Leakage detection method for refrigeration system

A refrigeration system and leak detection technology, which is applied in the direction of measuring the rate of increase and deceleration of the fluid, and using the liquid/vacuum degree to measure the liquid tightness, etc. It can solve the problems of human factors that are greatly affected, leaks that cannot be detected, and products that are damaged. , to achieve the effects of high leak detection accuracy, low detection cost and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will now be further described.

[0056] A leak detection method for a refrigeration system, comprising the following steps:

[0057] S101, vacuumize the refrigeration system once;

[0058] S102, vacuum pressure maintaining, vacuum pressure maintaining after the refrigeration system is evacuated, the pressure maintaining time is 1-5 minutes, if the pressure after vacuum pressure maintaining is not less than the first vacuum pressure, enter S103, if the pressure after vacuum pressure maintaining is less than Within the first vacuum pressure, a vacuum pressure alarm is performed;

[0059] S103, charging the detection gas, charging the refrigeration system with nitrogen-hydrogen mixed gas, and stopping charging when the detection pressure is reached;

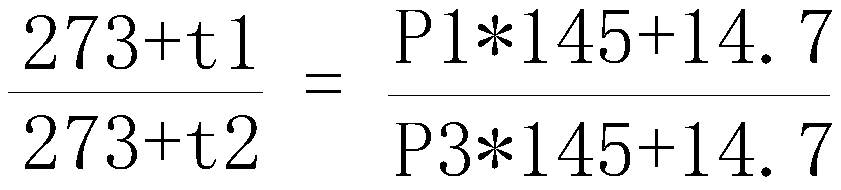

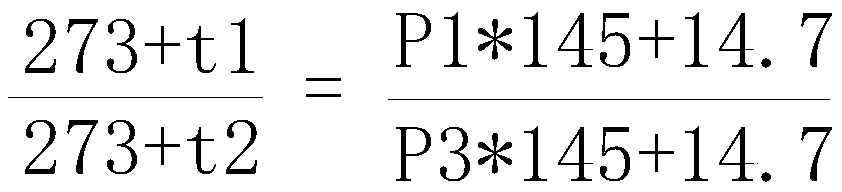

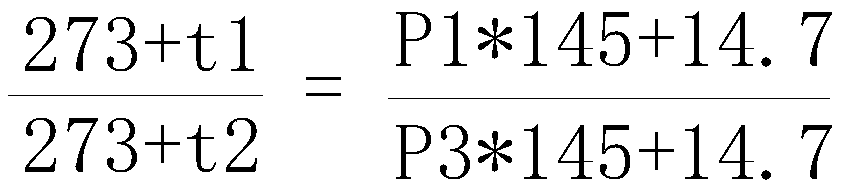

[0060] S104. Detect the pressure after charging, and detect the pressure after the refrigeration system is charged with nitrogen-hydrogen mixed gas. If the pressure is not less than the detection press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com