Method and apparatus for leak-testing electroluminescent device

An electroluminescence device and photoluminescence technology are applied in the field of electroluminescence device and electroluminescence device inspection, which can solve the problems of short storage period of leaking devices, difficulty in quickly identifying leaks in devices by visual inspection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

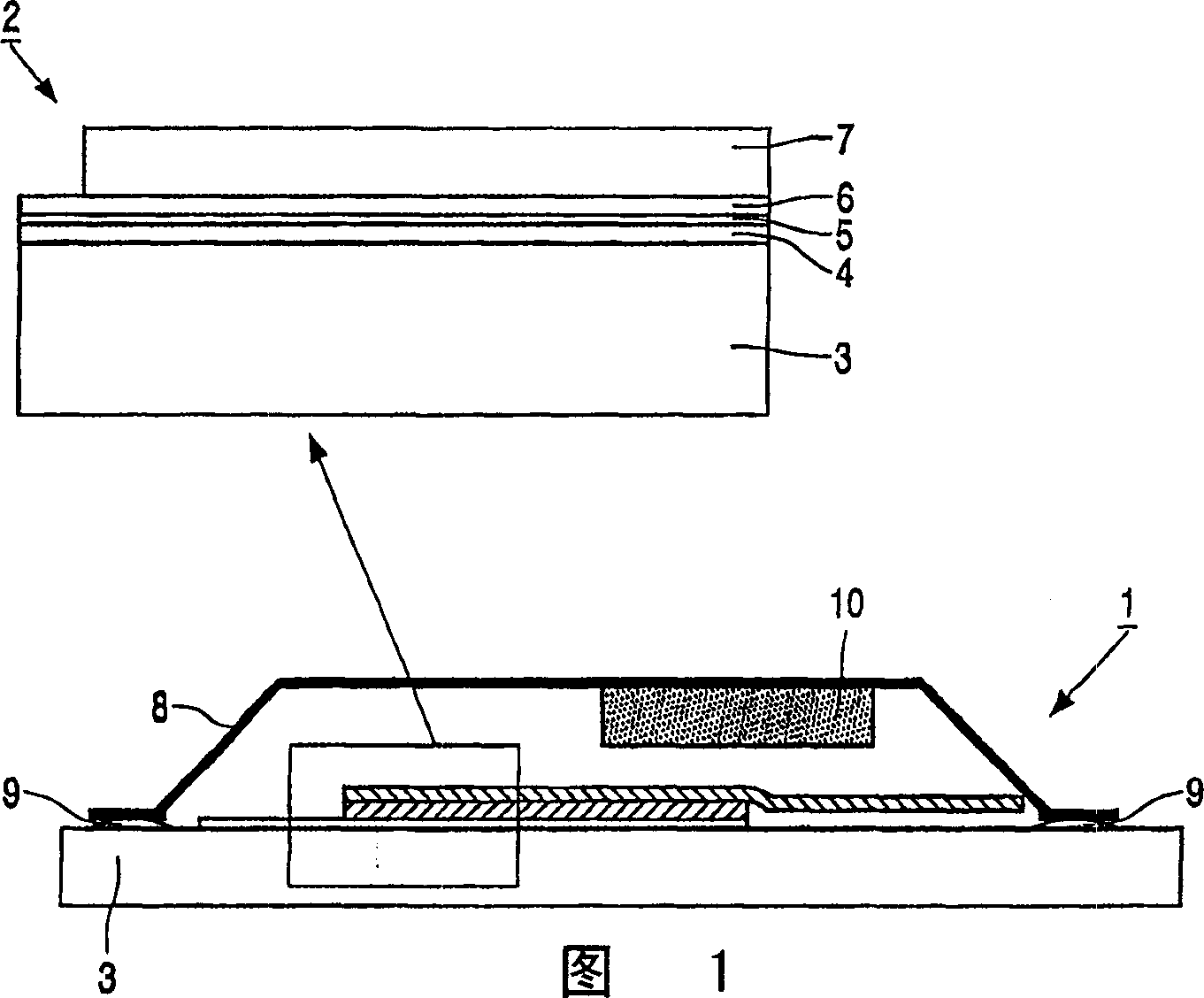

[0032] FIG. 1 schematically shows the main part of an electroluminescent device 1. As shown in FIG. The electroluminescent device 1 comprises a base layer 3 (of the order of 1 mm thick glass) carrying the EL element 2 . The EL element 2 is a laminate comprising an ITO (on the order of 150 mm thickness) conductive layer 4, a transparent PEDOT (on the order of 200 mm thickness) anode layer 5, an electroluminescent (organic on the order of 100 mm thickness) layer 6 and A (eg 5nmBA coated with 100nm Al) metal cathode layer 7. The EL element 2 is encapsulated between the glass substrate 3 and a separate metal cover 8 which is bonded to the glass substrate 3 by an epoxy edge seal 9 . A getter 10 (BaO and / or CaO) is placed inside the package to remove water penetrating through the epoxy edge seal 9 .

[0033] A particular embodiment of the invention is characterized in that the organic layer comprises an electroluminescent polymer. The electroluminescent polymer is a suitable EL m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com