Machine room inspection method and device

A technology for computer rooms and inspection points, applied in inspection time patrols, computer parts, instruments, etc., can solve the problems of false detection, false detection or missed detection, easy to be affected by external environment, increased detection cost, etc., and achieve data reduction. , The effect of improving generalization ability and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

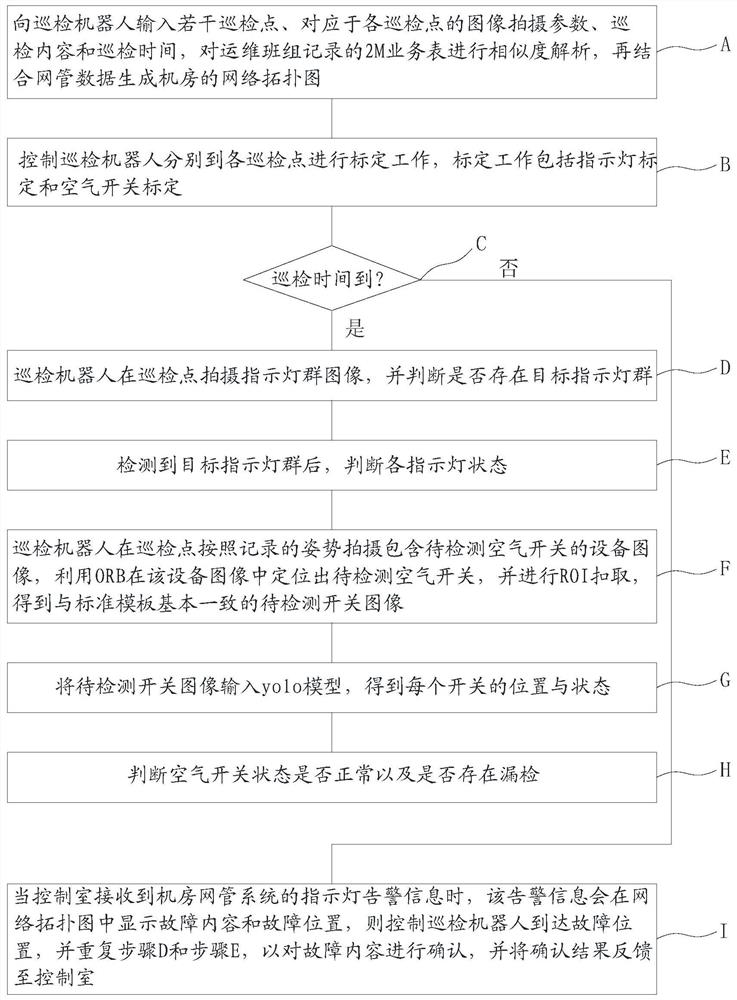

[0037] Such as figure 1 As shown, the computer room inspection method includes the following steps:

[0038] A. Use the mapping function of the inspection robot to build a two-dimensional planar map in the computer room, and set a number of inspection points on the map to realize the input of inspection points to the inspection robot and input corresponding to each inspection point to the inspection robot. The image shooting parameters, inspection content and inspection time of the inspection point, so that the robot regularly inspects the designated inspection point according to the inspection time. The inspection content includes switch state detection and indicator light state detection, and the image shooting parameters include Camera rotation and pitch angle and camera focal length, after completing the above preparations, place the inspection robot at the charging position; among them, the specific method of constructing a two-dimensional planar map is the existing techn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com