Nuclear power plant generator whole air tight test method

An air-tight test and generator technology, which is used in the use of liquid/vacuum for liquid-tightness measurement, and by detecting the appearance of fluid at the leak point. The effect of improving test accuracy, improving leak detection accuracy and continuous monitoring capability, and improving data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

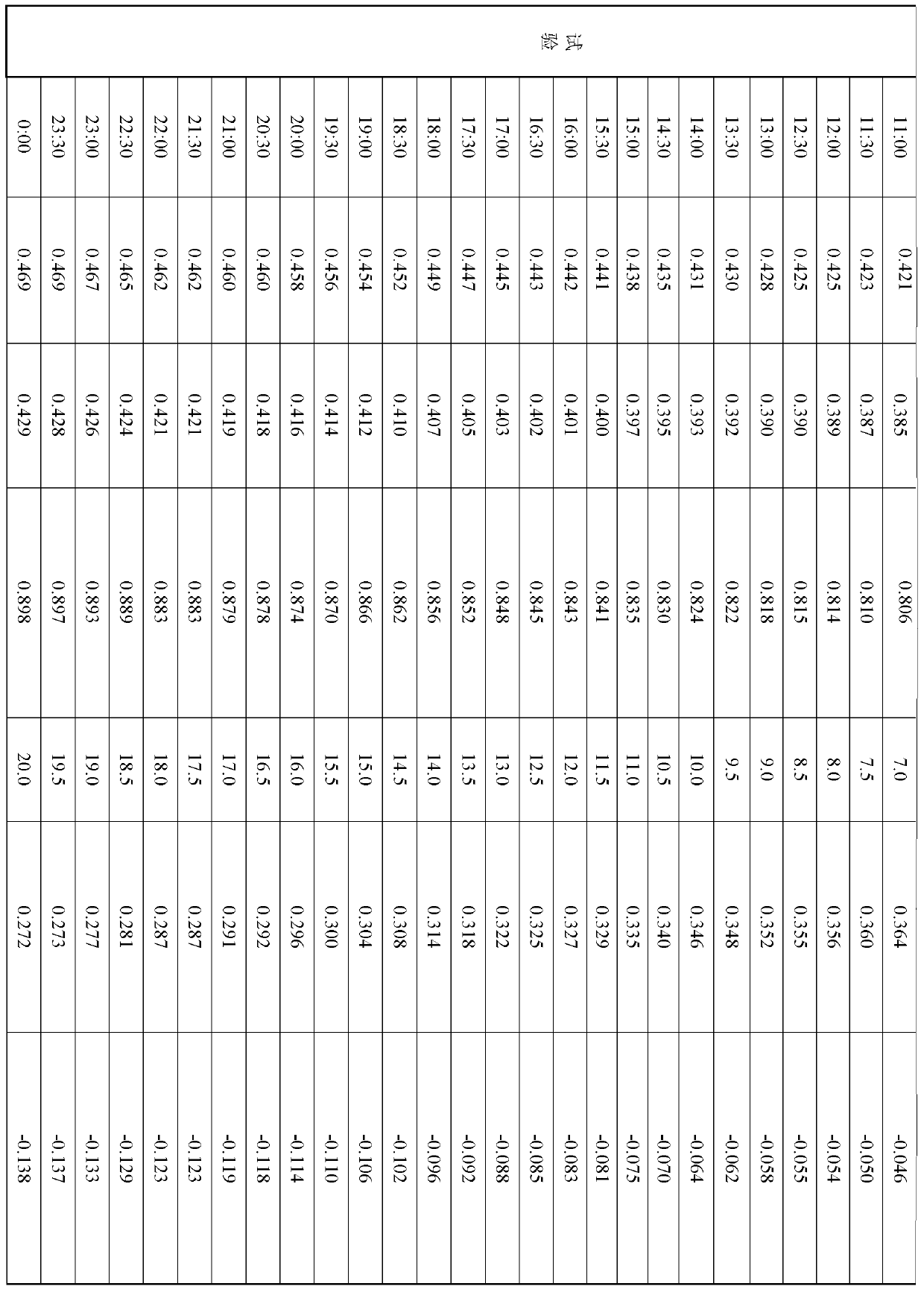

[0056] Embodiment 1, the overall airtight test method of the generator of nuclear power plant is to charge gas into the generator and the hydrogen system to boost the pressure to the working pressure and maintain the pressure, and monitor the gas temperature, pressure and ambient atmosphere inside the generator during the pressure maintenance process. pressure, detect leaks and treat leaks. Before filling the generator and the hydrogen system with gas and during the pressurization process, it also includes the temperature control operation steps to maintain the equilibrium temperature inside the generator and the gas leakage caused by the air-side and hydrogen-side seal oil leakage. The operation steps of preventing oil spillage also include the liquid level monitoring step of the sealed oil tank during the pressure maintaining process; the monitoring and recording time of the gas temperature, pressure, ambient atmospheric pressure and the liquid level of the sealed oil tank in...

