New method of intelligent repair monitoring equipment combining fault detection and workflow

A technology for fault detection and monitoring equipment, used in data processing applications, television, computing, etc., to solve complex and large problems in discovering and troubleshooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

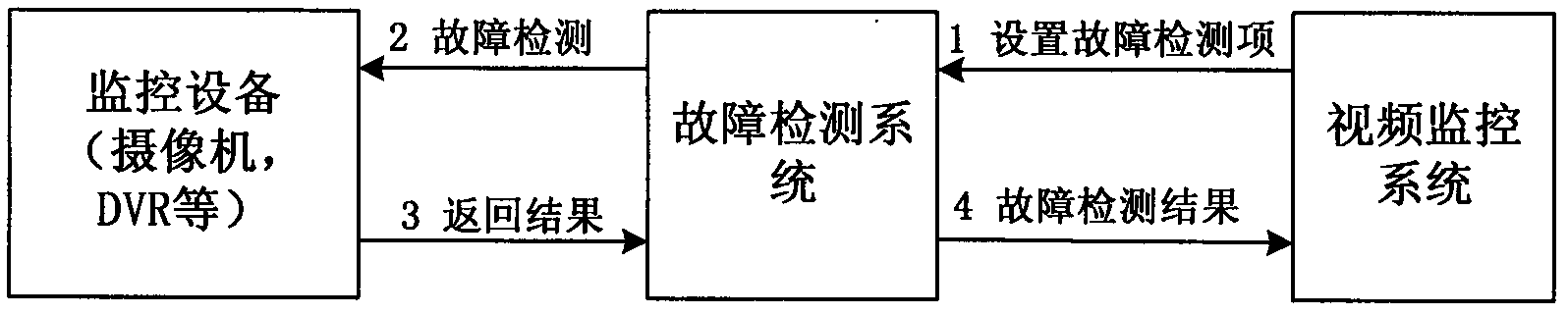

[0019] Embodiment 1, see FIG. 1 .

[0020] The invention provides a fault detection system and a workflow system, including the integration of the fault detection system and the workflow system by a video monitoring system;

[0021] Described fault detection system is used for: carrying out fault detection to video camera, monitoring equipment such as DVR, such as for video camera, can detect whether the video signal is interrupted, whether video is blocked, whether the state such as signal loss, then can detect whether hard disk is full for DVR , hard disk error;

[0022] The workflow system is used for: customizing the workflow, generating a work order according to the flow, and at the same time knowing the current processing status of a certain work order in real time, and deciding whether to automatically process the reminder according to the situation. The repair work orders generated by false positives can be cancelled.

[0023] By logging into the video surveillance s...

Embodiment 2

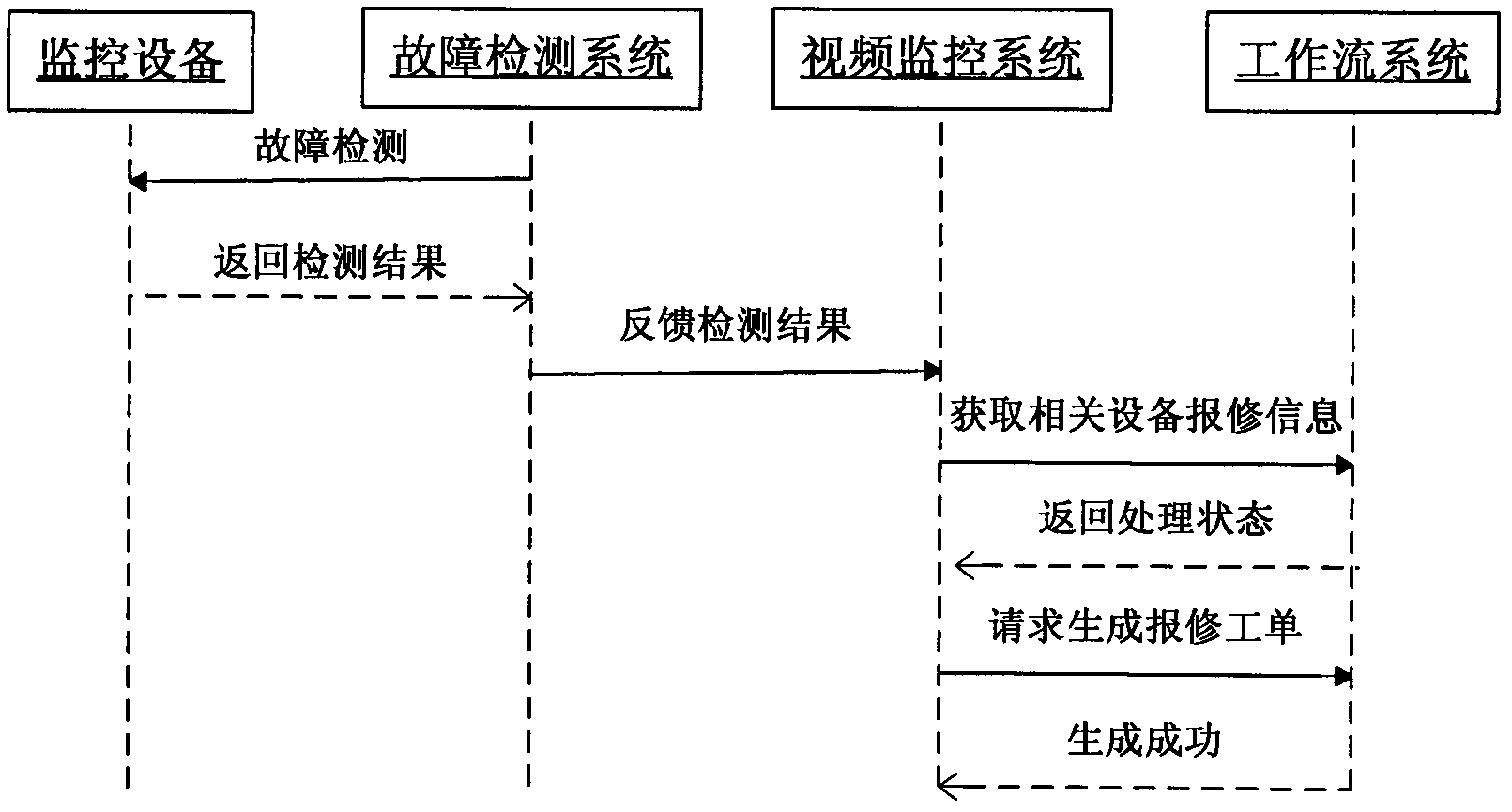

[0031] Example 2, see Fig. 2.

[0032] The present invention also provides a method for a video monitoring system to automatically generate a repair work order by using a workflow system, including:

[0033] According to the equipment repair requirements of the video surveillance system, the maintenance report workflow is customized. When the video surveillance system receives the detection results of the fault detection system, if it needs to generate a repair report work order, it only needs to notify the workflow system to generate a work order, and the work The flow system will generate corresponding repair work orders according to the requirements and enter the repair process flow. The workflow is shown in Figure 2, which specifically includes the following steps:

[0034] Step 1, the fault detection system detects the monitoring equipment;

[0035] Step 2, the fault detection system obtains the fault detection result;

[0036] Step 3, the fault detection system feeds b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com