYUN POWER NETWORK TECH CO LTD

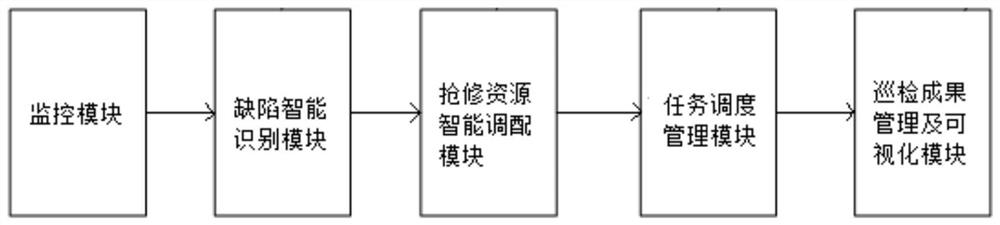

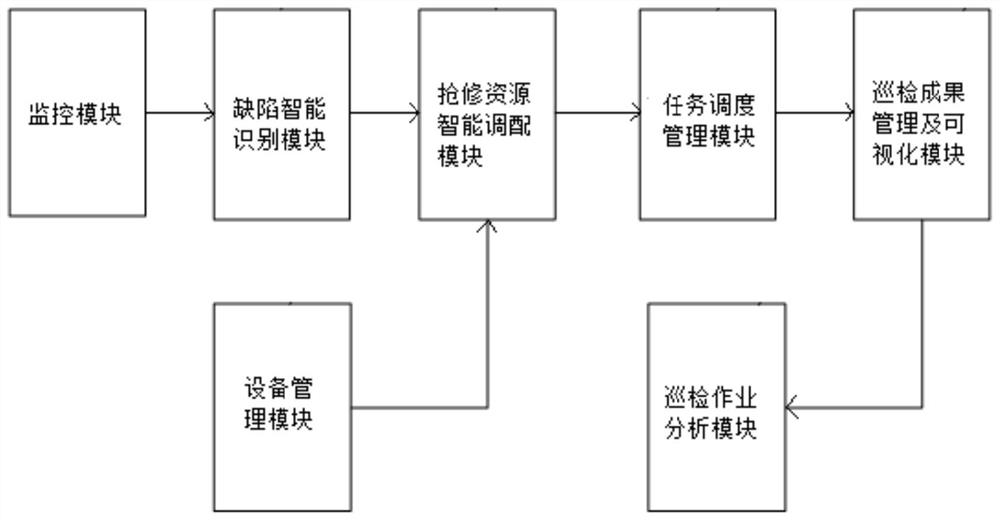

Distribution network line intelligent inspection system

PendingCN112564952AImprove fault detection efficiencyDeal with as soon as possibleChecking time patrolsClosed circuit television systemsMonitor equipmentResource allocation

The invention provides a distribution network line intelligent inspection system, which is provided with a monitoring module, a defect intelligent identification module, a first-aid repair resource intelligent allocation module, a task scheduling management module and an inspection result management and visualization module. The system can acquire inspection personnel information, machine inspection equipment information and equipment state information in real time through monitoring equipment, judges whether inspection equipment has a fault or not, identifies the fault according to a preset fault identification model, generates a first-aid repair resource allocation list for the fault, automatically generates a corresponding fault first-aid repair task and an inspection task, and issues the tasks to corresponding user sides, so that operation and maintenance personnel can know fault and inspection information as soon as possible, faults and inspection tasks are processed as soon as possible, the distribution line fault detection efficiency is improved, and the power supply reliability is improved.

Owner:GUANGDONG POWER GRID CORP ZHAOQING POWER SUPPLY BUREAU

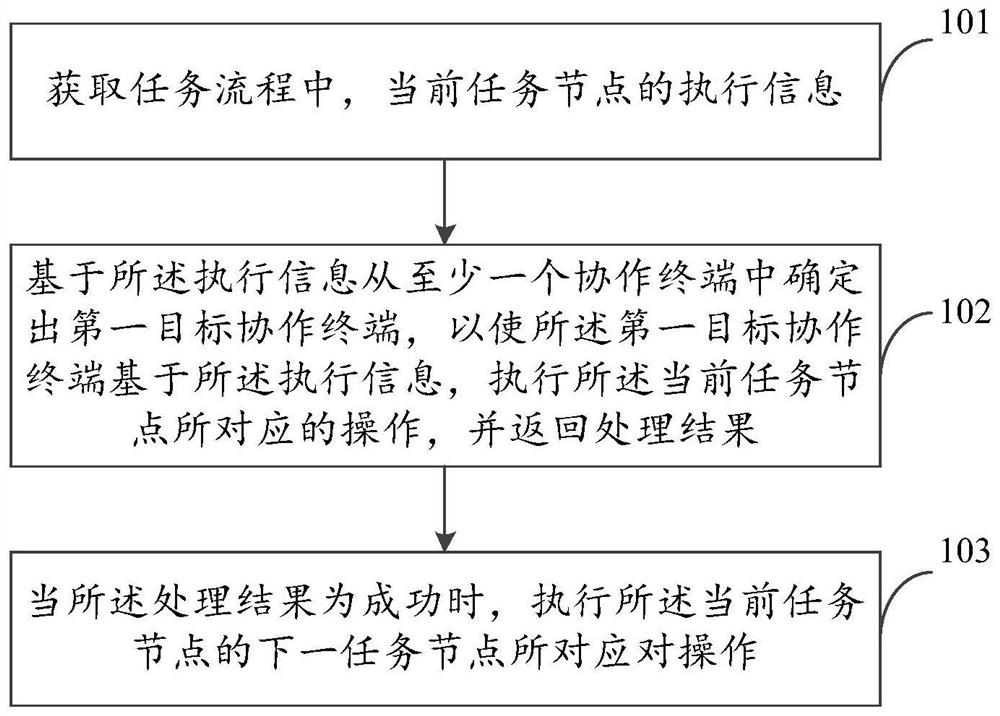

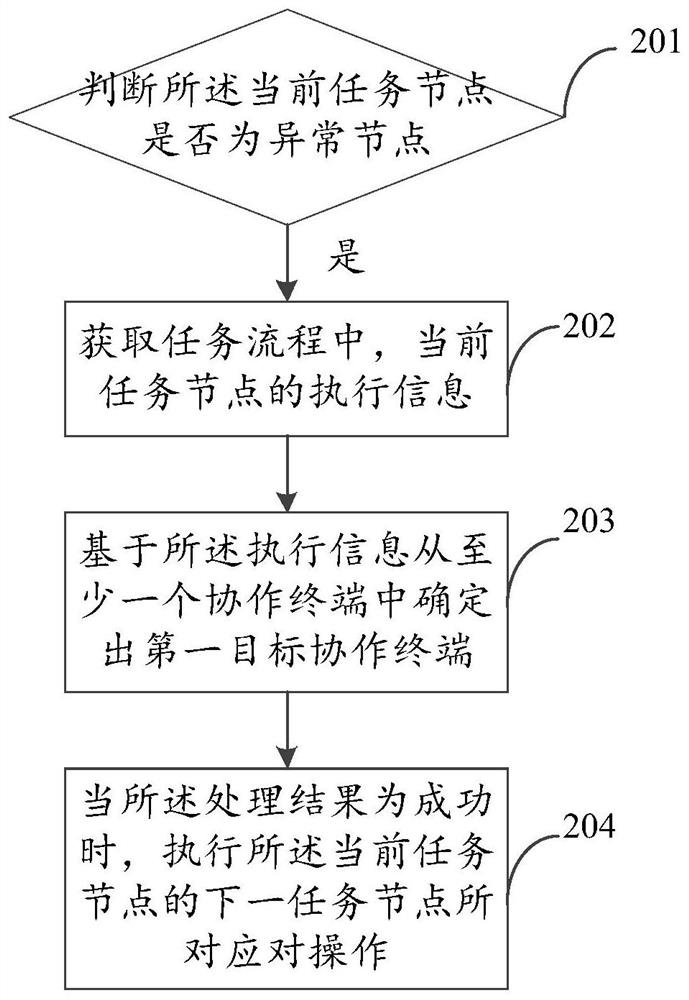

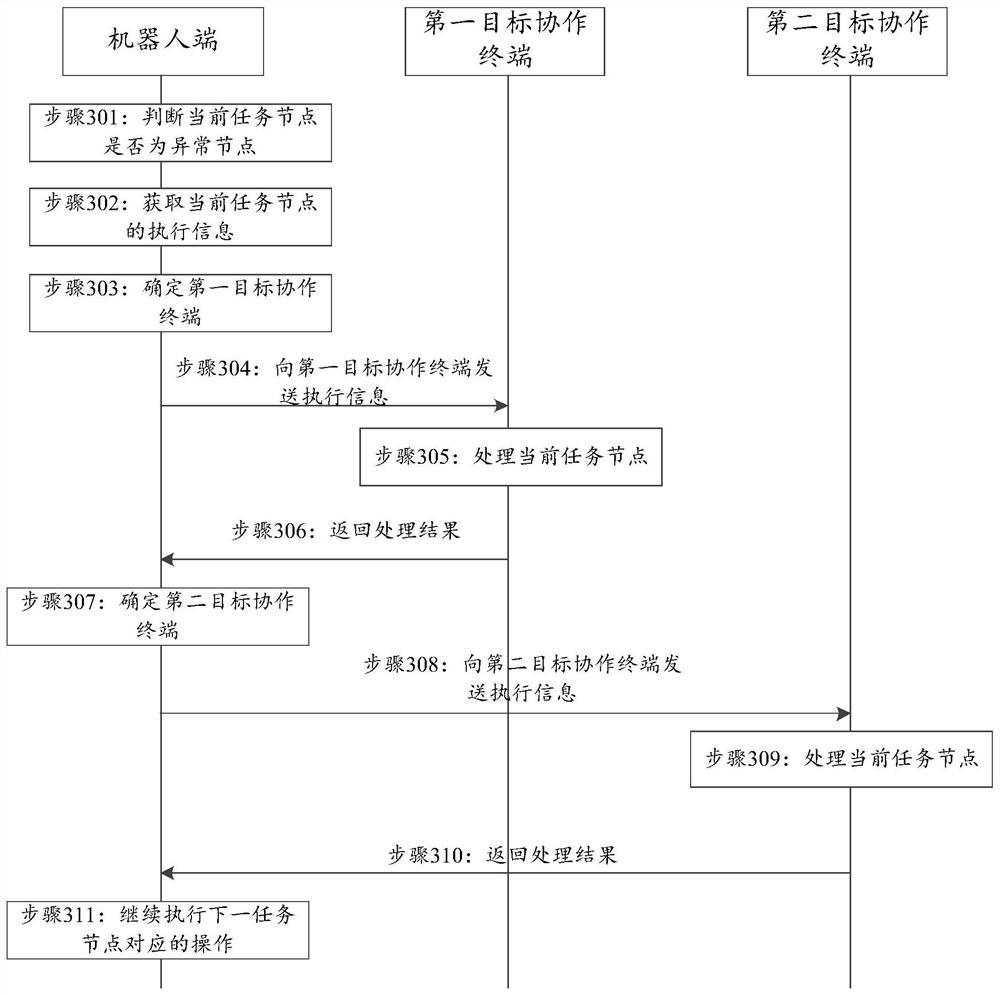

Flow processing method and device, electronic equipment, storage medium and system

PendingCN113220378AImprove execution efficiencyGuaranteed smooth executionExecution paradigmsComputer hardwareEngineering

The invention provides a flow processing method and device, electronic equipment, a storage medium and a system. The method comprises the steps of obtaining execution information of a current task node in a task flow, wherein the task flow comprises a plurality of task nodes, each task node in the plurality of task nodes corresponds to one piece of execution information; determining a first target cooperation terminal from at least one cooperation terminal based on the execution information, so that the first target cooperation terminal executes an operation corresponding to the current task node based on the execution information, and returns a processing result; and when the processing result is successful, executing corresponding operation corresponding to the next task node of the current task node. According to the embodiment of the invention, smooth execution of the task process is realized through interaction between the robot end and the cooperation terminal, so that the task flow execution efficiency is improved.