Embodiment 2

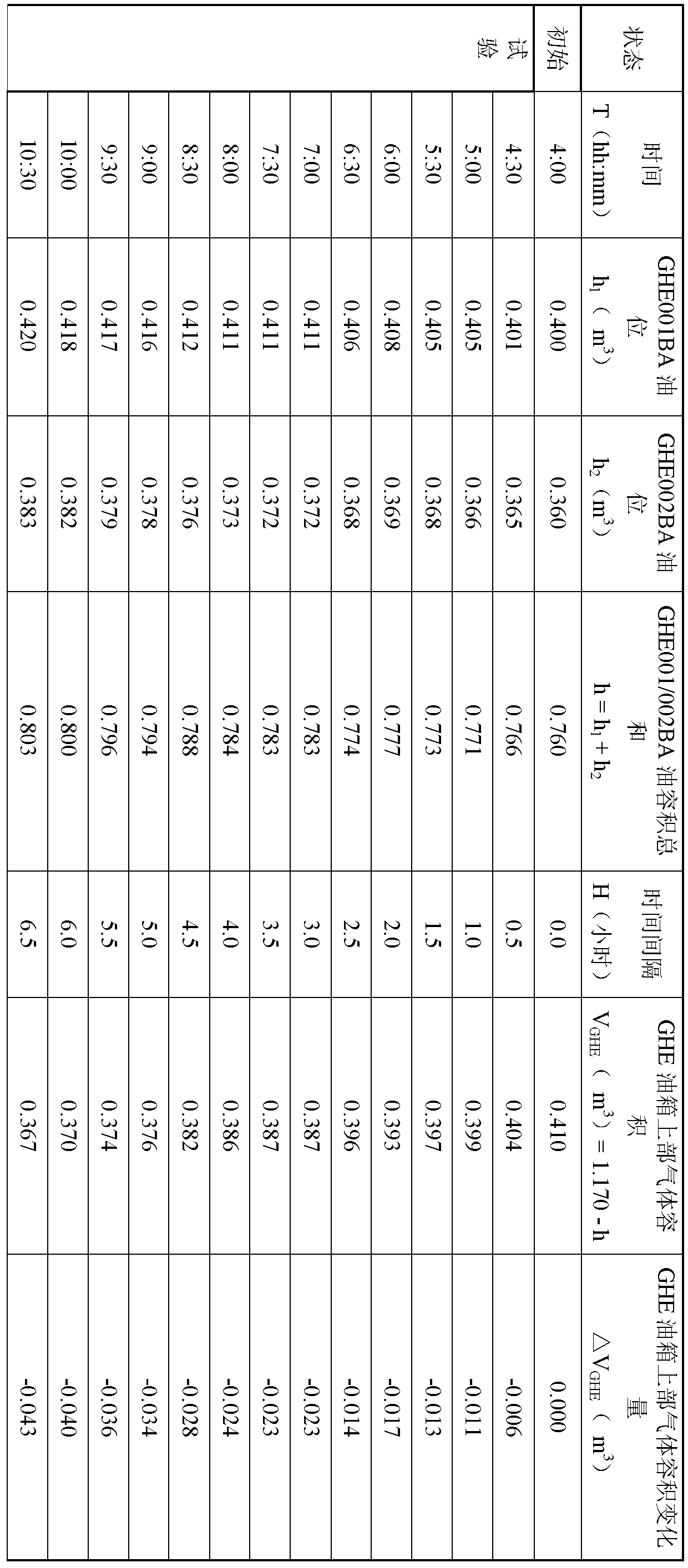

[0111] Embodiment 2, the overall airtight test method of the generator of nuclear power plant, charge the gas into the generator and the hydrogen system as a whole to increase the pressure to the working pressure and maintain the pressure, and monitor the gas temperature, pressure and ambient atmosphere inside the generator during the pressure maintenance process pressure, detect leaks and treat leaks.

[0112] Before filling gas into the generator and the hydrogen system, implement pure helium pressure to check for leaks and repair the parts that can be isolated separately.

[0113] In the airtight test, the gas that needs to be charged into the generator and the hydrogen system is a mixed gas of air and helium; the volume concentration of helium in the mixed gas is 15-18%. Since helium is an important condition in the airtight test, the detection accuracy of helium is very high, and the theoretical value of the detection concentration range of the helium mass spectrometer ca...

Embodiment 3

