High-precision detection test stand for leakage in hydraulic cylinder

A hydraulic cylinder and internal leakage technology, which is applied in the direction of fluid pressure actuation system testing, fluid pressure actuation device, fluid pressure actuation system components, etc., to improve the detection accuracy of the hydraulic cylinder to be tested, improve the calibration accuracy, and improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

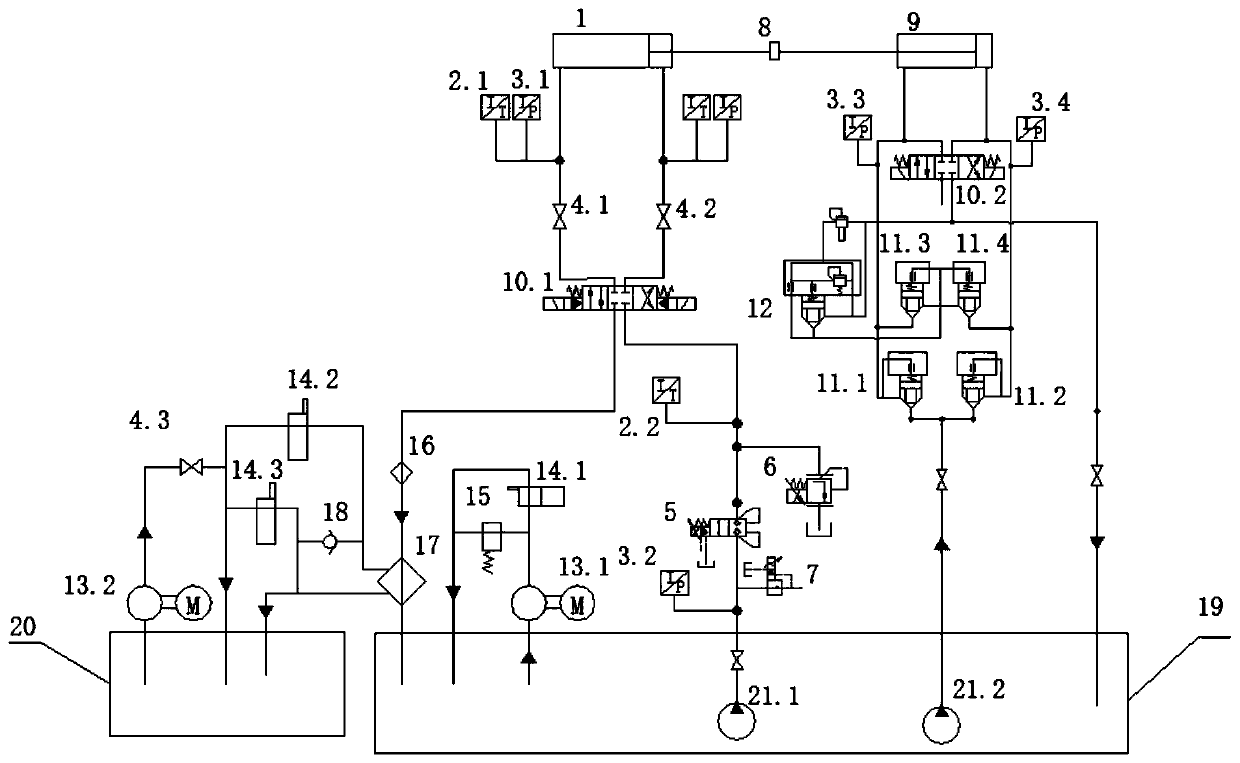

[0032] see figure 1 , figure 2 , a high-precision detection test bench for hydraulic cylinder leakage, including a hydraulic cylinder circuit, a hydraulic oil heating circuit and a cooling water circuit;

[0033] The hydraulic cylinder circuit includes a hydraulic cylinder 1, an electromagnetic reversing valve A10.1, a proportional flow cartridge valve 5 and an oil pump A21.1; the oil outlet of the oil pump A21.1 communicates with the oil inlet of the proportional flow cartridge valve 5 , the oil outlet of the proportional flow cartridge valve 5 communicates with the oil inlet of the electromagnetic reversing valve A10.1, and the two oil ports on the electromagnetic reversing valve A10.1 respectively pass through the stop valve A4.1 and the stop valve B4 .2 communicate with the corresponding oil port on the hydraulic cylinder 1, the oil return ports of the electromagnetic reversing valve A10.1 and the proportional flow cartridge valve 5 are connected with the hydraulic oil t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com