Owner:中电金信软件有限公司

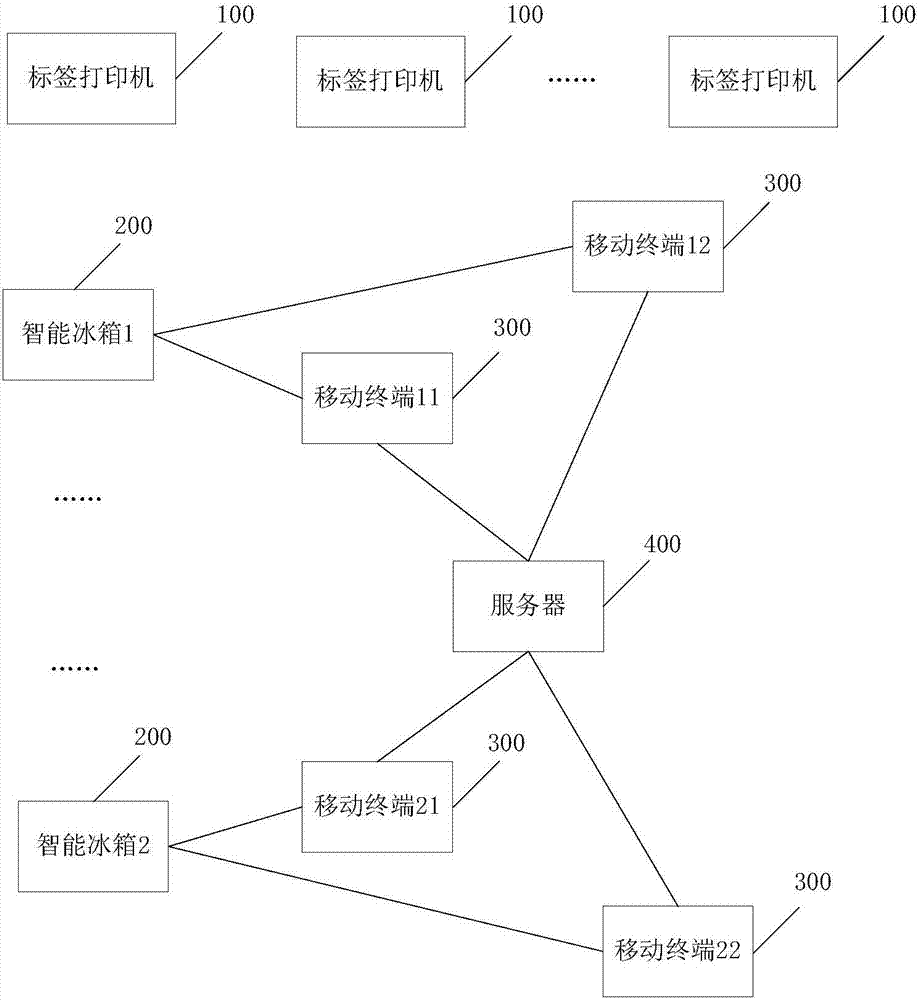

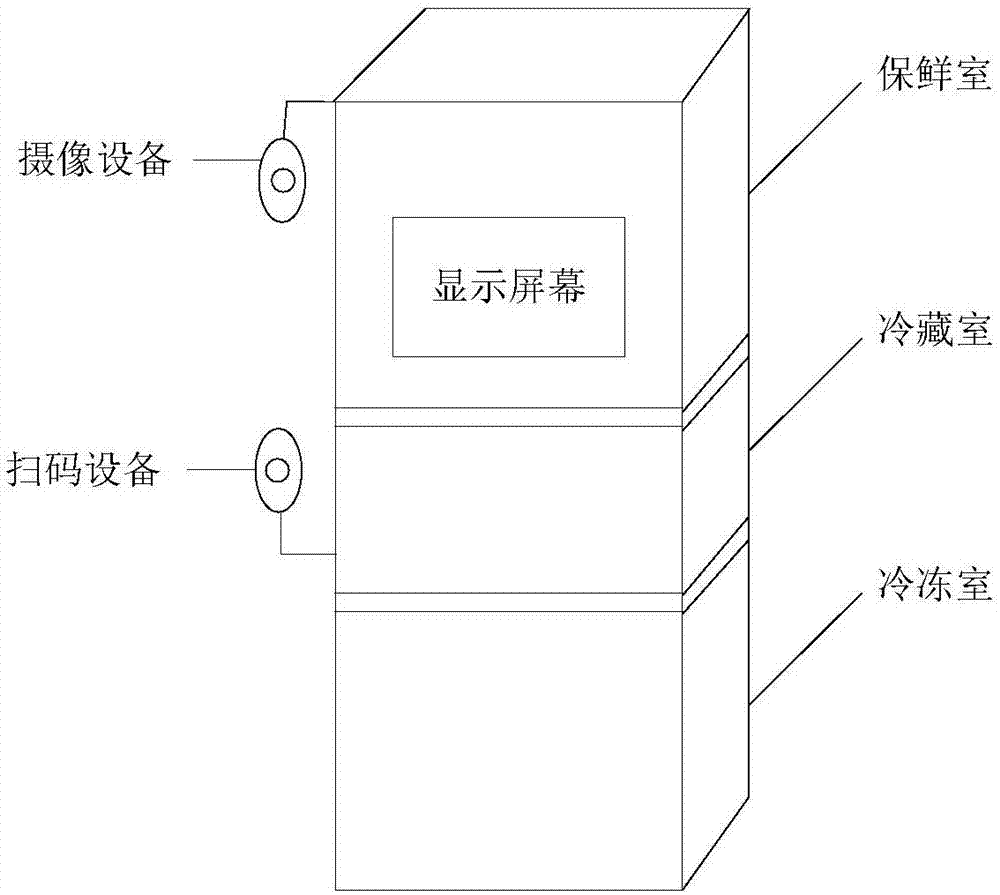

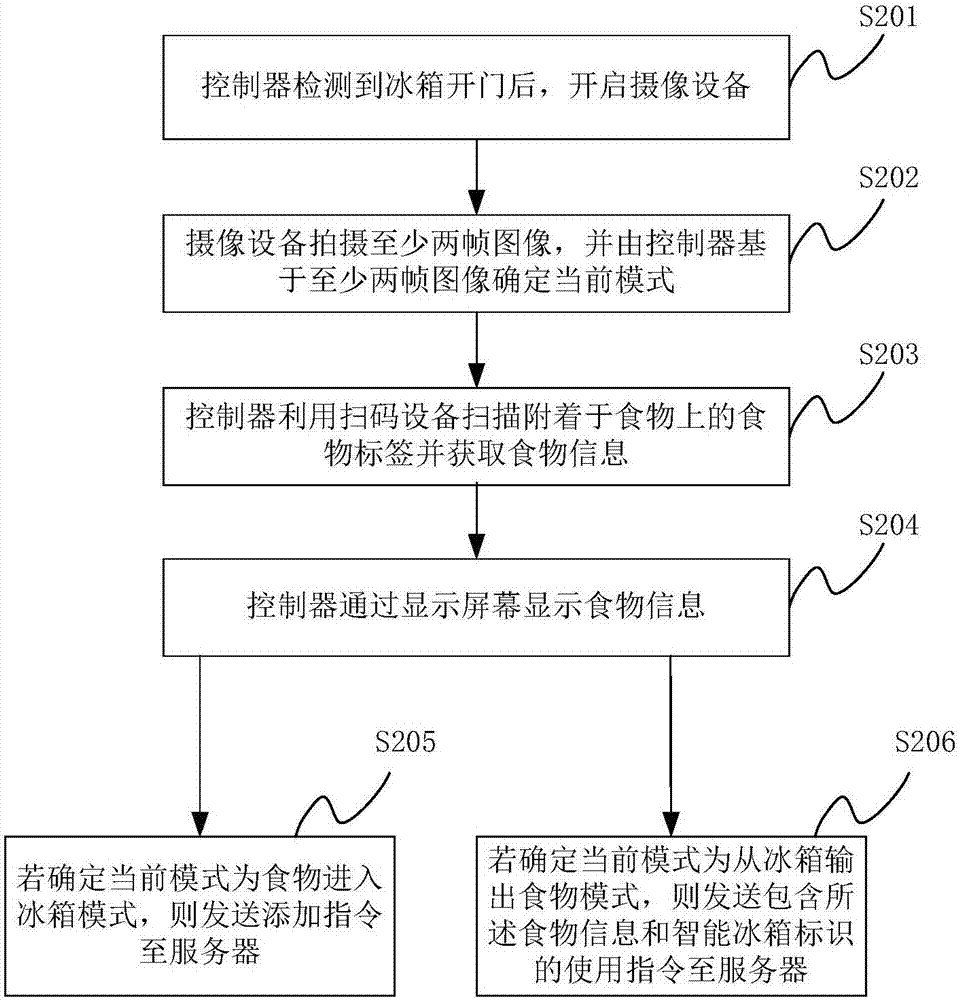

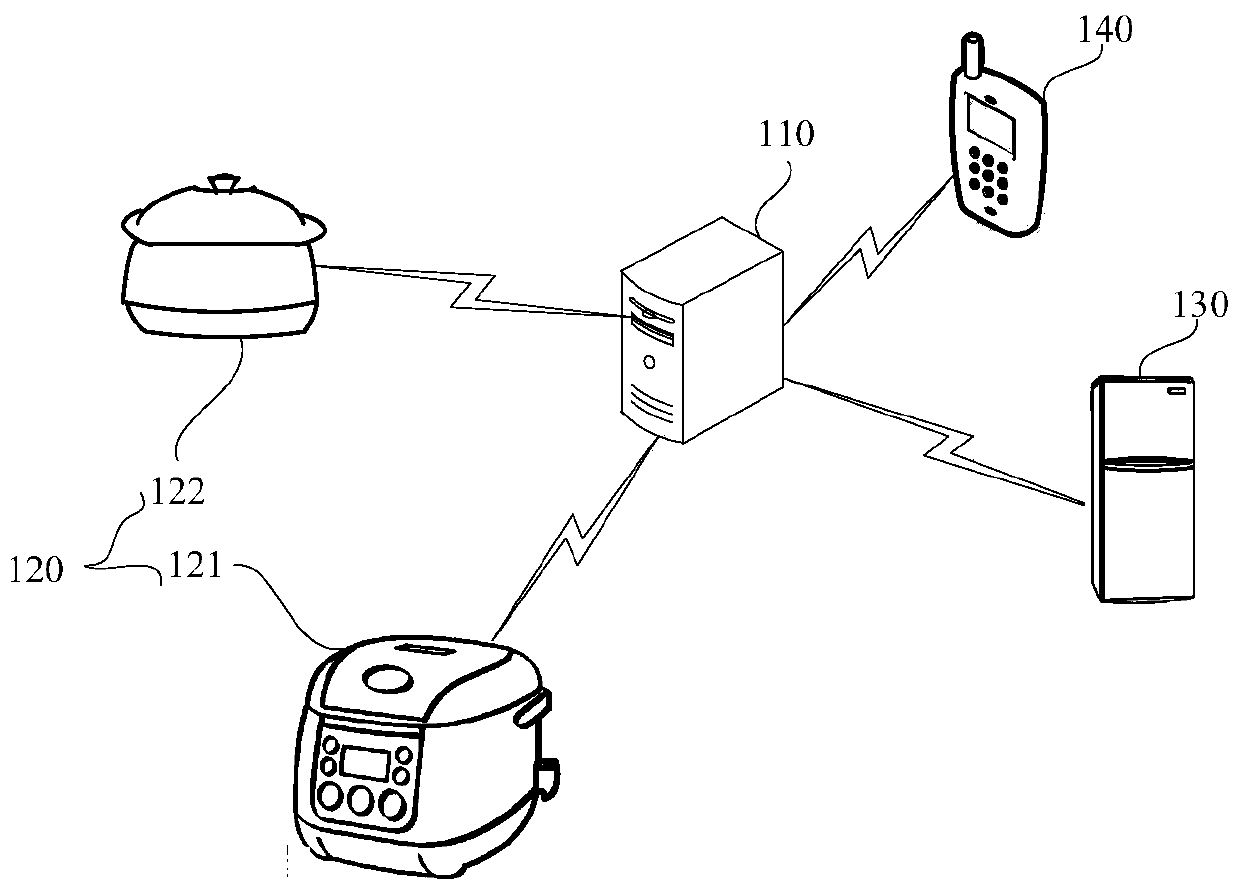

Food information processing method and system

InactiveCN107506973AEasy to handleDeal with as soon as possibleCo-operative working arrangementsOffice automationInformation processingComputer science

The invention provides a food information processing method and a food information processing system. The food information processing method comprises the steps of: scanning a food label attached to food, so as to obtain food information; determining remaining time length and reminding time length corresponding to the food information; and executing a preset processing operation when the remaining time length is less than or equal to the reminding time length. The food information processing method and the food information processing system can automatically execute the preset processing operation when the remaining time length is less than or equal to the reminding time length of the food information, so that a user can know in time that the food information is about to exceed normal preservation time, and the user can handle the food as soon as possible.

Owner:GREE ELECTRIC APPLIANCES INC

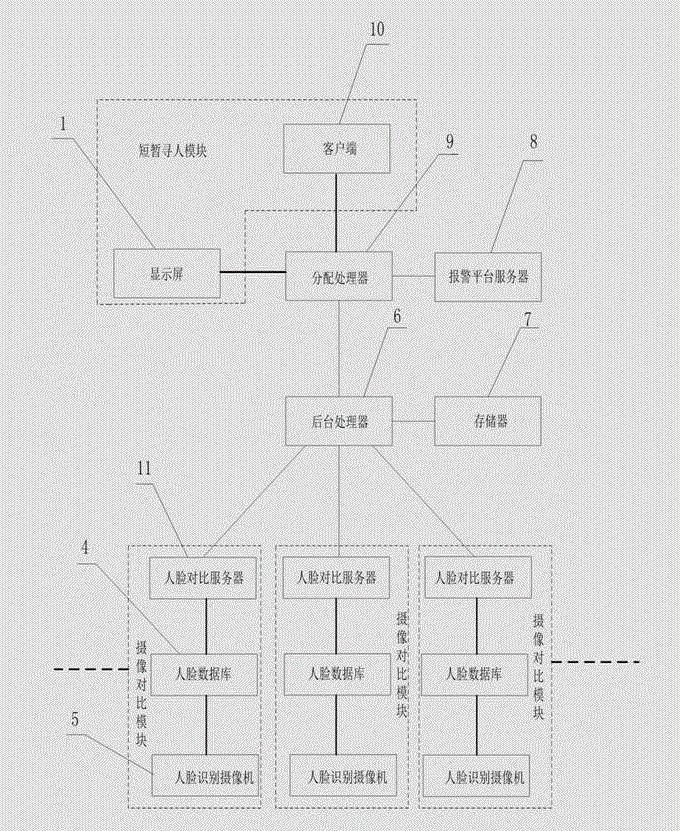

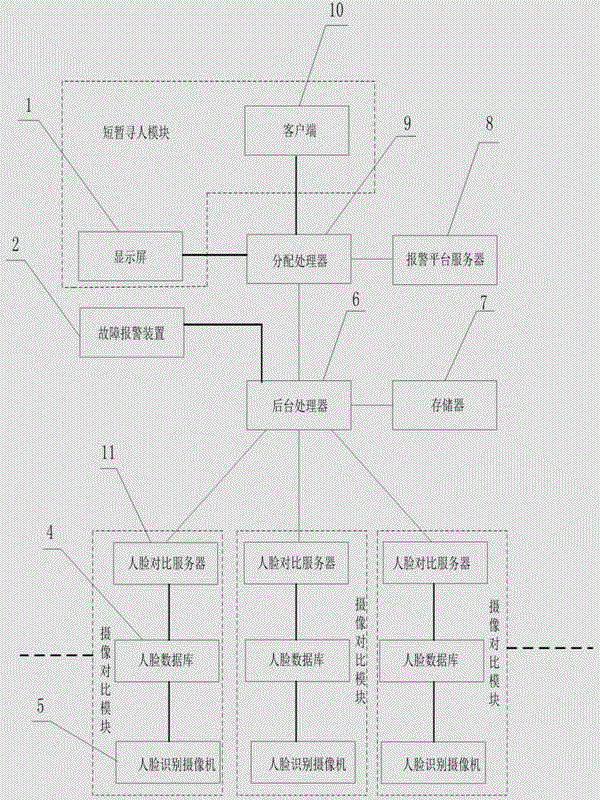

Alarm monitoring and people-searching system

InactiveCN104902237AReduce workloadIt is not easy to miss the best time to solve the caseClosed circuit television systemsTransmissionMonitoring systemWorkload

The invention discloses an alarm monitoring and people-searching system, which is mainly used for solving the problem that current monitoring system could not search lawbreakers by browsing monitor videos manually, and the workload is large, and optimum time for solving a case is easy to miss, and the current monitoring system could not provide accurate search of persons who get lost in short time. The alarm monitoring and people-searching system comprises a brief people-searching module for releasing and receiving people-search tasks within 24 hours, an alarm platform server for alarming and releasing a notice that the police search the people, a distribution processor for distributing processing results, a background processor for transmitting a people-searching instruction and receiving a searching result, a memory and a plurality of camera shooting comparison modules for shooting and searching. The brief people-searching module, the alarm platform server and the background processor are electrically connected with the distribution processor. The camera shooting comparison modules and the memory are electrically connected with the background processor. Through the above solution, the alarm monitoring and people-searching system of the invention could be used for automatically searching lawbreakers and providing accurate search of persons who get lost in short time.

