Transmission type photocathode and preparation method and application thereof

A photocathode and transmissive technology, which is applied in the direction of photoemission cathode, luminescent cathode manufacturing, electron multiplier cathode device, etc., can solve the problems that cannot meet the requirements of photocathode anti-reflection, anti-reflection effect is not obvious, weakened, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a method for preparing the transmissive photocathode described in the above technical solution, comprising the following steps:

[0054] Depositing an outer surface optical anti-reflection film on one side of the glass window to obtain a glass window deposited with an outer surface optical anti-reflection film;

[0055] After epitaxially growing a GaAs smooth layer, a barrier layer, an emission layer, a buffer layer and a protective layer on the GaAs substrate in sequence, the protective layer is removed by etching to expose the buffer layer;

[0056] Under vacuum conditions, use a mask plate to cover the part of the buffer layer to be deposited with an anti-reflection film on the inner surface, after depositing an adhesive film on the surface of the buffer layer, use a mask plate to cover the adhesive film, and deposit the inner surface. Surface anti-reflection film, obtain adhesive film / inner surface anti-reflection film, control th...

Embodiment 1

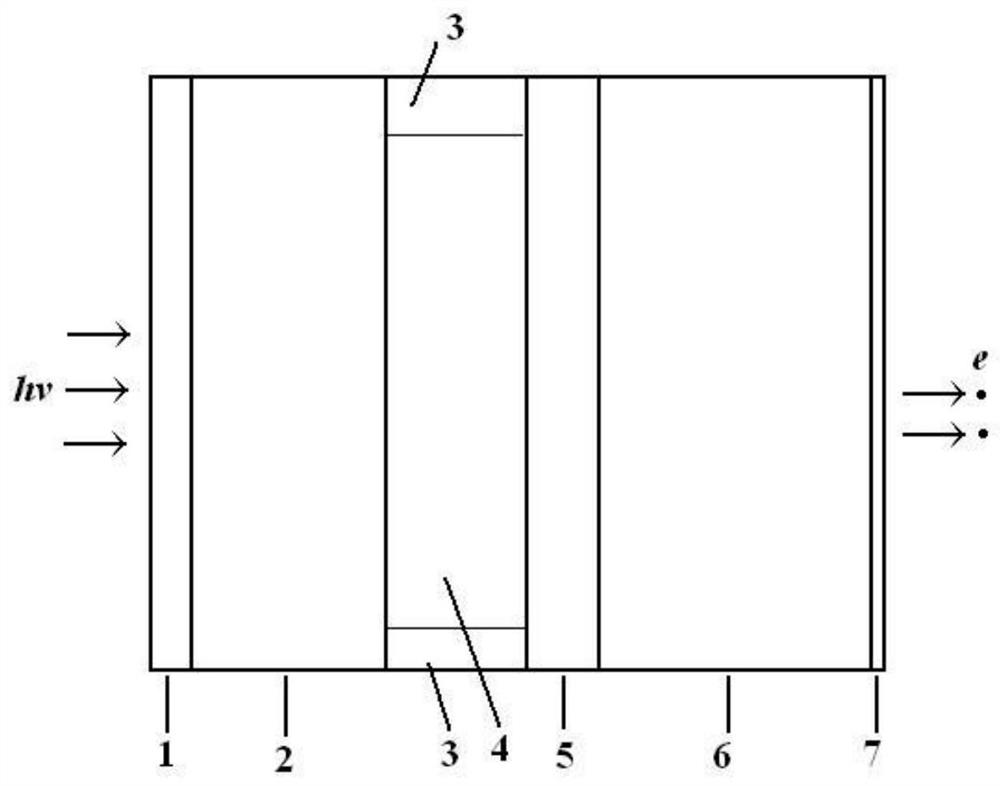

[0079] A kind of transmissive photocathode, the anti-reflection film on the outer surface, glass window, adhesive film / anti-reflection film on the inner surface, buffer layer, emission layer and active layer (structural relationship such as figure 1 shown);

[0080] Among them, the anti-reflection coating on the outer surface: TiO2 which is arranged sequentially from the glass window 2 layer (12.3nm), SiO 2 layer (33.5nm), TiO 2 layer (27nm), SiO 2 layer (13.5nm), TiO 2 layer (86.3nm), SiO 2 layer (18.3nm), TiO 2 layer (19nm) and MgF 2 layer (95nm);

[0081] Glass window: double-sided polished Corning 7056 borosilicate glass;

[0082] Adhesive film / inner surface anti-reflection coating: Adhesive film: Si installed sequentially from the buffer layer 3 N 4 film (170nm) and SiO 2 membrane;

[0083] Anti-reflection coating on the inner surface: Si in order from the buffer layer 3 N 4 layer (60nm), MgF 2 (71nm), Si 3 N 4 layer (7.3nm) and MgF 2 (91nm);

[0084] B...

Embodiment 2

[0099] A kind of transmissive photocathode, the anti-reflection film on the outer surface, glass window, adhesive film / anti-reflection film on the inner surface, buffer layer, emission layer and active layer (structural relationship such as figure 1 shown);

[0100] Among them, the anti-reflection coating on the outer surface: TiO2 which is arranged sequentially from the glass window 2 layer (13.3nm), SiO 2 layer (33.7nm), TiO 2 layer (27nm), SiO 2 layer (12nm), TiO 2 layer (79.5nm), SiO 2 layer (22nm), TiO 2 layer (17.3nm) and MgF 2 layer (99nm);

[0101] Glass window: 9741 transparent purple glass polished on both sides;

[0102] Adhesive film / inner surface anti-reflection coating: Adhesive film: Si installed sequentially from the buffer layer 3 N 4 film (270nm) and SiO 2 membrane;

[0103] Anti-reflection coating on the inner surface: starting from the buffer layer: Si 3 N 4 layer (62.5nm), MgF 2 (46.5nm), Si 3 N 4 layer (14.7nm) and MgF 2 (142.5nm);

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com