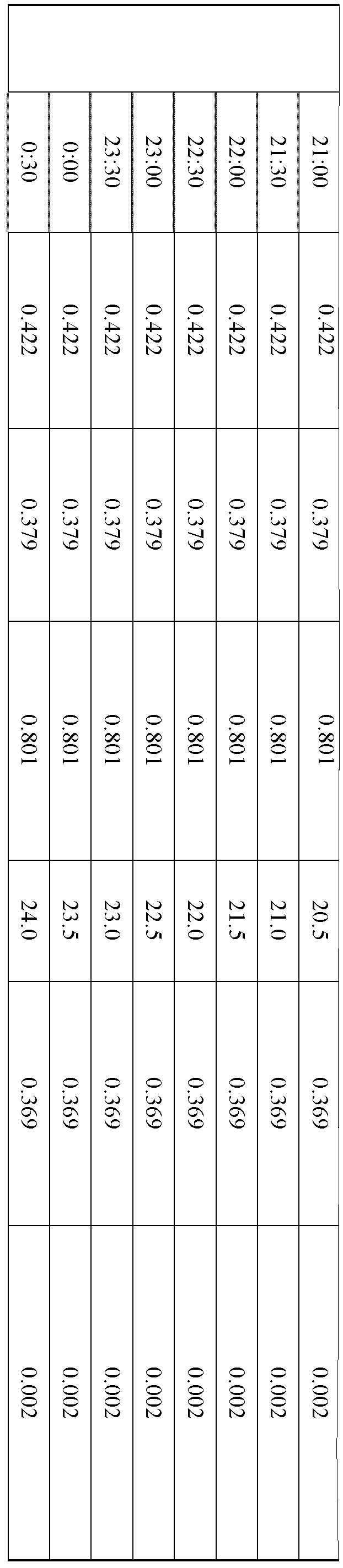

[0123] Embodiment 3, the overall airtight test method of the generator of nuclear power plant, charge gas into the generator and the hydrogen system as a whole to increase the pressure to the working pressure and keep the pressure, and monitor the gas temperature, pressure and ambient atmosphere inside the generator during the pressure keeping process Pressure, detect leaks and deal with leaks, before filling the generator and hydrogen system with gas and during the pressure holding process, it also includes the temperature control operation steps for maintaining the equilibrium temperature inside the generator, during the pressure holding process The gas temperature, pressure, ambient atmospheric pressure and liquid level of the sealed oil tank are monitored and recorded every 20 to 40 minutes. End the test when the leakage rate meets the predetermined requirements for a continuous time greater than or equal to 24 hours.

[0124] In this embodiment, before the airtight test, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com