Owner:四川正好科技发展有限公司

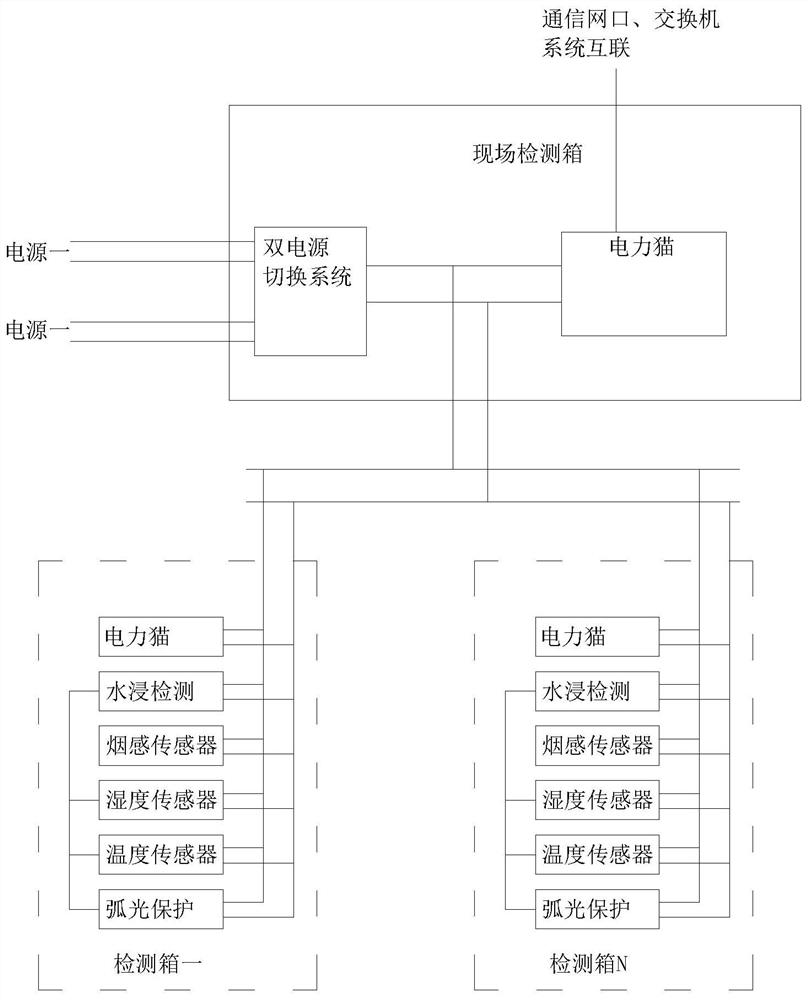

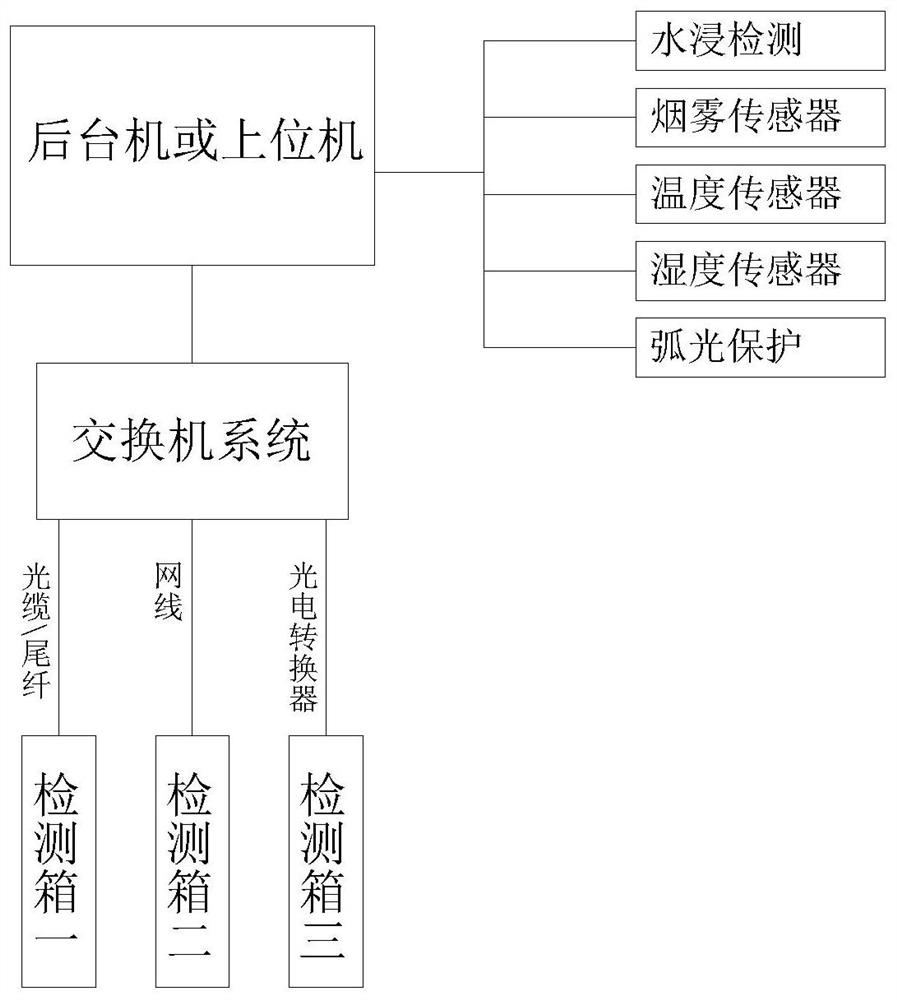

Transformer substation protection chamber cable layer water inflow damp fire and cable discharge alarm system

InactiveCN112185054ADeal with as soon as possibleFire alarm electric actuationFire alarm smoke/gas actuationConvertersMonitoring system

The invention discloses a transformer substation protection chamber cable layer water inflow damp fire and cable discharge alarm system. The system comprises a background computer, a switch, a detection box and a field detection box. And a PLC modem, a water immersion monitoring sensor, a temperature sensor, a humidity sensor, a smoke sensor, an arc light protection module and a monitoring moduleare arranged in the detection box. When the detection box is far away from the background computer and the switch, the switch with an optical port can be selected or an optical cable, a tail fiber andthe like are adopted for direct connection; when the investment is limited, a common electro-optical port switch or a photoelectric converter is adopted for switching; when distance exchange is carried out, network cable arrangement can be directly adopted; the system comprises water immersion monitoring, temperature and humidity detection, fire detection and arc light protection, sensor data aretransmitted to a monitoring system of a main control room, faults are found in time and processed as soon as possible, all related detection boxes can be monitored in a unified mode, a protection chamber cable layer can be monitored, and effective measures can be taken.

Owner:CHINA SOUTHERN POWER GRID EHV POWER TRANSMISSION COMPANY WUZHOU BUREAU

Multi-functional humanoid marker for classifying the wounded on battle site

The invention discloses a multi-functional humanoid marker for classifying the wounded on a battle site, and relates to the technical field of the classification of the wounded on the battle site. Themultifunctional humanoid marker for classifying the wounded on the battle site comprises a humanoid wound marker and a clamping device, wherein the humanoid wound marker is fixed on a patient throughthe clamping device in a detachable manner; a main body of the humanoid wound marker is a three-dimensional human body model; the interior of the humanoid wound marker is divide into different cavitychannels by opaque partition according to the anatomical parts of the human body; an LED light source is arranged in each cavity channel; the surface outline of the front surface of the humanoid wound marker corresponds to the anatomical parts of the human body, and a control button of the LED light source is correspondingly arranged; and a timer, a lithium battery, a voice module and an alarm device are mounted on a base seat at the lower end of the humanoid wound marker. The marker can accurately identify wounds, improve the efficiency and accuracy of wound detection and classification, further improve the efficiency of wounded treatment, is less affected by environmental and human factors, and has timing and alarm functions, so that the marker is suitable for popularization and application of wound identification in battlefield rescue or disaster rescue sites.

