Quick helium mass spectrum leakage detecting device for diaphragm inner circle welding joint

A technology of helium mass spectrometry and circular welds, which is applied in the field of rapid helium mass spectrometry leak detection devices for the inner circular welds of diaphragms. The effect of mass spectrometry leak detection and fast helium mass spectrometry leak detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

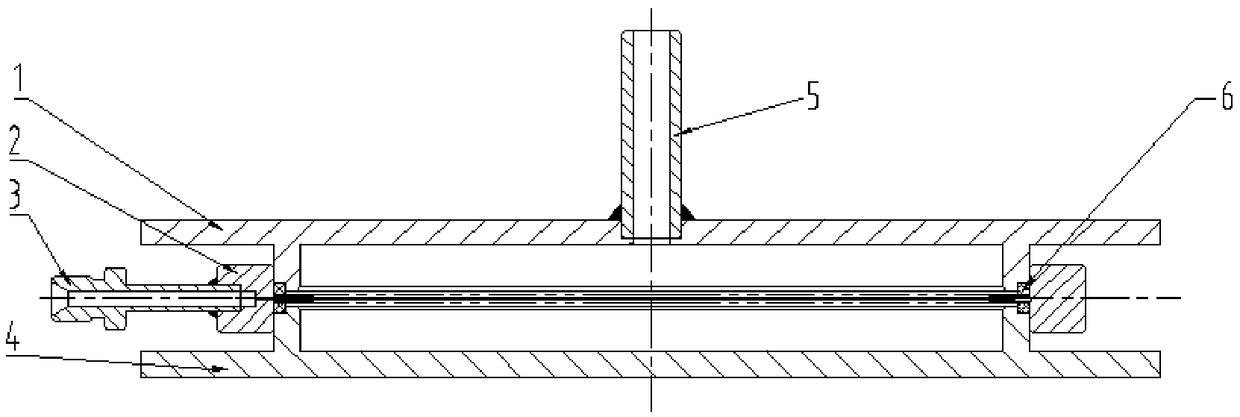

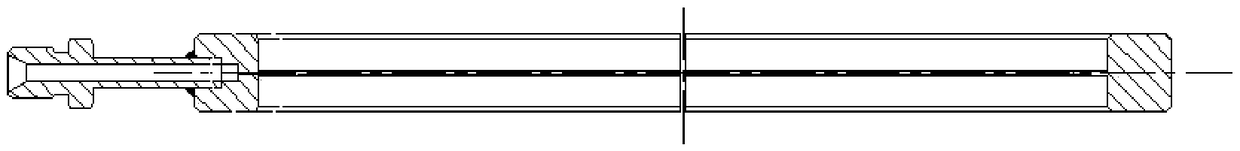

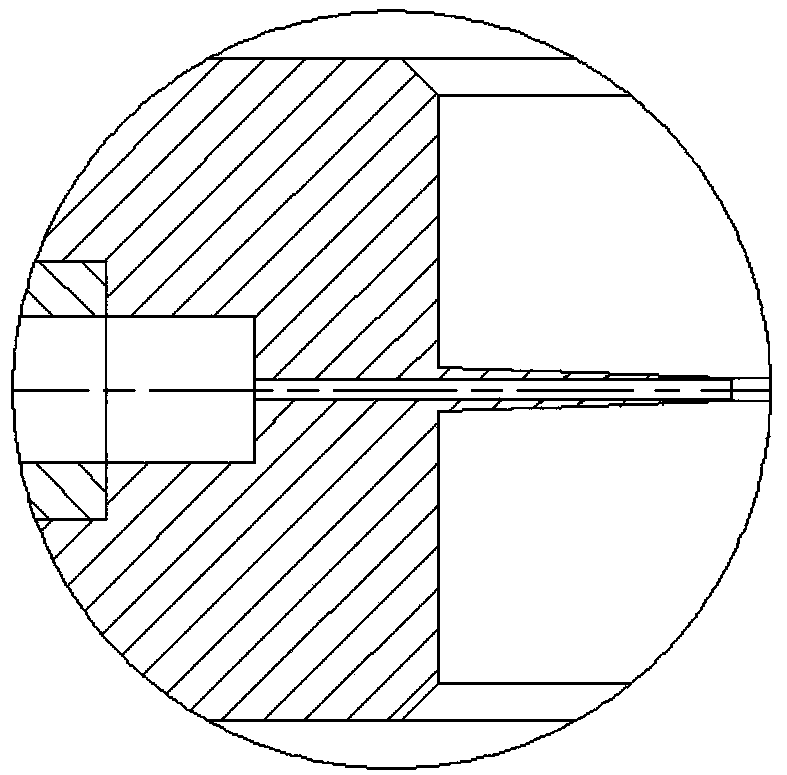

[0025] A rapid leak detection device for the inner circular weld of a diaphragm, the structure is shown in figure 1 , including diaphragm inner support tooling 2, sealing ring 6, upper cover 1, lower cover 4, nozzle intake port 3, and vacuum polished rod 5. Through assembly, inner support tooling 2, diaphragm, upper cover 1, lower cover The cover 4 and the sealing ring 6 form a closed space, and the closed space is evacuated. If the inner circular weld of the diaphragm leaks, helium will enter the helium mass spectrometer leak detector through the leak point, and the diaphragm leak can be calculated by the helium mass spectrometer leak detector. Rate. Diaphragm inner support tooling 2 is used to stretch the diaphragm so that the diaphragm is evenly pasted on the inner support tooling 2, and the sealing ring 6 on the upper cover 1 and lower cover 4 compresses the diaphragm to perform a sealing function, and the inner support tooling 2 has a φ0.5 hole through which helium gas c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com