Owner:中国人民解放军联勤保障部队第九二〇医院

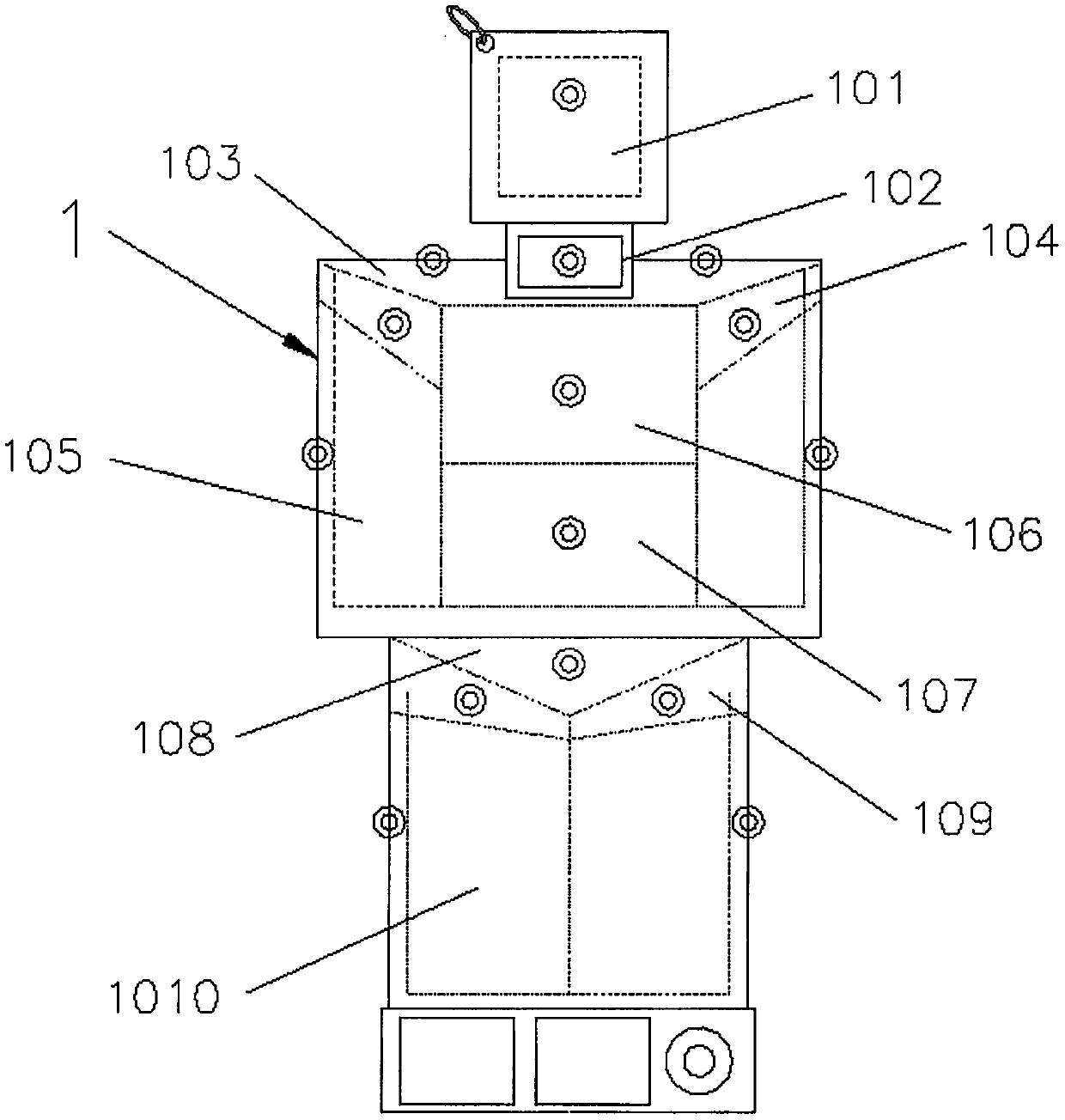

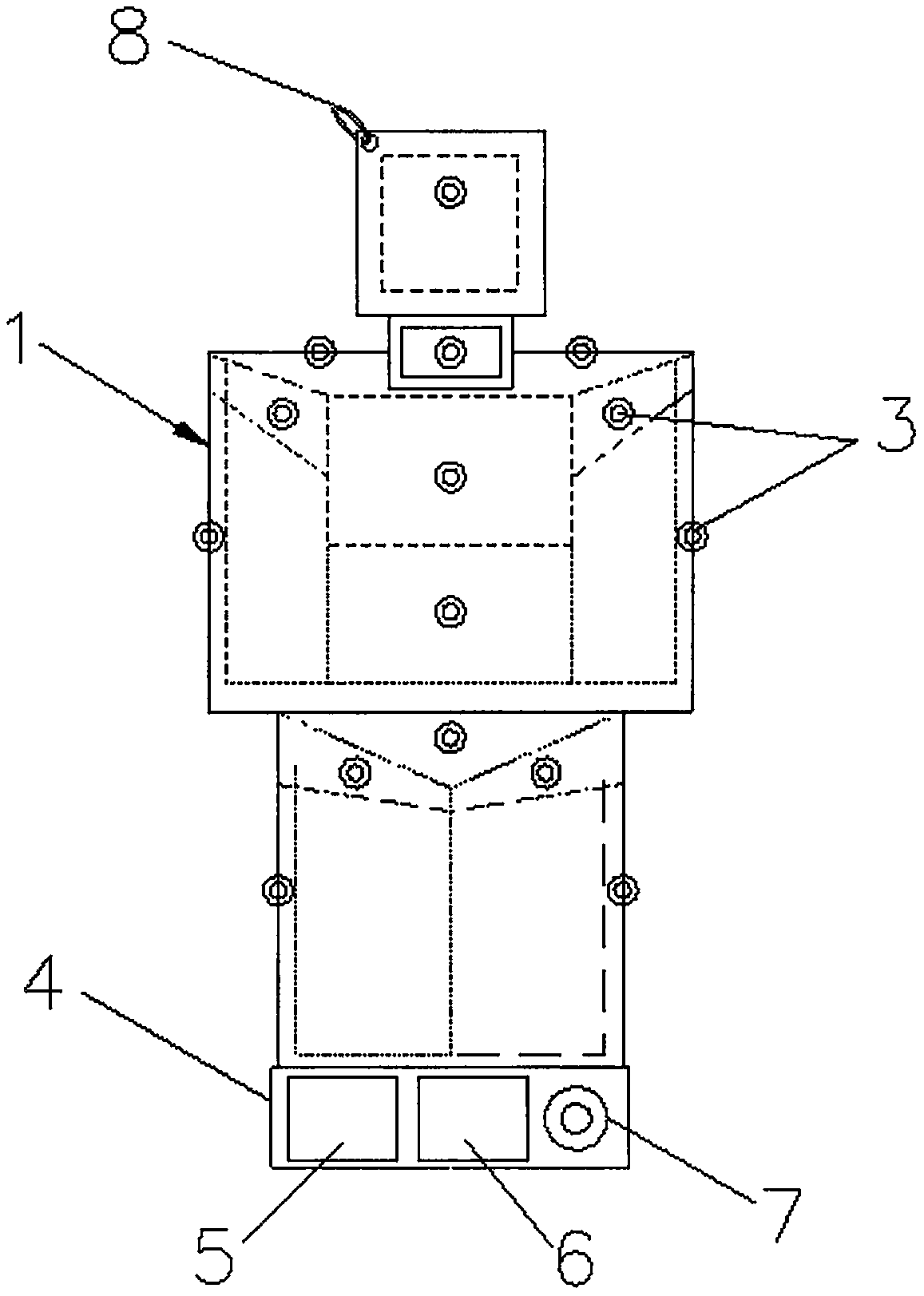

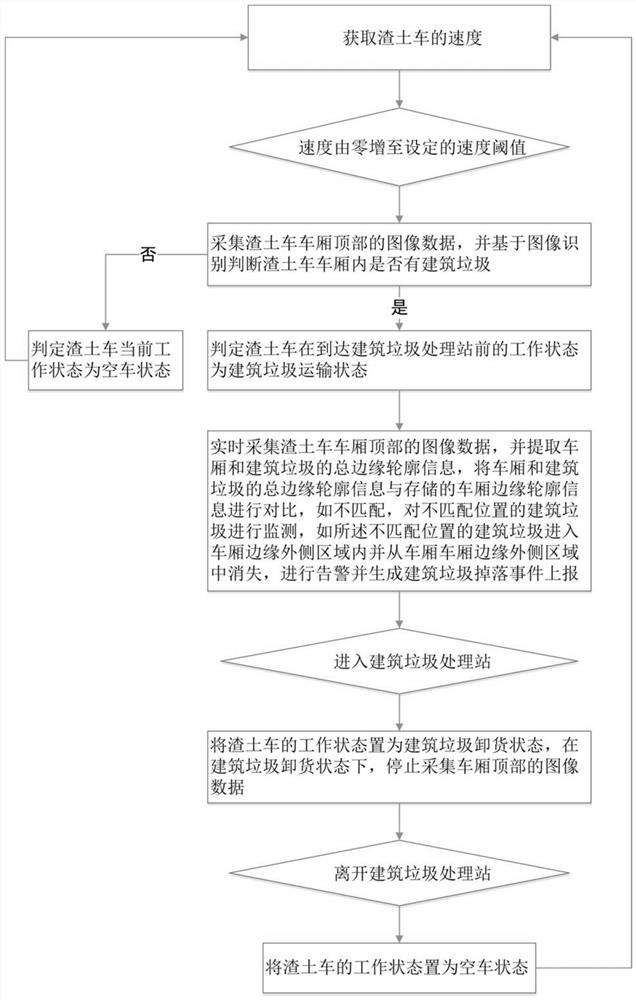

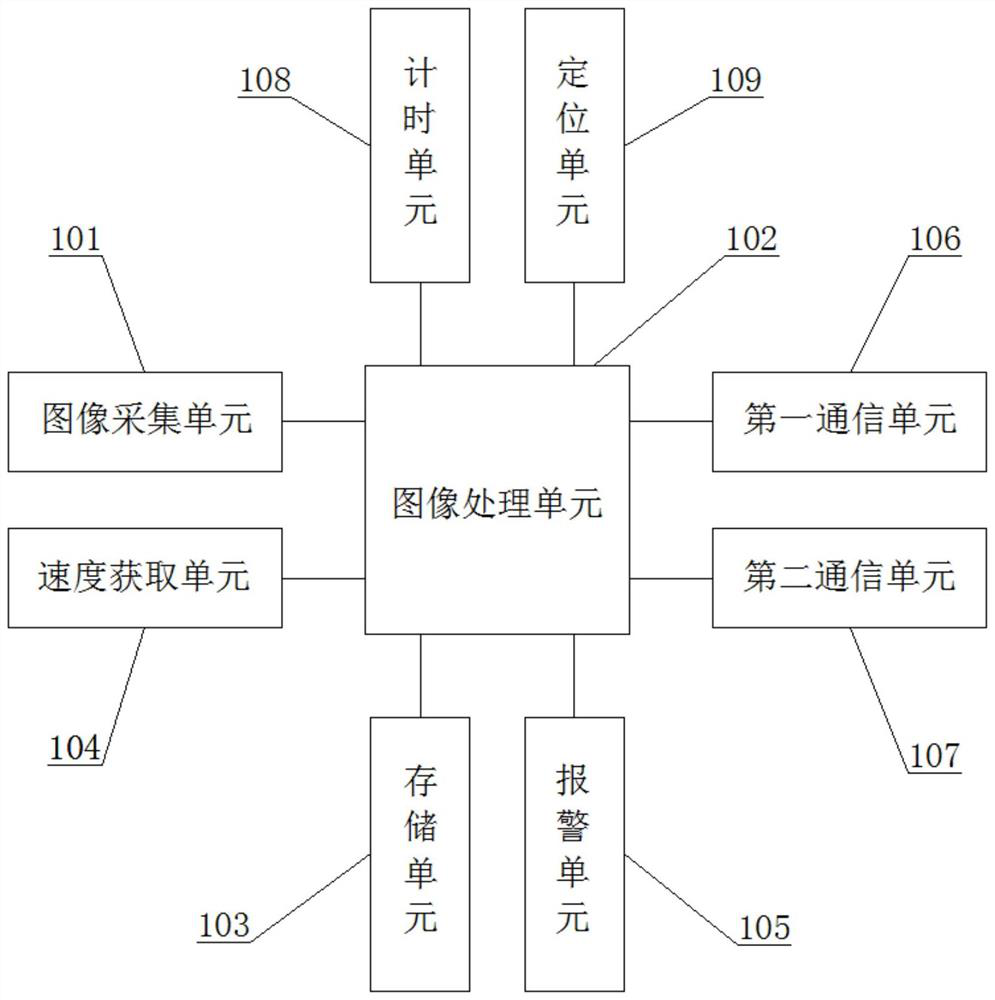

Construction waste operation supervision method and system

PendingCN114463699AReasonable and effective supervisionDeal with as soon as possibleData processing applicationsLinear/angular speed measurementTruckRefuse Disposals

Owner:南京精筑智慧科技有限公司

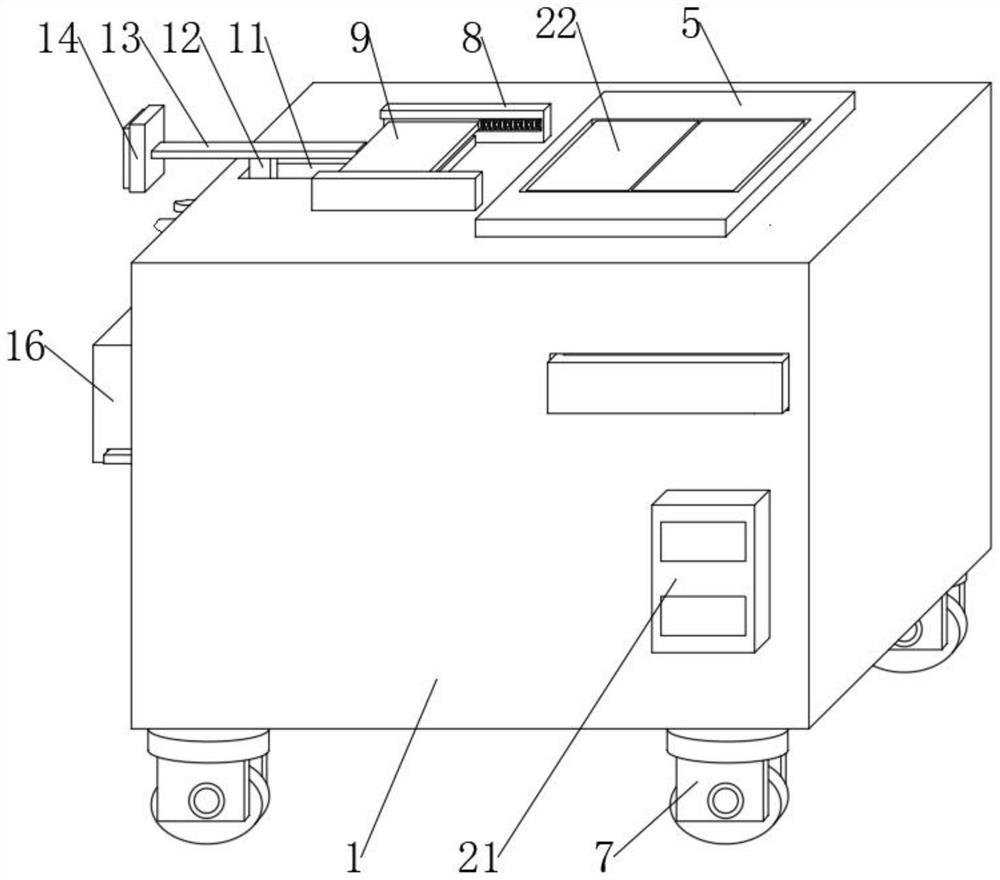

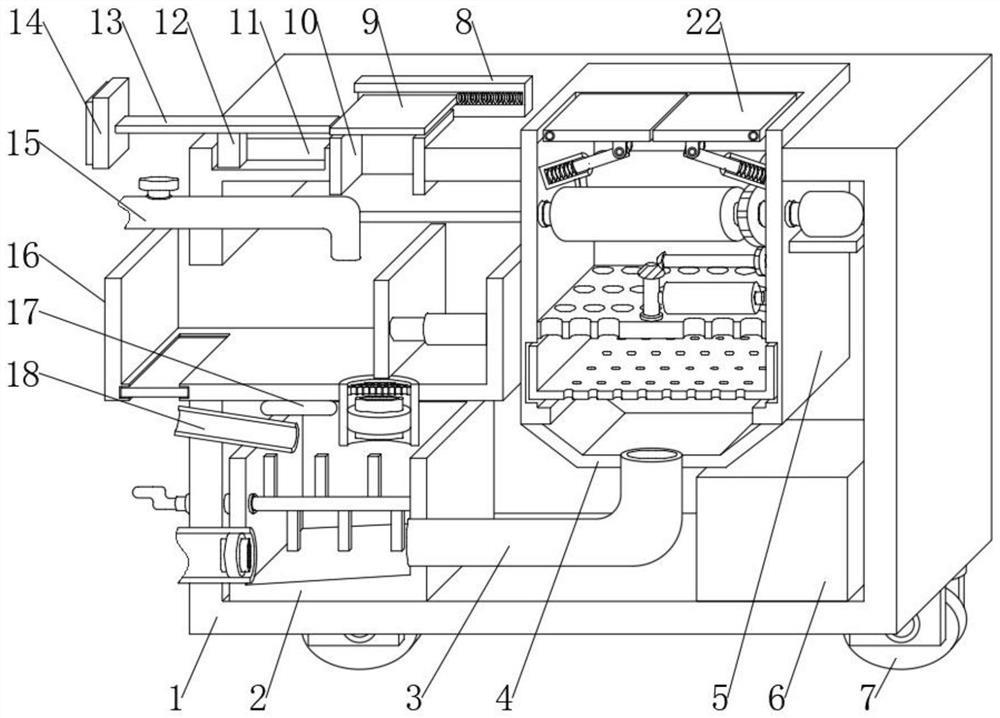

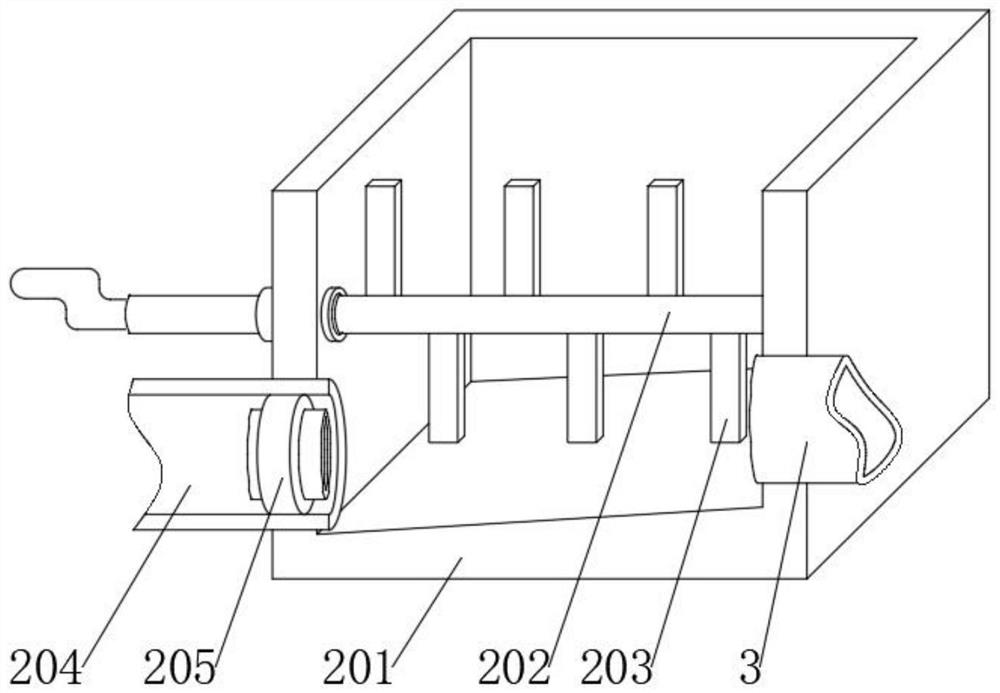

Automatic wire harness winding device

Owner:深圳壹连科技股份有限公司

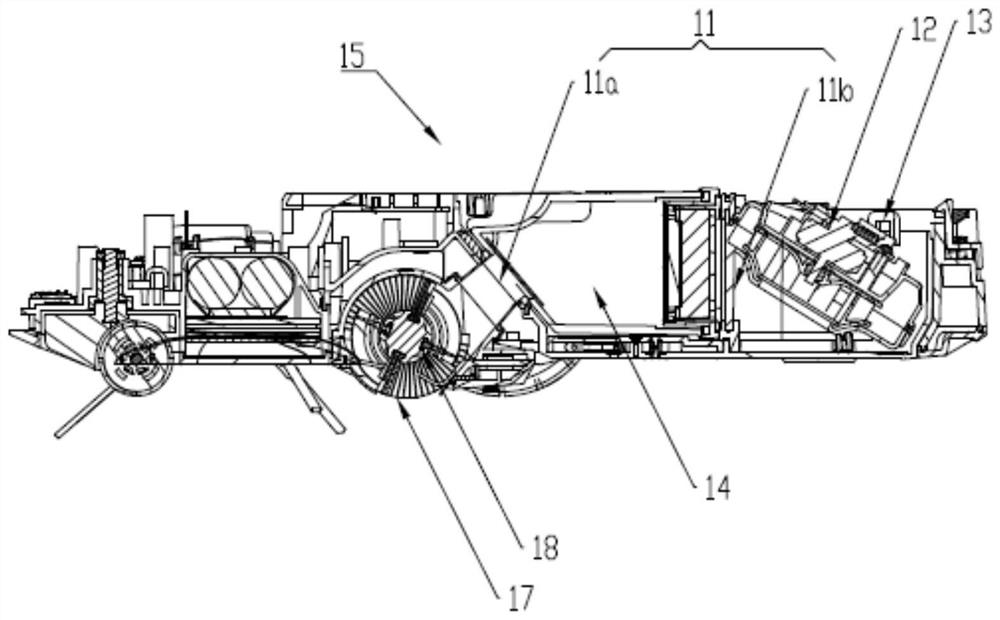

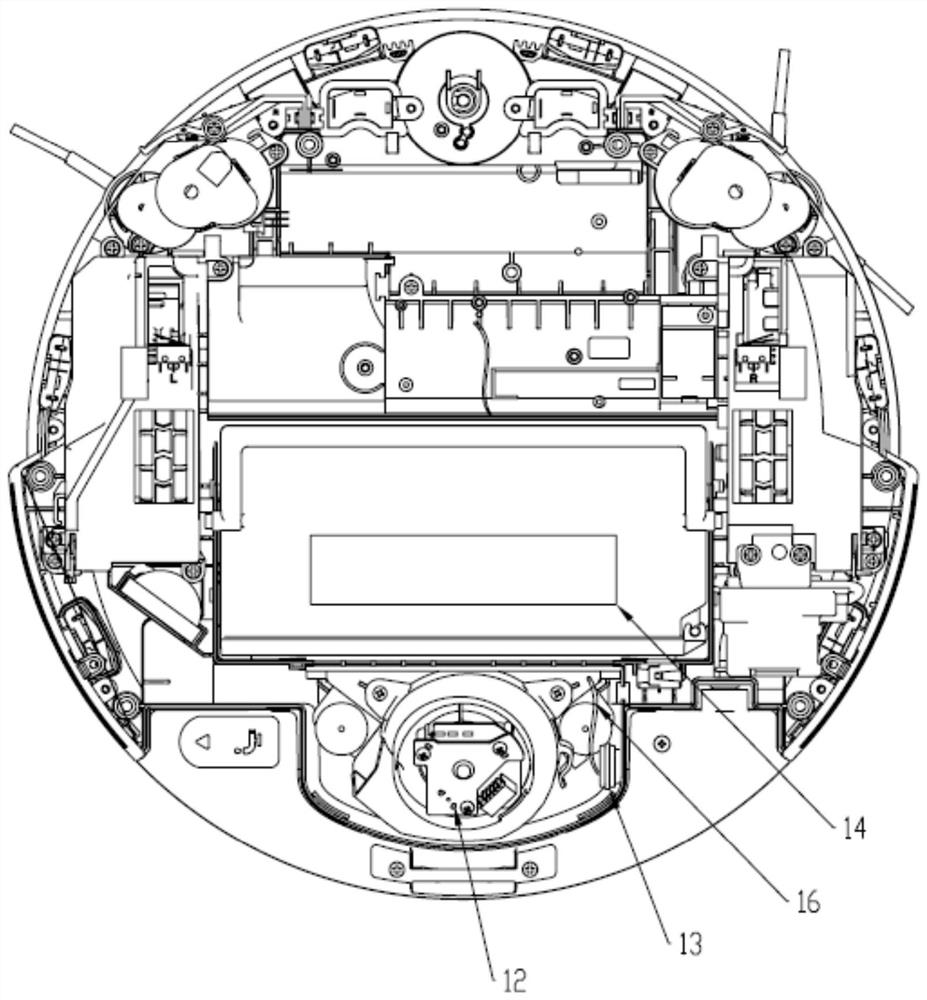

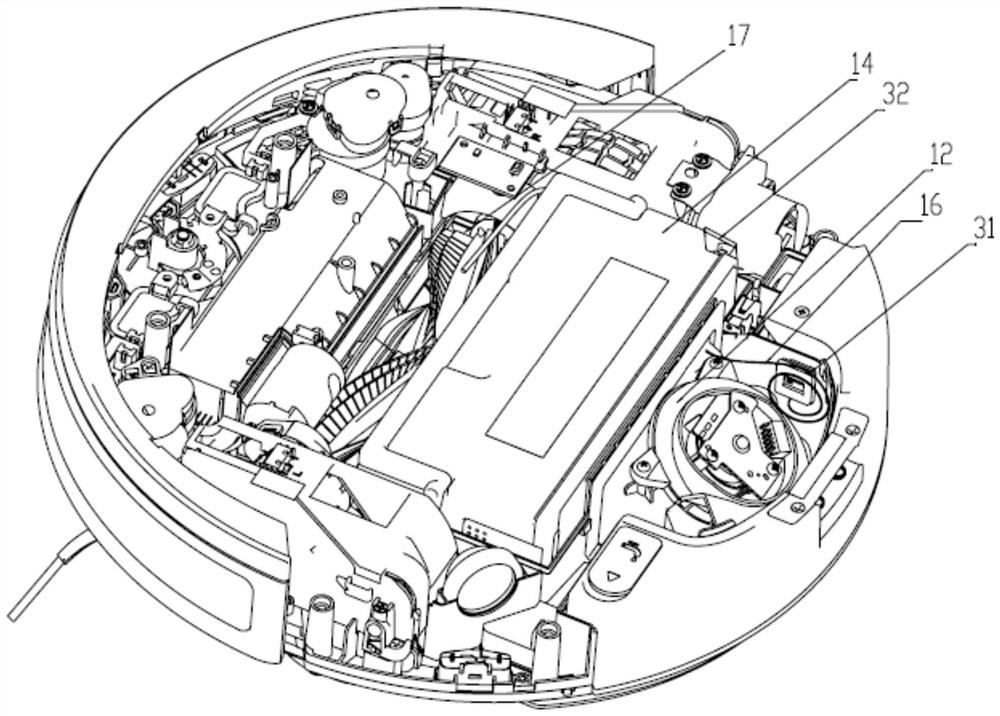

Cleaning device, cleaning detection method, robot, and storage medium

PendingCN113080769ADust collection efficiency monitoringDeal with as soon as possibleCarpet cleanersFloor cleanersEngineeringGas pressure transducer

The embodiment of the invention provides a cleaning device, a cleaning detection method, a robot and a storage medium. The cleaning device comprises an air duct, a fan assembly and an air pressure sensor, wherein the fan assembly is used for generating suction airflow circulating in the air duct; and the air pressure sensor is used for detecting the air pressure value in the air duct so as to determine the dust collection efficiency of the cleaning device according to the air pressure value detected by the air pressure sensor. The device can timely detect unsmooth air inlet and low dust collection efficiency caused by full dust box or air duct blockage, reminds a user to process as soon as possible, avoids influence on the cleaning effect, and avoids the problem of damage to dust collection equipment.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

An operating room waste collection and treatment device

ActiveCN113213009BDeal with as soon as possibleReduce processing timeGlass recyclingWaste collection and transferRefuse collectionOperating theatres

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

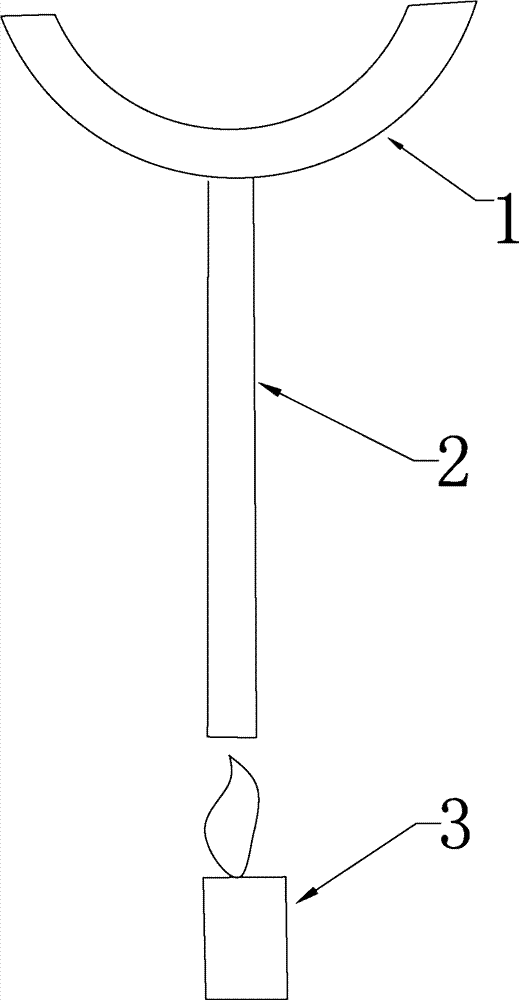

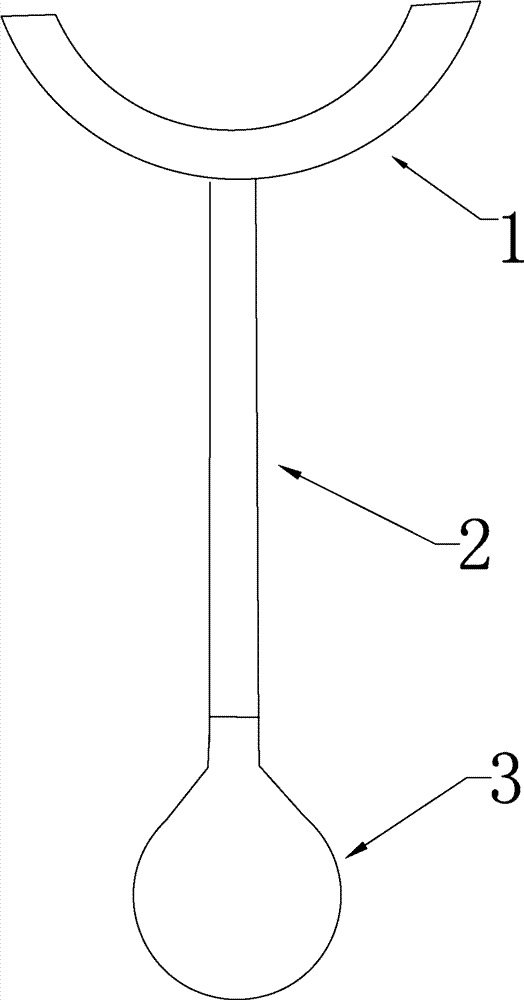

Leak detector of vacuum system

InactiveCN102759432AEnsure personal safetyConvenient and effective detectionDetection of fluid at leakage pointPipeMechanical engineering

The invention belongs to the technical field of leak detection for pipelines of vacuum systems and particularly relates to a leak detector of a vacuum system. The leak detector comprises a detection part, a connection part and a sensing device, wherein the connecting part is provided with a hollow pipe, the detection part is provided with a detection hole, one end of the hollow pipe is connected with the detection hole of the detection part, an air runner is formed between the detection hole and the hollow pipe, and the sensing device is arranged at the other end of the hollow pipe. When the leak detector is used, a unit is unnecessary to decelerate and stop and can be used under a normal operation state, not only is time consumption prevented, but also losses caused by continuous top can be reduced, the cost can be saved, furthermore, the personal safety of workers can be guaranteed and leaks can be rapidly detected and handled as soon as possible.

Owner:DONGGUAN NINE DRAGONS PAPER IND

Intelligent home system

InactiveCN103149902BConvenience to followImprove life experienceProgramme total factory controlUser needsLife quality

Owner:孙凯祺

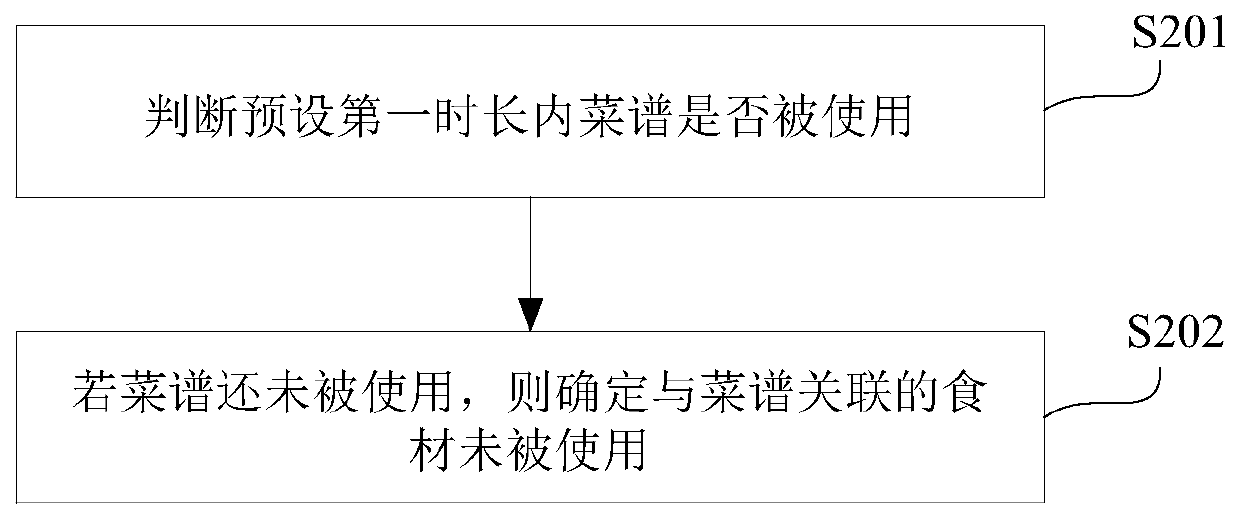

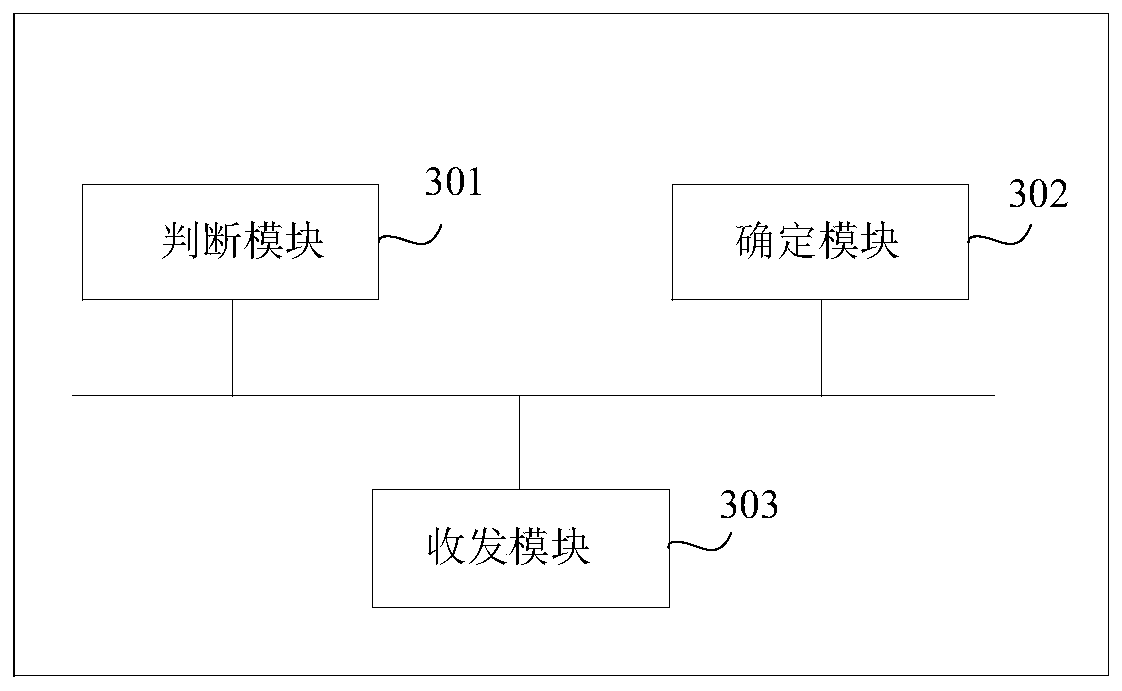

Food material monitoring method and device

InactiveCN110855798ADeal with as soon as possibleDetermine how long to keepData processing applicationsTransmissionProcess engineeringFood material

The invention provides a food material monitoring method and device which is used for improving the food material monitoring accuracy. The method comprises the steps of judging whether a menu is usedwithin a preset first duration or not; and if the menu is not used yet, determining that the food materials associated with the menu are not used. According to the method, by monitoring whether the food materials are used, the food materials are monitored, and the food material monitoring accuracy can be improved; meanwhile, by monitoring the menus, various food materials can be monitored at the same time, and the food material monitoring efficiency is improved.

Owner:ZHUHAI YOUTE SMART KITCHEN TECH CO LTD

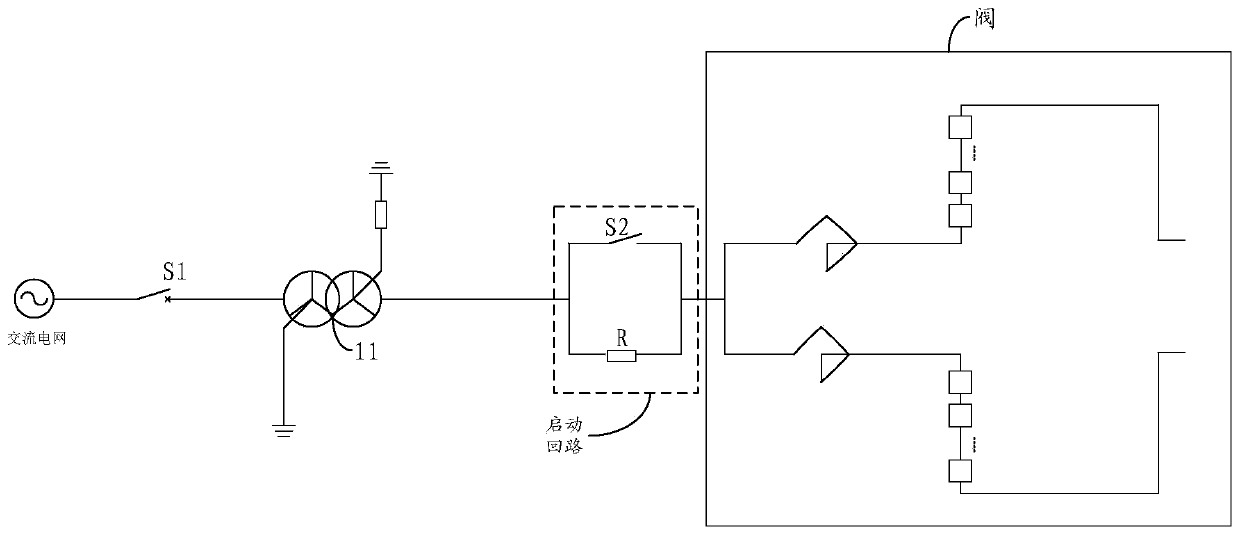

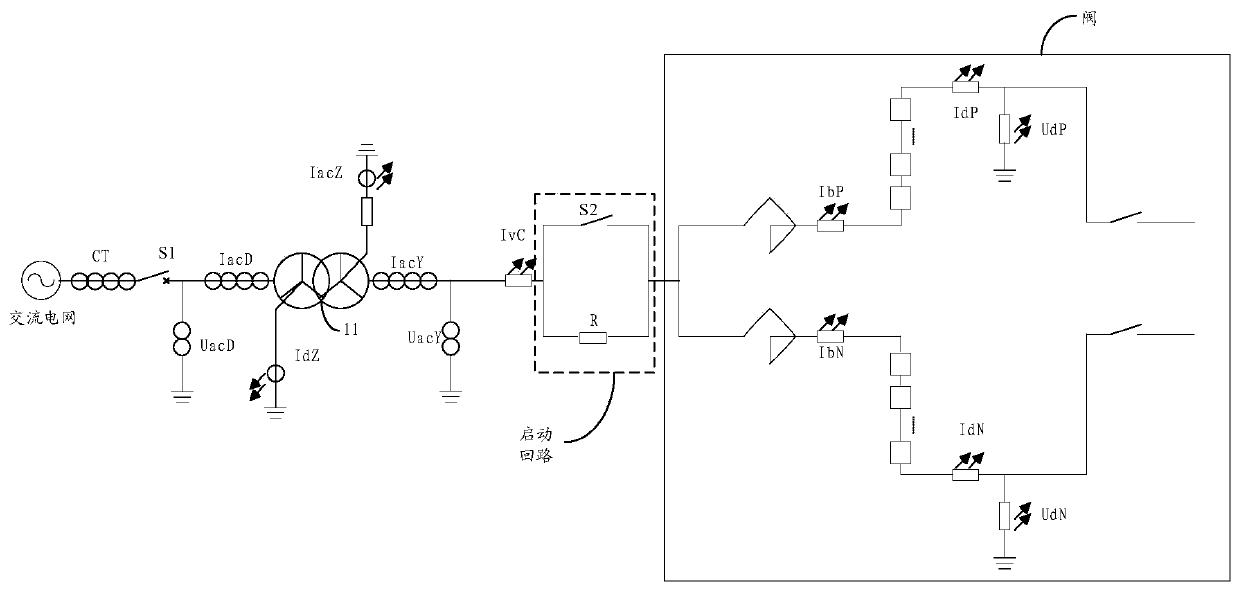

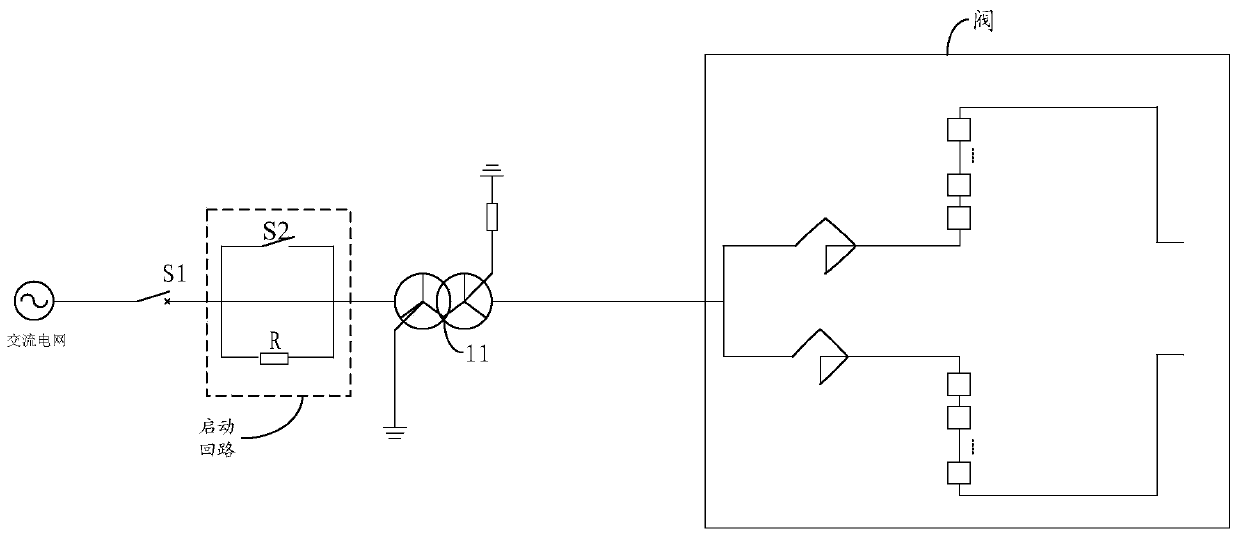

Fault detection method and device for starting loop of UHV flexible direct current transmission system

ActiveCN107490749BAvoid lasting effectsAccurate detectionFault location by conductor typesInformation technology support systemStopped workElectrical resistance and conductance

The invention provides a fault detection method and device for an UHV flexible DC transmission system start loop and can realize accurate fault detection on a start loop of a charging loop of an UHV flexible DC transmission system. The device comprises a first current measurement module used for measuring a first current value between an output end of an AC power grid and a first switch, a second current measurement module used for measuring a second current value between a start resistor and a first node, a third current measurement module used for measuring a third current value between a connection transformer and an input end of a valve, a voltage measurement module used for measuring a three-phase voltage value between a second node and a ground end, and a processing module used for connecting with the various modules to acquire the first current value, the second current value, the third current value and the three-phase voltage value, determining a fault type of a fault generated in the start loop according to the first current value, the second current value, the third current value and the three-phase voltage value, emitting the corresponding alarm information and simultaneously controlling the charging loop for stopping work.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD

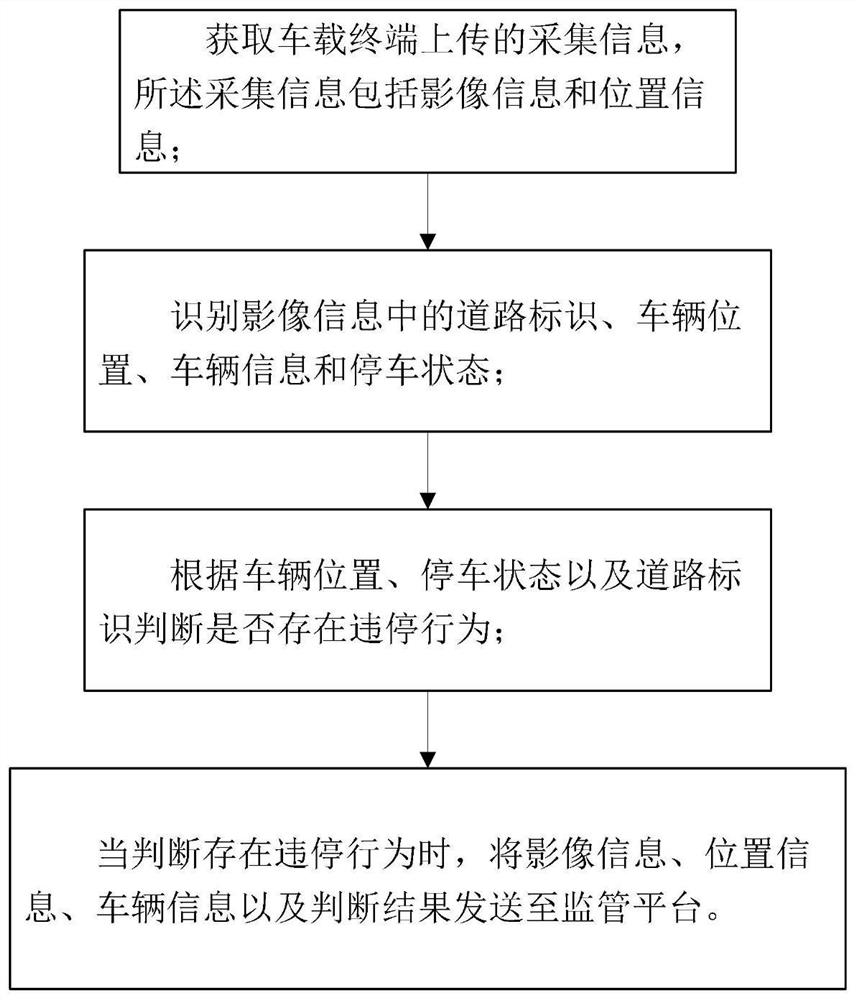

Visual identification-based illegal parking detection system

ActiveCN114613132AFull and real-time acquisitionDeal with as soon as possibleDetection of traffic movementScene recognitionIn vehicleEngineering

The invention relates to the technical field of intelligent traffic, in particular to an illegal parking detection system based on visual identification, comprising the following steps: S100, acquiring acquisition information uploaded by a vehicle-mounted terminal, the acquisition information comprising image information and position information; s200, identifying a road sign, a vehicle position, vehicle information and a parking state in the image information; s300, whether illegal parking behaviors exist or not is judged according to the vehicle position, the parking state and the road sign; and S400, when it is judged that the illegal parking behavior exists, the image information, the position information, the vehicle information and a judgment result are sent to a supervision platform. According to the illegal parking detection system based on visual identification, detection of illegal parking in the whole road section can be realized, and the processing efficiency of illegal parking behaviors is improved.

Owner:CHONGQING UNIV

A method and device for providing high-frequency question answering

ActiveCN104834651BDeal with as soon as possibleImprove processing efficiencySemantic analysisText database queryingText categorizationKnowledge management

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com